Roll-on/roll-off shipping method for long large steel box girder segment across obstacles

A technology that overcomes obstacles and long sections, and is applied in storage devices, transportation and packaging, loading/unloading, etc., and can solve the problems of rail docking on steel box girder moving rail ships, large weight of long sections, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

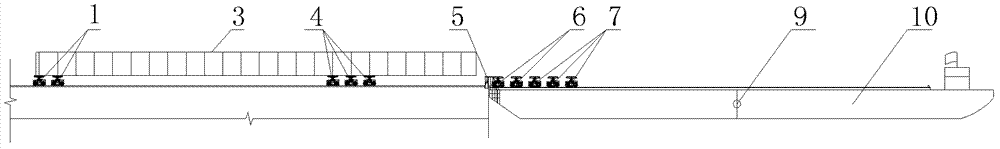

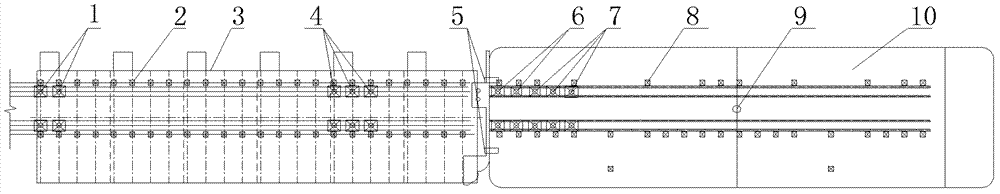

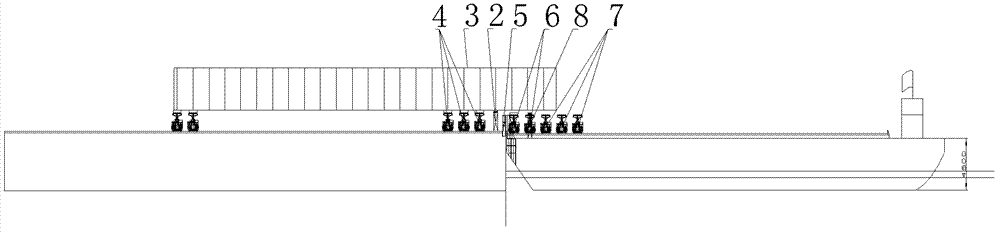

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] The method for crossing obstacles and rolling-on-rolling ships with steel box girder long sections of the present invention is a new technology for crossing obstacles and rolling-on-rolling ships with a long section of steel box girder on the shore and on board for relay transfer: firstly, the hydraulic ship berth is used on the shore After the cantilever end of the steel box girder is moved to the upper deck of the ship, the section is transferred to the transport ship by the relay of the hydraulic truck on the ship. Move the long section of super steel box girder across obstacles to the ship, and at the same time use the ballast water of the transport ship to adjust the floating state of the transport ship, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com