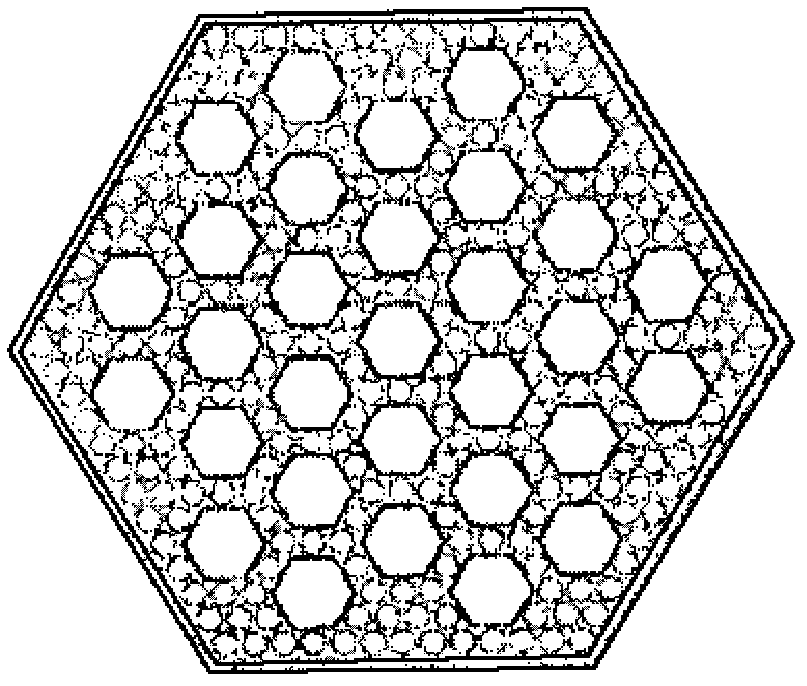

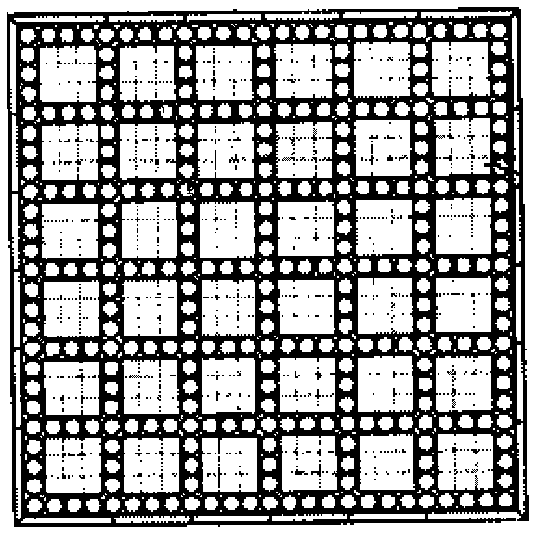

Double-layer water rod assembly structure for supercritical water cooled reactor

A component structure and water-cooled reactor technology, applied in the field of reactor components, can solve the problems of not applying supercritical component design, affecting the axial power distribution of components, affecting the neutron moderation performance in the reactor, and achieving uniform axial moderation The effect of temperature distribution of agent, uniform distribution of axial power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

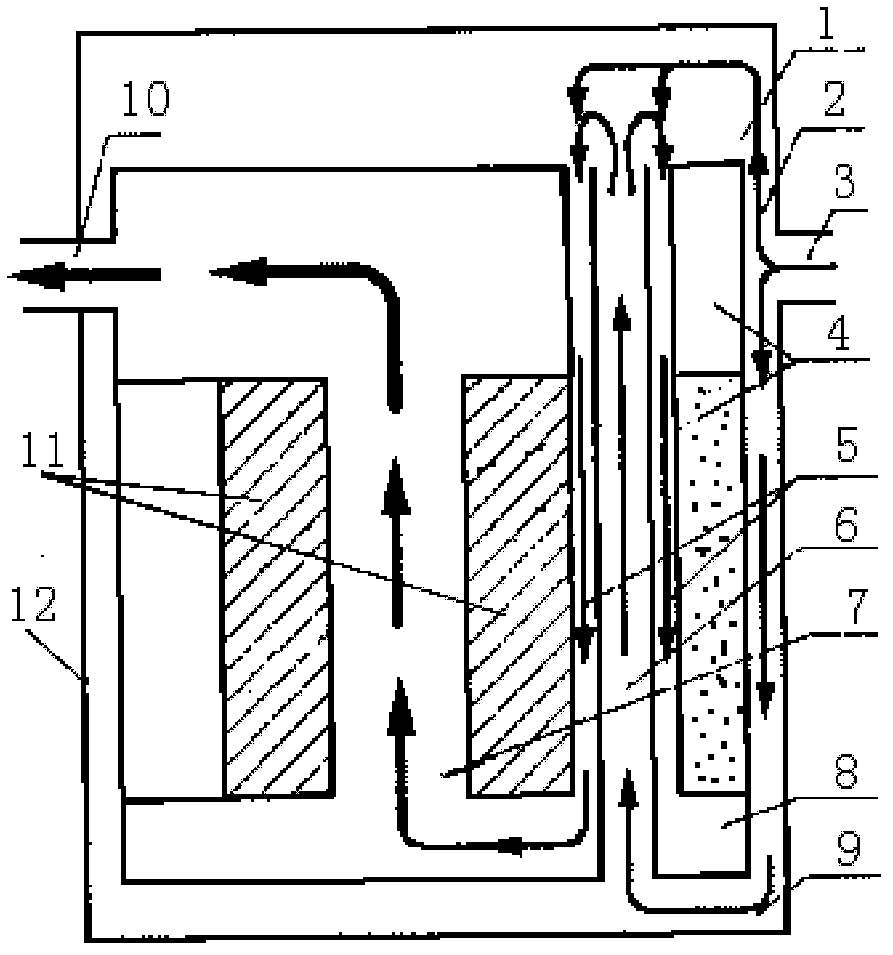

[0019] In the component proposed by the present invention, a layer of water rod wall is added, so that the moderator flows in the opposite direction in the water rod, and then enters the double-layer water rod structure of the coolant channel. Be described below in conjunction with accompanying drawing.

[0020] image 3 It is a diagram of the flow mode of the working fluid in the core using a double-layer water rod assembly, which illustrates the flow mode of the working fluid in the core after adding a layer of water rod wall. image 3 Among them, the two ends of the channel 2 between the hanging basket 4 and the outer wall 12 of the component (pressure vessel) are respectively connected to the upper chamber 1 and the lower chamber 9, and the inlet 3 of the working medium is connected to the upper part of the channel 2 between the hanging basket 4 and the outer wall 12 of the component, double-layer The lower end of the water rod inner pipe wall 13 of the water rod communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com