Full-hardware servo power-assisted steering controller

A power steering and controller technology, applied in automatic steering control components, steering mechanisms, steering rods, etc., can solve the problems of limiting the control accuracy of the controller, unsatisfactory control effect, system lag, etc., so as to improve the corresponding speed and avoid disadvantages. Affects, the effect of realizing the requirements of the assist characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

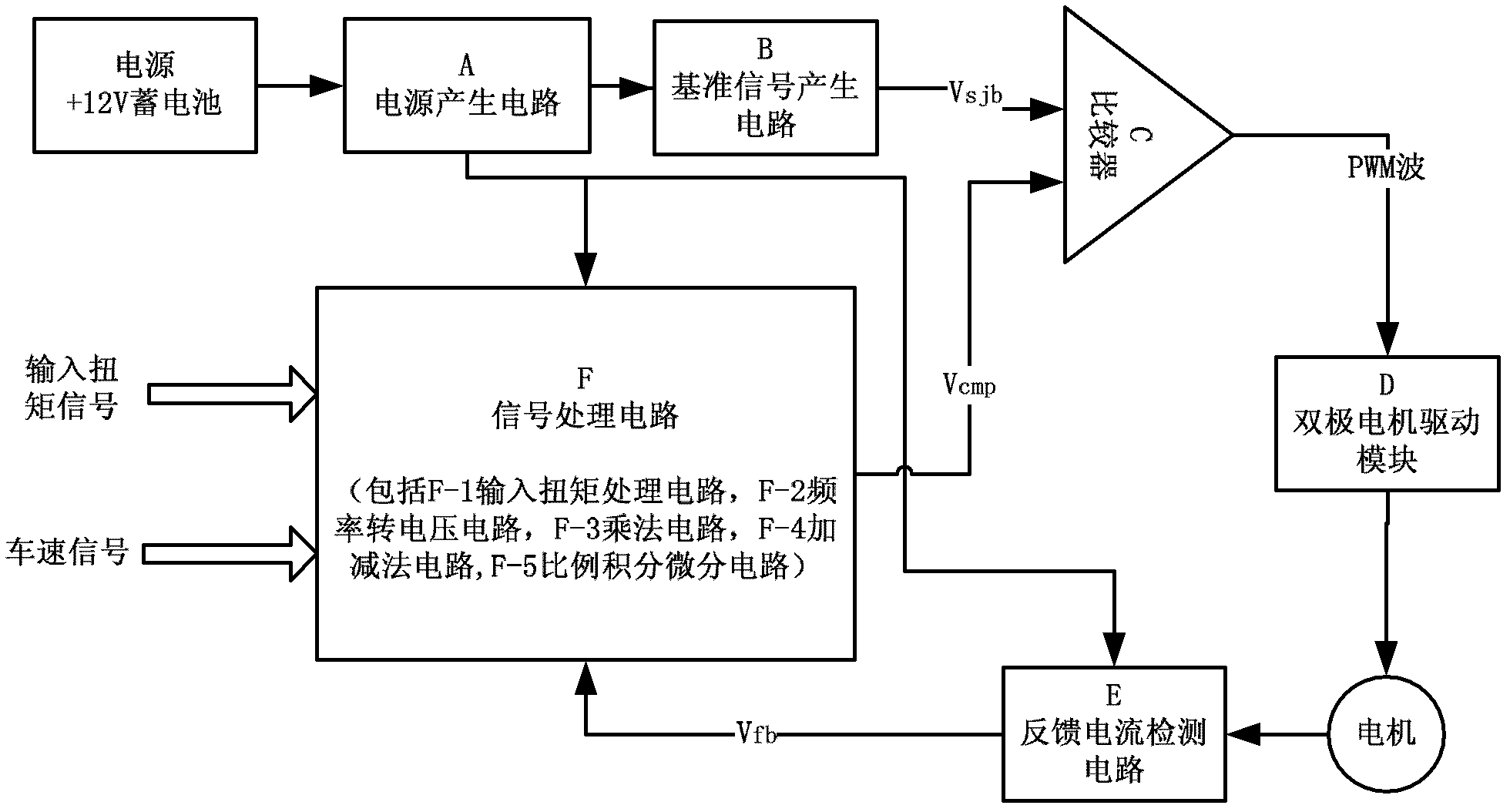

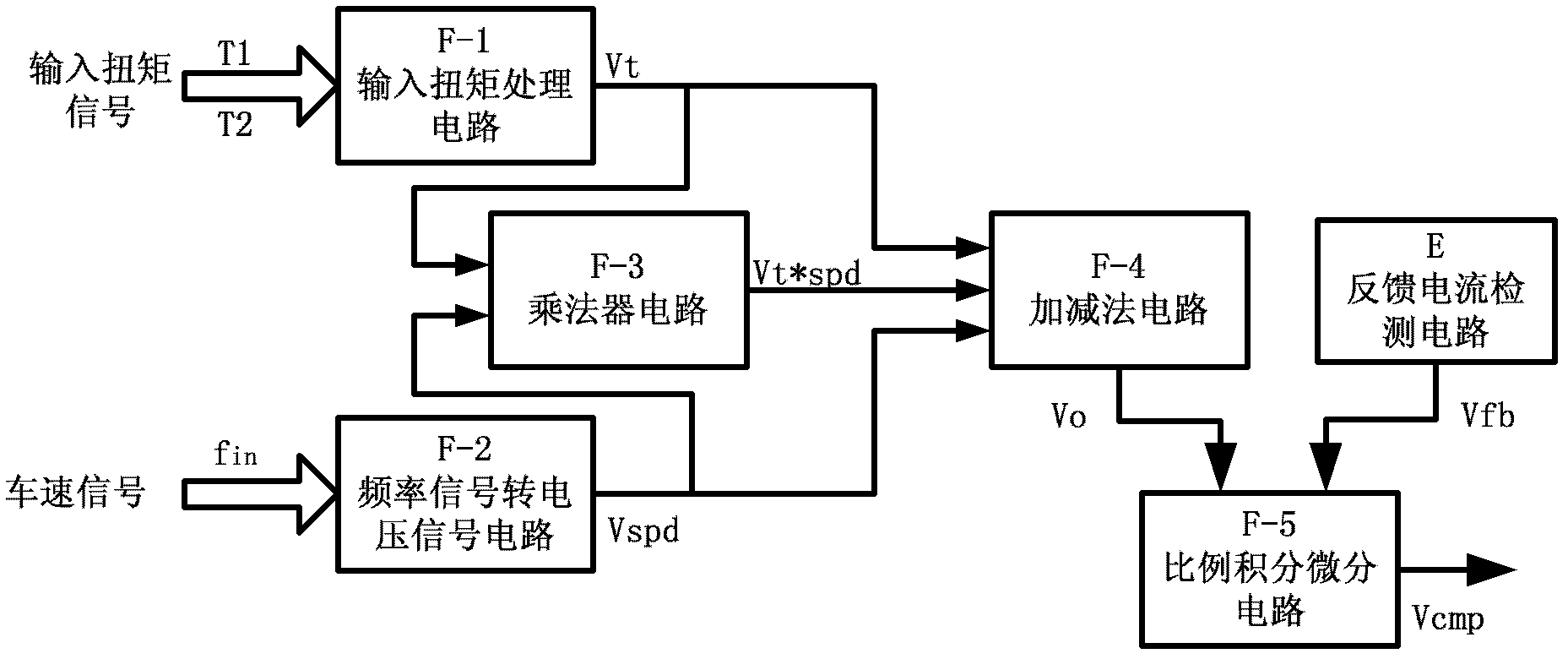

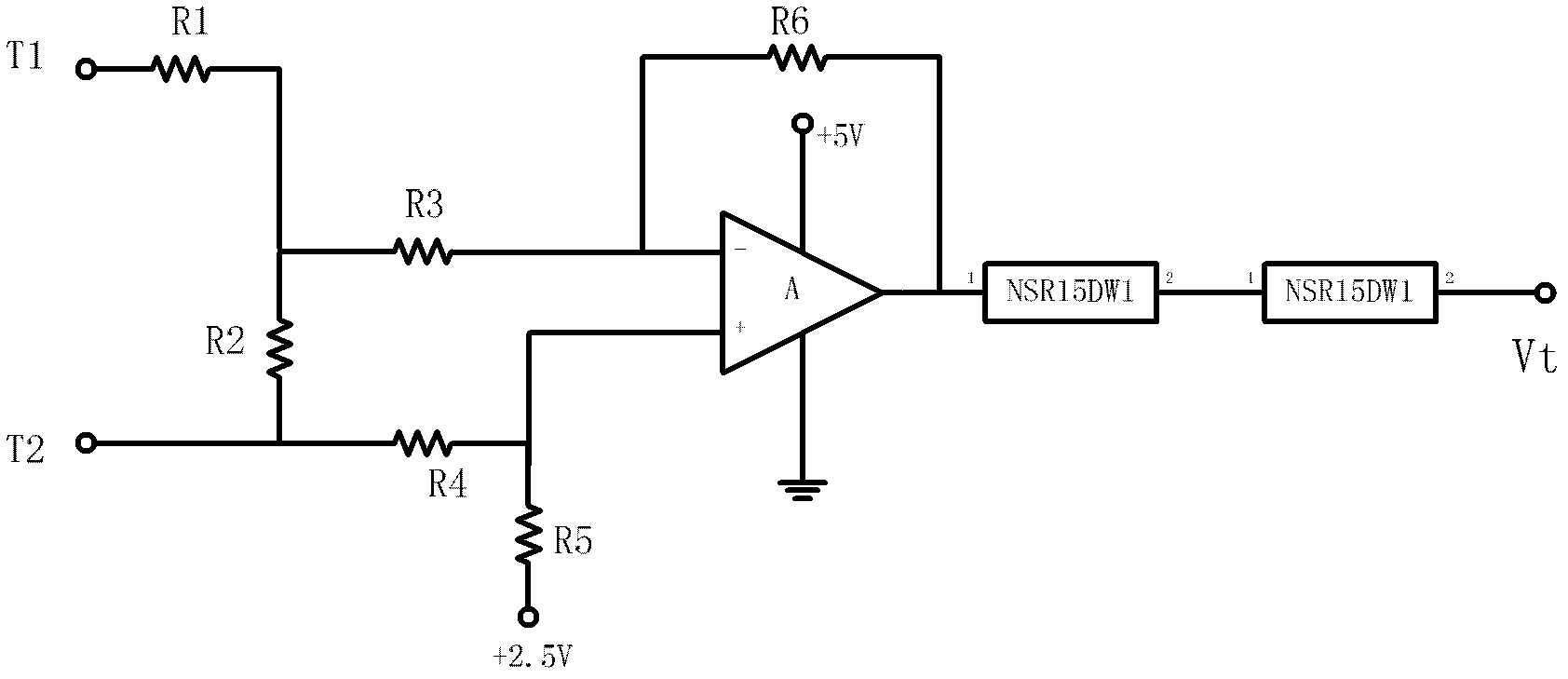

[0021] refer to figure 1 , the electric power steering controller based on the analog circuit of the present invention, its composition structure includes a power generation circuit A, a reference signal generation circuit B, a comparator C, a bipolar motor drive module D, a feedback current detection circuit E, the signal processing Circuit F (including input torque signal processing circuit F-1, frequency signal to voltage signal circuit F-2, multiplier circuit F-3, addition and subtraction circuit F-4, proportional integral differential circuit F-5).

[0022] The power generation circuit A generates the 12V, +5V, +2.5V voltage required by the entire controller, and the signal processing circuit F combines the input signals of the controller (vehicle speed signal, input torque signal) and the motor feedback obtained by the feedback current detection circuit E After the signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com