Buckling restrained brace with energy dissipation device sandwiched with lead layer and provided with steel plates at two ends and method for manufacturing buckling restrained brace

An energy-consuming device and constrained buckling technology, which is applied in the processing of building materials, building components, building structures, etc., can solve the problems of difficulty in establishing a constrained buckling bracing design method, material properties cannot be fully exerted, and buckling is prone to occur. Overcome the effect of energy efficiency not being fully utilized, avoiding premature yielding, and increasing energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

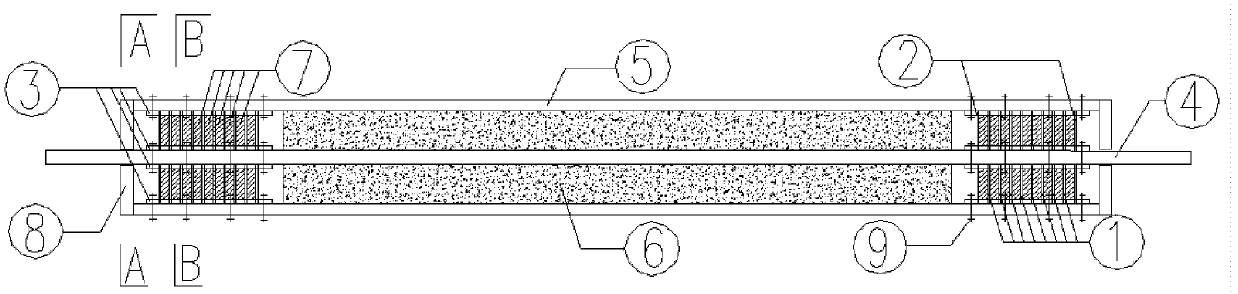

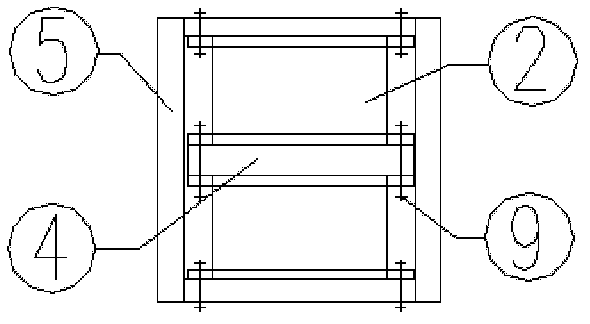

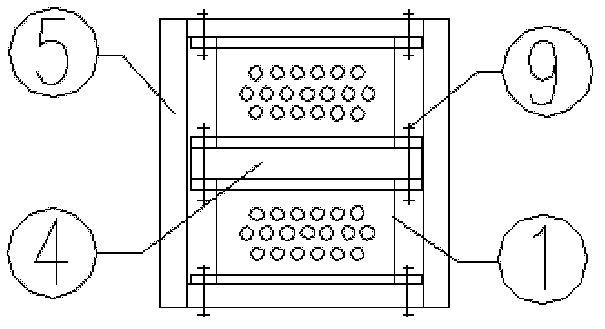

[0032] The restrained buckling brace with lead layer energy dissipation devices between parallel mild steel plates at both ends is as follows: Figure 1 to Figure 6 . The restrained buckling support with lead layer energy dissipation devices between parallel soft steel plates at both ends of this embodiment includes outer steel pipes, end steel plates 8, inner steel plates 4 and energy dissipation of lead layers between parallel soft steel plates connecting these two parts Device and Internal Constraint Filling Material6. The outer layer steel pipe is welded by the outer layer steel pipe steel plate 5. The energy-dissipating device of the lead layer between parallel soft steel plates is composed of parallel energy-dissipating steel plates 1 (for the interior of the energy-dissipating device of the lead layer between parallel mild steel plates) and steel plates 2 (used for energy dissipation of the lead layer between parallel mild The two ends of the device) are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com