Mobile unloading machine

A kind of unloading machine and mobile technology, applied in the mechanical field of operation, can solve the problems of slow loading and unloading speed, low efficiency, long time consumption, etc., and achieve the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

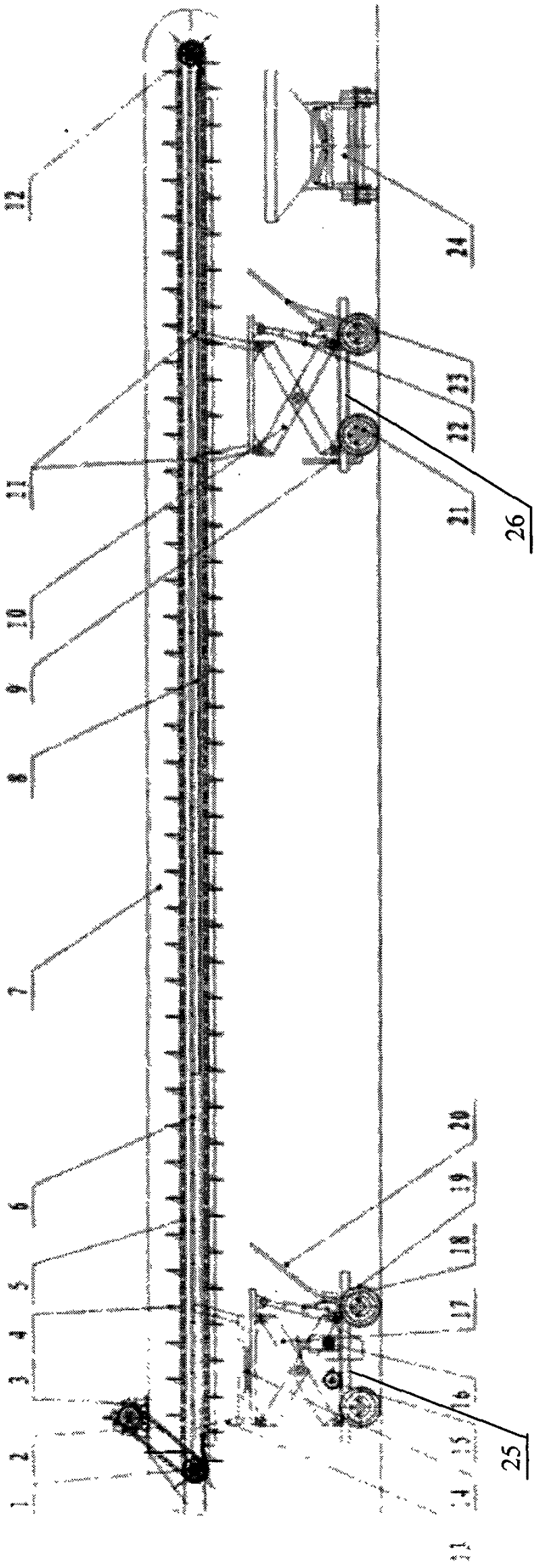

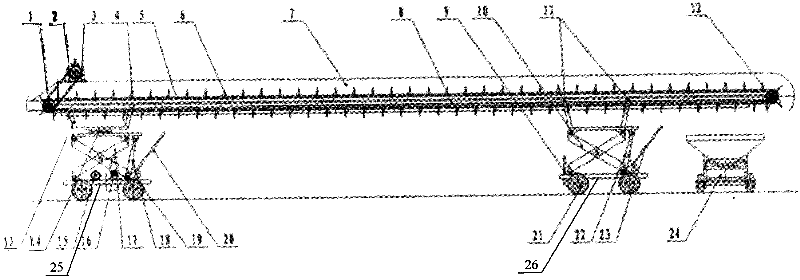

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] As shown in the figure, the mobile unloader is composed of three parts: a chain scraper conveyor, a walking support and a discharge conveyor. At the working height, the discharge conveyor is located under the head of the chain scraper conveyor. The grains and other materials scraped by the grain scraper 4 fall on the grain discharge conveyor 24 and are transported to the destination to complete the material unloading process.

[0014] The chain scraper conveyor is composed of a grain scraper 24, a scraper chain 5, a main frame 6, a protective cover 7, and a reversing sprocket 12, and a driving shaft and a chain are arranged at the front end of the chain scraper conveyor. Wheel 1, transmission chain 2 and drive motor 3, main frame 6 is provided with grain scraper 4, scraper chain 5, and the end is provided with reversing sprocket wheel 12, and grain scraper 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com