Tank for fermentation and method, device, and use for fermentation

A fermentation tank and equipment technology, applied in the field of fermentation equipment, can solve the problems of expensive, uneconomical fermentation methods, complexity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

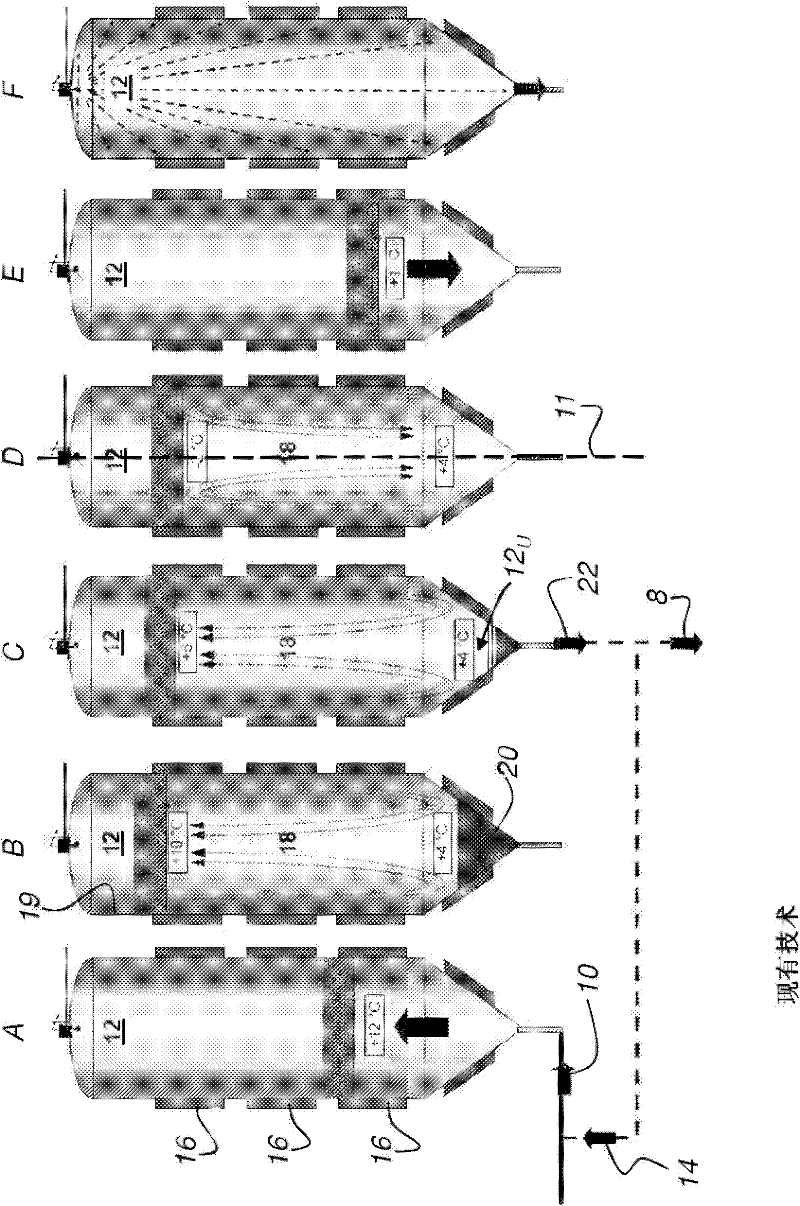

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

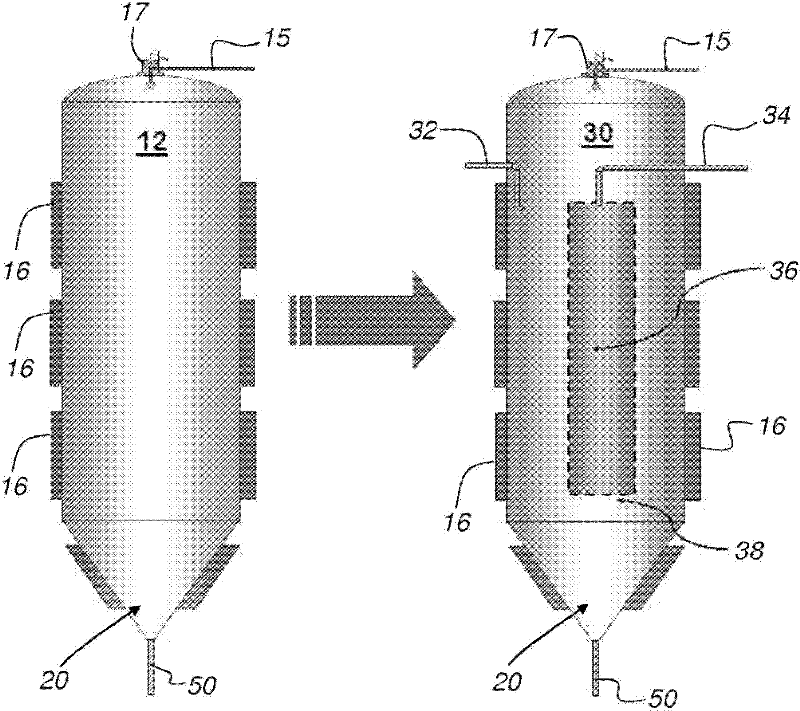

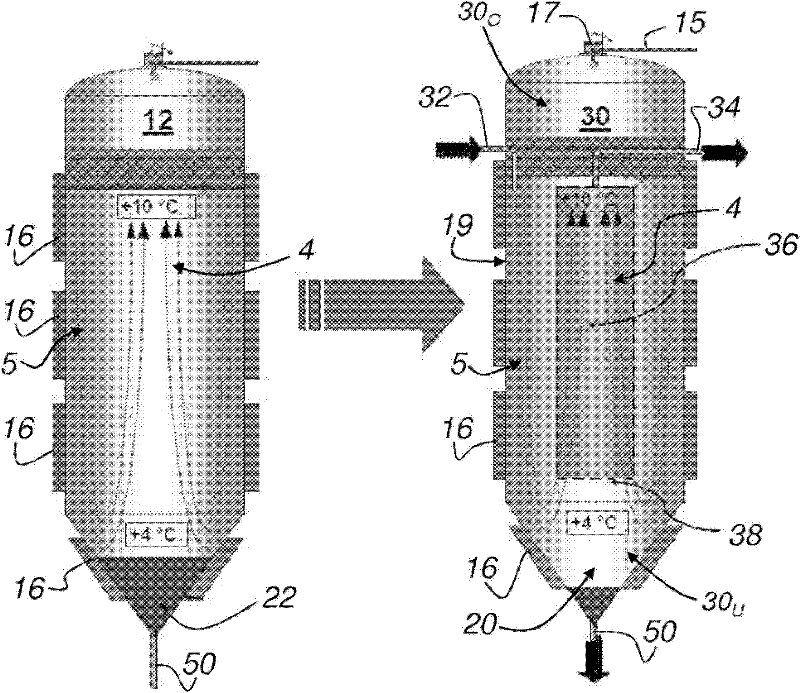

[0056] The same reference numerals will be used for identical or identically acting elements of the invention. Furthermore, for the sake of clarity, the individual figures are marked with only the reference numerals which are necessary for the description of the respective figure. The described embodiments represent only examples of how the fermenter according to the invention, the plant according to the invention and the method according to the invention can be designed and do not represent a limitation of the invention.

[0057] Figure 2A The cross-sectional view schematically shows a comparison of a conventional fermenter 12 (left) and a fermenter 30 modified according to the present invention (right). The fermenter 30 according to the invention has at least one filling line 32 for the preferably continuous introduction of fresh liquid and at least one discharge line 34 for the likewise preferably continuous discharge of preferably at least partially fermented liquid. Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com