Automatic discharger of tea leaf firing machine

An automatic discharge device, tea frying machine technology, applied in tea processing before extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

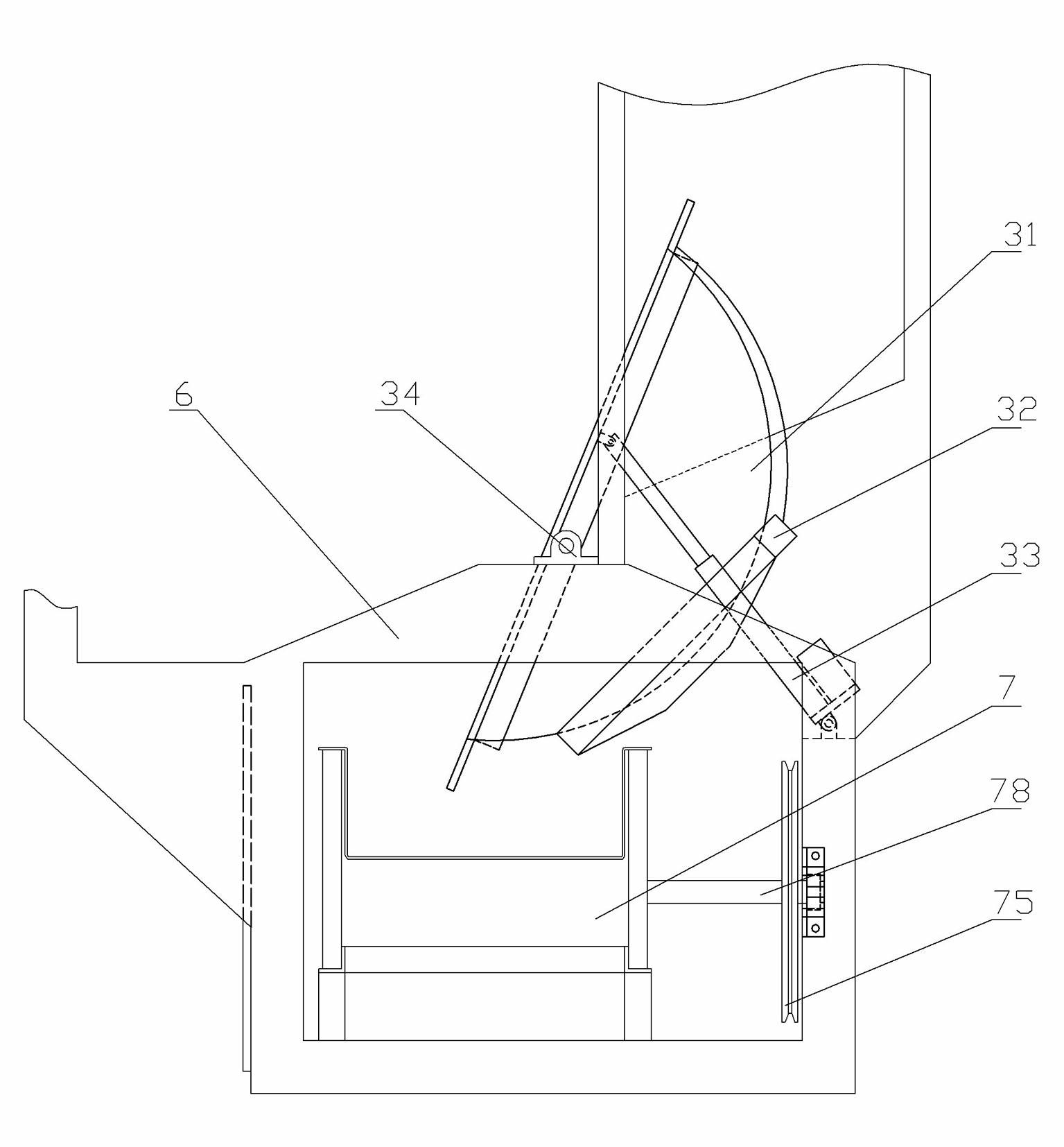

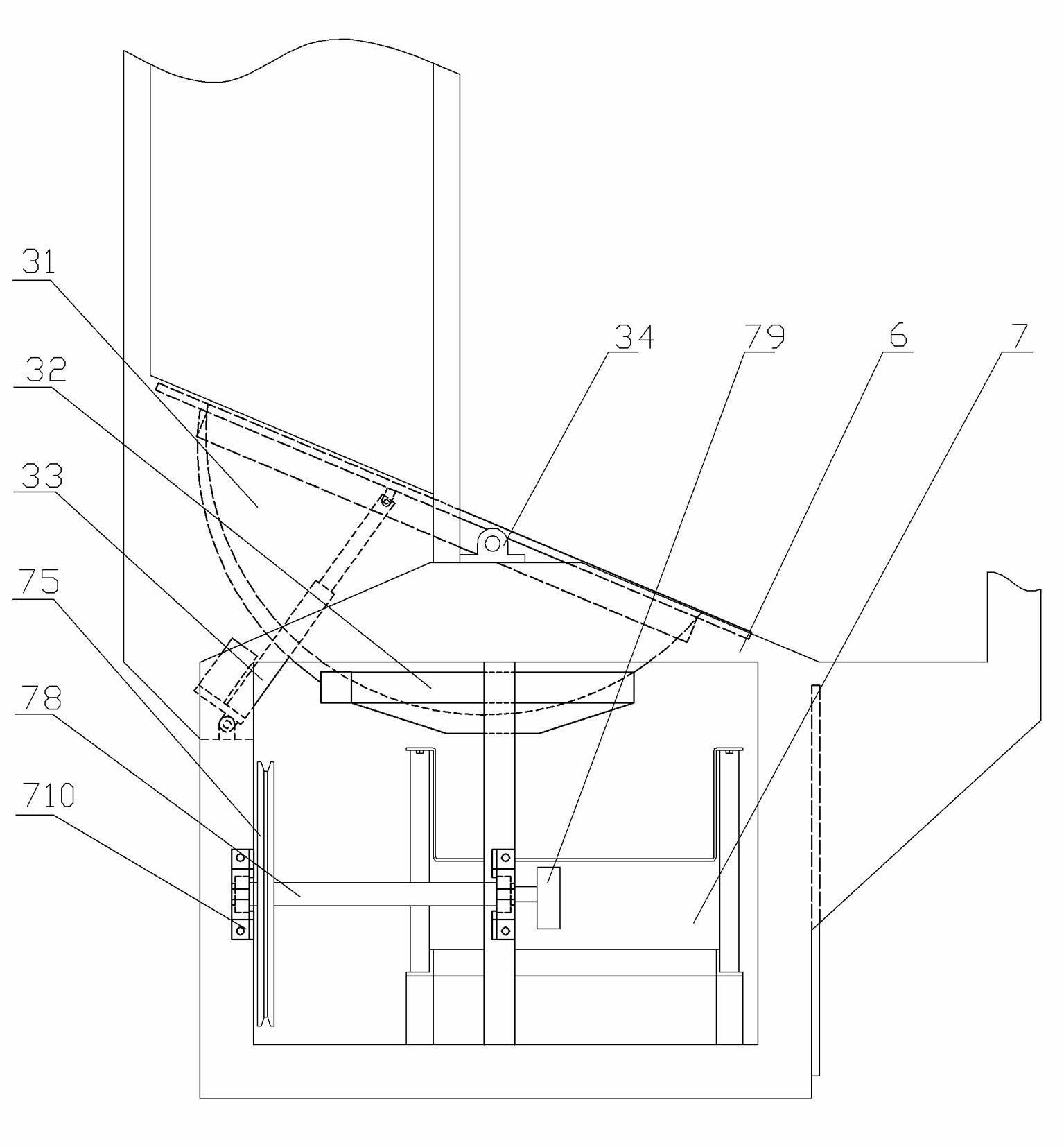

[0021] The tea frying pot 31 pot is installed along the middle protruding shaft with the bearing 34 on the frame 6. The bearing 34 is fixed on the middle part of the crossbeam on the frame 6 top. The automatic discharge device of the tea machine also includes an electric push rod 33, one end of the electric push rod 33 is hinged to the middle upper part of the tea pot 31, and the other end of the electric push rod 33 is hinged on the frame 6, and the automatic discharge device of the tea machine It also includes an electric heater 32 and a temperature controller, and the electric heater 32 is fixed on one side of the middle part of the outer surface of the bottom of the frying tea pot 31 .

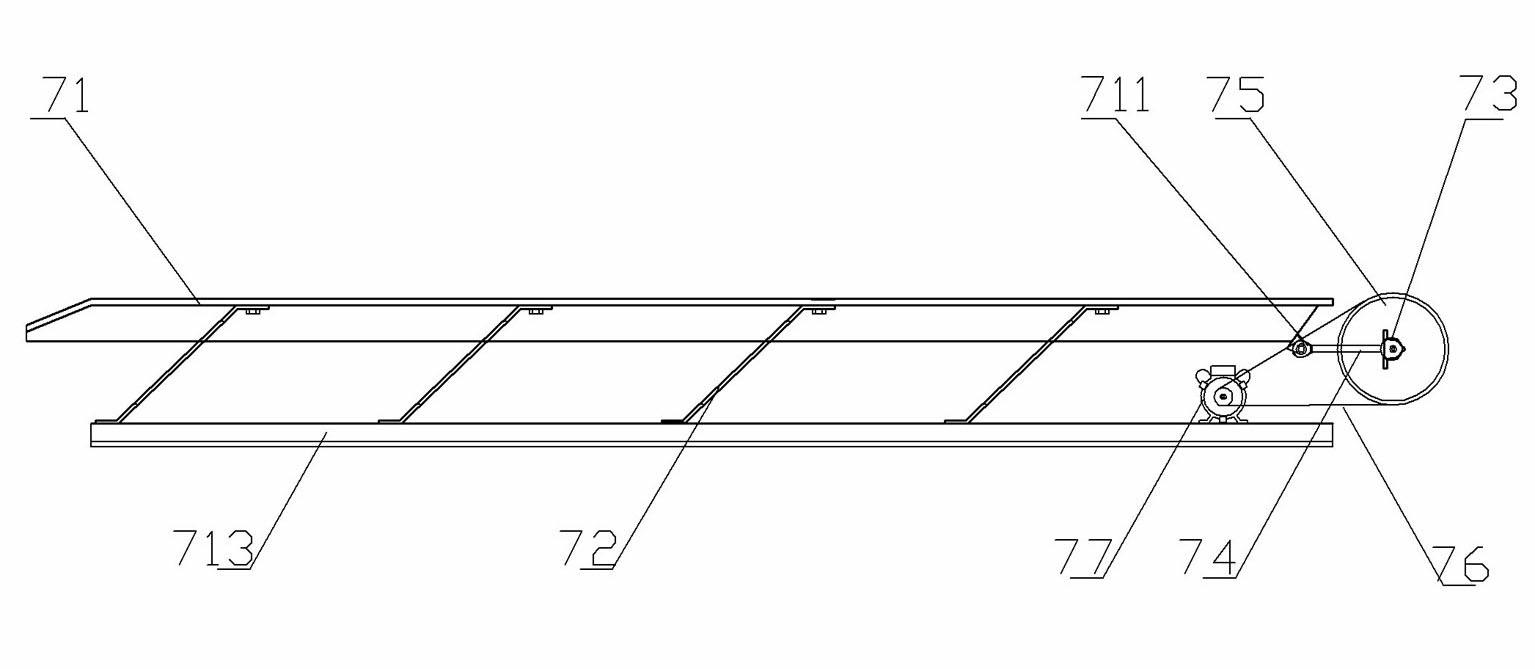

[0022] The vibration delivery tank 7 includes a tank body 71, the lower longitudinal rod 713 of the intermediate bracket, the vibrating piece 72 and a driving mechanism. , deceleration mechanism and reversing mechanism, motor 77 is installed on the longitudinal rod 713 under the middle bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com