Precision millet seeding machine

A seeder and precise technology, applied in the directions of sowing seeders, seeder parts, planting methods, etc., can solve the problems of difficult to control sowing, difficult sowing of millet, small seeds of millet, etc., to achieve convenient production operations and consistent sowing depth. Good, accurate broadcast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

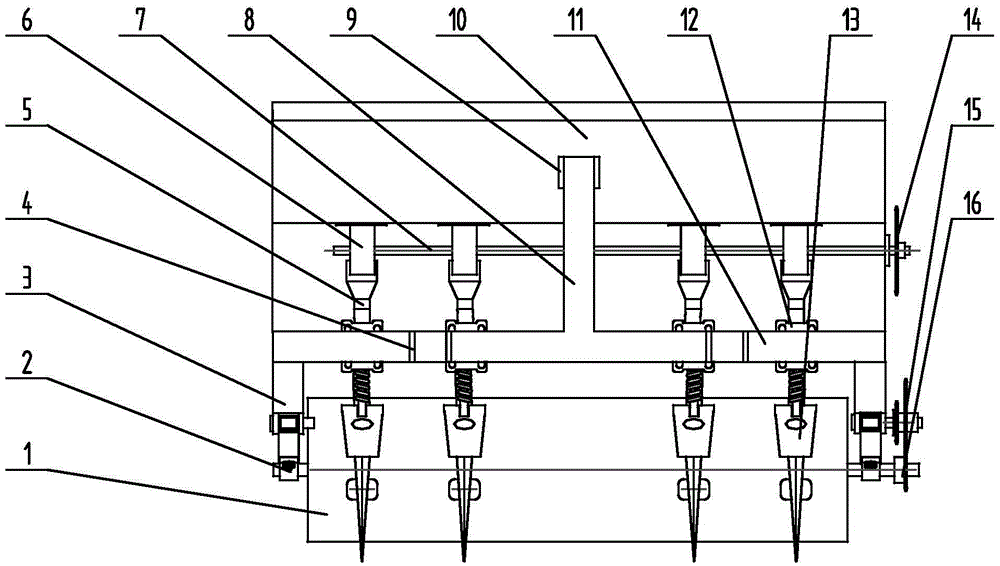

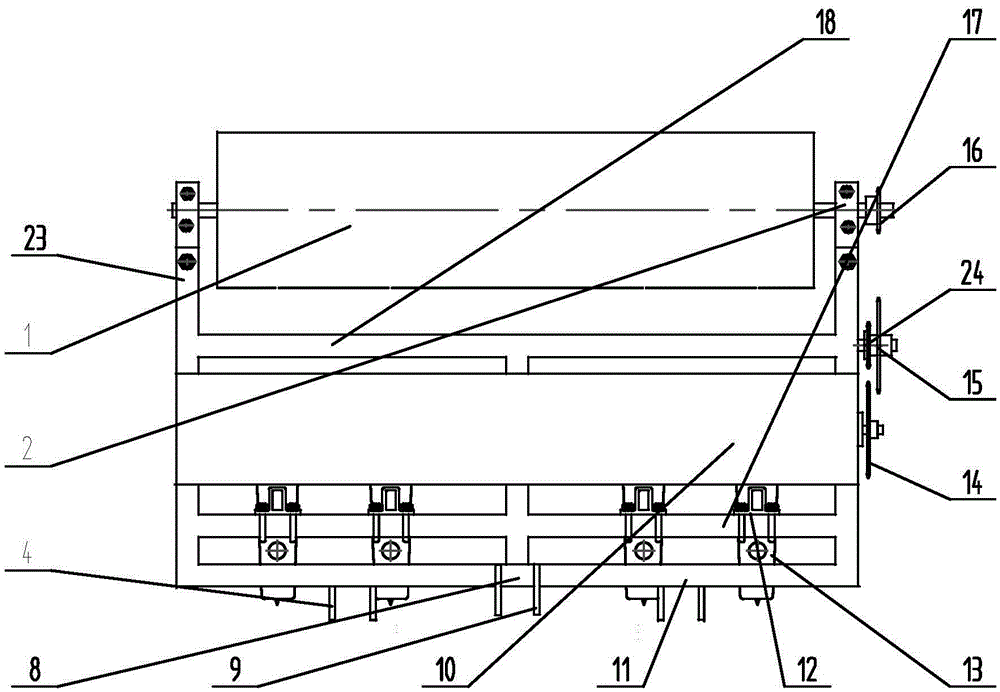

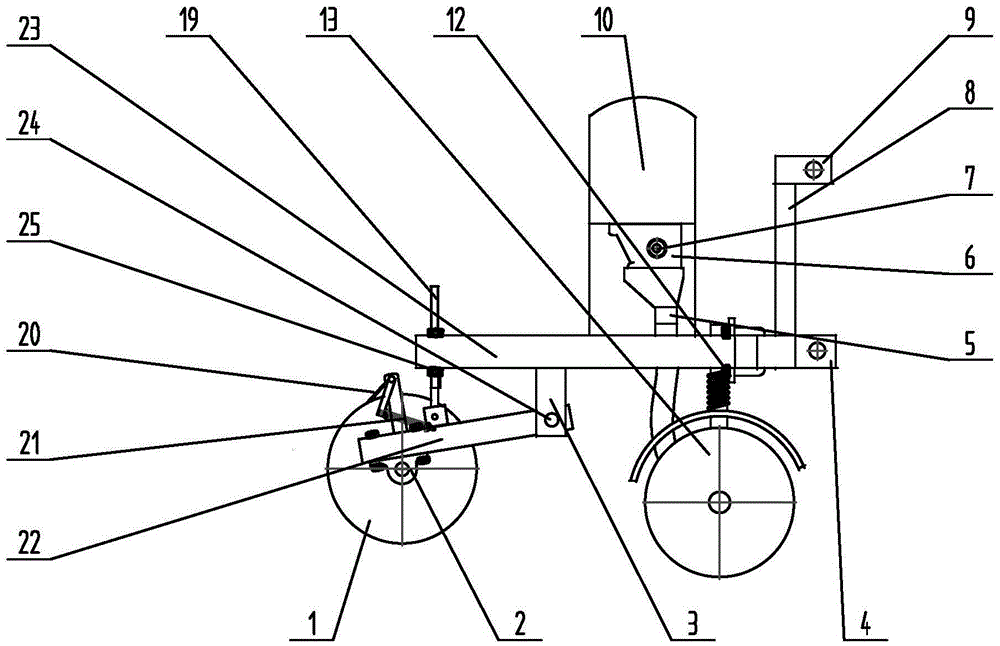

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The present embodiment will be described. This embodiment consists of a ground roller 1, a ground roller shaft seat 2, a ground roller articulated column 3, a hydraulic suspension lower articulated pin groove 4, a funnel seed delivery pipe 5, a precision seed meter 6, a seed meter shaft 7, and a suspension column 8 , Pin groove 9 on the hydraulic suspension, seed box 10, frame front beam 11, opener assembly plate 12, disc opener 13, seed sprocket 14, transfer deceleration wheel set 15, ground roller chain Wheel 16, frame middle beam 17, frame rear beam 18, ground roller adjusting screw 19, ground roller traction frame 22, two side frames 23, long axis pin 24 and nut 25 are formed, and the frame front beam 11 is formed on the front end surface There are two articulated pin grooves 4 under the hydraulic suspension symmetrically, the upper articulated pin groove 9 of th...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination image 3 and Figure 4 and Figure 5 The present embodiment will be described. The difference between this embodiment and the first embodiment is that it also includes a scraper 20 and a tension spring 21. The scraper 20 is arranged on the roller surface, and the scraper 20 is fixed on the roller of the ground roller 1 by the extension spring 21. On the surface, one end of the extension spring 21 is connected with the soil scraper 20, and the other end of the extension spring 21 is hung on the ground roller traction frame 22. Prevent ground roll 1 from sticking to dirt.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 The present embodiment will be described. The ground roller 1 described in this embodiment adopts an iron-skinned roller or a grid-shaped round roller.

[0010] work process:

[0011] When the tractor hangs the planter and drives forward, the ground roller 1 is driven to rotate, and the ground roller sprocket 16 rotates the large sprocket of the transfer deceleration sprocket set 15 through the chain drive, and the other small sprocket of the transfer deceleration sprocket set 15 passes through the chain The transmission drives the seeding sprocket 14 to rotate, drives the seeding shaft 7 to rotate, and impels the precision seed metering device 6 to accurately seed the seeds according to the walking distance, and the seeds are introduced into the small ditch opened by the disc opener 13 through the funnel seeding pipe 5 . It is rolled by ground roller 1. Sowing depth is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com