Looseness detecting method and looseness detecting system for transmission shaft couplers of rotary furnace

A detection method and transmission system technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem that the transmission system of the converter body cannot be detected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

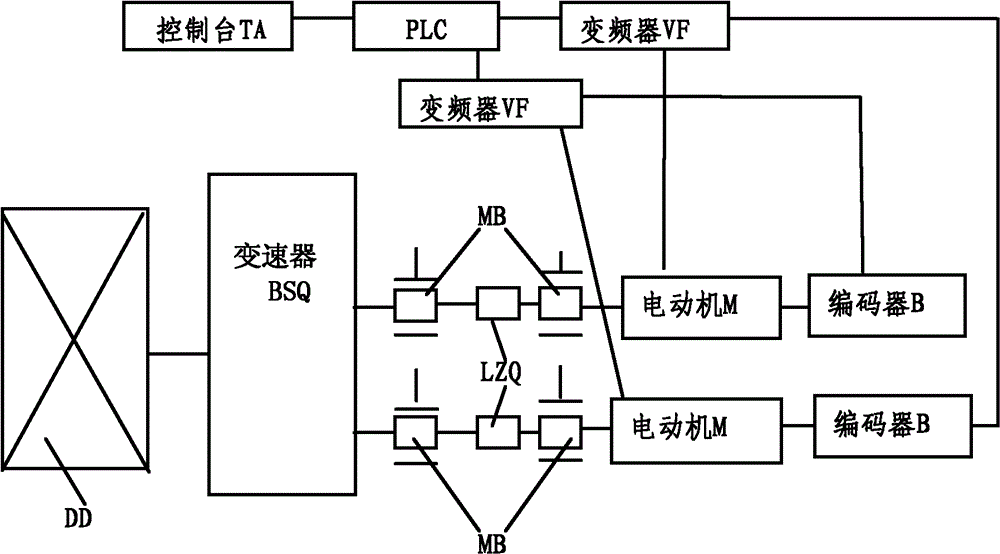

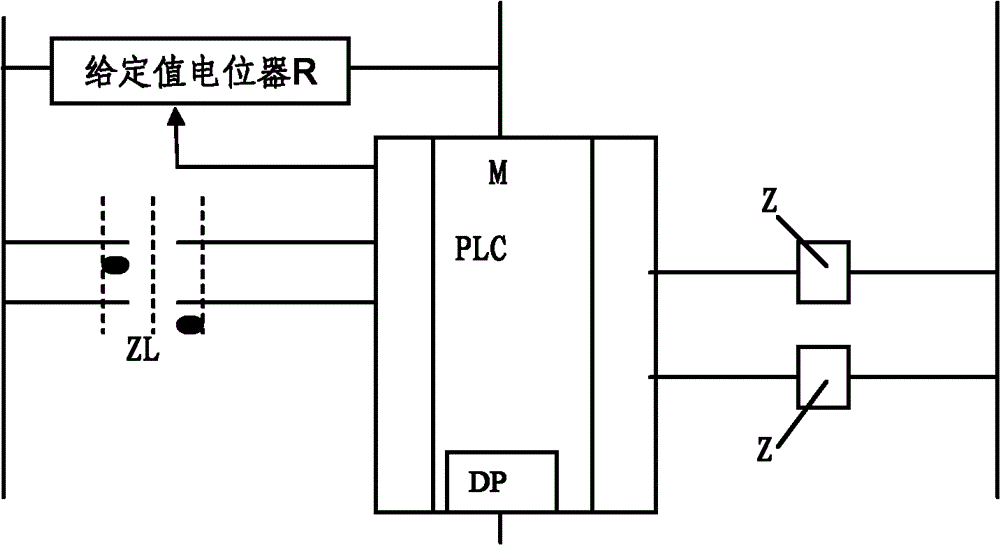

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

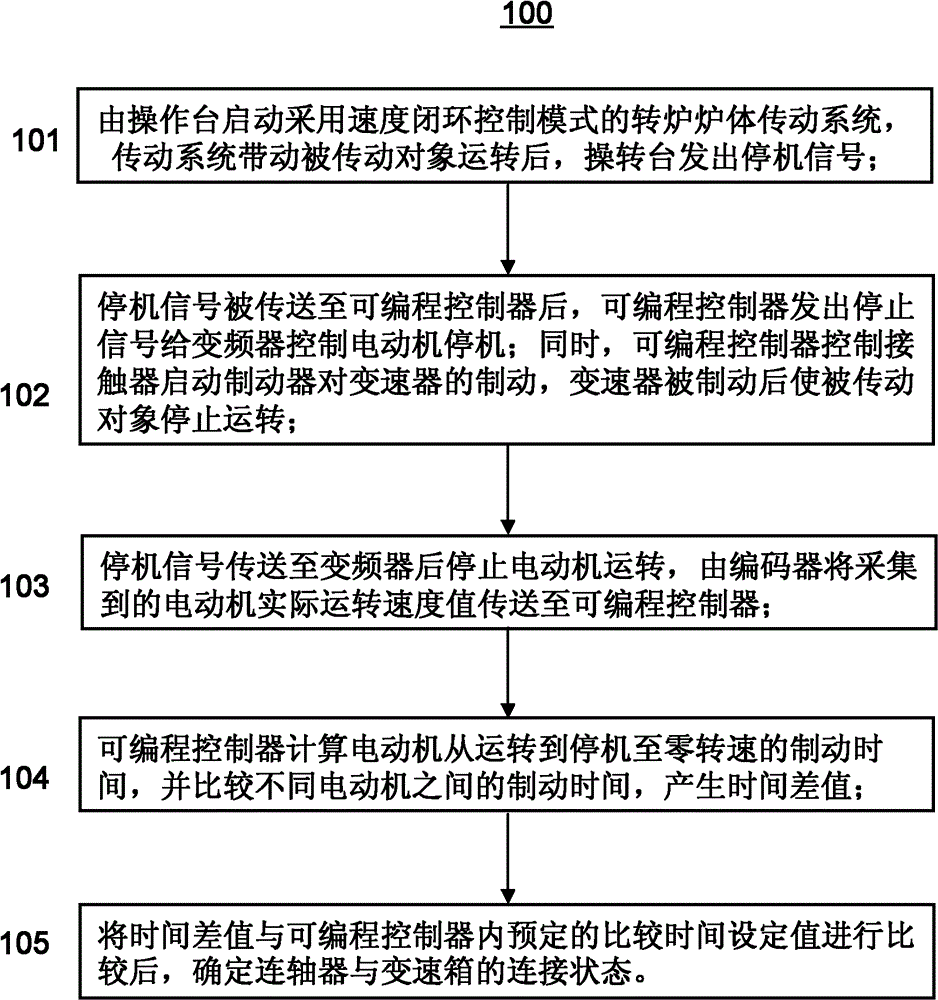

[0026] see image 3 A loose detection method 100 for a converter drive coupling is shown, which is characterized in that,

[0027]The concrete steps of this loose detection method are:

[0028] 101. The converter body transmission system adopting the speed closed-loop control mode is started by the operation console. After the transmission system drives the driven object to run, the operation console sends a stop signal;

[0029] 102. After the stop signal is sent to the programmable controller, the programmable controller sends a stop signal to the inverter to control the motor to stop;

[0030] At the same time, the programmable controller controls the contactor to start the brake to brake the transmission, and the transmission is braked to stop the transmission object;

[0031] 103. After the stop signal is transmitted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com