Porous boring machine for combined boring bar

A combined type and boring bar technology, which is applied in the direction of boring bar, boring/drilling, boring machine/drilling machine parts, etc., can solve the problems such as the difficulty and deformation of ultra-long boring bars, and achieve simple and convenient adjustment, easy operation, and ensure The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

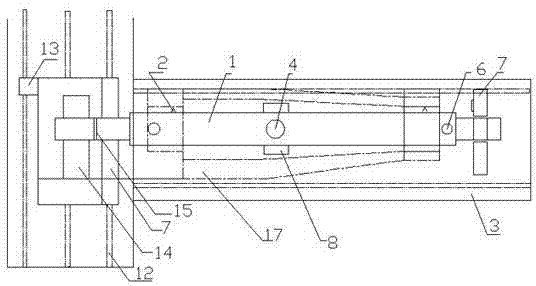

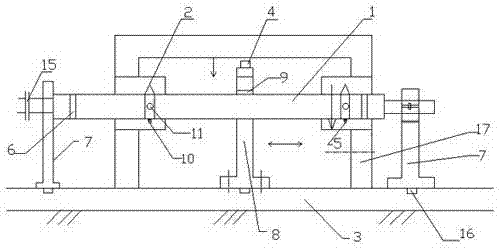

[0032] A multi-hole boring machine with a combined boring bar, including a driving device, a boring bar 1 driven by the driving device, a boring tool 2 arranged on the boring bar 1, a boring platform 3, and a deflection for adjusting the deflection of the boring bar 1 The fine adjustment mechanism 4 and the boring knife adjusting mechanism 5 for adjusting the telescopic length of the boring knife 2, the boring knife 2 is at least two, respectively arranged in the boring knife installation hole on the boring bar 1, the boring bar 1 There is a deflection detection hole 6 on the top, the two ends of the boring bar 1 are respectively connected to the movable support seat 7, the deflection fine adjustment mechanism 4 is located between the two movable support seats and connected with the boring bar 1, the boring knife adjustment mechanism 5 is set Installed in the hole and connected with the boring tool 2, the movable support seat 7 and the deflection fine adjustment mechanism 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com