Automatic identifying and grading method for bamboo chips

A grading method and automatic identification technology, applied in sorting and other directions, can solve the problems of high labor intensity, low grading efficiency and low accuracy, and achieve the effect of flexible operation, high grading accuracy and fast grading speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

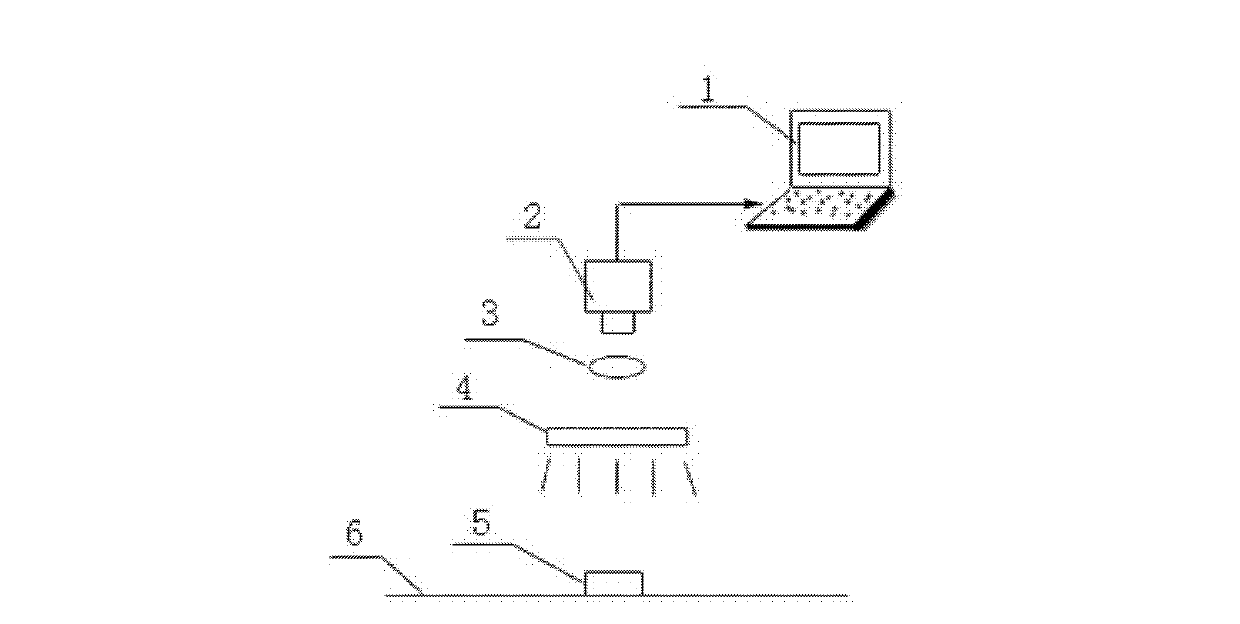

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

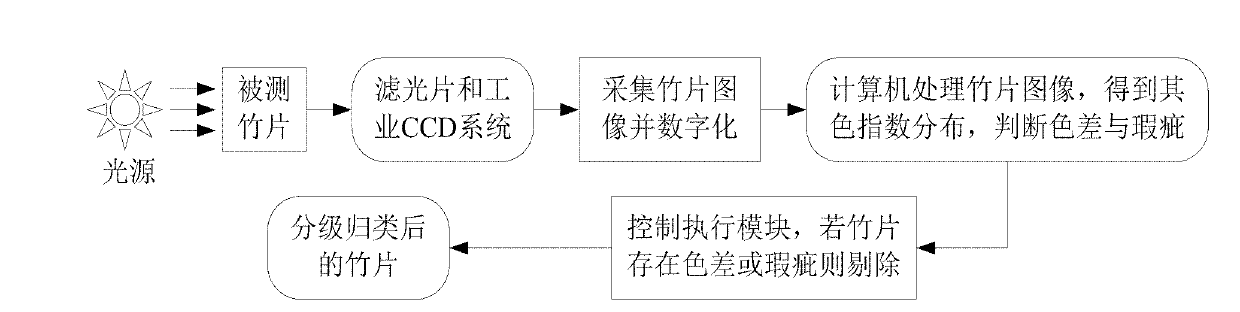

[0029] refer to Figure 1 to Figure 6 , a kind of bamboo chip automatic identification classification method, described identification classification method comprises the following steps:

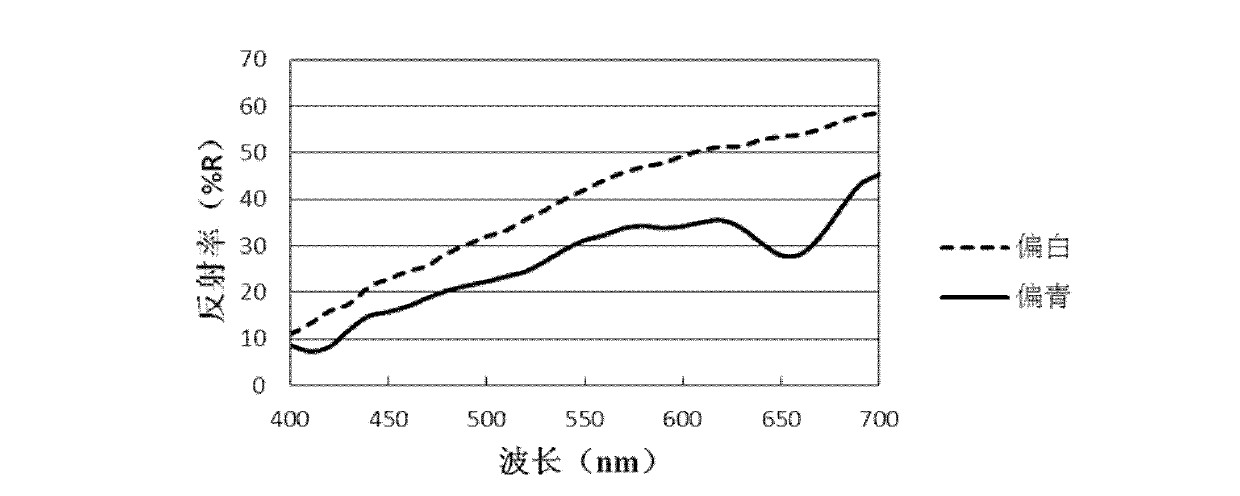

[0030] 1) shoot the bamboo chip image of the bamboo chip to be classified through the light filter;

[0031] 2) two screenshots of the same size are intercepted at the bamboo slice part and the background part of the bamboo slice image, and the screenshot has N pixels, and the gray value of the i pixel of the screenshot defining the bamboo slice part and the background part is respectively G 竹片i and G 背景i , with its difference (G 竹片i -G 背景i ) as the sample grayscale reference value G of the i-th pixel in the screenshot i , according to the sample gray reference value G i Compute sample gray mean and the gray scale fluctuation value

[0032] 3) Compare the measured graysc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com