Slip type precise filming and seeding roller and seeding machine

A precise and film-laying technology, applied in the parts of the planter, sowing, plant protection cover, etc., can solve the problems of inaccurate control of the seeding drum, too fast rotation of the seed taking plate, and unreliable seed suction. The effect of compactness, accurate plant spacing and improved seed suction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

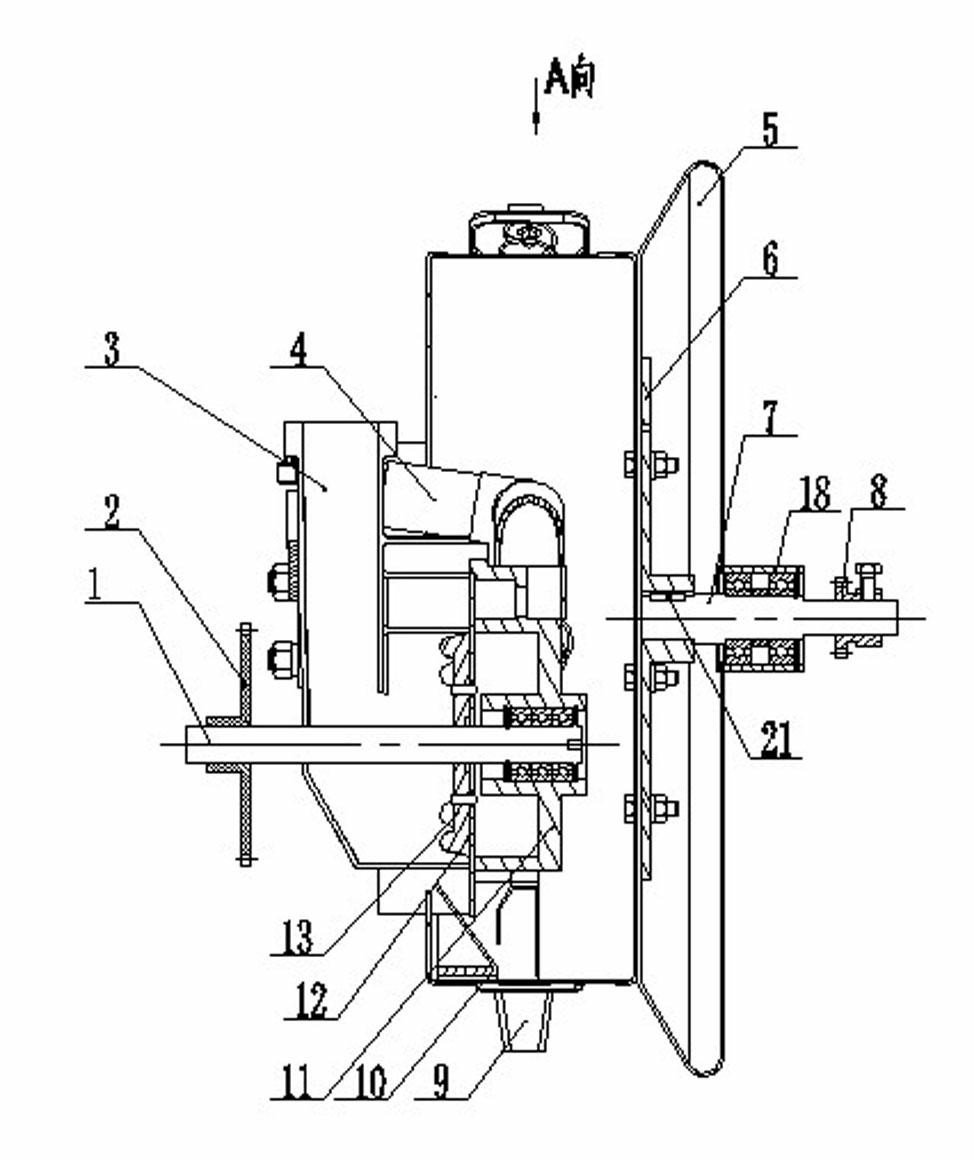

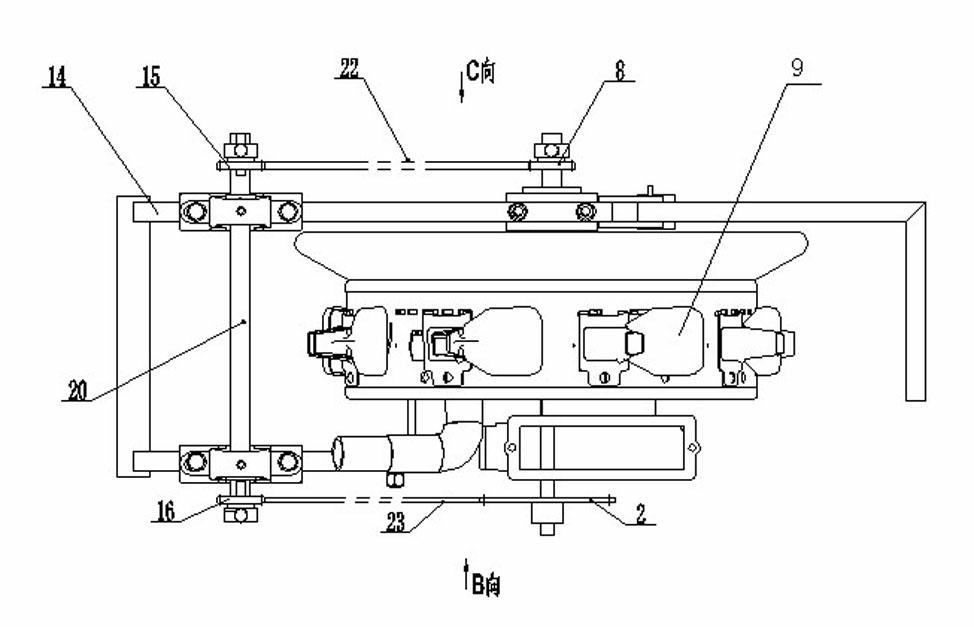

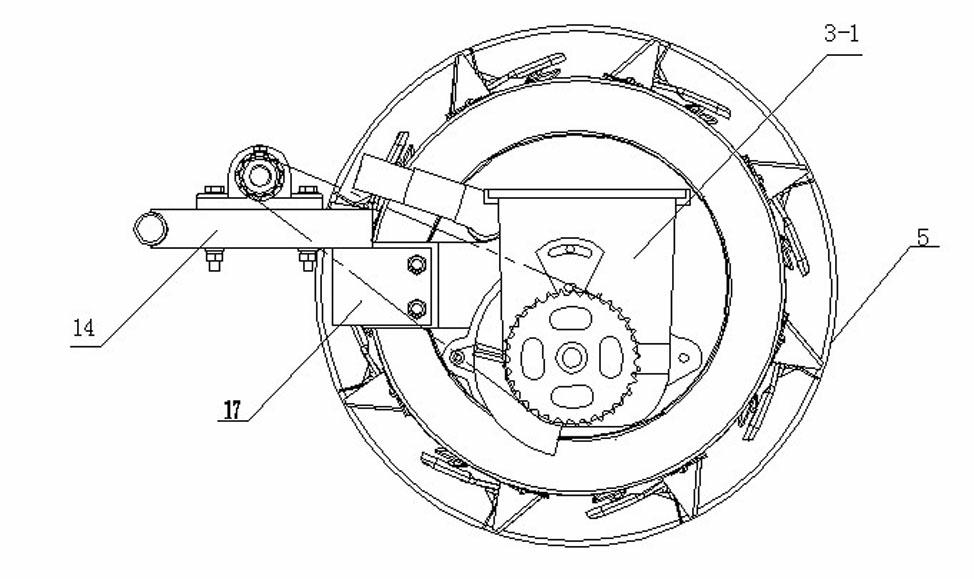

[0024] see Figure 1 to Figure 4 , the present invention relates to a slip-type precision film-spreading seeding roller, comprising a roller support 14, a film-pressing wheel 5, a connecting plate 6, a seed-taking mechanism, a seed-out mechanism and a transmission mechanism, and the film-pressing wheel 5 passes through The bolt is equipped with a connection plate 6, and the seed-taking mechanism is connected to the connecting vertical plate 17 welded on the roller support 14 through bolts. Fixedly installed on the connection plate 6, the other end realizes deceleration transmission through the transmission mechanism and the seed picker shaft 1 of the seed picking mechanism. The transmission mechanism is installed on the drum support 14. The frame of the film seeder is connected together, and connected with the frame of the film seeder through the roller bracket, so that the film can be planted while the film is being laid.

[0025] The described seed picking mechanism also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com