Hydraulic damper spool valve

A technology of hydraulic damping and hydraulic damper, which is applied in the valve field of hydraulic damper, can solve problems such as difficult mathematical technology, complexity and cost constraints, and restrictions, and achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

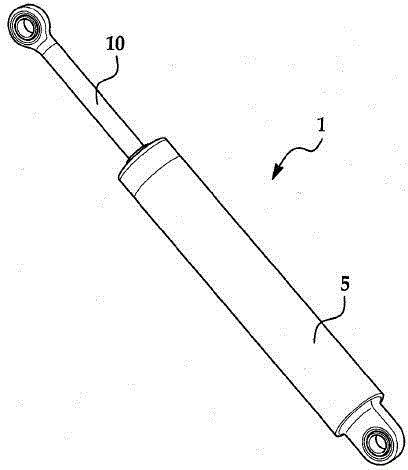

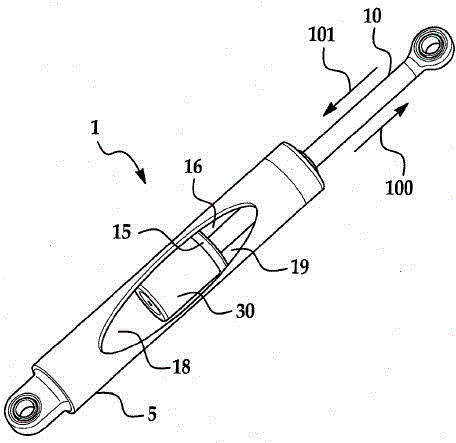

[0031] refer to figure 1 , figure 2 and Figure 4 , the hydraulic damper assembly (1) comprises: a main body (5), a shaft assembly (10) and a main piston (15) configured to divide the inner chamber of said main body (5) into an upper portion (16) and lower part (18). The upper (16) and lower (18) portions of the hydraulic damper contain hydraulic fluid (19). In a particular embodiment of the invention, a valve body (30) is mounted to the main piston (15) of said hydraulic damper. The valve body (30) may be mounted to the main piston (15) by mechanical fasteners or similar means. Such as figure 1 , figure 2 and Figure 4 As shown in the non-limiting embodiment shown, one or more seals (80) may be provided between the valve body (30) and the main piston (15). Also, said shaft assembly (10) may be threaded so that the shaft assembly can be engaged with the main piston (15) and valve body (30), as Figure 4 Non-limiting example shown.

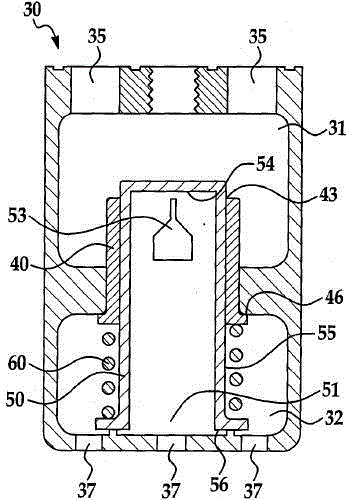

[0032] refer to image 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com