Industrial robots and method for operating same

A technology of industrial robots and driving methods, which is applied in the direction of instruments, manipulators, manufacturing tools, etc., can solve the problems of expensive rotary encoders, and achieve the effects of low cost, reliable position detection, high precision and high dynamic position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

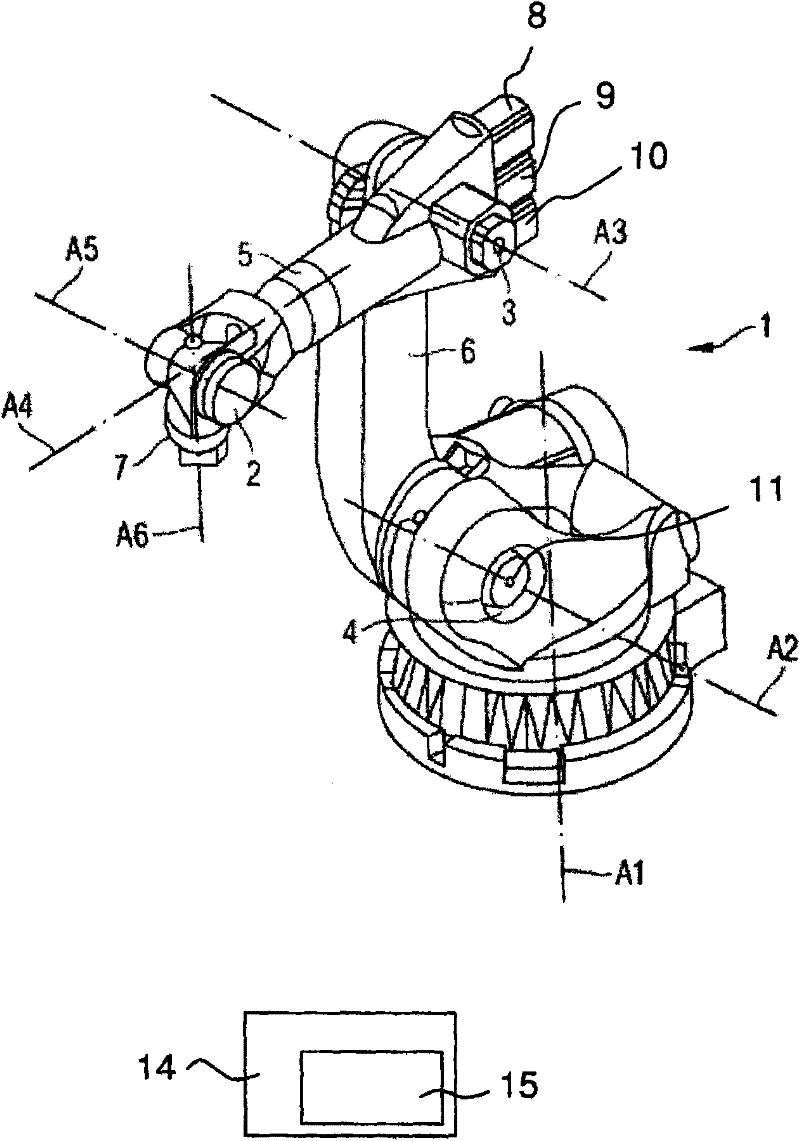

[0034] figure 1 An industrial robot 1 is shown, which is movable in six degrees of freedom. In a generally known manner, the industrial robot 1 has joints 2 , 3 , 4 , 5 ; a lever 6 ; six axes of movement A1 , A2 , A3 , A4 , A5 , A6 ; and a flange 7 .

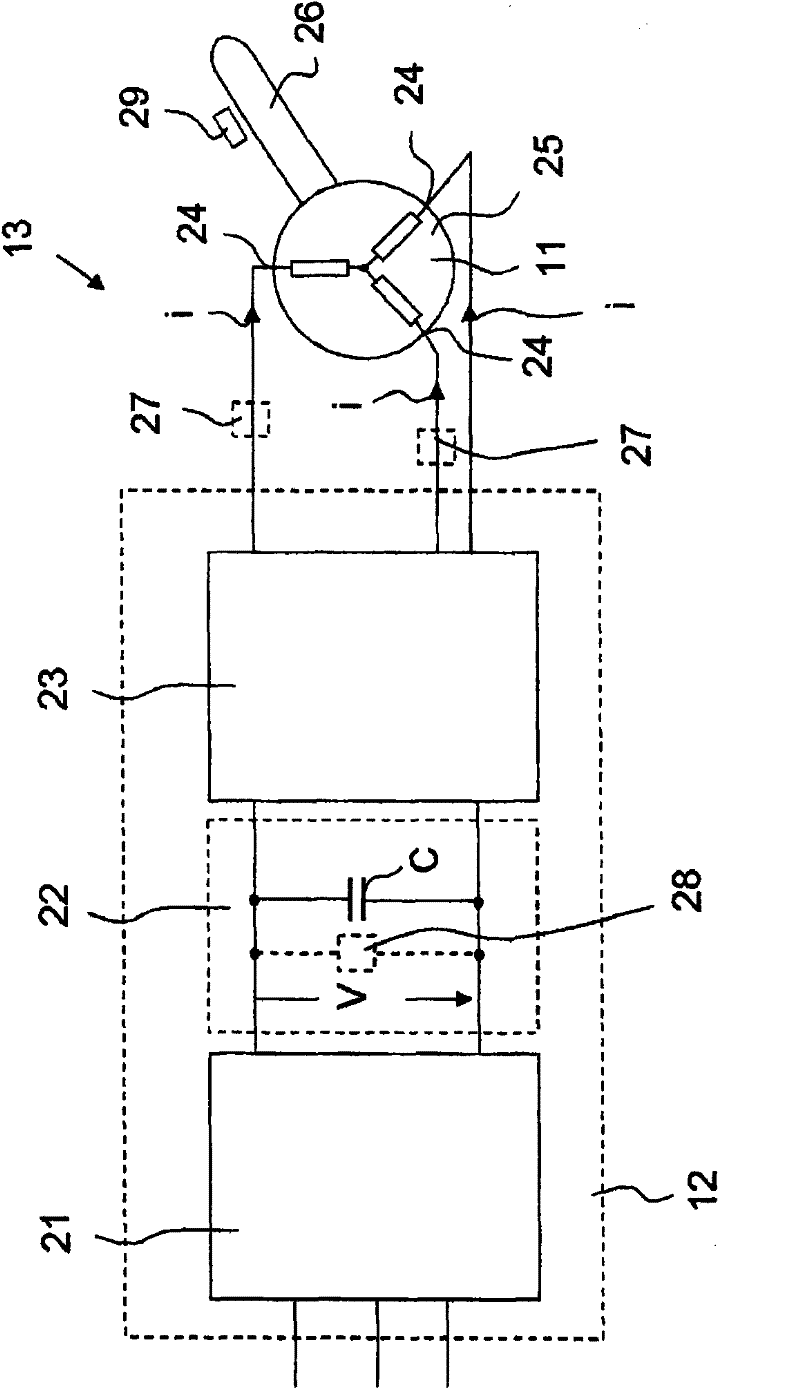

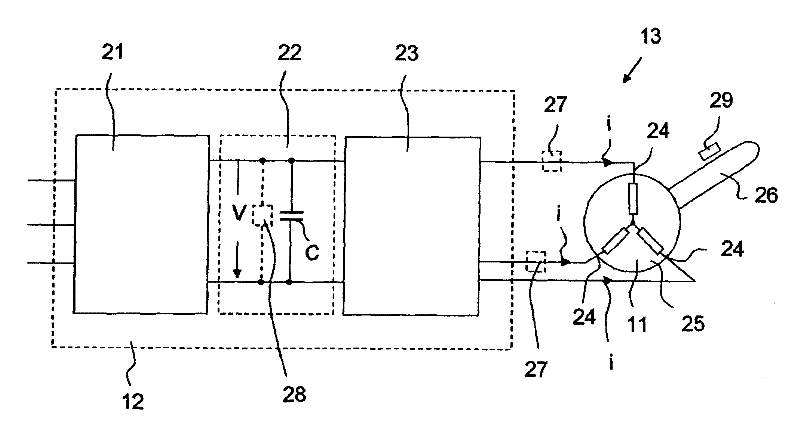

[0035] Each of the axes A1 - A6 is moved by the drive of a drive 13 , which in the case of this embodiment is an electric drive and has an electric motor 8 , 9 , 10 , 11 respectively. For example, in figure 2 The electric motor 11 shown in , or a corresponding electric drive 13 , can move the shaft A2 via transmissions that are not shown in detail and are generally known to those skilled in the art.

[0036] In the case of this embodiment, the motors 8-11 are three-phase AC synchronous motors, in particular permanent magnet excited synchronous motors. The electric motors 8 - 11 are each controlled by electronics 12 , so-called inverters, which in the exemplary embodiment are arranged in a control unit 14 . The electronic de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com