Device for evaluating sound insulation and absorption performance of automobile body part

A technology for evaluating devices and components, which is used in measurement devices, machine/structural component testing, and vehicle testing. The effect of sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

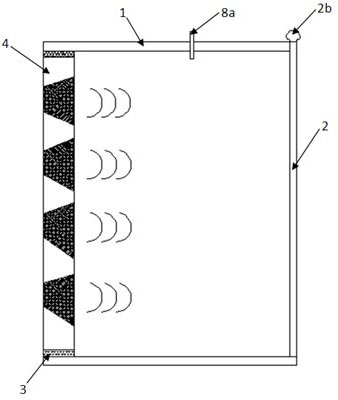

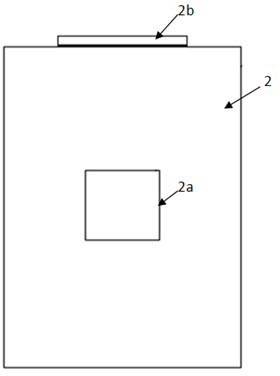

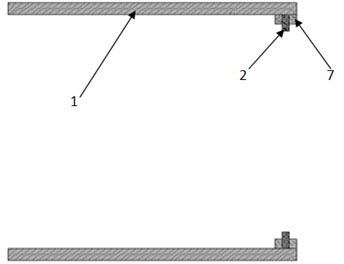

[0013] Embodiment one: if figure 1 , figure 2 , image 3 As shown, a device for evaluating sound insulation and absorption performance of vehicle body components includes a pre-receiver 10, a computer testing system 9 connected to the output end of the pre-receiver, and a first computer test system connected to the input end of the pre-receiver 10. Microphone 8a, second microphone 8b, the device also includes a box, which is surrounded by four panels 1 on the top, bottom, front, and rear, a volume sound source 4 on the left, and a movable cover 2 on the right , and ensure that each surface is well sealed, an opening 2a is provided in the middle of the movable cover plate 2, and the vehicle body component to be tested is arranged in the opening 2a; the first microphone 8a is arranged on the panel 1 on the top surface, Its sound-receiving end extends into the box, and the second microphone 8b is arranged outside the box, and its sound-receiving end faces the movable cover pla...

Embodiment 2

[0016] Embodiment two, when testing the solid acoustic material alone, such as Figure 6 As shown, because the measured area of the solid acoustic material is relatively large, the opening 2c on the solid movable cover is relatively large, and the remaining implementation methods and technical features are the same as those of the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com