Method for producing HRB 600 high-strength steel through micro-alloying

A technology of micro-alloying and high-strength steel, which is applied in the field of steel production, can solve the problems of small production scale of high-strength steel bars, and achieve the effect of uniform temperature composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

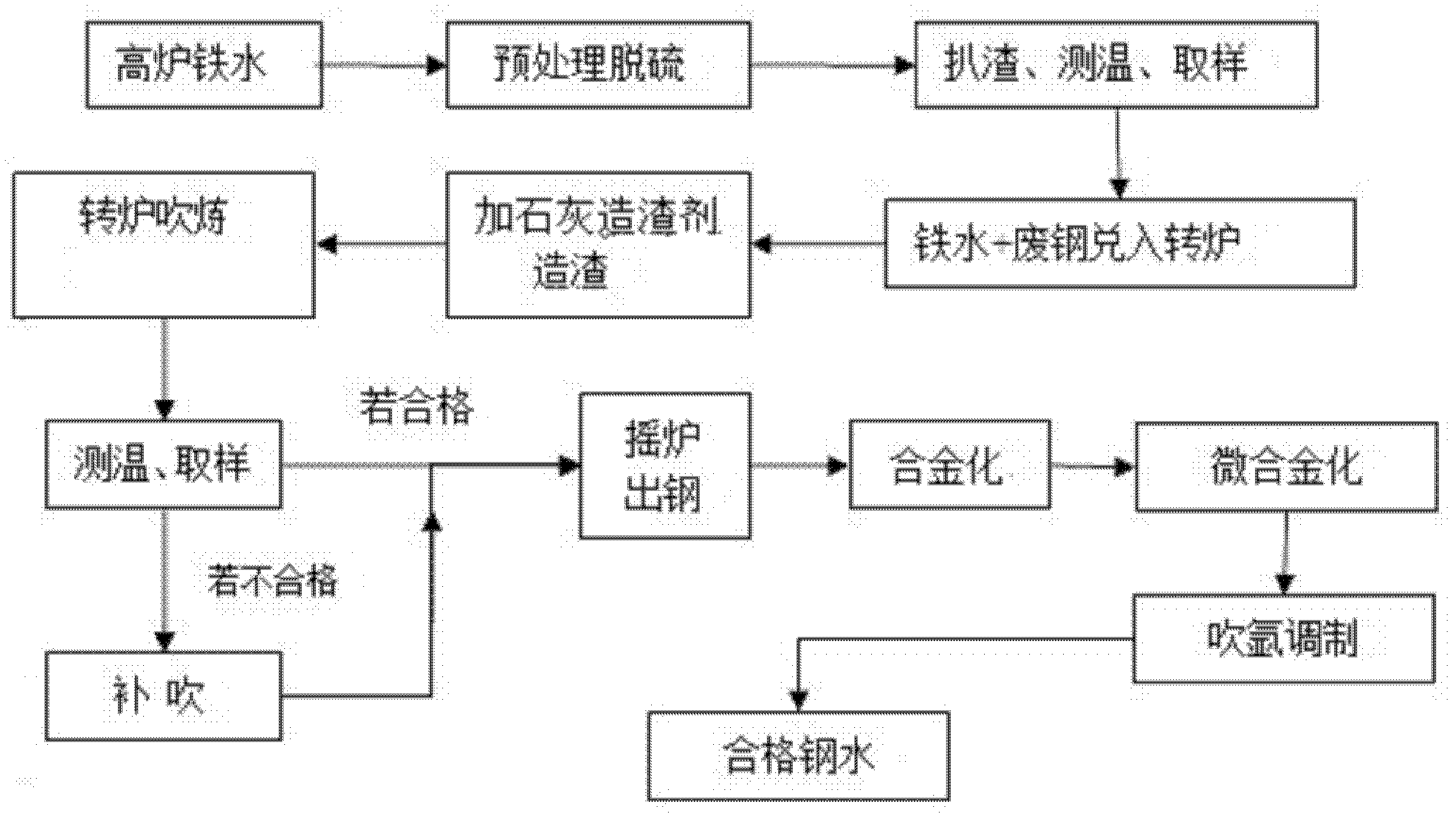

Method used

Image

Examples

Embodiment 1

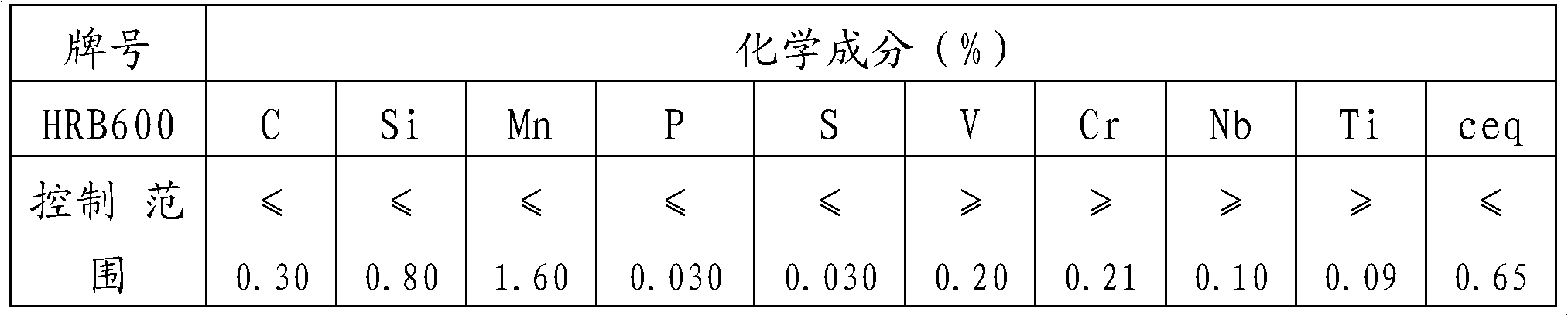

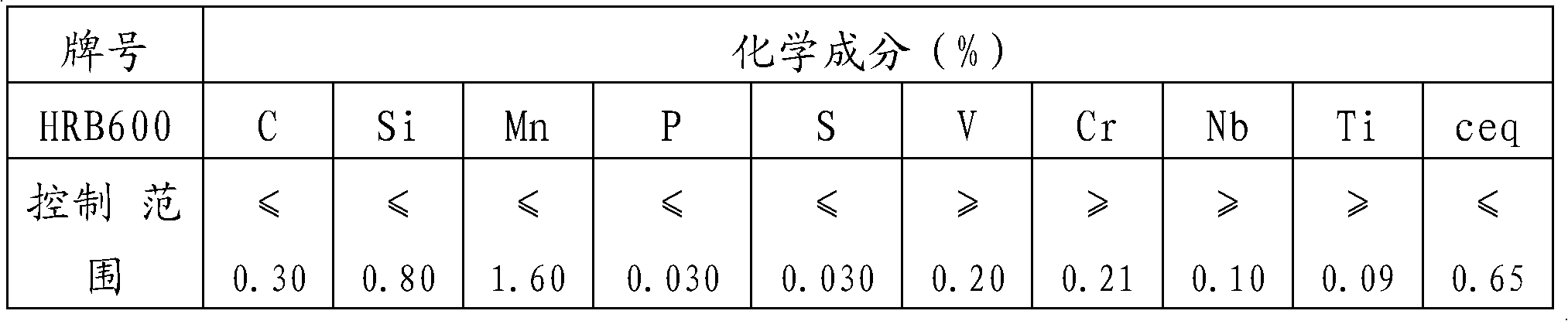

[0034] The method for producing HRB600 high-strength steel by microalloying provided by the present embodiment comprises the following steps:

[0035] (1) Put the molten iron into the converter, wherein the carbon content of the molten iron is not less than 3.6%, the temperature of the molten iron is between 1280°C and 1330°C, the silicon content is not more than 0.60%, the P content is not more than 0.100%, and the S content is not more than 0.080%;

[0036] (2) Desulfurization of molten iron pretreatment, desulfurization of molten iron to less than 0.050%, and the slag in the molten iron must be removed after desulfurization, so that the amount of slag in the molten iron is less than or equal to 0.5%, and the temperature of the molten iron after desulfurization is not lower than 1250°C ;

[0037] (3), temperature measurement and sampling of molten iron, so that the composition and temperature of molten iron entering the furnace must meet the requirements of conditions (1) a...

Embodiment 2

[0054] The method for producing HRB600 high-strength steel by microalloying provided by the present embodiment comprises the following steps:

[0055] (1) Put the molten iron into the converter, wherein the carbon content of the molten iron is not less than 3.6%, the temperature of the molten iron is between 1280°C and 1330°C, the silicon content is not more than 0.60%, the P content is not more than 0.100%, and the S content is not more than 0.080%;

[0056] (2) Desulfurization of molten iron pretreatment, desulfurization of molten iron to less than 0.050%, and the slag in the molten iron must be removed after desulfurization, so that the amount of slag in the molten iron is less than or equal to 0.5%, and the temperature of the molten iron after desulfurization is not lower than 1250°C ;

[0057] (3), temperature measurement and sampling of molten iron, so that the composition and temperature of molten iron entering the furnace must meet the requirements of conditions (1) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com