A transfer trolley for tobacco logistics

A logistics and tobacco technology, applied in trolleys, multi-axle trolleys, trolley accessories, etc., can solve the problems of inconvenience, low handling, waste of human resources and work efficiency, and achieve the effect of ingenious structure, unloading operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

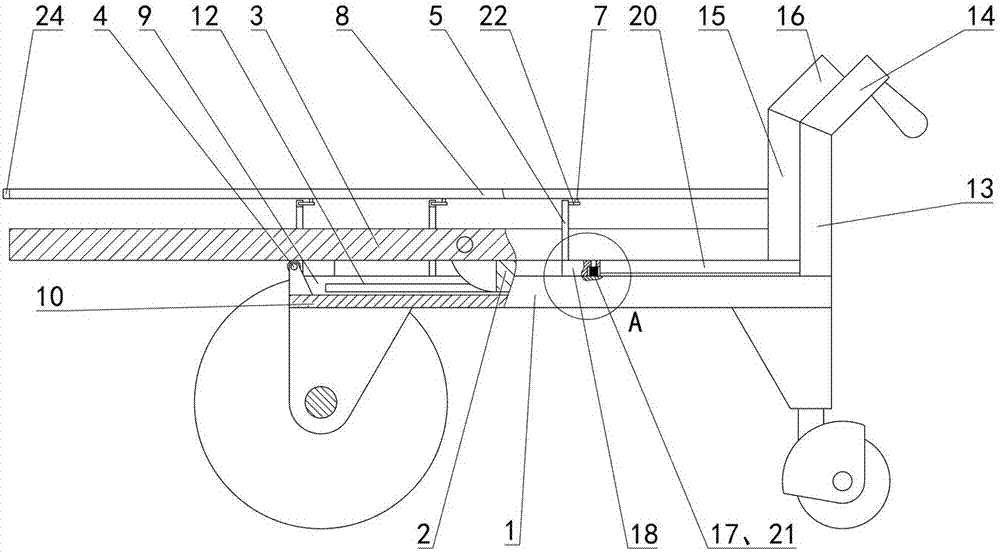

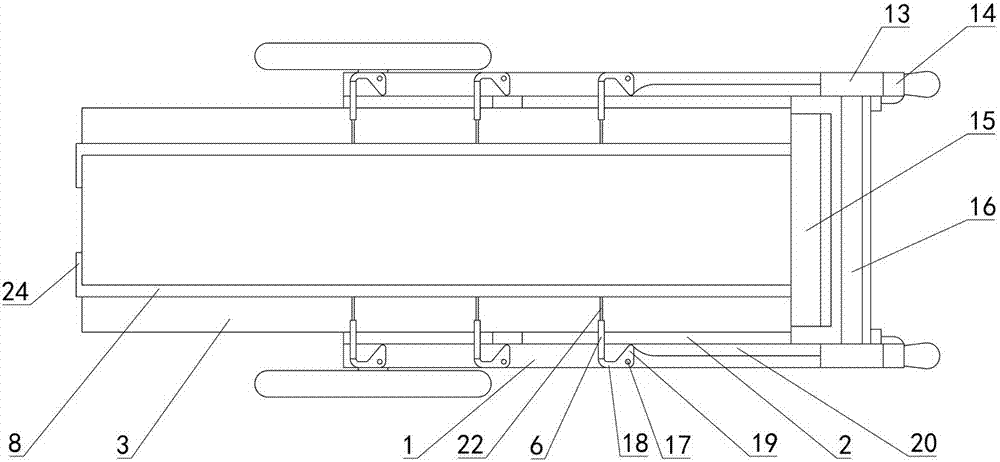

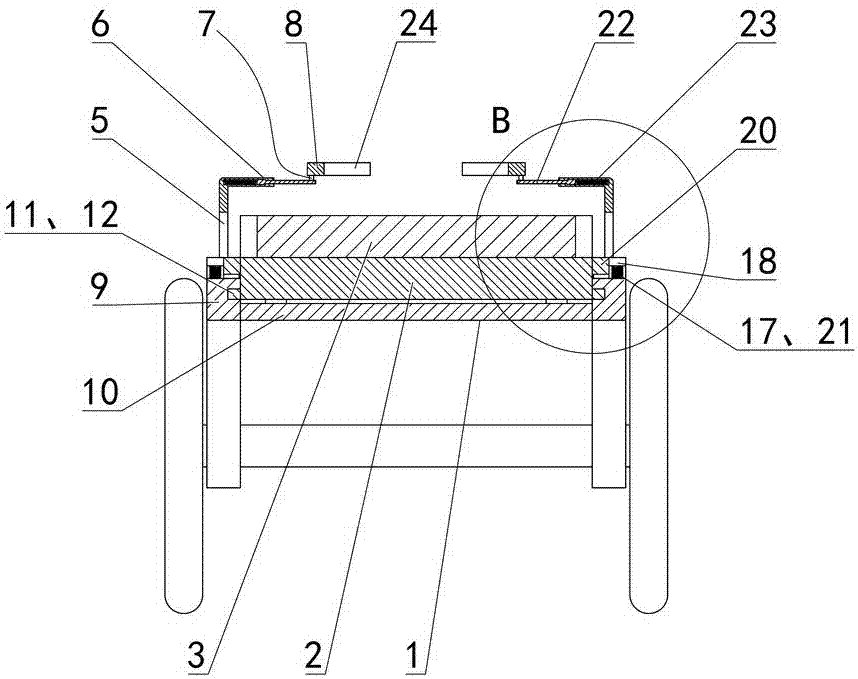

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Depend on Figure 1 to Figure 11 Provide, the present invention comprises a first vehicle frame 1, the second vehicle frame 2 that can slide left and right on the first vehicle frame 1 is housed on the first vehicle frame 1; The third vehicle frame 3, the left end of the second vehicle frame 2 is hinged with the third vehicle frame 3 via the hinge shaft, forming the structure that the third vehicle frame 3 rotates on the hinge shaft;

[0022] The left end of the first vehicle frame 1 is equipped with a supporting wheel 4 placed on the left side of the hinged shaft, the axis of the supporting wheel 4 is arranged parallel to the axis of the hinged shaft, and the supporting wheel 4 contacts with the lower end surface of the third vehicle frame 3, forming the first vehicle frame 3. The second vehicle frame 2 slides t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com