Idle detection device of elevator drive

A detection device and drive device technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of expensive rotating equipment, troubles in configuration space, and rising costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

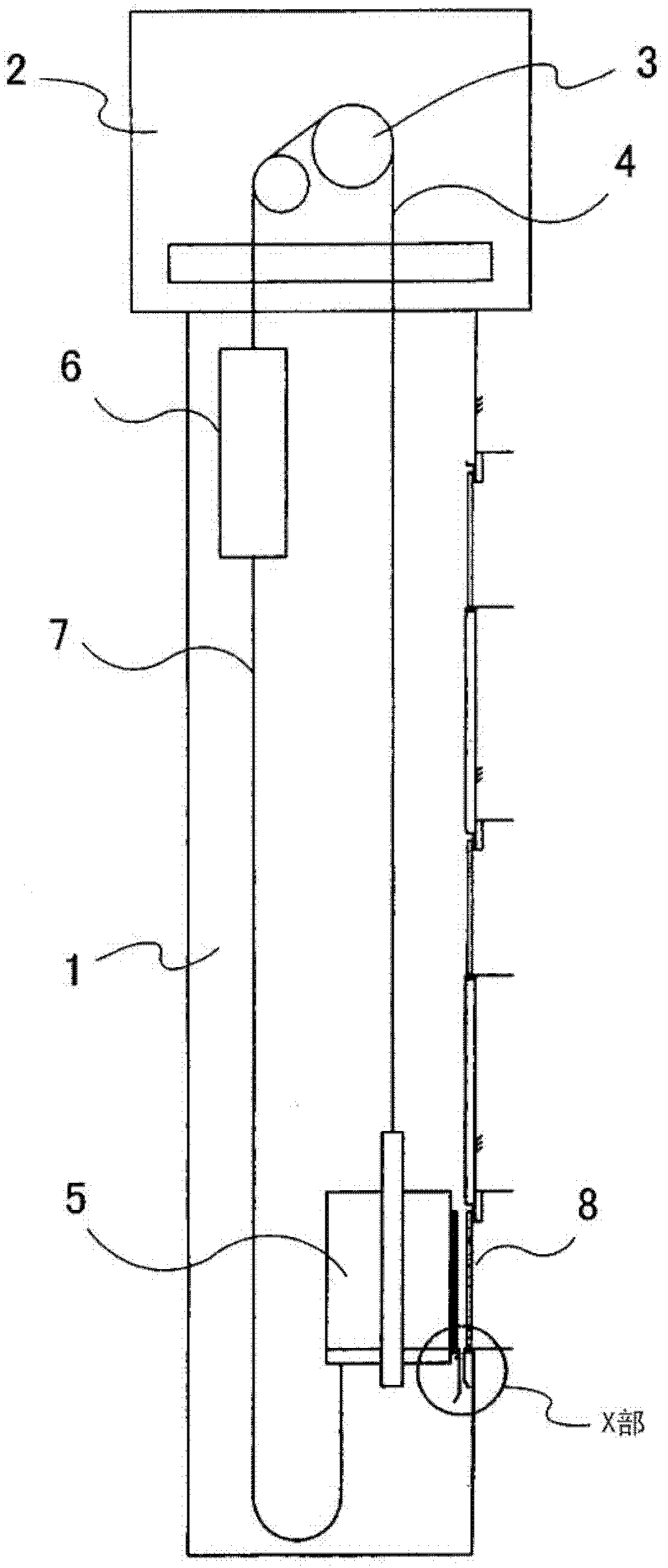

[0022] First, a general elevator to which the idling detection device of the elevator drive device is applied will be briefly described. figure 1 It is a figure which shows the whole structure of a general elevator. like figure 1 As shown, in the machine room 2 in the upper part of the hoistway 1 of an elevator, the hoisting machine (not shown) is installed. A car 5 is suspended from one end of a main rope 4 suspended from a drive sheave 3 of the hoisting machine. On the other hand, at the other end of the main rope 4, a counterweight 6 is suspended.

[0023] In order to eliminate the change in the mass of the main rope 4 due to the position of the car 5 , a compensation rope (or a compensation chain) 7 is attached to the lower sides of the car 5 and the counterweight 6 . On each floor, the car 5 and the hoistway 1 for getting in and out of passengers are opened, and a landing door 8 is provided.

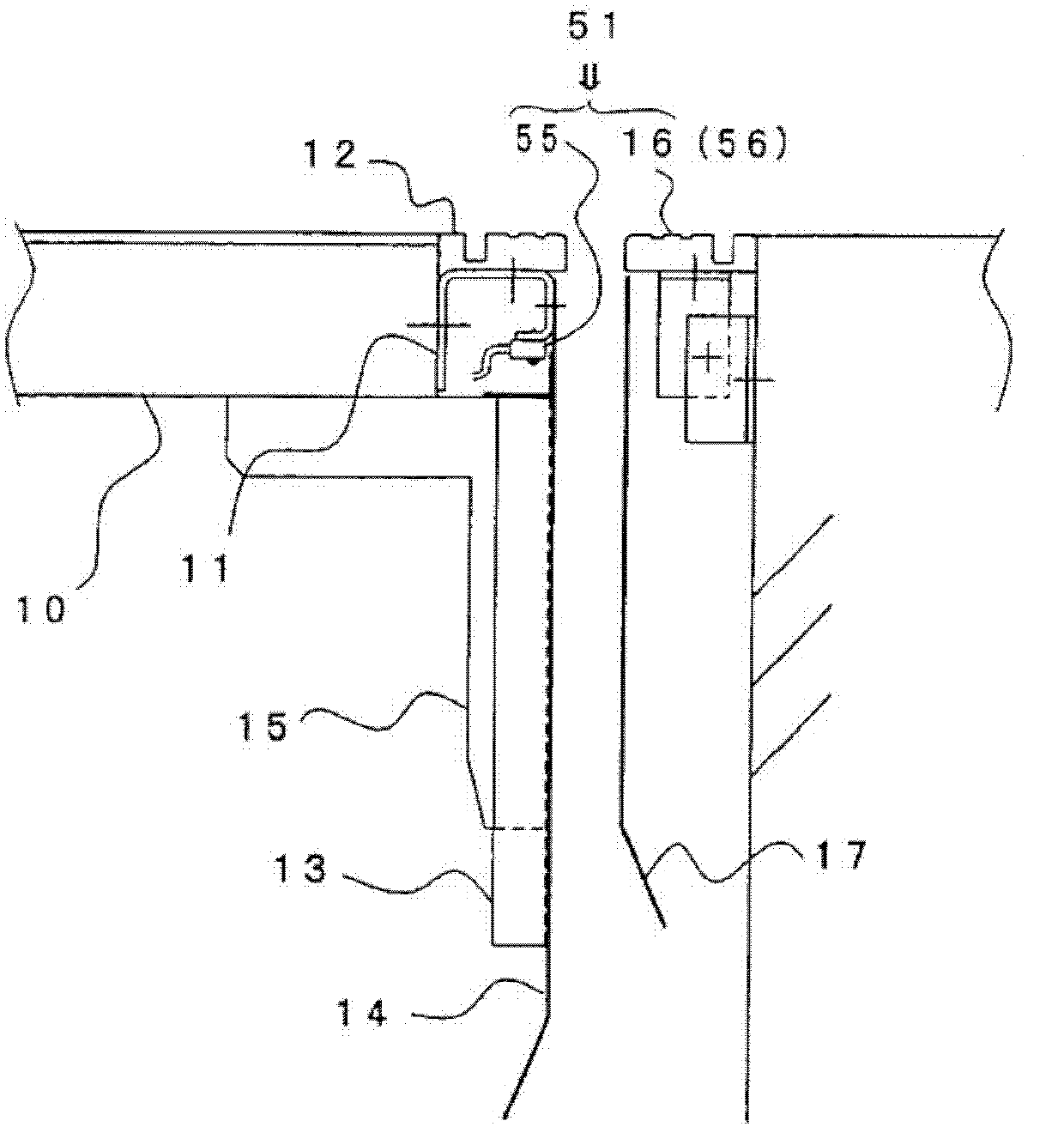

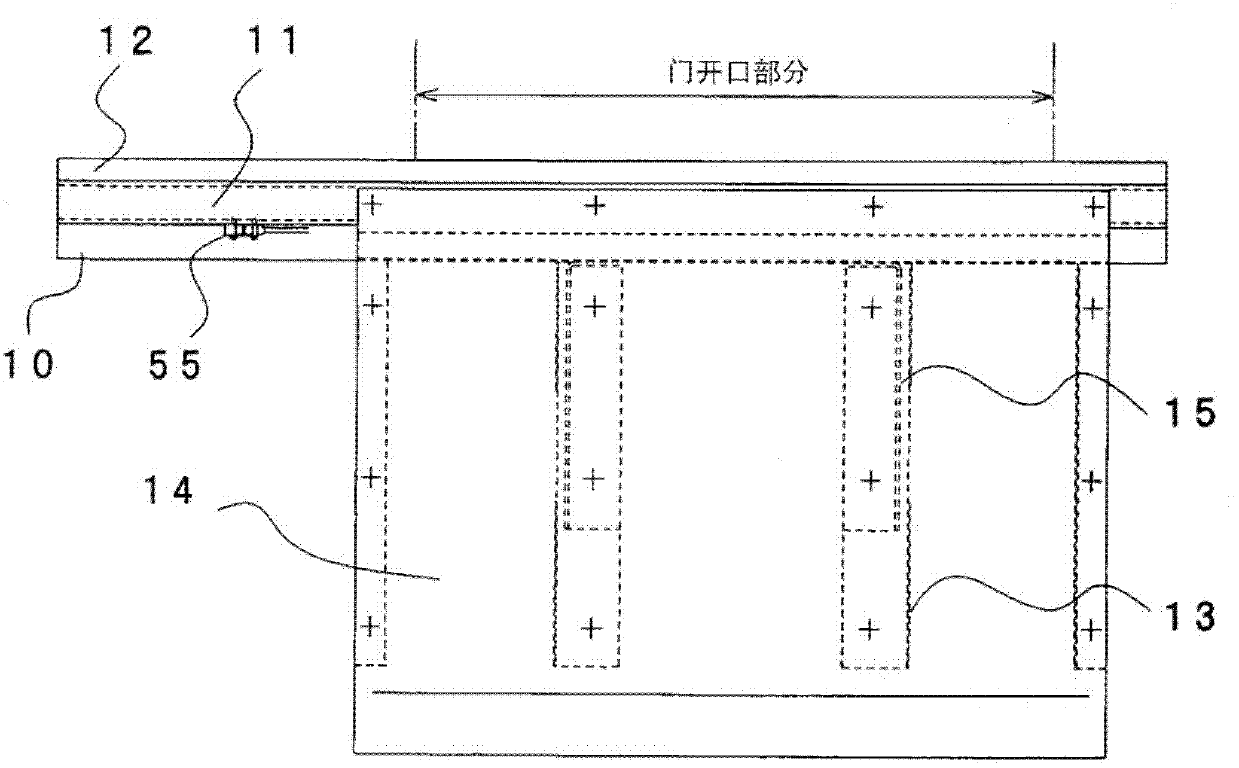

[0024] figure 2 is as figure 1 A detailed view of part X of the car 5 an...

no. 2 approach

[0039] Next, the second embodiment will be described. FIG. 6( a ) is a plan view showing the second embodiment, and FIG. 6( b ) is a vertical cross-sectional view.

[0040] As in the first embodiment, when the hall-side door sill 16 is used as a reflection member for the object 56 to be detected, it is necessary to have an entrance and exit of the hall on each floor. On the other hand, in the case of a fast-moving zone type elevator having a passing floor, there are cases where there is no entrance and exit at each floor.

[0041]In the second embodiment, the detector 55 is arranged so as to face the car side on the front surface of the rail bracket 70 to which the guide rail 83 is fixed.

[0042] Generally, one or more rail brackets 70 are provided on each floor of an elevator. By equipping the detector 55 with the function of projecting and receiving light, the rail bracket 70 can be used as a reflection member as the object to be detected 56, and can function as a positio...

no. 3 approach

[0045] Next, the third embodiment will be described. FIG. 7( a ) is a plan view showing the third embodiment, and FIG. 7( b ) is a vertical cross-sectional view. In the third embodiment, the structure of the detector 55 in the first and second embodiments is changed. like Figure 4 As shown, in the front portions of the light-emitting portion 58 and the light-receiving portion 59 of the detector 55, the polarizing filters 60a and 60b that transmit only the light that vibrates in a certain direction are transmitted by the vibration of the respective transmitted light. The direction is set at right angles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com