The structure of the tray module

A gas, inlet and outlet technology, applied in the field of tray modules, can solve the problems of partition deformation, reduced hydrogen efficiency, uneven heating, etc., to achieve the effect of contributing to structural strength, ensuring safety, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

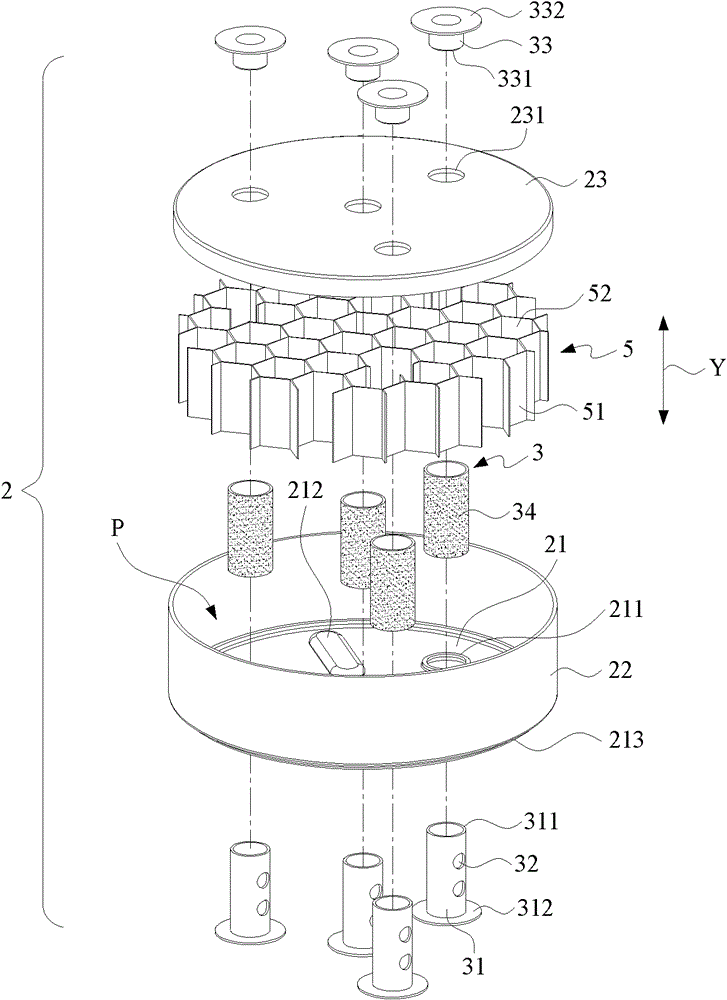

[0060] The specific embodiments adopted by the present invention will be further described through the following embodiments and accompanying drawings.

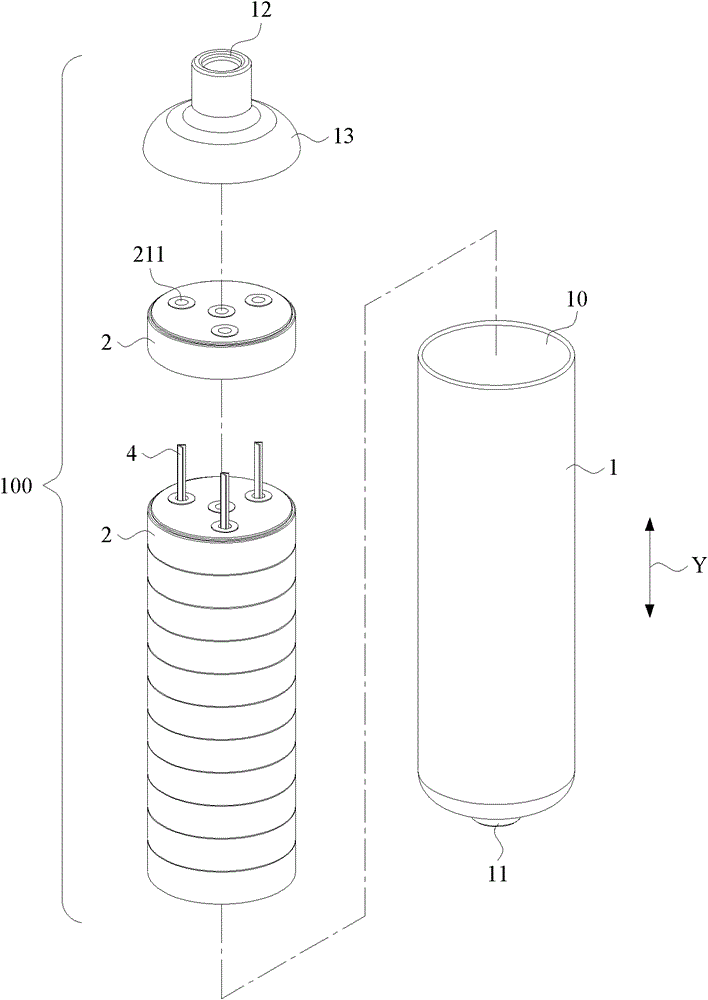

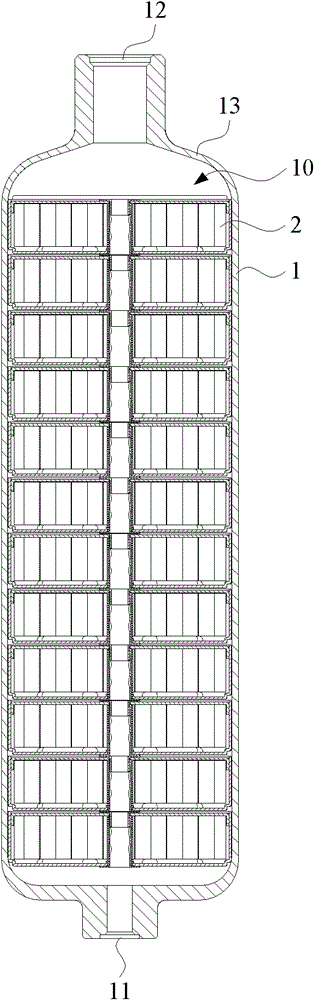

[0061] see figure 1 and figure 2 The three-dimensional exploded view and the side view sectional view of the first embodiment of the present invention are respectively shown when they are applied. The storage tank 100 includes a tank body 1 and a plurality of tray modules 2 stacked in the inner space 10 of the tank body 1 . The tank body 1 has a bottom end 11 and a release port 12 opposite to the bottom end 11, and its shape can be circular, square or polygonal, etc., depending on the needs of practical applications. A long axis direction Y is defined between the bottom end 11 of the tank body 1 and the release port 12 . Each susceptor module 2 is adjacently stacked in the inner space 10 in the direction Y of the long axis. In this embodiment, the tray module 2 is made of thermally conductive material.

[0062] see im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com