Patents

Literature

73results about How to "Even heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

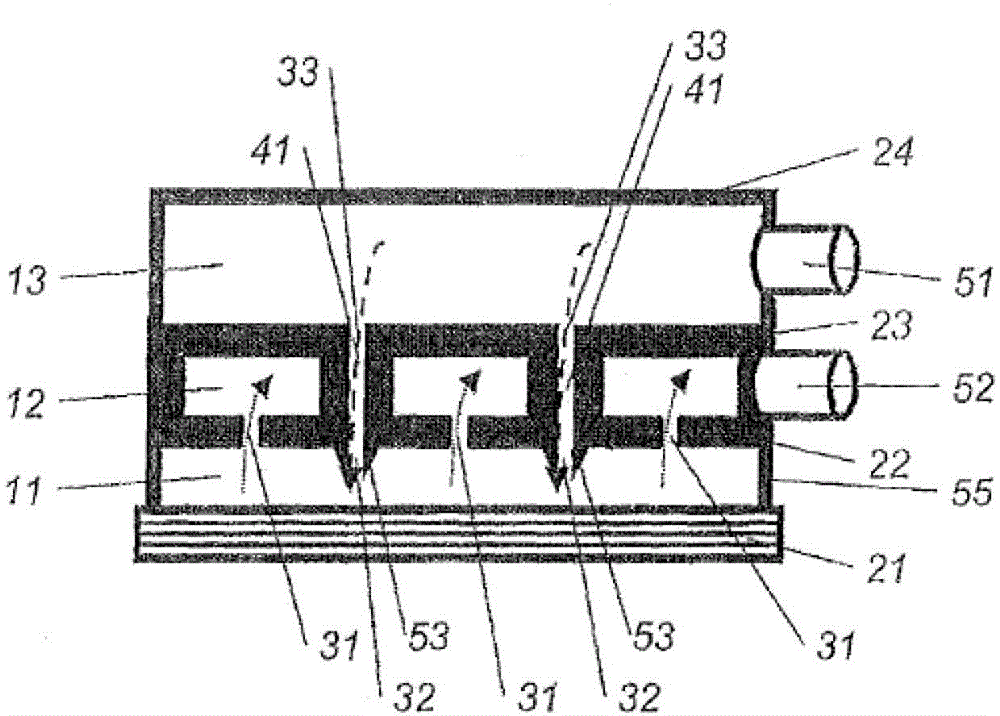

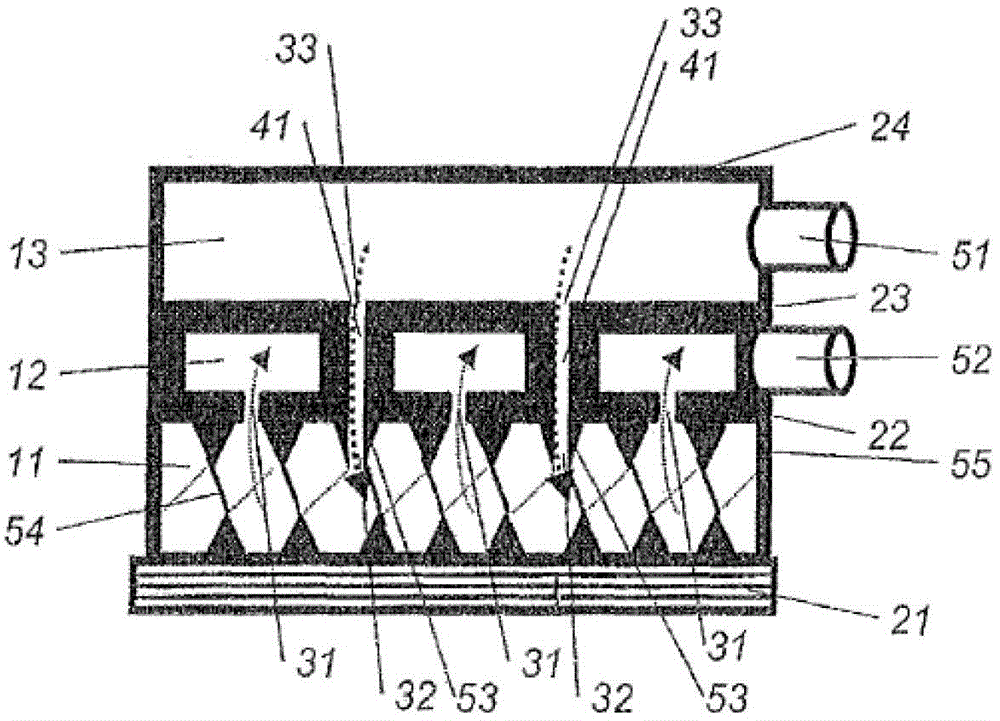

Means, method and system for heat exchange

ActiveCN102803886AEasy to manufactureImprove thermal efficiencyBoilers/analysersEnergy efficient heating/coolingEngineeringHeat transfer

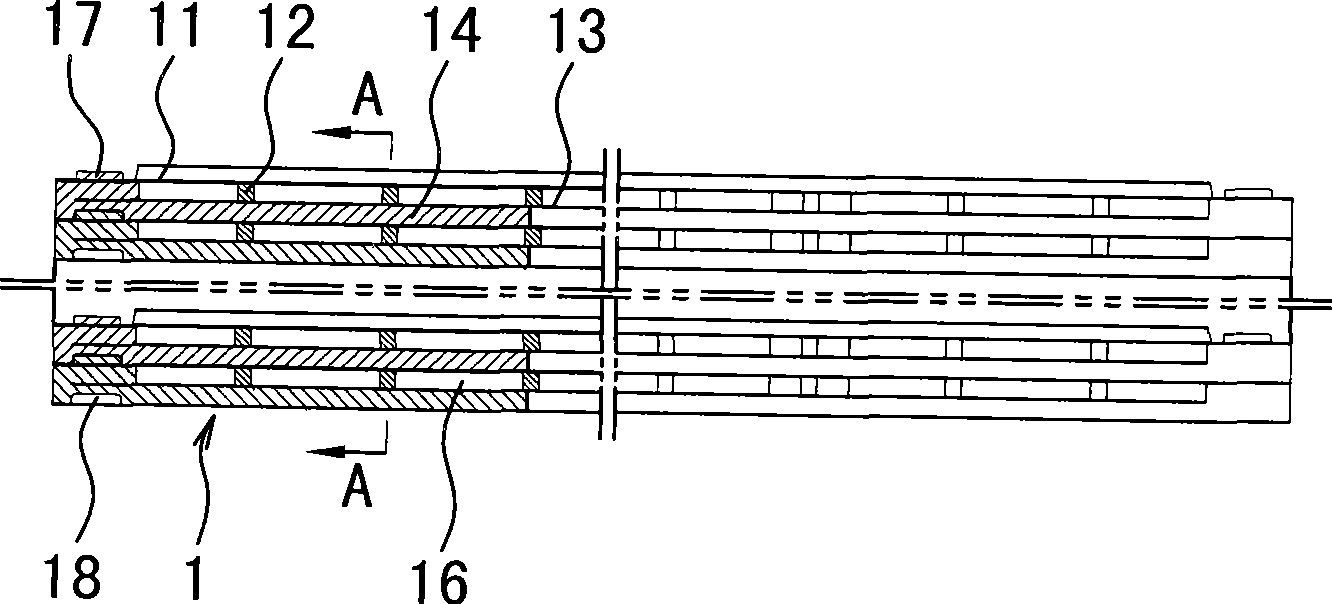

A heat transfer device and its manufacturing method are provided. The heat transfer device has a heat transfer member defining a heat exchange surface with which a heat transportable medium contact in use and via which heat is transferable between the heat transportable medium and a working medium, and a device body for containing the heat transportable medium. The body of the device defines a first chamber (11), a second chamber (12) and a third chamber (13) which is in fluid communicable relationship. The body is configured to allow the heat transportable medium fluid to pass from the second chamber (12) to the first chamber (11) and then to the third chamber (13), or from the third chamber (13) to the first chamber (11) and then to the second chamber (12), and the second chamber (12) is sandwiched or positioned between the first chamber (11) and the third chamber (13) in the body.

Owner:BESTRONG INT

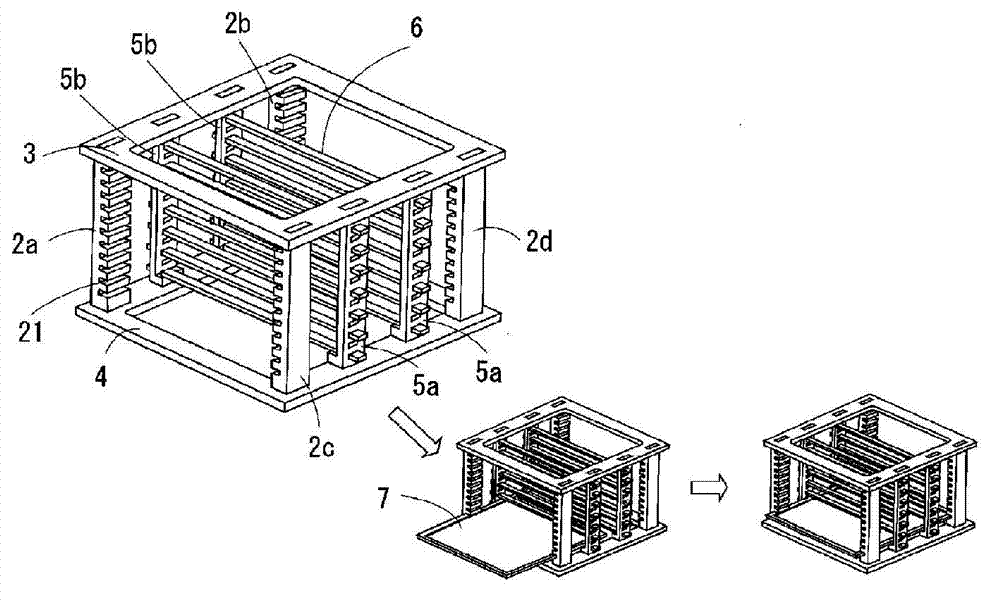

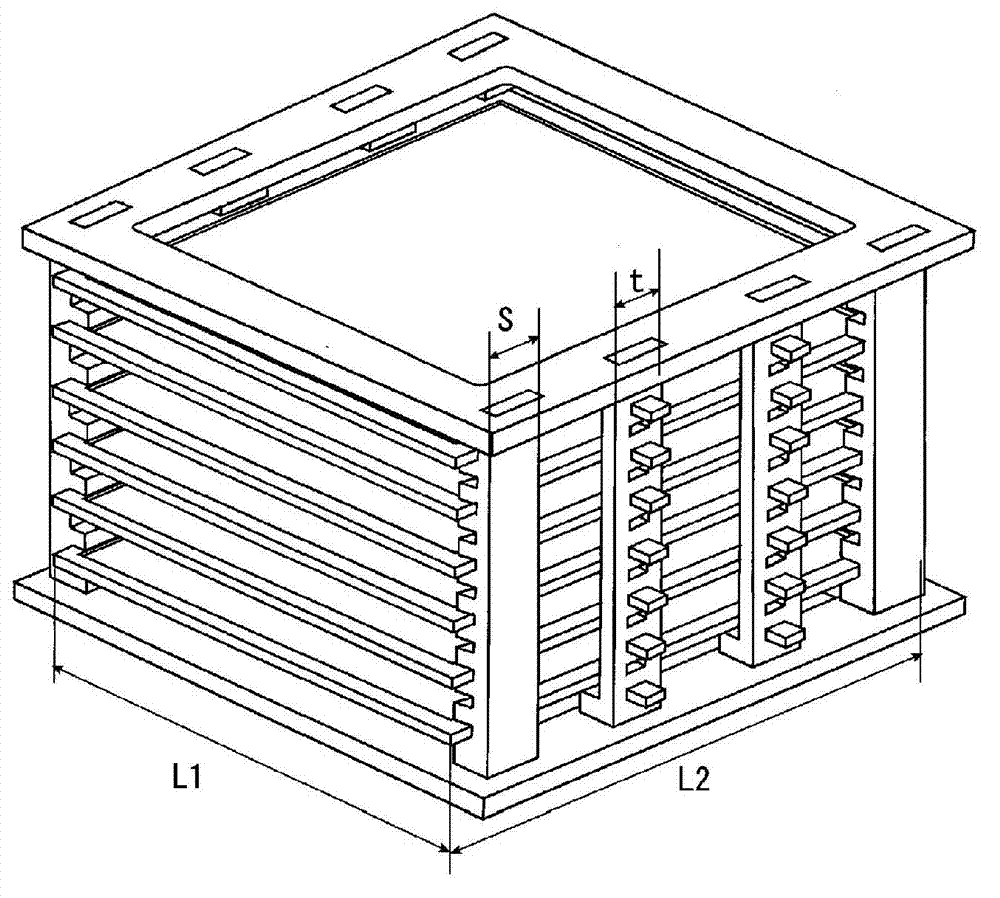

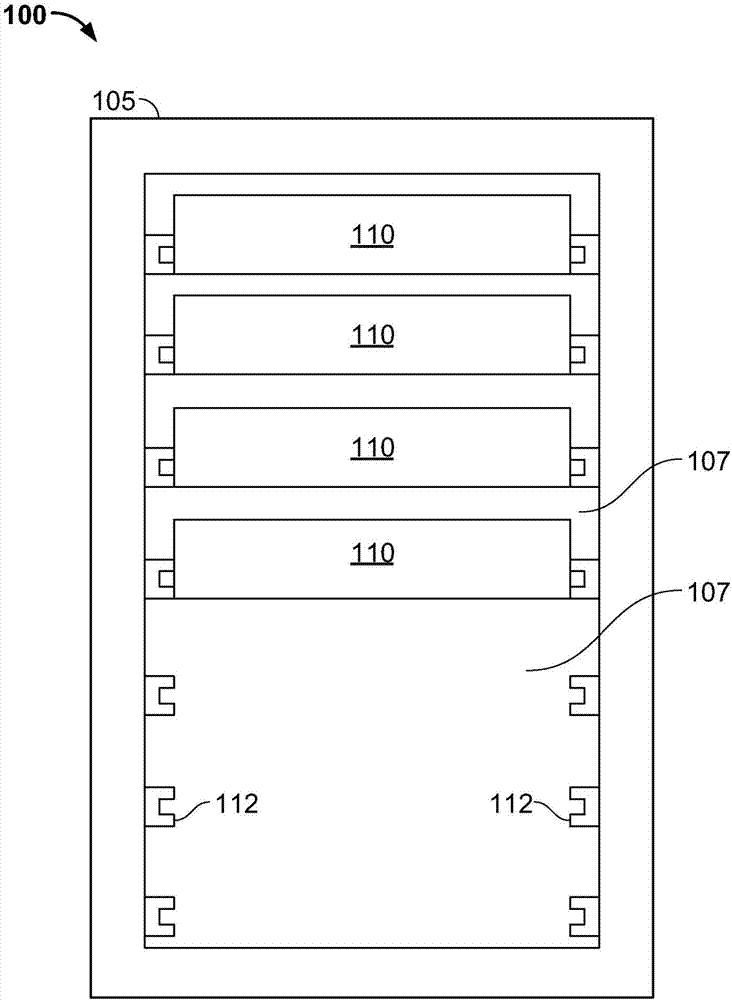

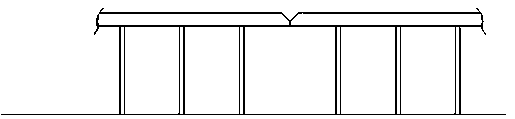

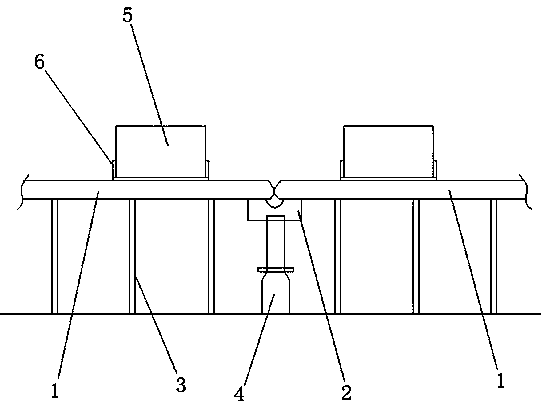

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

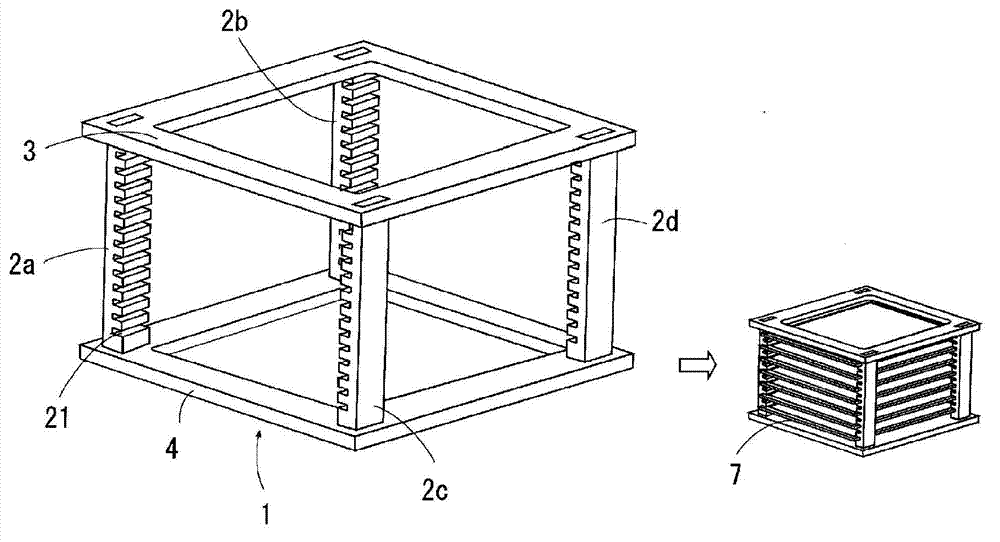

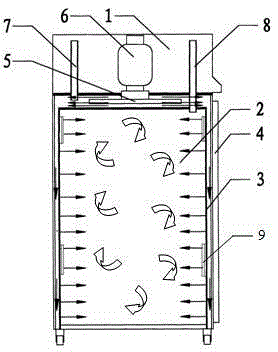

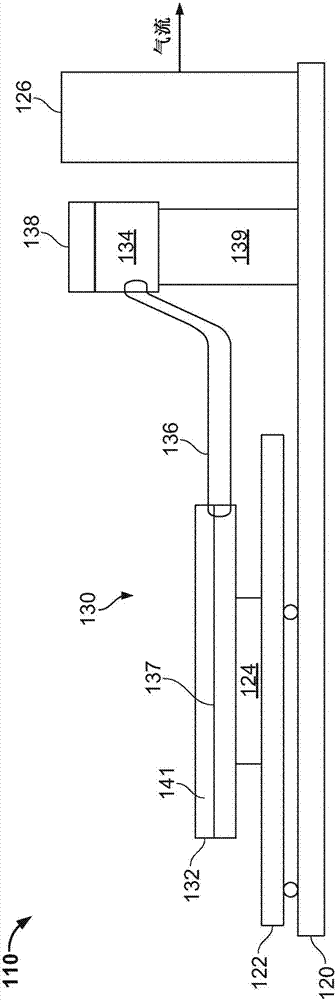

Lithium battery baking oven

InactiveCN106813464AReduction of blocked surfacesStable hot air circulationFinal product manufactureDrying gas arrangementsFiberTemperature control

The invention discloses a lithium battery round baking oven, which comprises a case and an oven body arranged in the case, wherein the oven body uses a round structure; a heater and a heat insulation layer are arranged on the inner wall of the case; an air inlet opening and an air outlet opening are formed in the top of the case; a blower device positioned on the top of the oven body is arranged in the case, and is connected with a motor; when the blower device is driven by the motor, eddy current is generated between the case and the oven body; after a plurality of exhaust holes are formed in the oven body, high-speed flowing hot air is formed in the oven body, so that each corner in the oven body can receive heat radiation; in addition, the heated condition is uniform; the baking effect is greatly improved. A certain number of adsorbent fiber materials are arranged on the inner wall of the oven body. The lithium battery round baking oven has the characteristics that the battery temperature can fast reach the process baking temperature; drying and dewatering are performed; the cost is lower; the humidity and temperature control on the external environment is not needed; the equipment and the energy sources are saved; the baking cost is reduced.

Owner:陕西融泰企业管理咨询有限公司

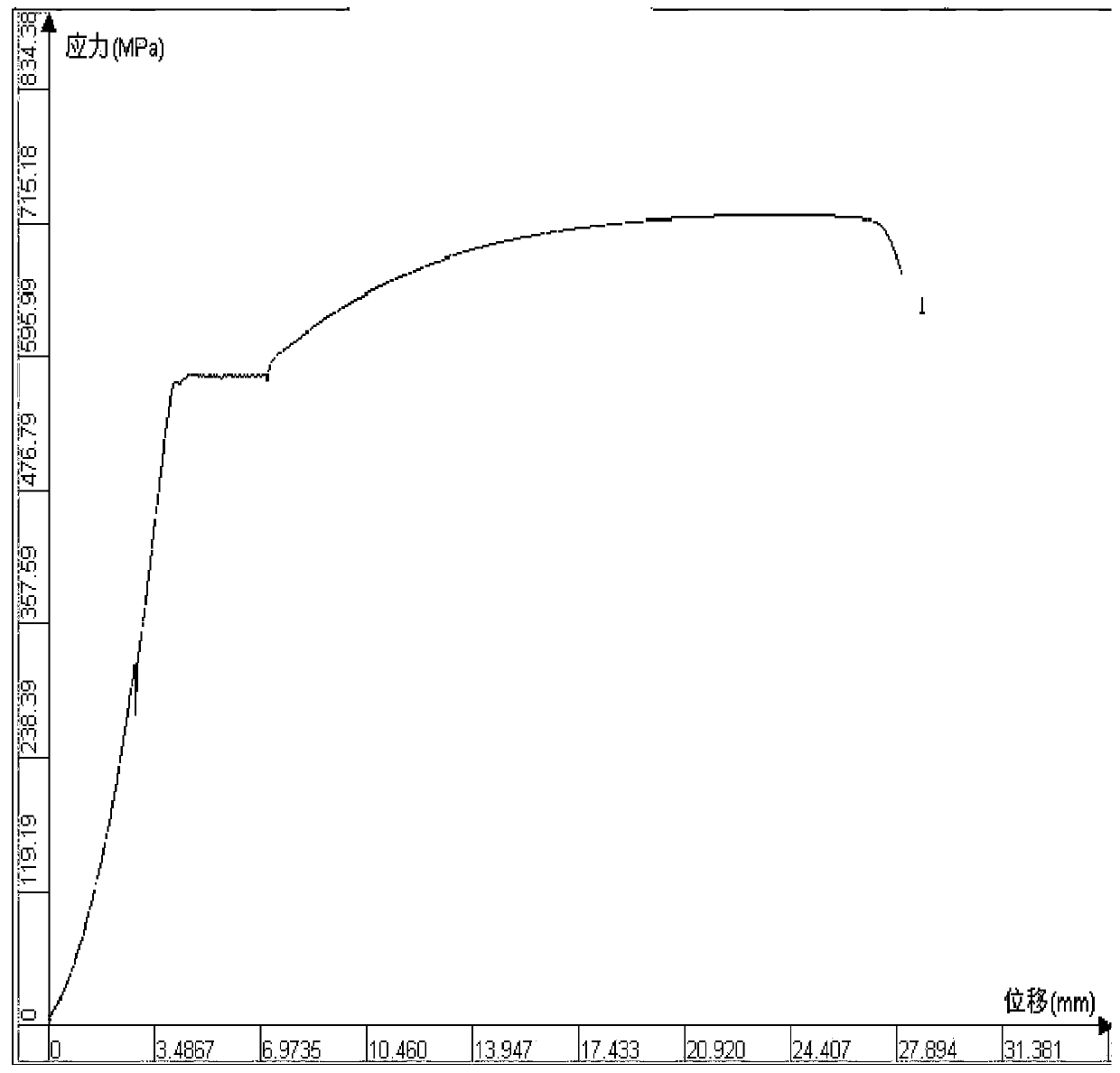

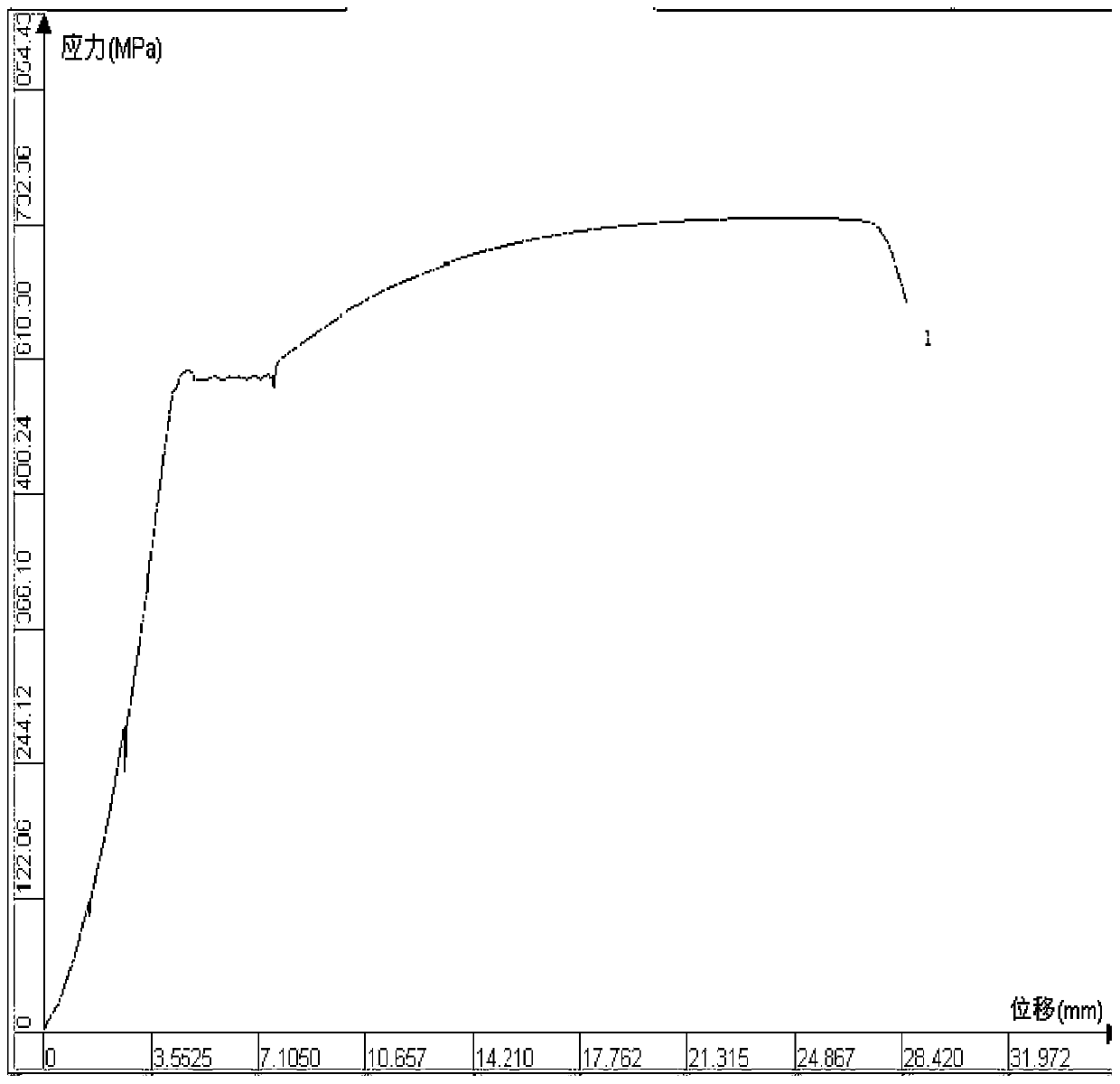

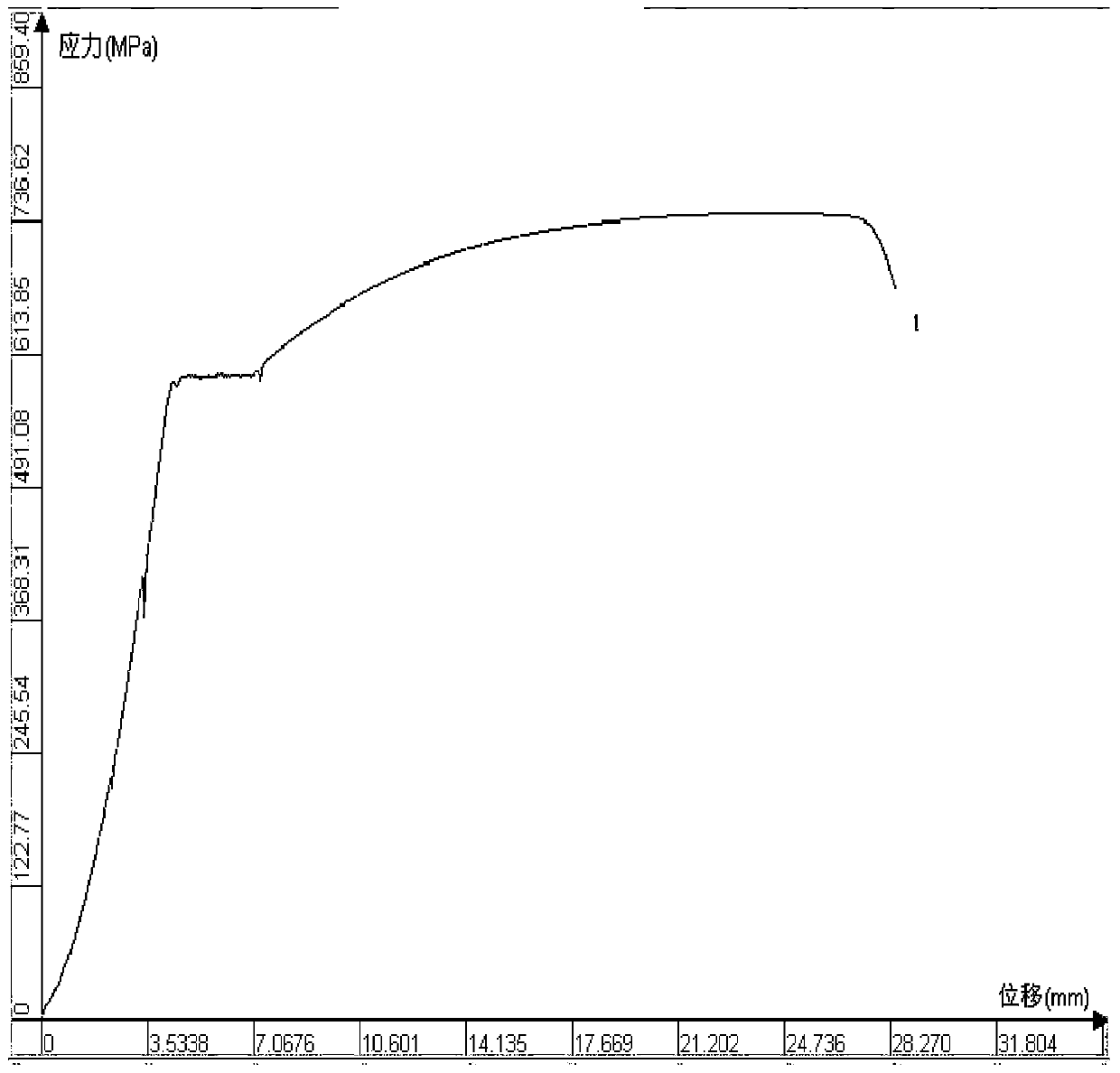

HRB500E Nb-Ti microalloy high-strength aseismic reinforcement bar and production process

ActiveCN110295326AIncreased crack susceptibilityReduced crack susceptibilityProcess efficiency improvementChemical compositionFerrosilicon

The invention provides an HRB500E Nb-Ti microalloy high-strength aseismic reinforcement bar and a production process and belongs to the technical field of metallurgy. Chemical components of the reinforcement bar comprise, by weight, 0.20-0.25% of C, 0.005-0.03% of Ti, 0.01-0.04% of Nb, 0.60-0.80% of Si, 1.40-1.60% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, and thebalance Fe and inevitable impurities. A preparation method comprises the steps of (1) converter smelting, specifically, adding ferrosilicon, silicomanganese and ferrocolumbium alloys in the steel tapping process, conducting deoxidation alloying, adding ferrotitanium and conducting soft blowing to feed the mixture to be subjected to continuous casting and pouring; (2) continuous casting, specifically, conducting protective casting in the whole continuous casting process; and (3) heating and rolling, specifically, conducting shearing through the water pre-cooling process and then conducting check and warehousing, wherein according to the specifications of the reinforcement bar, the yield strength of the reinforcement bar is greater than or equal to 500 MPa, the tensile strength is greater than or equal to 630 MPa, the yield strength ratio is greater than or equal to 1.25, the yield standard ratio is less than or equal to 1.30, the percentage elongation after fracture is greater than orequal to 15, and the maximum elongation Agt is greater than or equal to 9.0%.

Owner:苏州东大汉森冶金实业有限公司

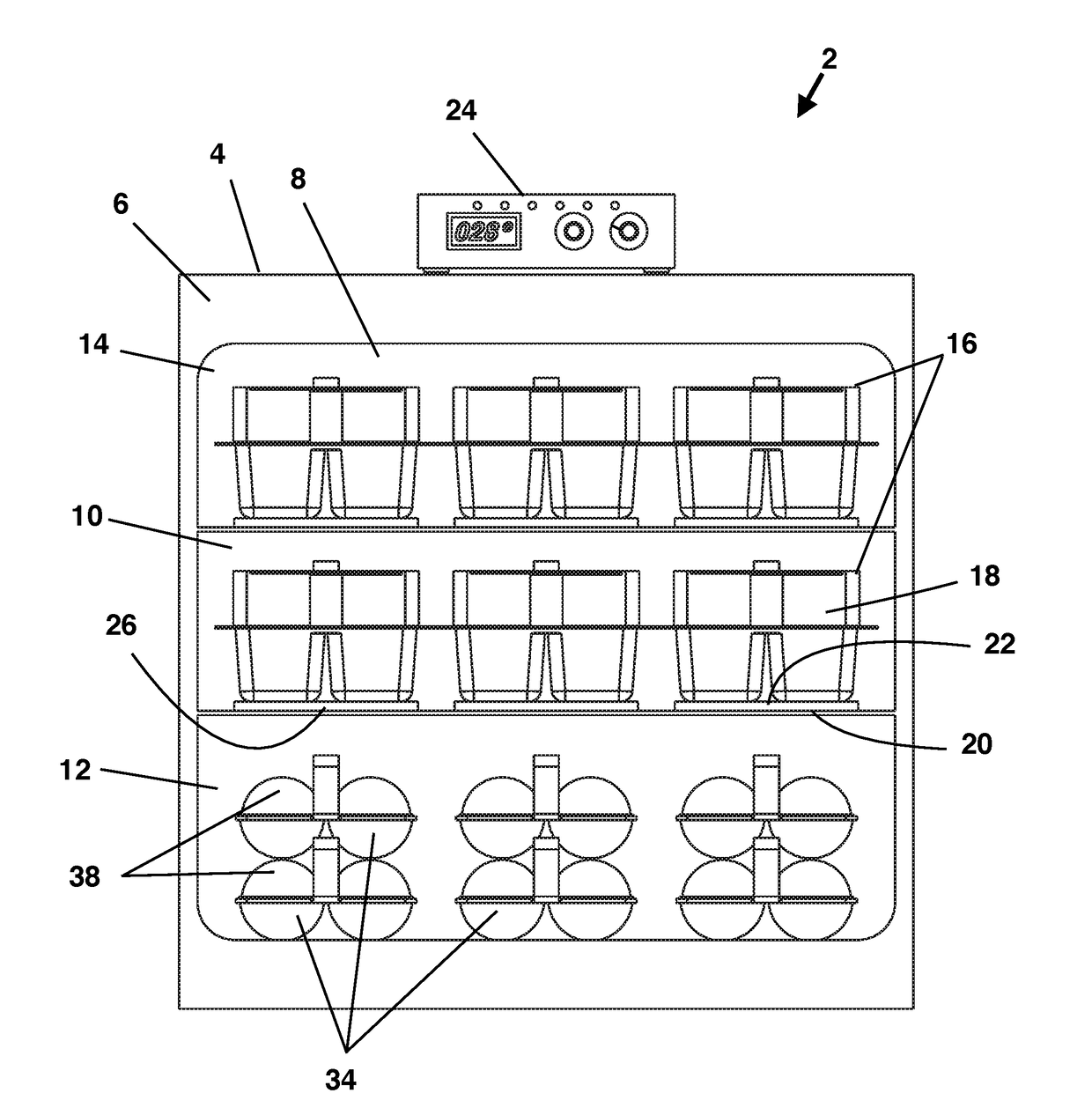

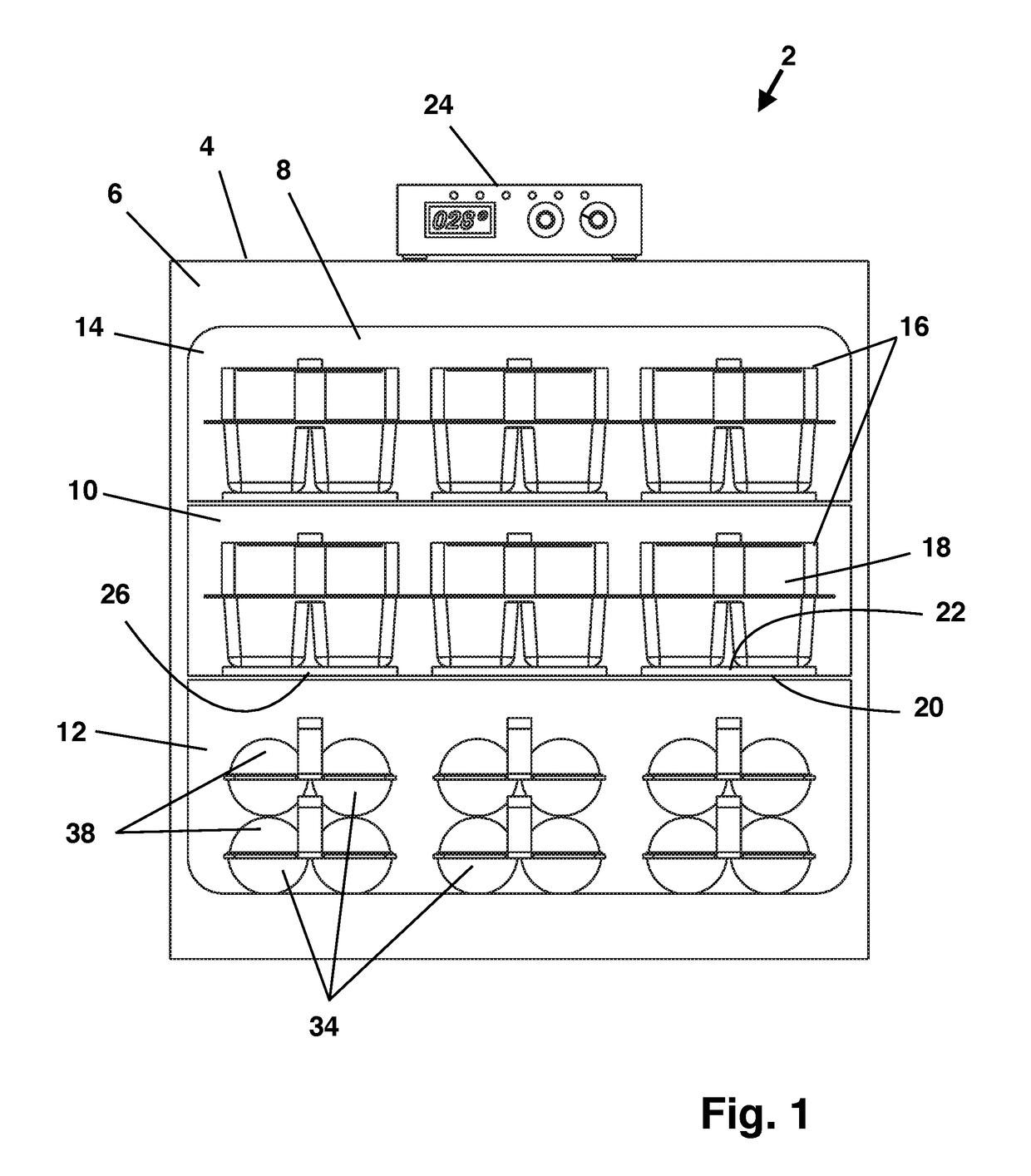

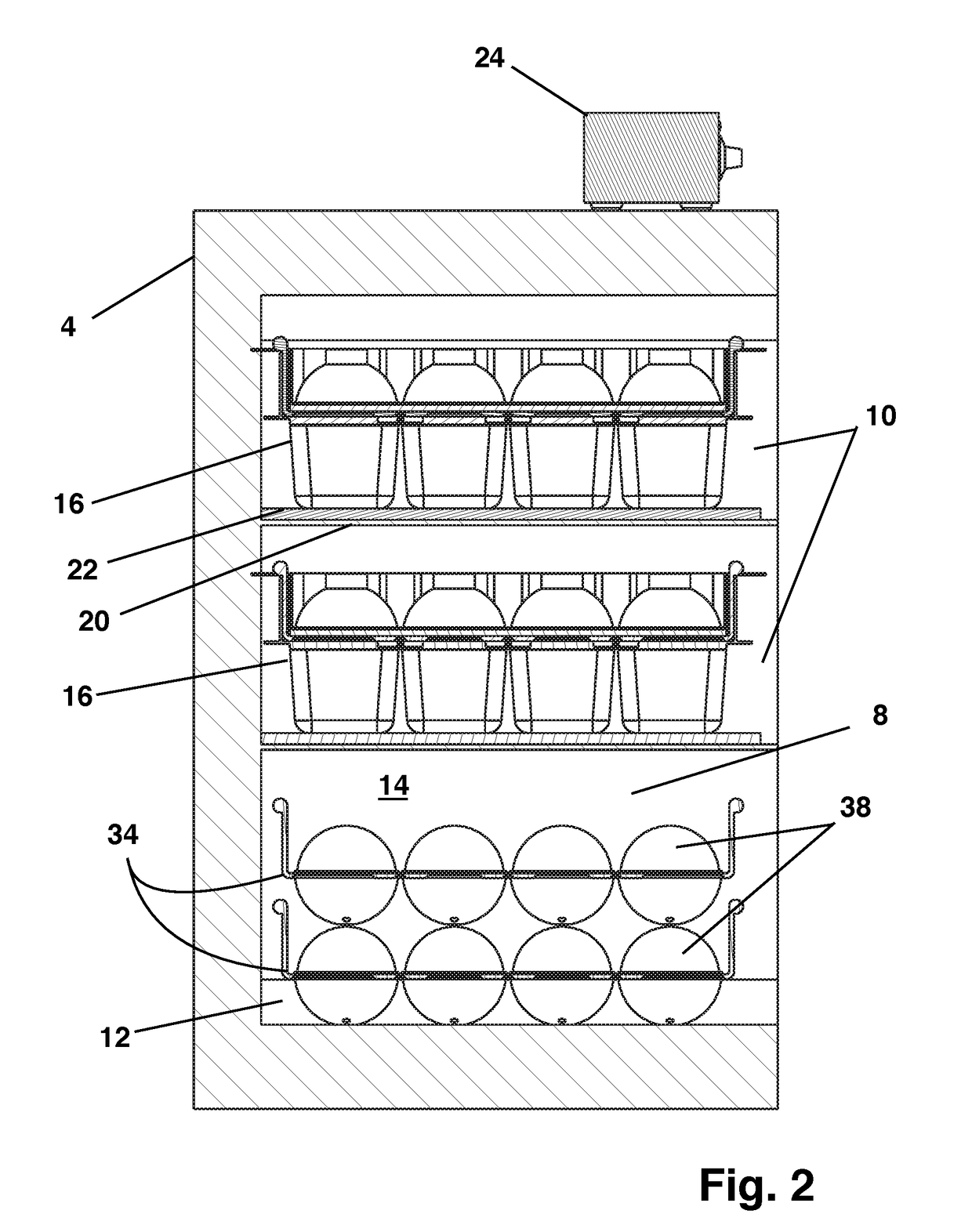

Artisan Ice System, Method and Apparatus

InactiveUS20180335238A1High rate of freezingUniform heat transferLighting and heating apparatusIce productionWater bathsWater level

In a system for production of artisan ice, a freezer receives an artisan ice production unit comprising a water bath, a mold bottom and a mold top. The mold bottom and top define a mold that is partially immersed in the water bath when the water bath and mold are engaged and filled with water. The water bath may be heated by a heat source to control freezing of the water in the mold. The water bath, and mold top define lips above the level of water in the mold to prevent leakage of water from the mold and water bath. The mold bottoms may be stacked when the mold bottoms contain artisan ice portions for compact storage of the artisan ice portions.

Owner:CRE8VPROD LLC

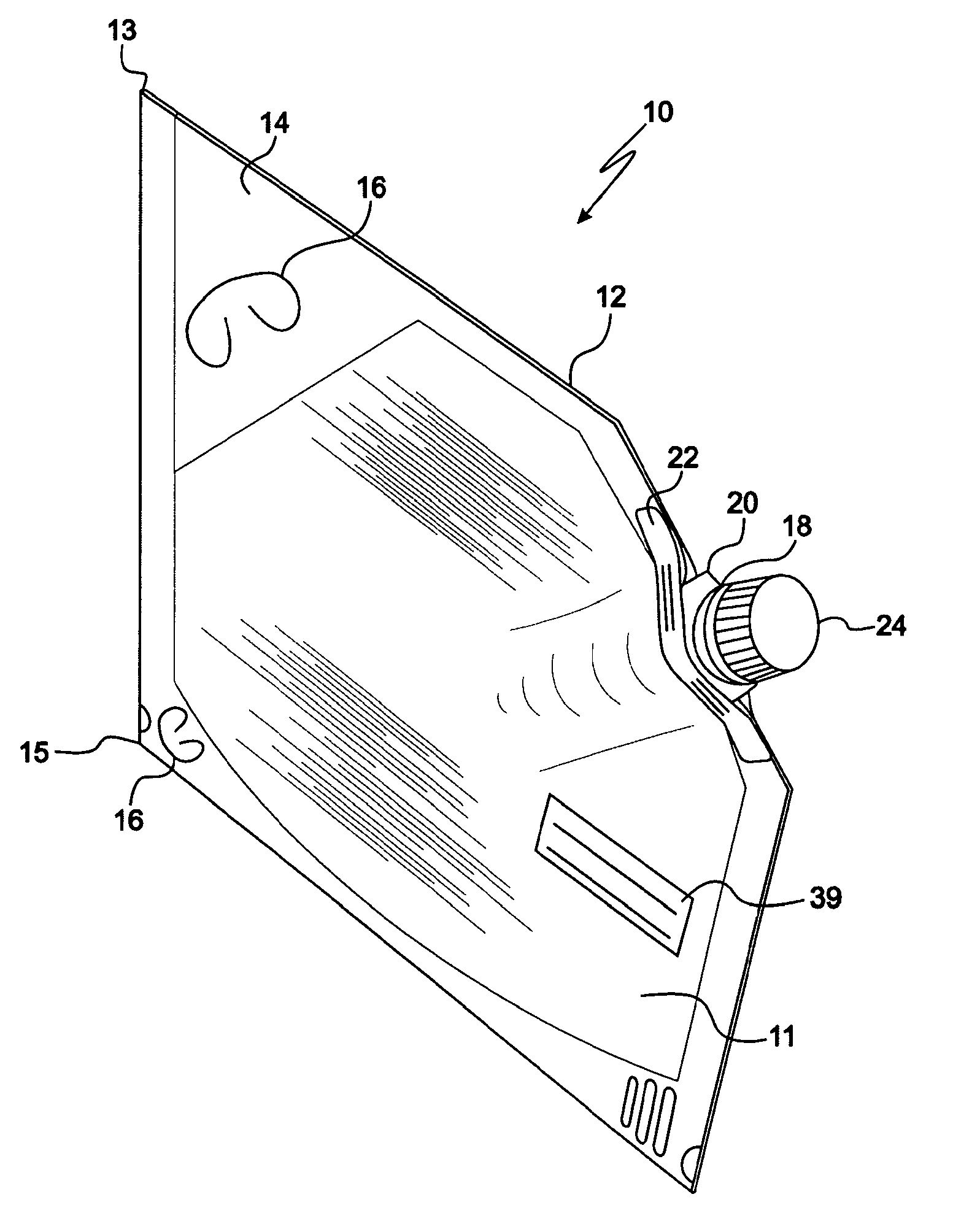

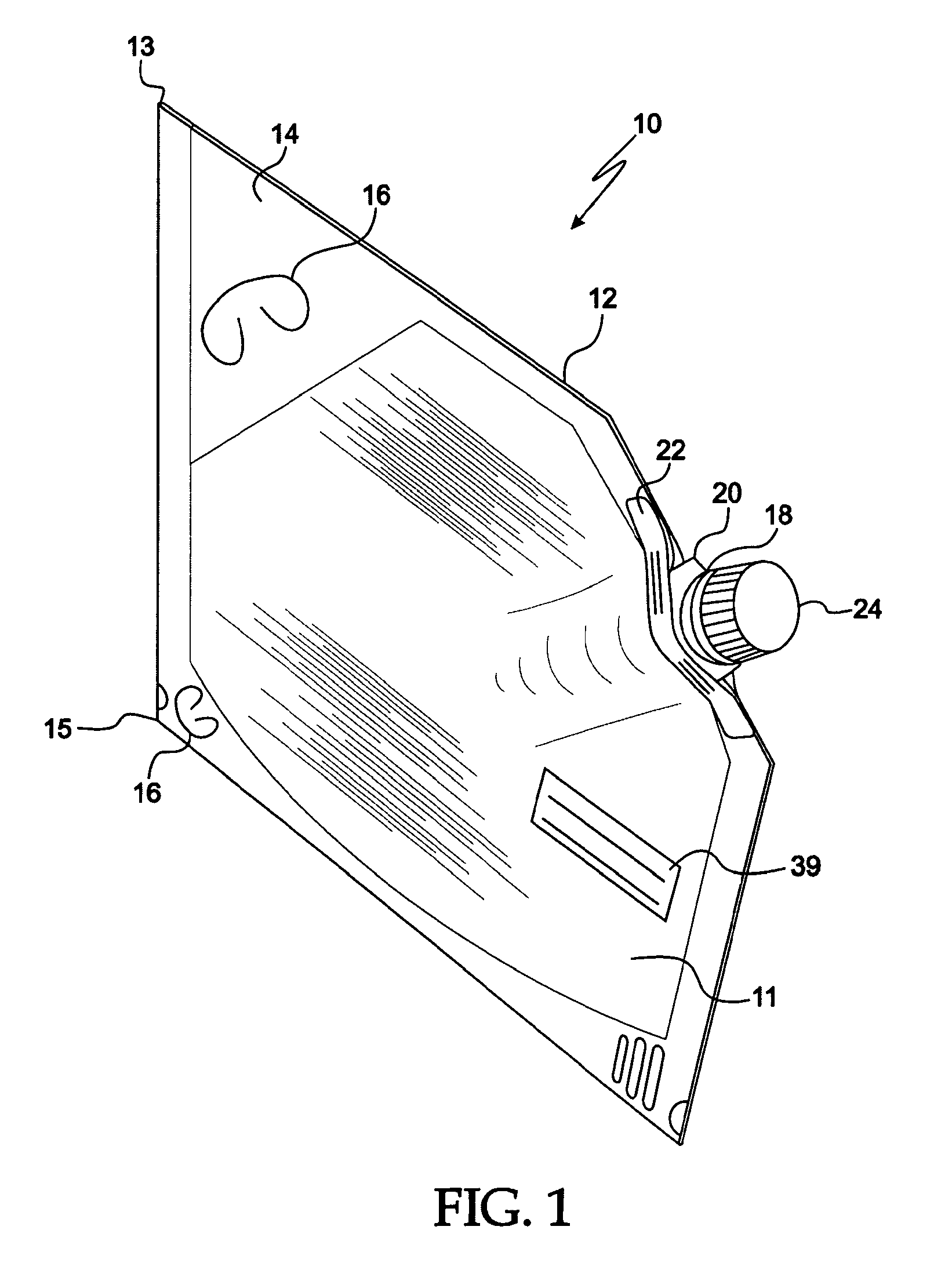

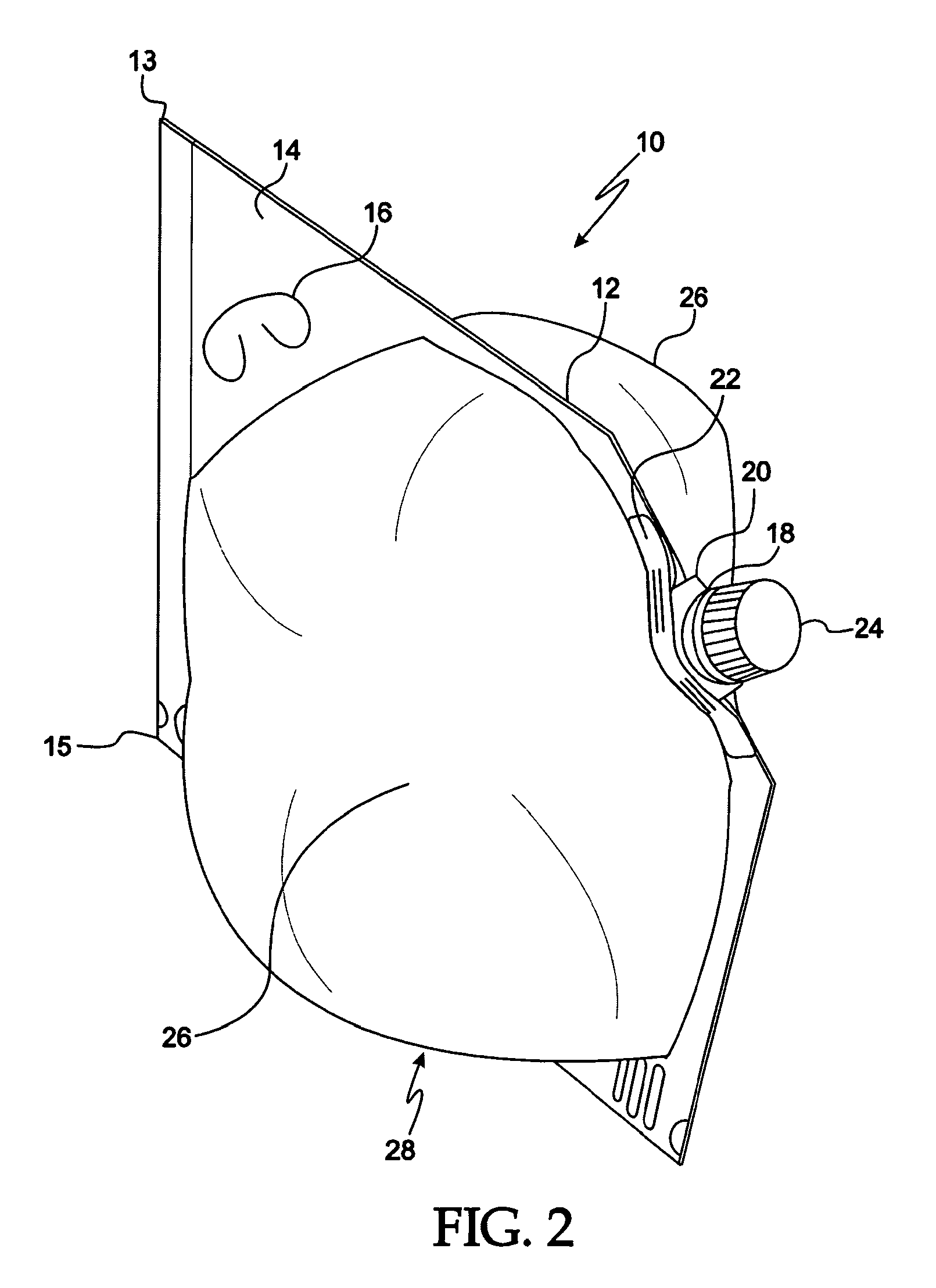

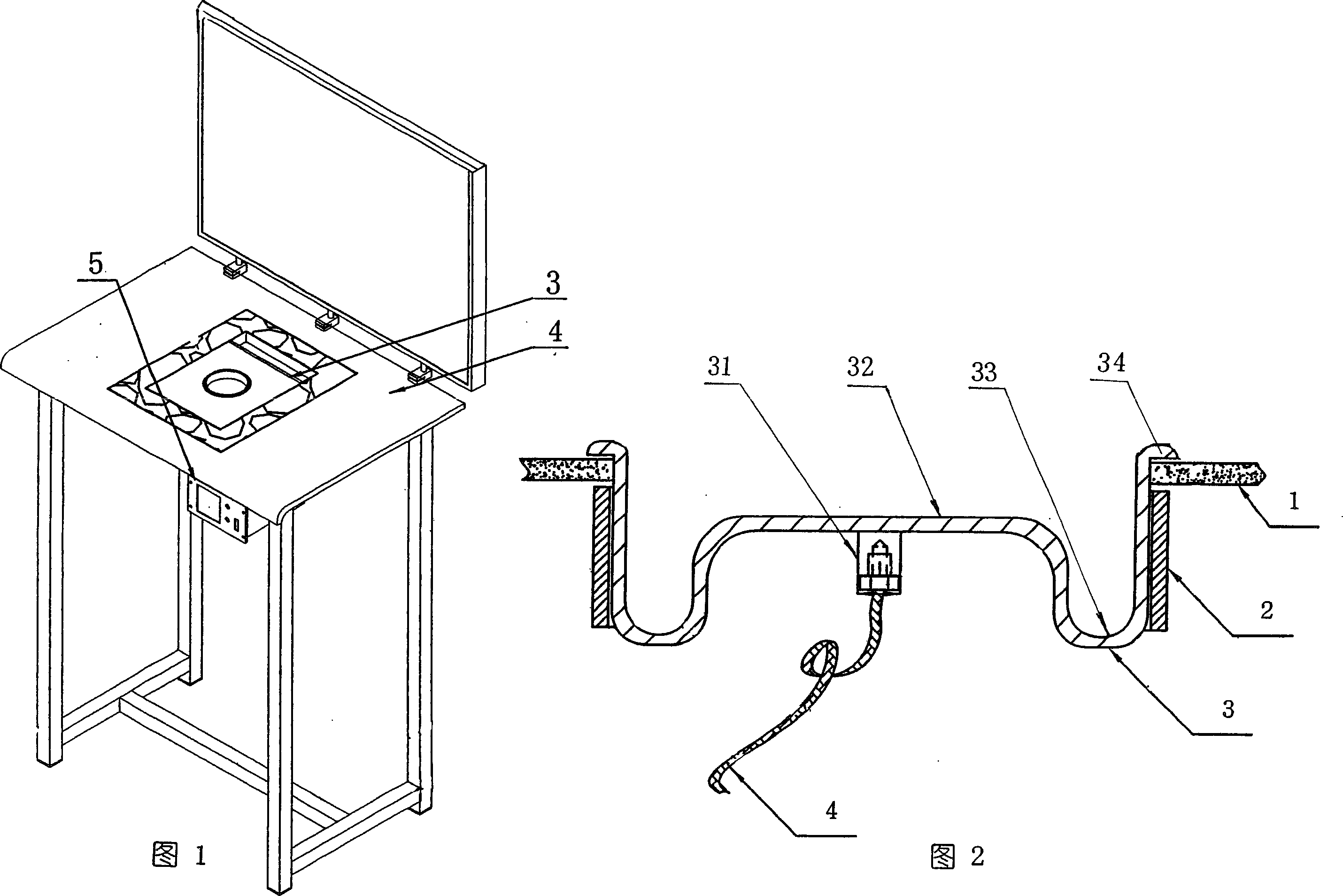

Feeding method using a flexible heat treatment and storage bag

ActiveUS8490577B1Easily agitatedConveniently tippedMilk preservationAnimal feeding devicesSmall animalPasteurization

Flexible, collapsible, liquid-tight containers are described. The containers are typically formed of sheet material and having a pouring or dispensing spout with closure for same. The sheet material is preferably a laminate having at least three layers, including a central, heat-conductive layer, an outer layer of a polymer resistant to physical damage and an inner layer of a thermoplastic polymer which can be fused to another inner layer to seal the edges of the bag. Dispensing fixtures such as a nipple assembly and an esophageal feeder are described, and can be used in feeding calves and other young animals. Processes of heat treating liquids in the containers, including the pasteurizing of dairy products, are described. Methods of using the containers for feeding animals are also described.

Owner:DAIRY TECH CO LTD

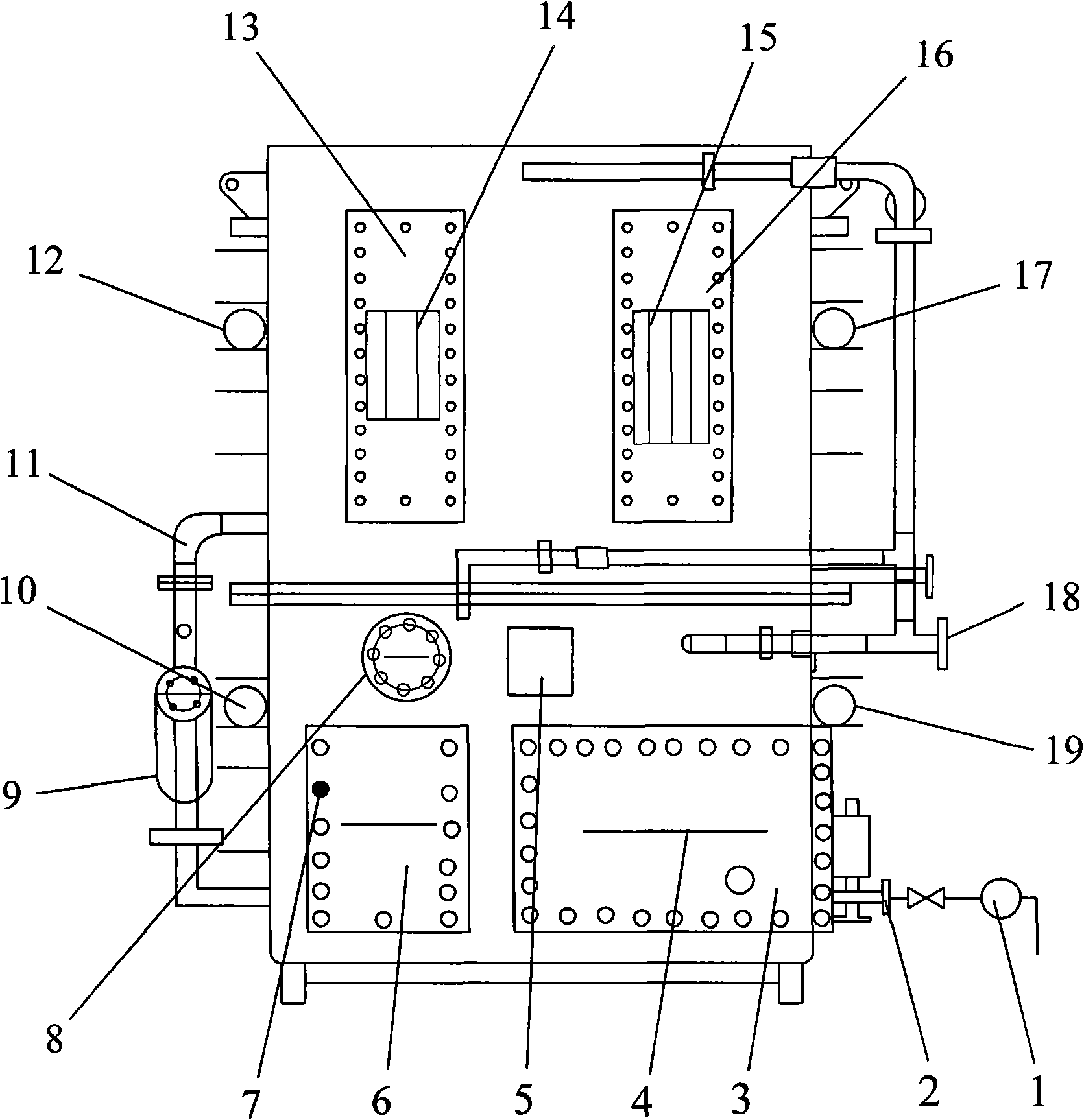

Marine oil-water separator and separation method thereof

ActiveCN101597094AReduce volumeSave boat spaceFatty/oily/floating substances removal devicesAuxillariesUltrafiltrationEmulsion

The invention relates to a marine oil-water separator and a separation method thereof. The marine oil-water separator comprises a case body, the side wall of which is provided with an inlet and an outlet. The marine oil-water separator is characterized in that the case body is divided into four separation cavities, progressive separation and filtration is carried out, a first separation cavity carries out primary separation by an advection type Brown sloping plate, a second separation cavity carries out emulsion breaking by a steam heating emulsion breaking device and solid emulsion, a third separation cavity carries out filtration by a medium-grade filtration core and a fourth separation cavity carries out ultrafiltration by an ultrafiltration core; and the separation method of the marine oil-water separator comprises four steps of primary separation: primary separation, emulsion breaking, filtration and ultrafiltration. The oil-water separator has small volume and saves the space of a boat; the oil-water separator adopts the residual heat of an engine or other steam energy sources to work, a steam pipe is in a spiral type structure and has uniform and fast heat transfer, and the efficient utilization of energy sources is realized; and the content of oil in the bilge water of the boat after being processed by the four steps of primary separation, emulsion breaking, filtration and ultrafiltration is less than 3ppm and far exceeds an environmental protection emission standard stated by the international maritime organization.

Owner:无锡强工机械工业有限公司

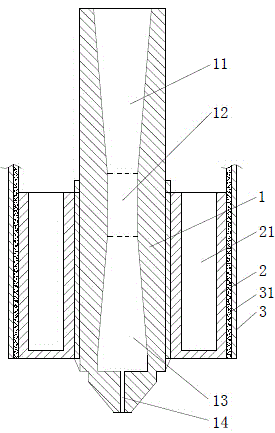

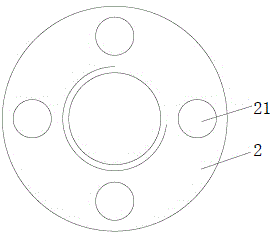

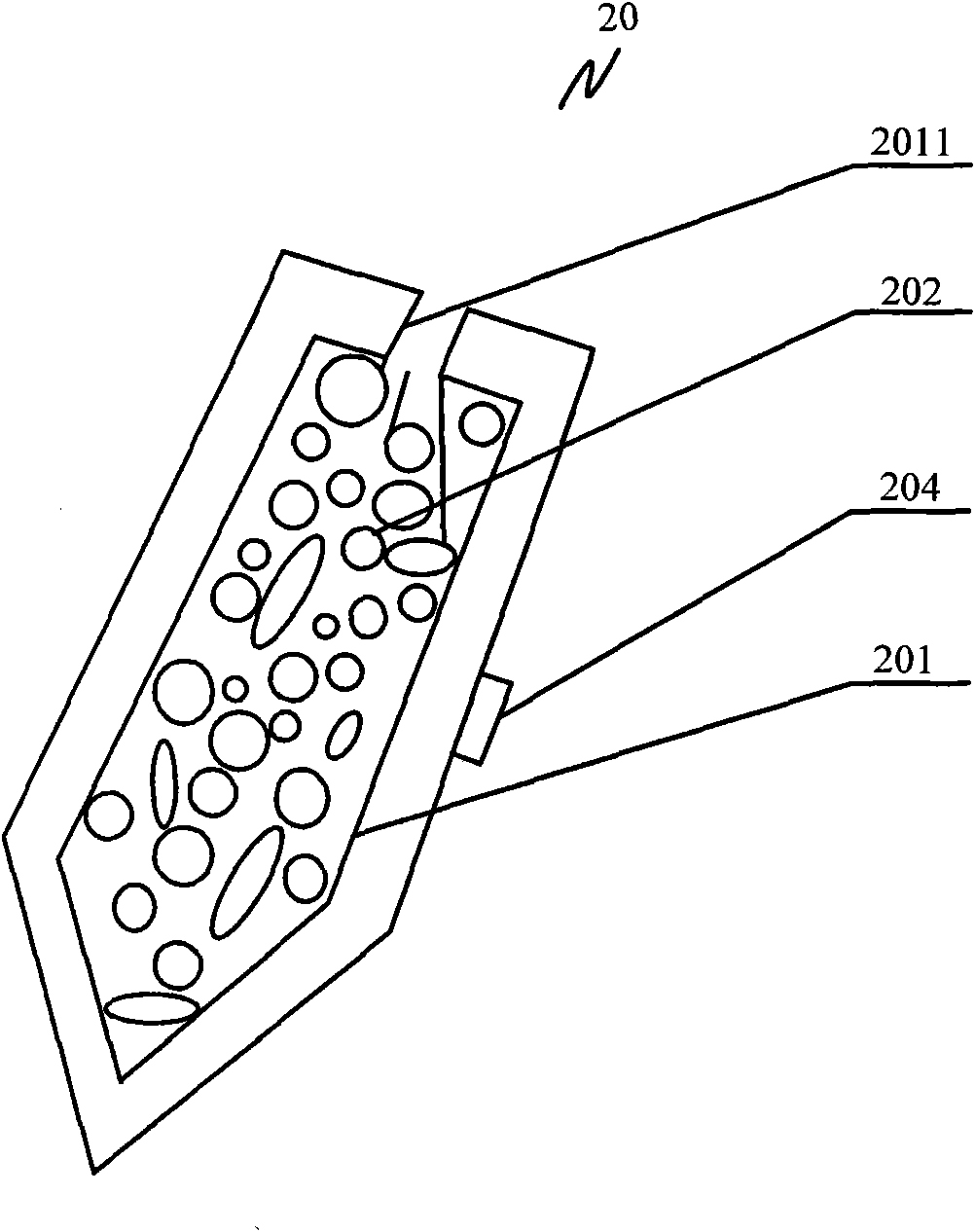

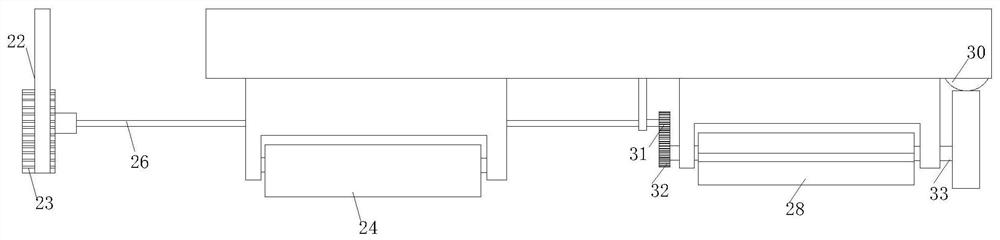

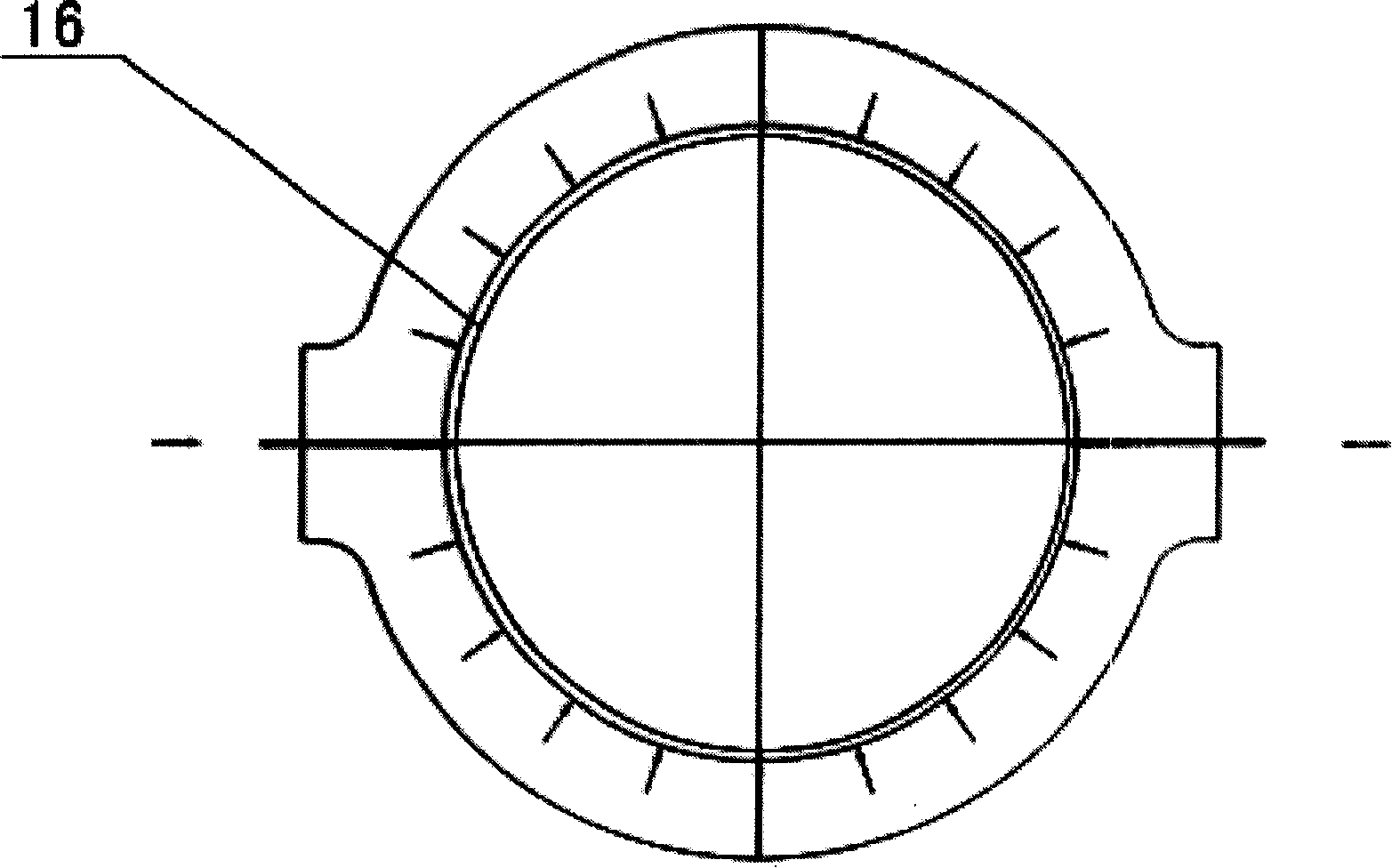

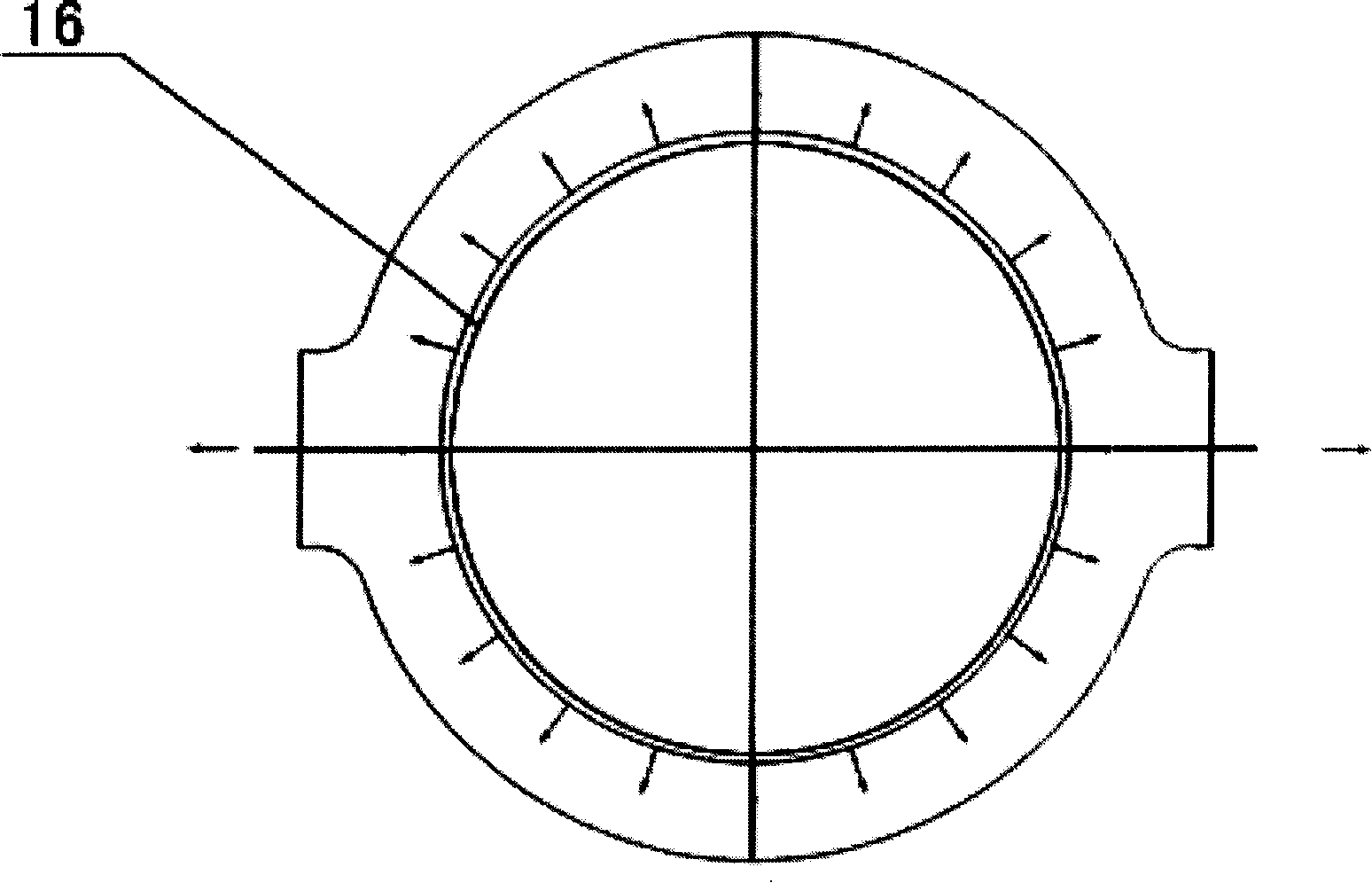

3D printer nozzle structure

InactiveCN104972654AEven heat transferStable insulationAdditive manufacturing apparatusThermal insulationHeating element

The invention discloses a 3D printer nozzle structure, and belongs to the 3D printing technology field. The nozzle comprises a vertically-arranged nozzle body, and a heating sleeve, which is sleeved on the nozzle body, wherein the lower end of the nozzle body stretches out of the heating sleeve. The external surface of the nozzle body and the internal surface of the heating sleeve are both provided with screw threads, and the screw threads cooperate with each other. The top surface of the heating sleeve is provided with heating blind holes which are evenly distributed in the circumferential direction, and a heating element is arranged in each heating blind hole. The external round cover of the heating sleeve is provided with a box, and the internal wall of the box is provided with a thermal insulation layer. The nozzle body is provided with a material hole, and the material hole is composed of an upper reverse-conical hole, a middle cylindrical hole, and a lower normal-conical hole. The lower end of the nozzle body is provided with an extrusion hole that is communicated with the normal-conical hole. Through the provided technical scheme, the heat can be more conveniently transported to the nozzle body, the heat transmission is uniform, and the heating and thermal insulation are stable.

Owner:CHENGDU I MAKE SCI & TECH

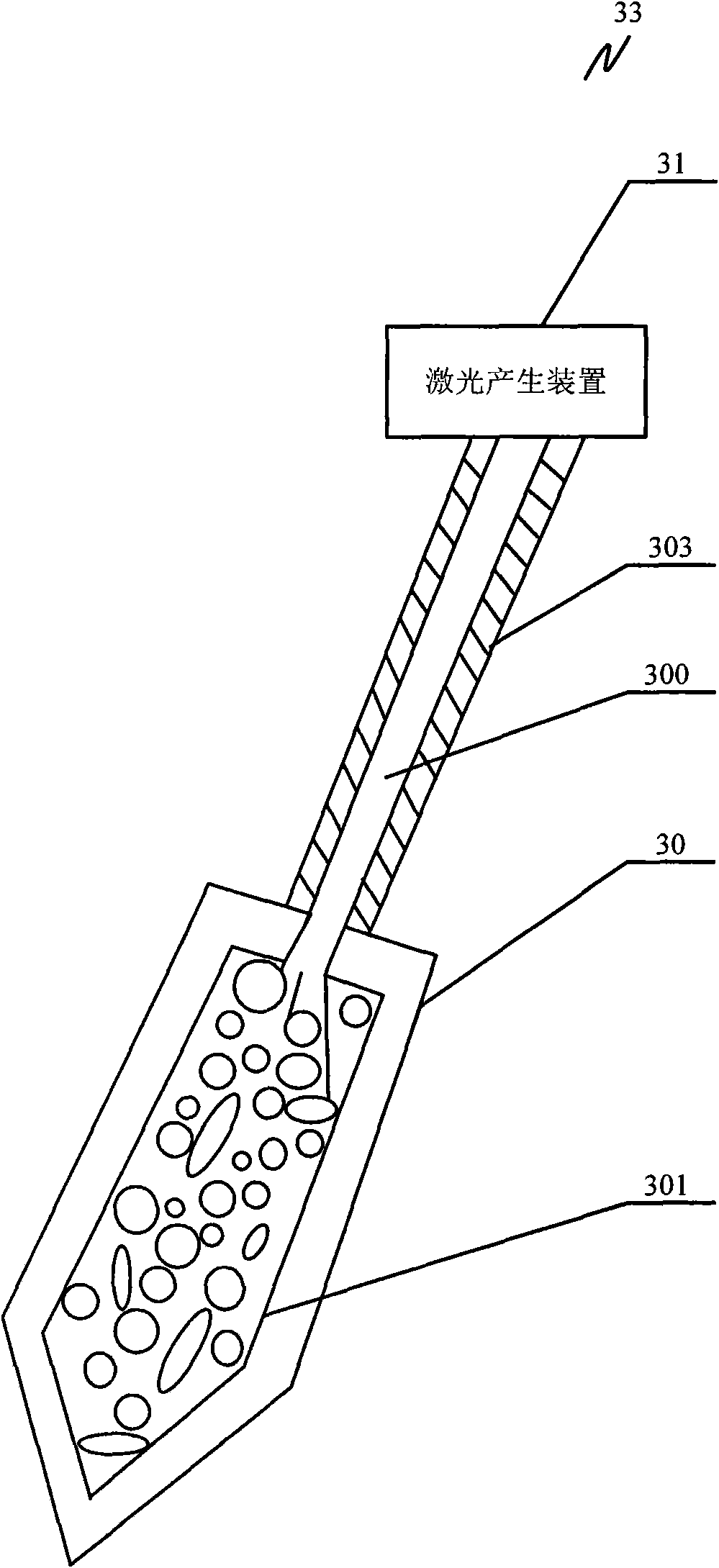

Solder horn and laser soldering iron using same

InactiveCN101664838AFast conductionUniform heat transferSoldering ironLaser beam welding apparatusLaser solderingMetallurgy

The invention discloses a solder horn and a laser soldering iron using same. The laser soldering iron comprises a laser generating device and a solder horn, wherein the solder horn is provided with acavity part, and heat-resisting and heat-conduction materials are arranged in the cavity part; the cavity part is provided with an open end arranged on the non-working part of the solder horn, and laser generated by the laser generating device can be injected in via the open end. The invention uses heat-resisting and heat-conduction materials as the conducting medium so as to quickly diffuse and conduct laser to the inner wall of the cavity part of the solder horn; thus, the invention has the characteristic of quick conduction and avoids harm to the solder horn caused by overquick local warming of the solder horn because laser conduction paths are excessively centralized.

Owner:李卓

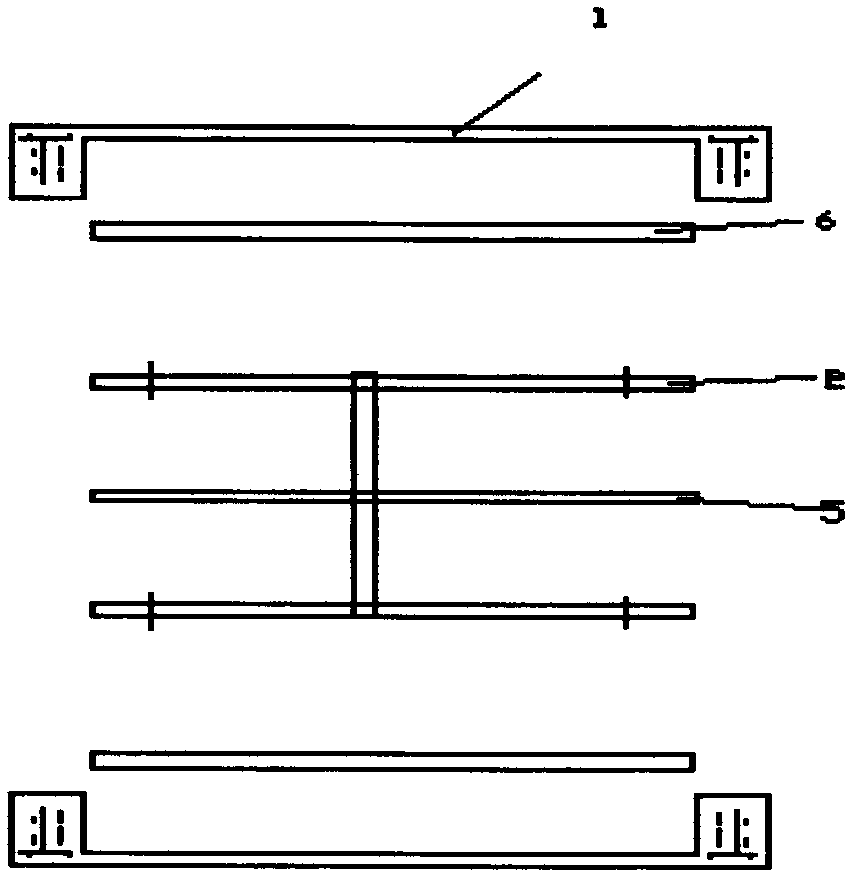

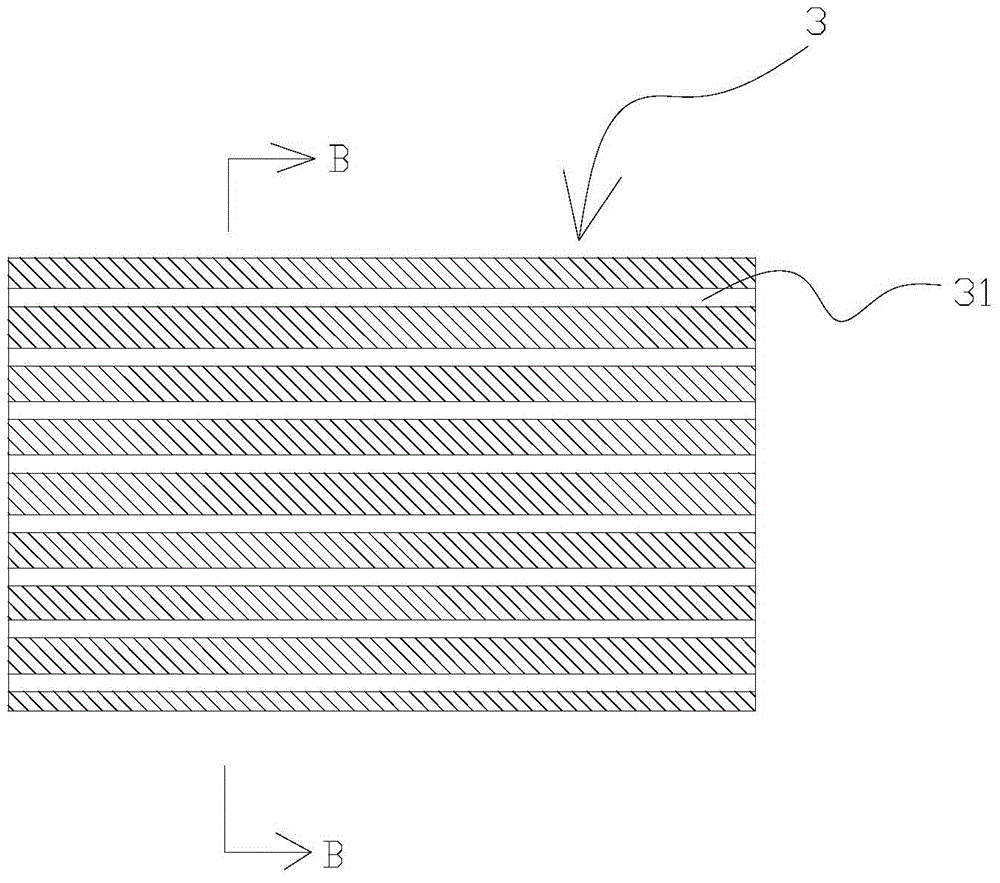

Wire-wound resistor with aluminum shell

InactiveCN102682936AAvoid displacementPrevent looseningResistor mounting/supportingResistor housing/enclosing/embeddingElectrical resistance and conductanceMultiple layer

The invention relates to a wire-wound resistor with an aluminum shell, which comprises the aluminum shell and a resistor framework, wherein two ends of the resistor framework are connected with resistor leading-out wires, and multiple layers of resistance wires are wound on the resistor framework to form a resistor body; isolation insulating discs are arranged between the multiple layers of resistance wires; insulation barriers are arranged on the upper surface and lower surface of the resistor body; the aluminum shell is groove type, and is fixedly arranged outside the insulation barriers in an up and down opposite manner; and the resistor framework is I-shaped, and the multiple layers of resistance wires are wound in the concave region of the I-shaped resistor framework. The wire-wound resistor with the aluminum shell provided by the scheme is stable in quality and performance, convenient for installation, and uniform in overall dimensions.

Owner:SUZHOU GUANGFU TELECOMM EQUIP FACTORY

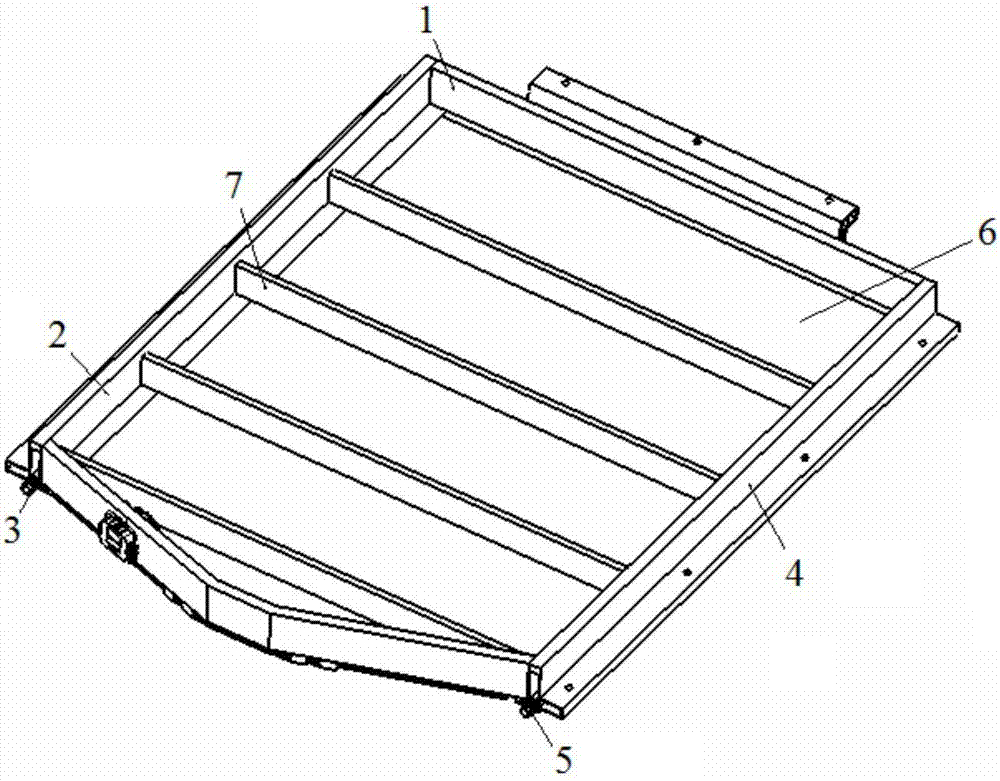

Power battery water-cooling box for electric vehicle

The invention relates to a power battery water-cooling box for an electric vehicle, relates to the field of power battery cooling, and aims at solving the problems that a power battery box is high and uneven in temperature, and meanwhile, a traditional cooling method is poor in effect. The power battery water-cooling box for the electric vehicle comprises a box body and a cooling liquid pipeline; the cooling liquid pipeline is laid in a rectangular bottom plate of the box body; a water inlet and a water outlet of the cooling liquid pipeline extend outwards through the side wall of the box body; an upper groove is arranged in an area, in which no cooling liquid pipeline is laid, on the bottom plate of the box body; a plurality of vertical ribs are arranged in the upper groove; and the upper surfaces of the vertical ribs do not exceed the upper surface of the bottom plate of the box body. The power battery water-cooling box is suitable for cooling a power battery.

Owner:江苏和中普方新能源科技有限公司

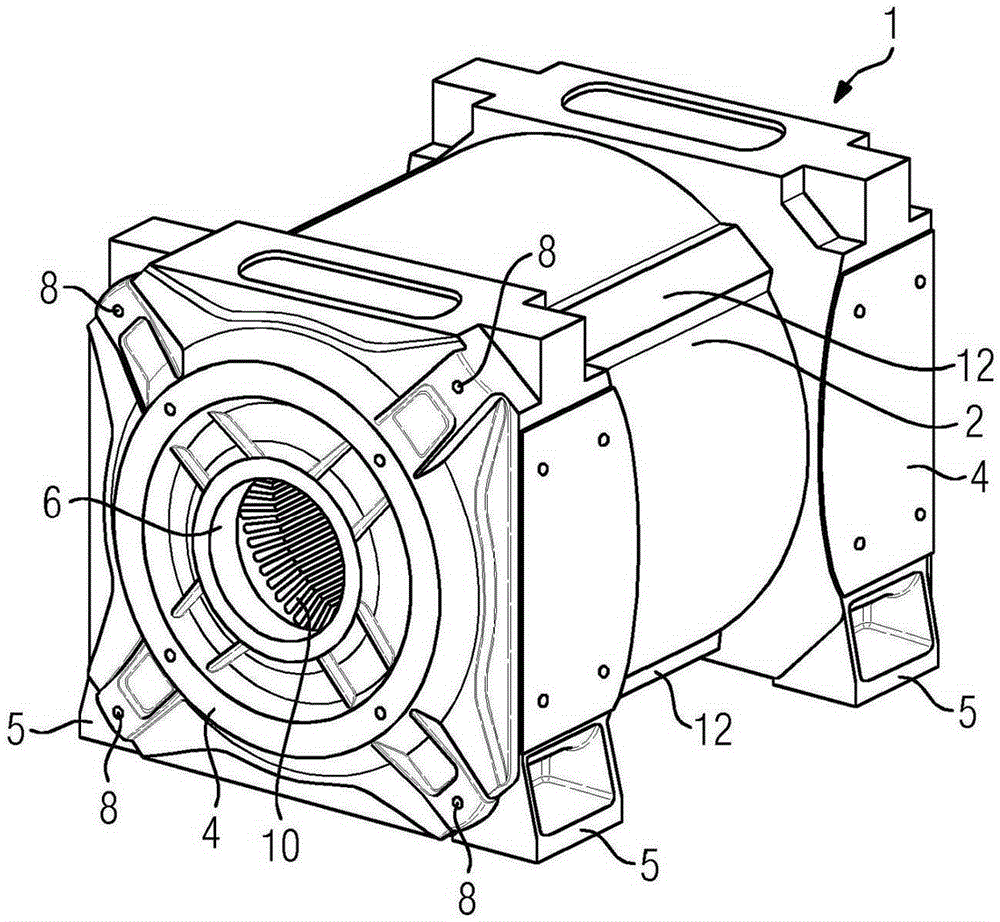

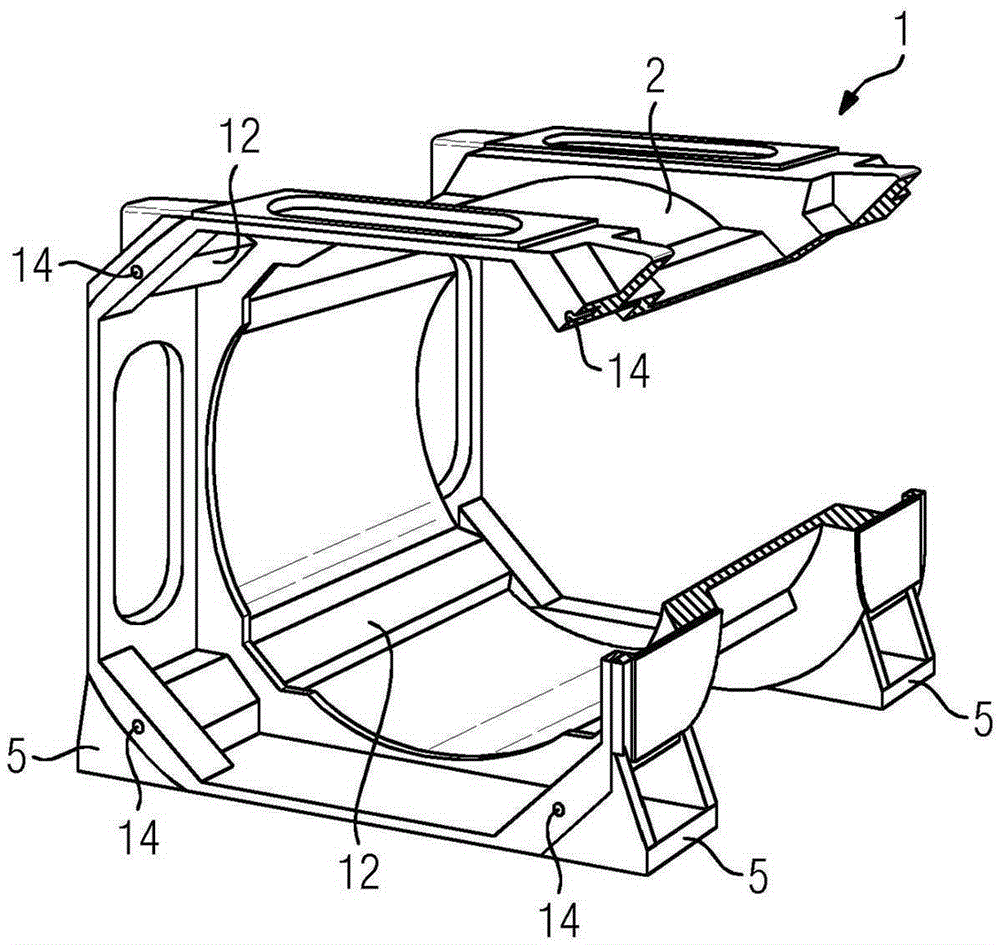

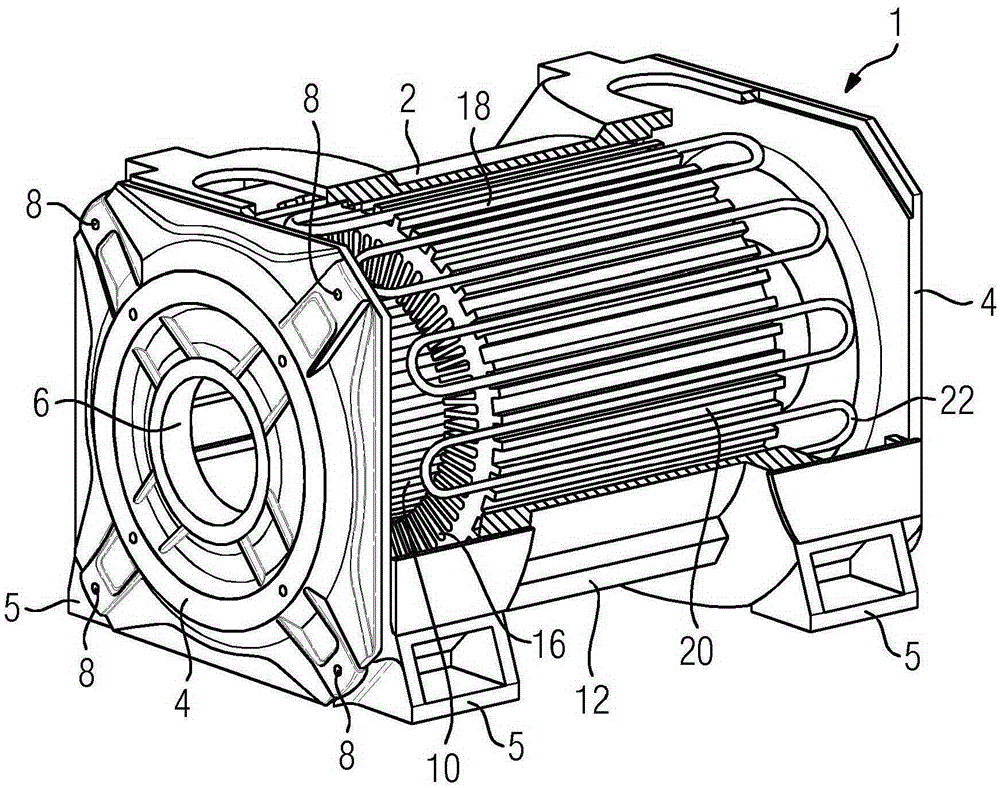

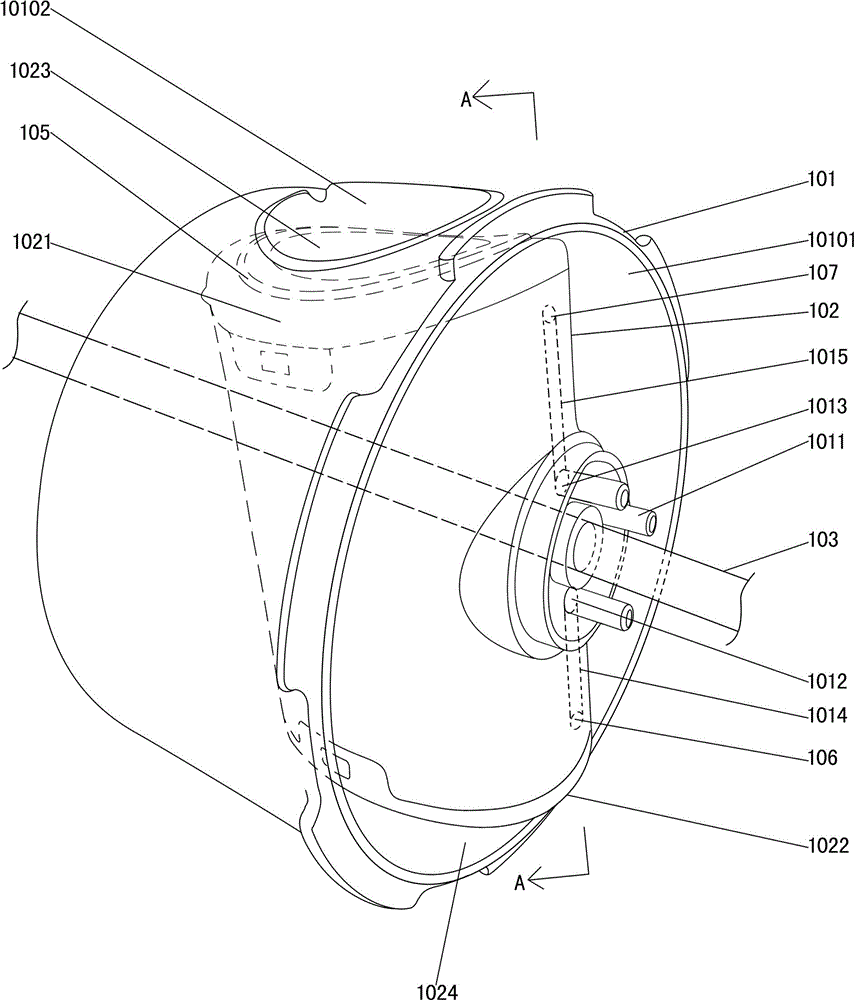

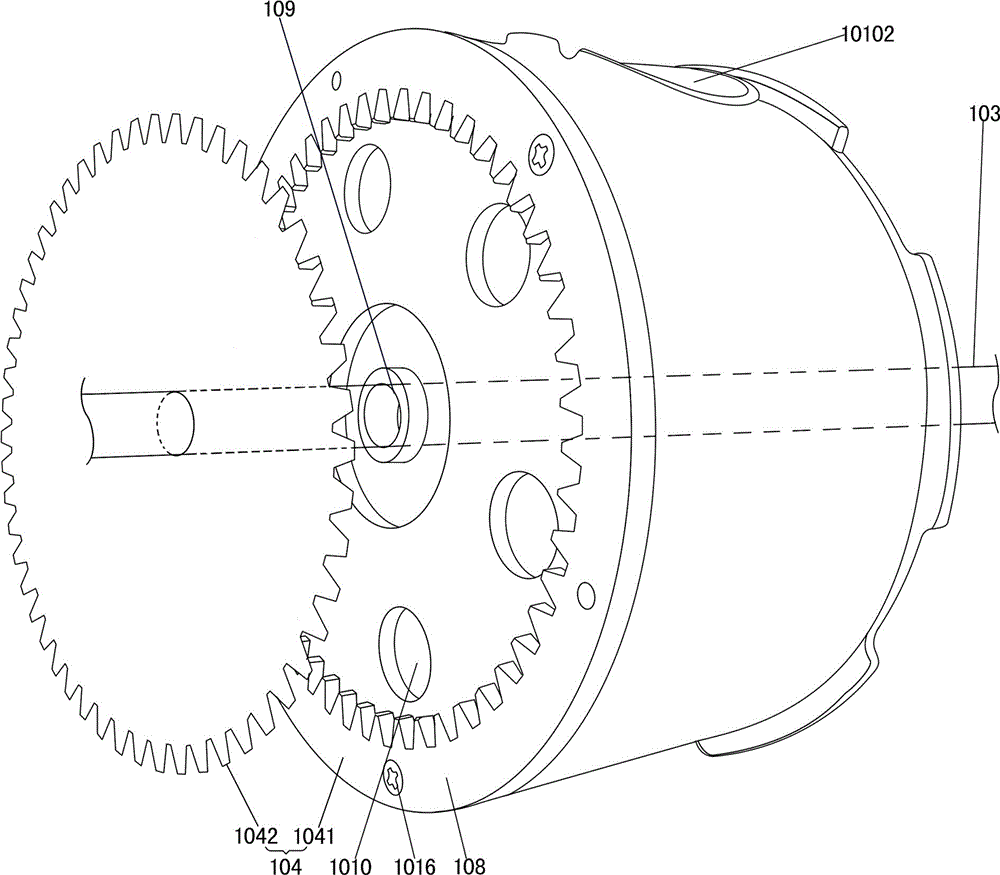

Electric motor

ActiveCN105284032AImprove cooling effectAchieve internal coolingMagnetic circuit stationary partsCooling/ventillation arrangementElectric motorHollow cylinder

The problem addressed by the invention is that of providing an electric motor having a stator, a rotor, and a cooling circuit for the rotor, comprising a substantially cylindrical-shell-shaped casing (2), which permits an especially technically simple integration of an inner cooling circuit for the rotor. To solve this problem, an outwardly directed cavity (12), which extends in an axial direction with respect to the cylinder, is introduced into the casing (2) and a hollow-cylinder-shaped laminated stator core (10) is arranged inside the housing (1), said stator core having grooves (18) arranged on the outside. The cooling lines (22) are arranged in the grooves (18), and the laminated stator core (10) has recesses (20), which are arranged on the outside and extend in an axial direction and which are part of a cooling circuit for the rotor.

Owner:SIEMENS AG

Tin bath for forming float glass

The invention discloses a tin bath for forming float glass. A connecting plate is fixed in a bath body; the interior of the bath body is divided into a processing tank and a heating tank by the connecting plate; the heating tank is located under the processing tank; a temperature control device, circulating devices and a baffle are fixed in the processing tank; the two ends of the baffle are fixedtogether with the side walls of the heating tank; openings are formed between the other two ends of the baffle and the side walls of the heating tank; the circulating devices are arranged on the middle parts of the openings; each circulating device comprises a stirring shaft, a connecting gear, a driving gear, a driving chain and a driving motor; the two ends of the stirring shaft are in rotatable connection with the side walls of the heating tank by bearings; one end of the stirring shaft penetrates through the heating tank and is fixed together with the connecting gear; the connecting gearis in meshed connection with the driving gear through the driving chain; an output shaft of the driving motor is fixed together with the driving gear. The tin bath for forming the float glass is capable of improving the uniformity of the temperature of the liquid tin in the processing tank and is capable of avoiding the phenomenon of uneven thickness in the glass forming process.

Owner:TG ANHUI GLASS

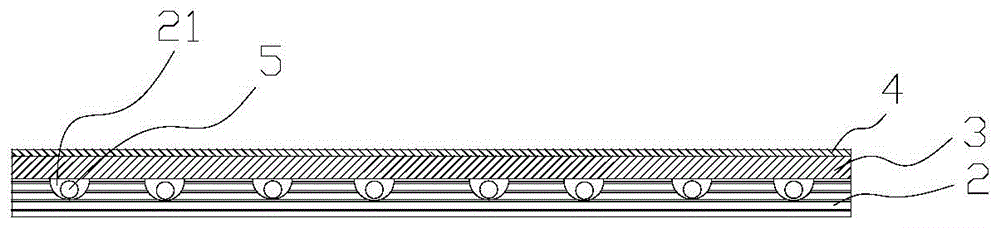

Cooling and heating floor

InactiveCN104652770ASmooth structureSimple structureLighting and heating apparatusFlooring insulationsThermodynamicsHeat transmission

The invention discloses a cooling and heating floor. The cooling and heating floor comprises a floor body, wherein water pipe mounting grooves used for paving water pipes are formed in the upper surface of the floor body; the floor further comprises a heat conduction plate which covers the floor body; at least one heat conduction groove is formed in the lower surface of the heat conduction plate; the mounting grooves and the heat conduction grooves are interpenetrated. According to the cooling and heating floor, a layer of metal heat conduction plate covers the floor body, so that the heat transmission between the water pipes and the floor is more uniform; the overall structure of the floor is more flat; the floor is high in compression resistance, is not deformed after being used or loaded for a long time, and is simple in structure; the heat conduction grooves are formed in the lower surface of the metal heat conduction plate; the heat conduction grooves and the water pipe mounting grooves are intercrossed and interpenetrated; the heat transmission of the floor is more quick and uniform; an outer layer made of wood material is paved at the uppermost layer of the floor, so that the comfort level of the floor is improved.

Owner:KOM FLOORING SUZHOU

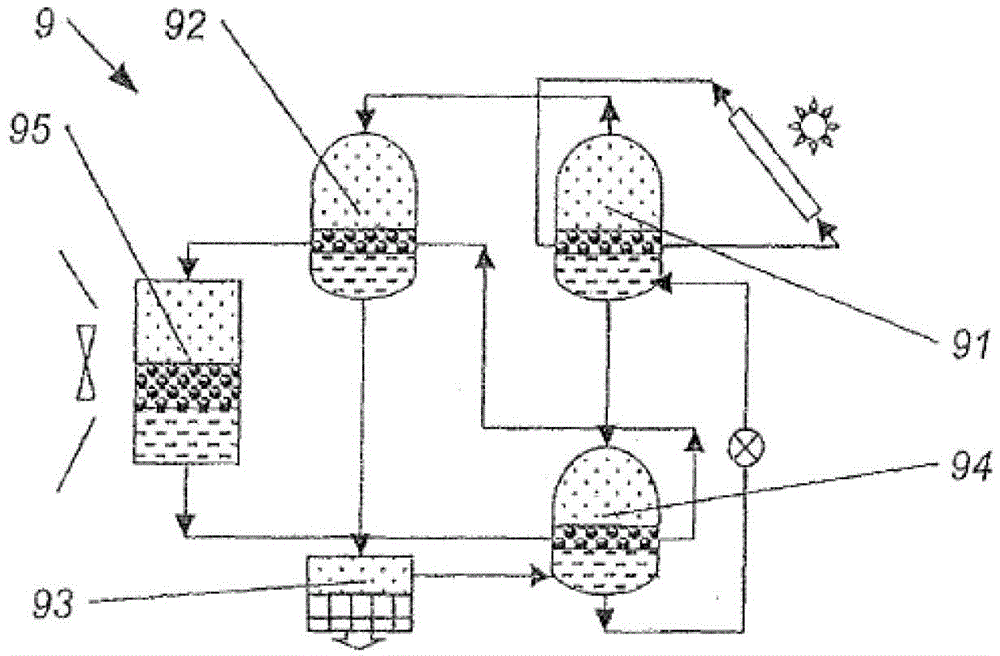

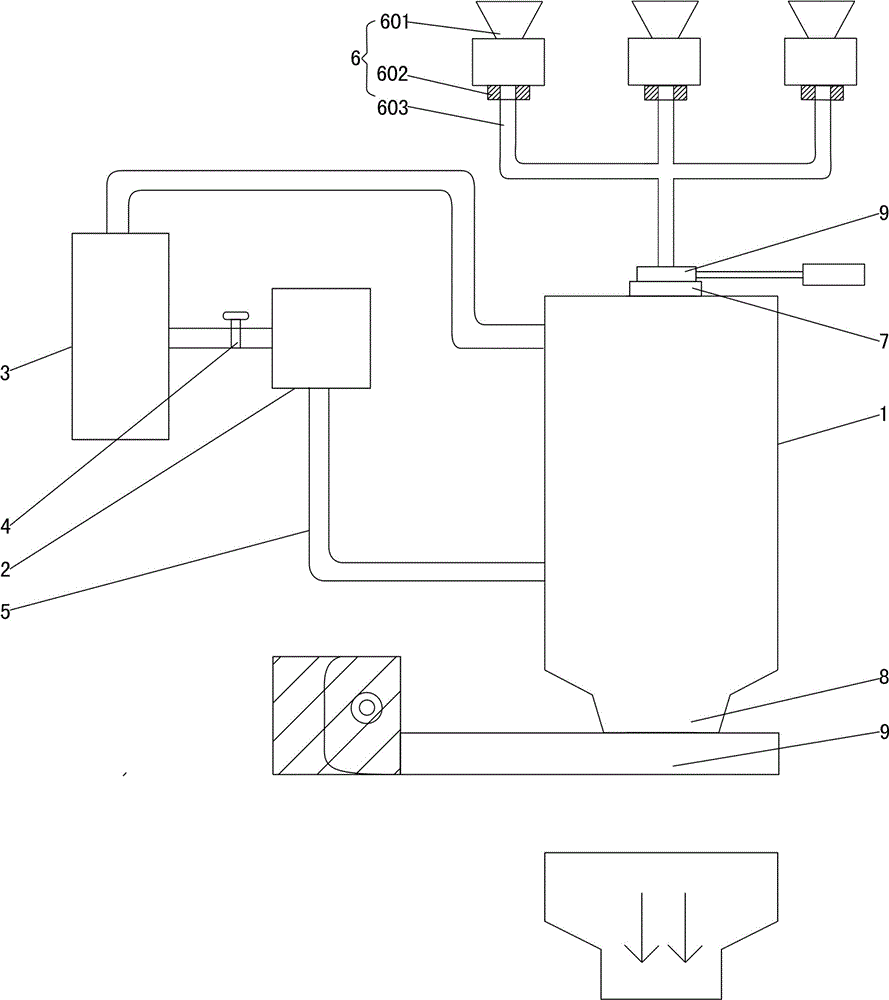

Full automatic steam food boiling device

ActiveCN103976650AIncrease profitIn line with the law of flowCooking vesselsFood preparationEngineeringAir pollution

The invention relates to a full automatic steam food boiling device, comprising a material boiler, a steam generator, a water tank, a valve, a water pipe and material suppliers; each material supplier comprises a material storeroom, a supplying control mechanism and a material pipe; the material storerooms of all the material suppliers are connected with a charging port by the material pipes; the supplying control mechanisms are arranged on the material pipes between the material storerooms and the charging port; the water tank, the steam generator and the lower part of the material boiler are sequentially connected by the water pipe. The upper part of the material boiler is connected with the upper part of the water tank by the water pipe; the valve is arranged on the water pipe between the water tank and the steam generator. Materials are directly boiled by adopting high temperature steam, the utilization rate of the steam is high and a greater energy-saving effect is realized; the high temperature steam is input from the lower end and achieves a stirring action, so the materials are more uniformly heated, the heat transfer is accelerated, the boiling time is shortened and the food boiling device is suitable for the fast food industry; the steam is collected into the water tank for reuse instead of being directly discharged to avoid air pollution and greater environment-friendly and sanitary effects are achieved.

Owner:汕头市自在天茶道科技有限公司

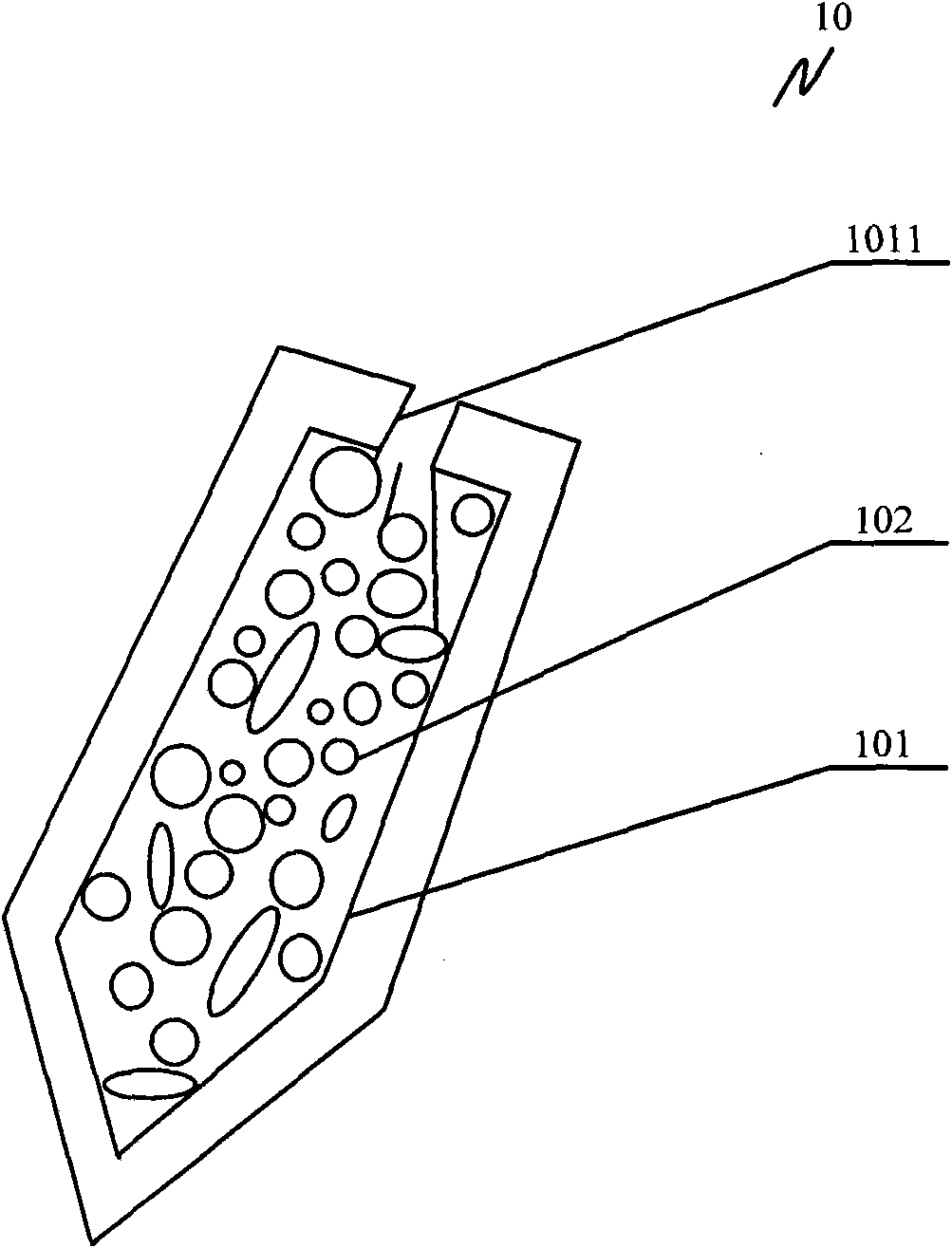

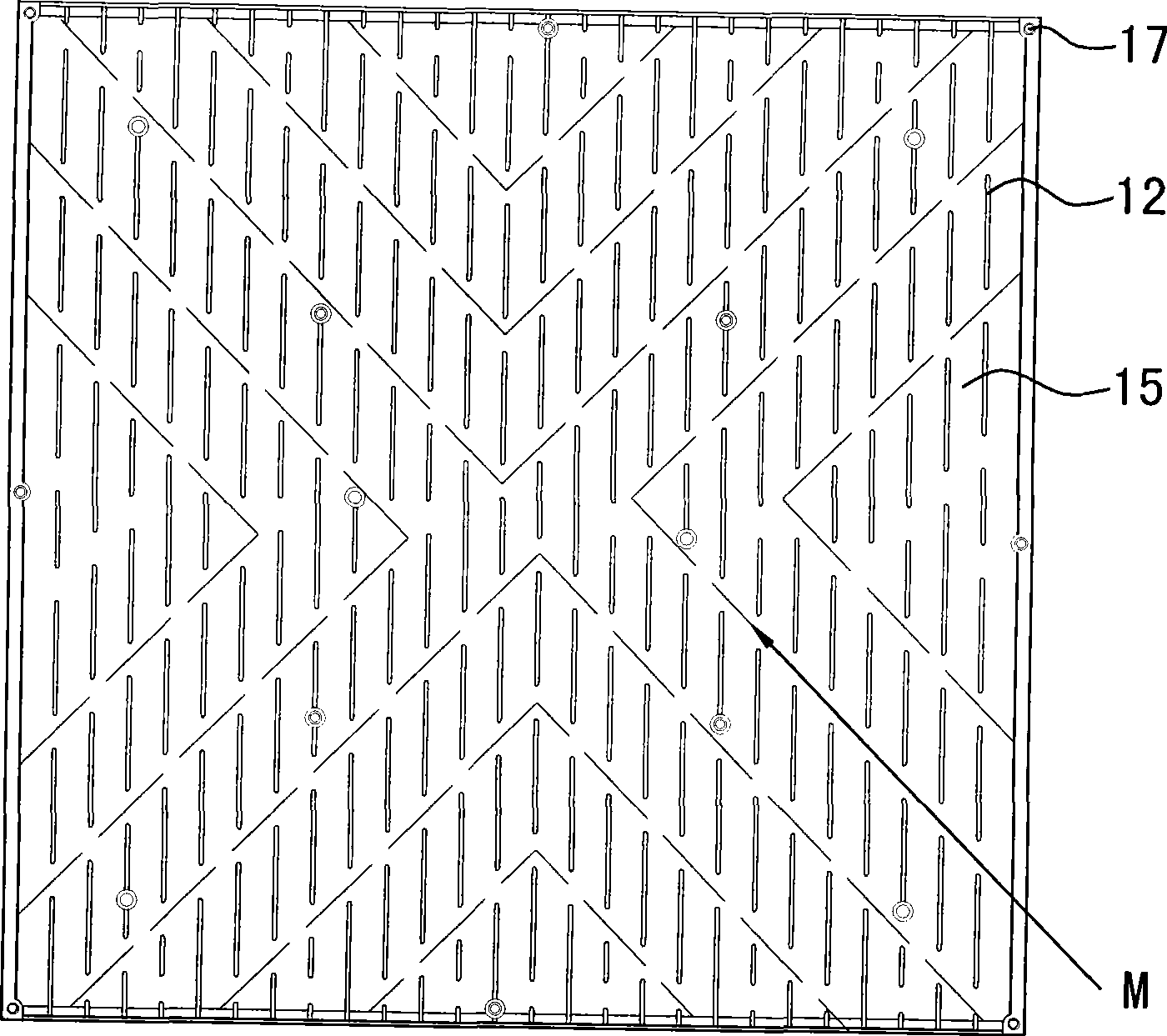

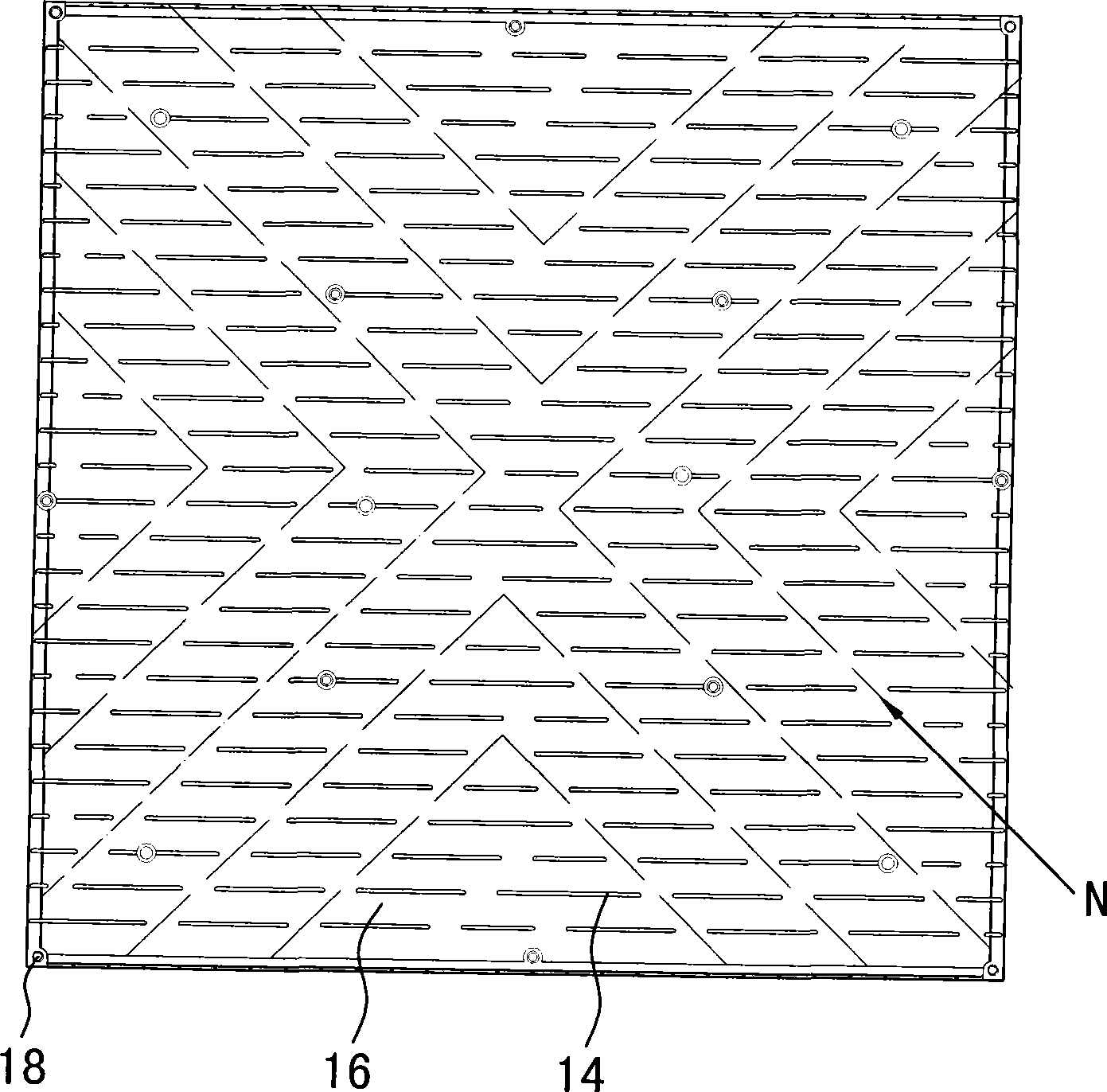

Long life highly effective energy-conserving type heat exchanging core

InactiveCN101419033AImprove permeabilityIncrease the areaStationary plate conduit assembliesKeelEngineering

The invention relates to an energy-saving type heat exchange core body with long service life and high efficiency. The core body is formed through overlaying a plurality of monomer heat exchange chips; each monomer heat exchange chip consists of a keel and a heat exchange membrane; and an air channel is divided into a new air channel and an air exhaust channel by the heat exchange membrane. The heat exchange core body is characterized in that the monomer heat exchange chip comprises four layers; the first layer is a heat exchange membrane 1, the second layer is a longitudinal keel; the third layer is a heat exchanger membrane 2; the fourth layer is a transverse keel; and the longitudinal keel and the transverse keel are separately disconnected and form a rectangular transverse air channel and a rectangular longitudinal air channel respectively. The heat exchange core body can be detached, maintained and cleaned, has long service life of the whole machine, even and full heat transfer and high thermal reclaiming efficiency, and can realize outsize wind amount of 50,000m<3>h.

Owner:浙江德普莱太环境科技股份有限公司

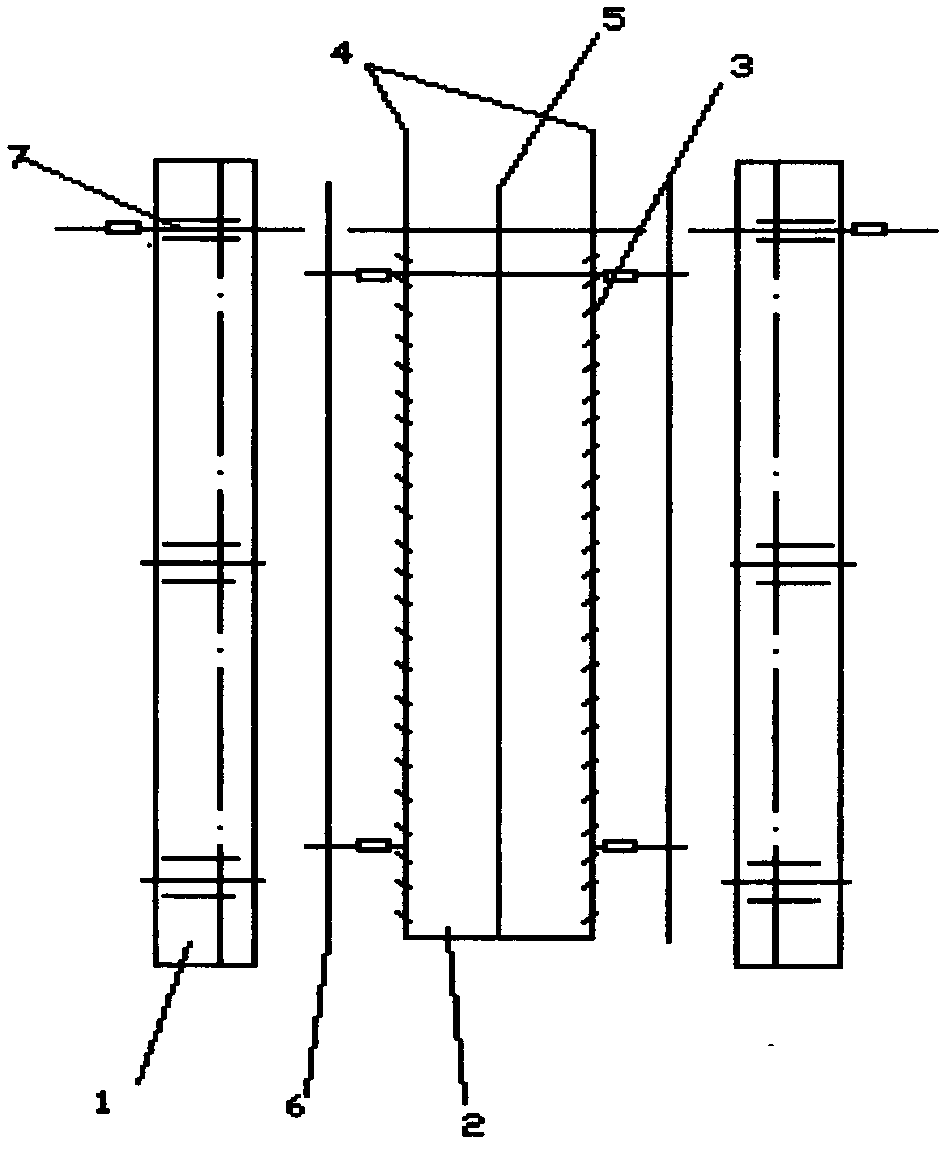

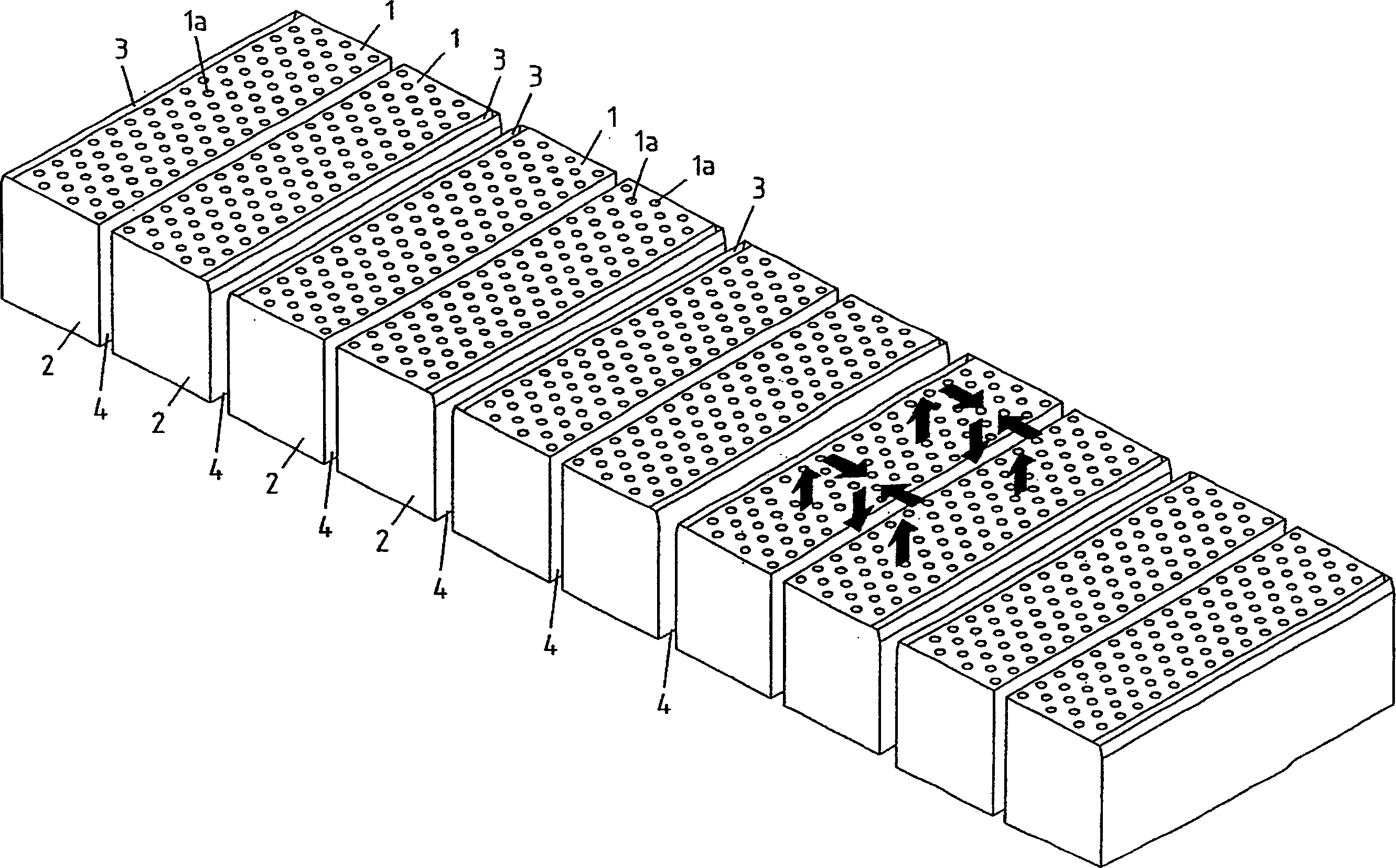

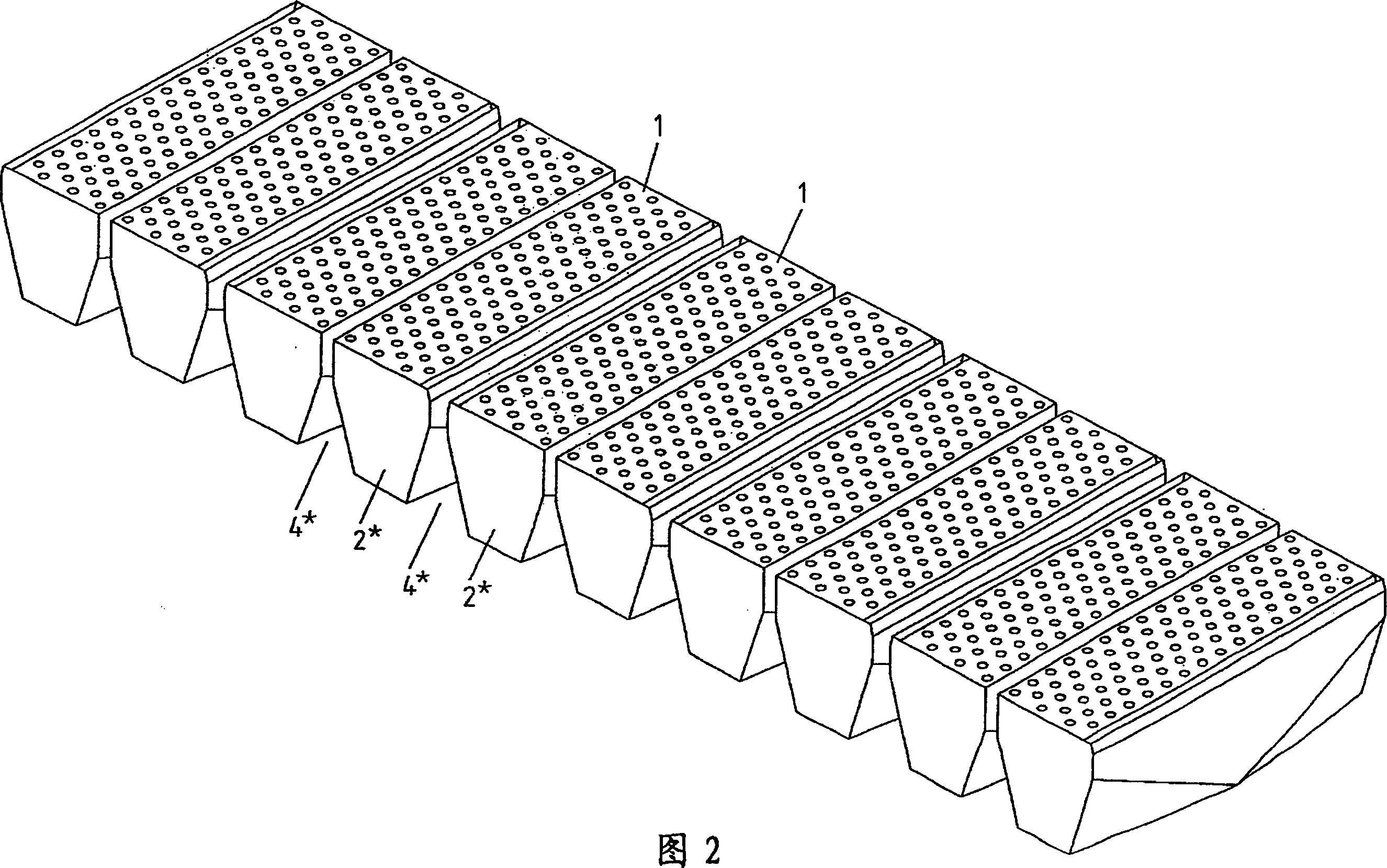

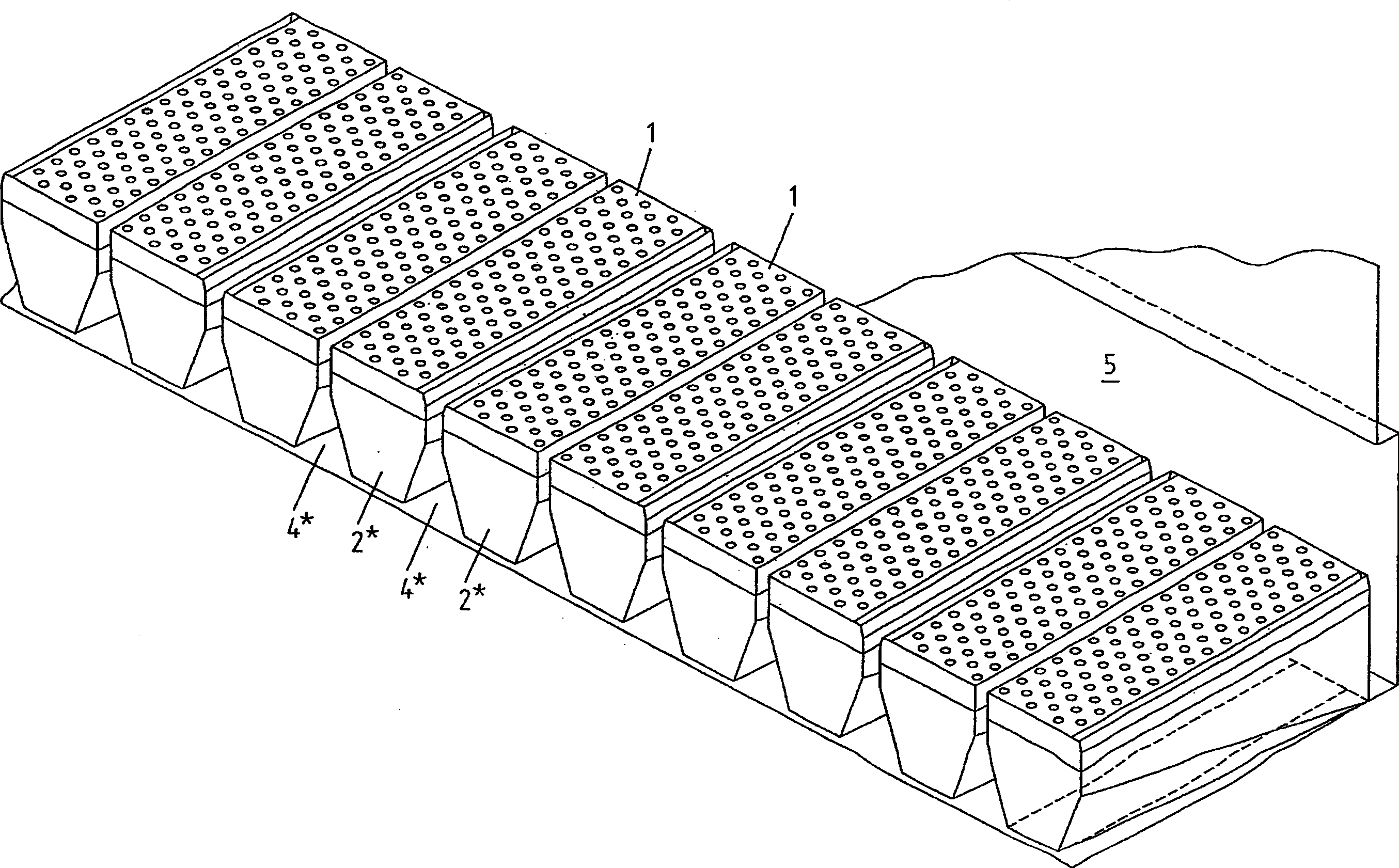

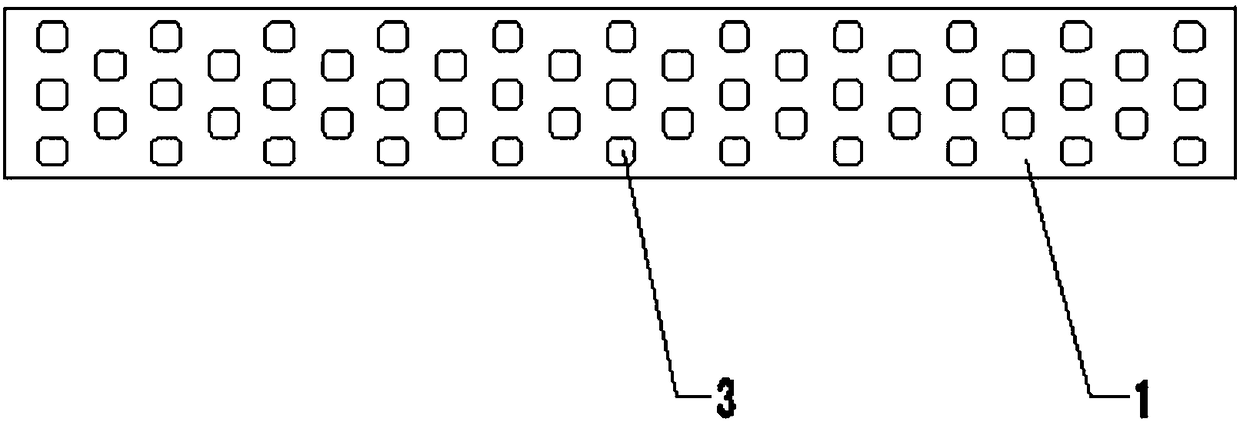

Nozzle system for processing netted material

InactiveCN1904089AImprove carrying capacityEven heat transferLiquid surface applicatorsFurnace typesEngineeringNozzle

The invention relates to a nozzle system for the treatment of web-shaped material, especially metal strip, comprising nozzle surfaces (1, 1*, 1**), each having a plurality of nozzle apertures (1a), disposed at least on one side of the web-shaped material and located successively in the direction of transport of the web-shaped material. The nozzle system is characterized in that the nozzle surfaces (1, 1*, 1**) are bordered in groups by slit-shaped nozzles (3, 3*, 3**) running transverse to the direction of transport of the material.

Owner:OTTO JUNKER GMBH

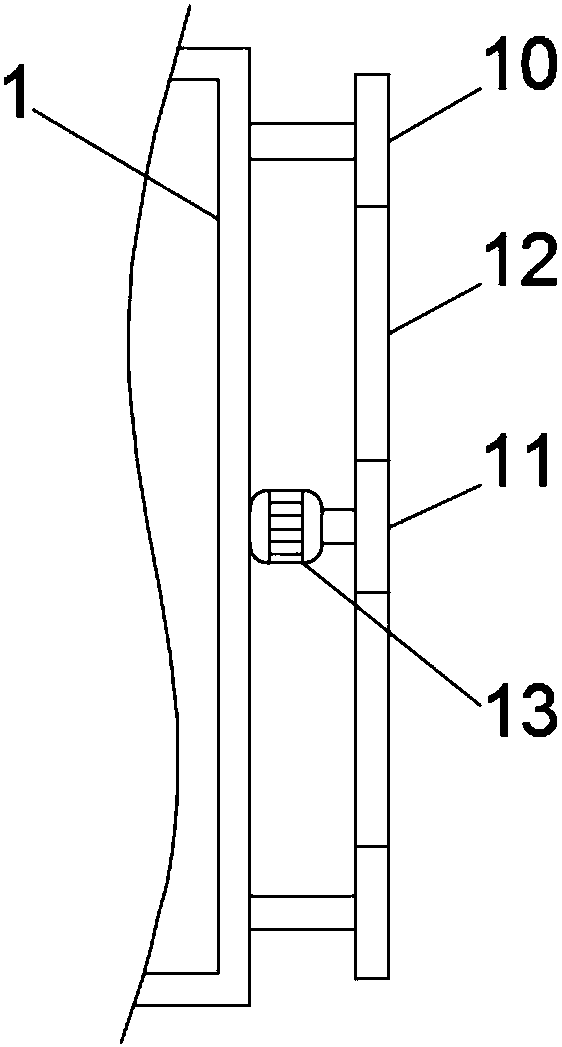

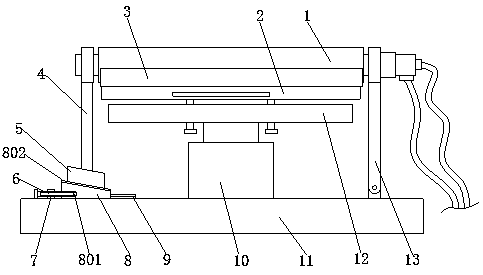

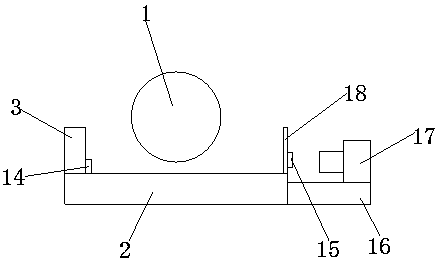

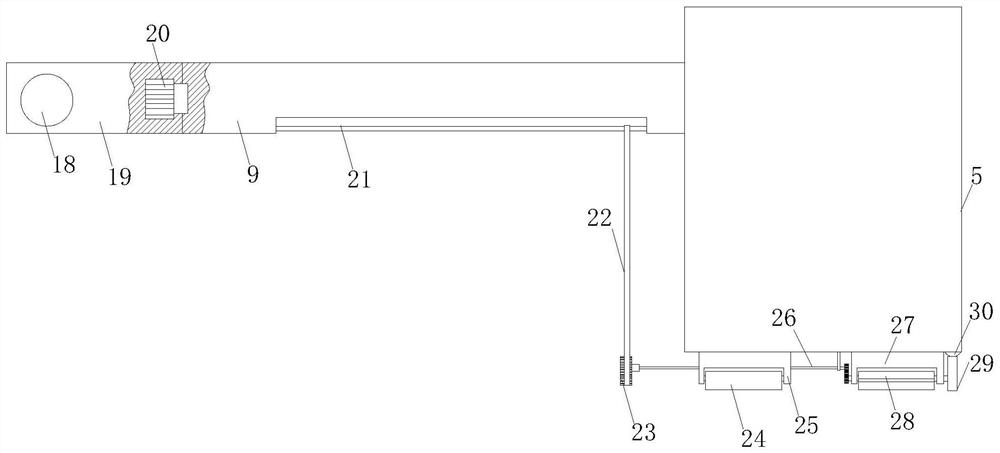

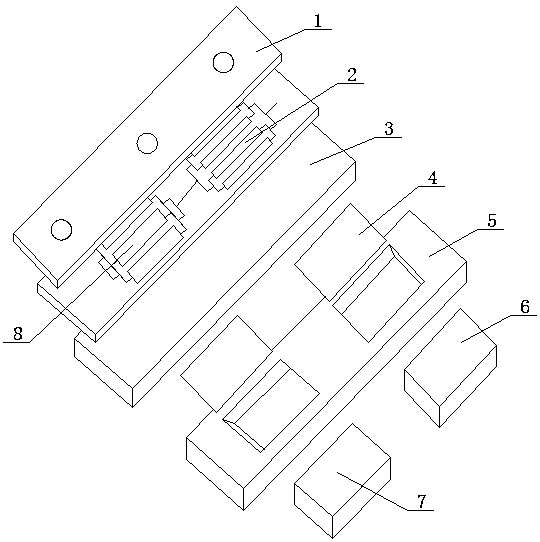

Cooling roller lifting fine-adjustment positioning mechanism for printing equipment

ActiveCN111421947AEven heat transferTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention relates to the technical field of printing equipment, in particular to a cooling roller lifting fine-adjustment positioning mechanism for printing equipment. The cooling roller lifting fine-adjustment positioning mechanism for the printing equipment is characterized in that a wedge-shaped sliding block is connected with a guide rail in a sliding mode; a bearing seat is fixedly arranged on a base; a rod body of a threaded rod is rotationally connected with the bearing seat; the threaded rod is in threaded connection with a threaded hole; image acquisition equipment are arranged along the axial direction of a cooling roller body; parallel line groups are arranged on the outer side surface of a light-transmitting plate; a gradienter is fixedly arranged on the outer side surfaceof the light-transmitting plate; the third image acquisition equipment is arranged over against the gradienter; and the third image acquisition equipment is arranged between the first image acquisition equipment and the second image acquisition equipment. When the cooling roller lifting fine-adjustment positioning mechanism is used, levelness of the cooling roller body can be adjusted, so that thetension of a printing material in the width direction is adjusted, the printing material can be subjected to uniform heat transfer, and accordingly the printing quality is improved.

Owner:汕头市晟涛印刷有限公司

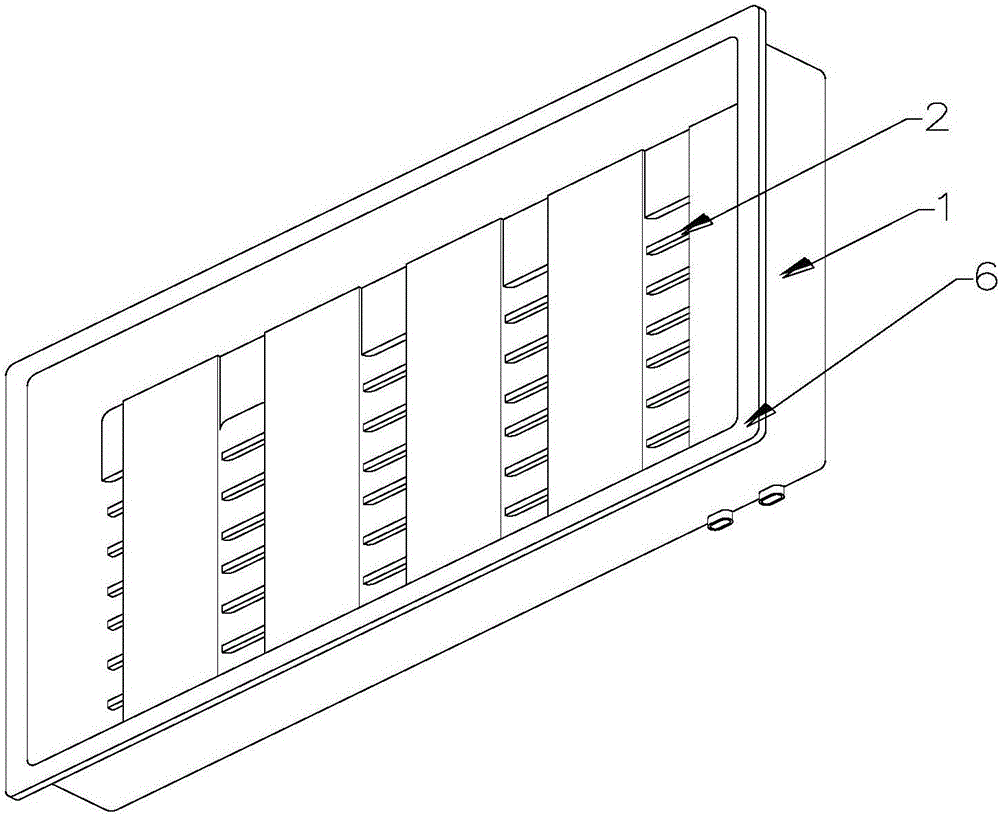

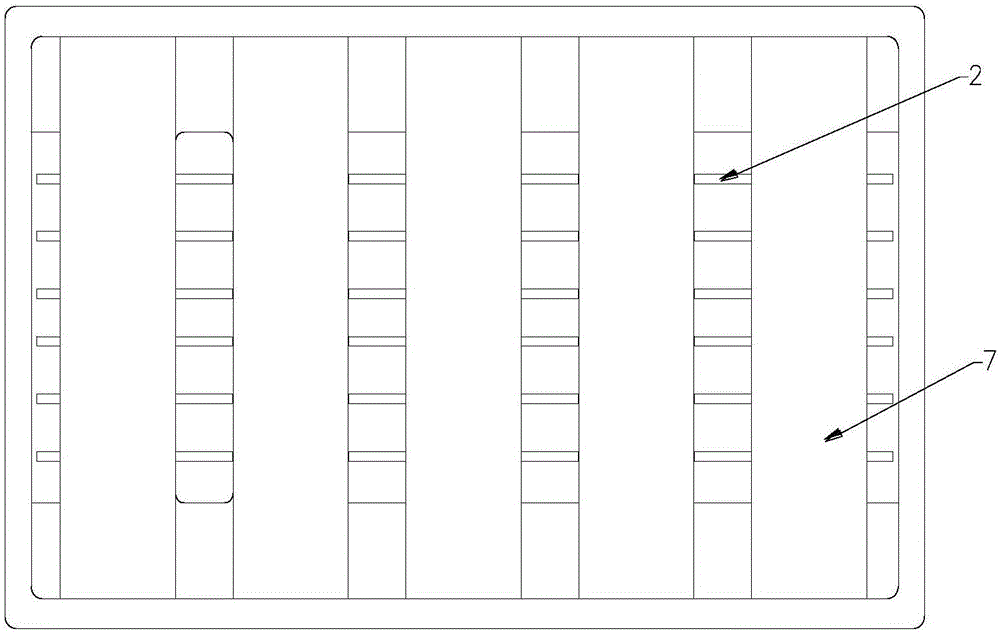

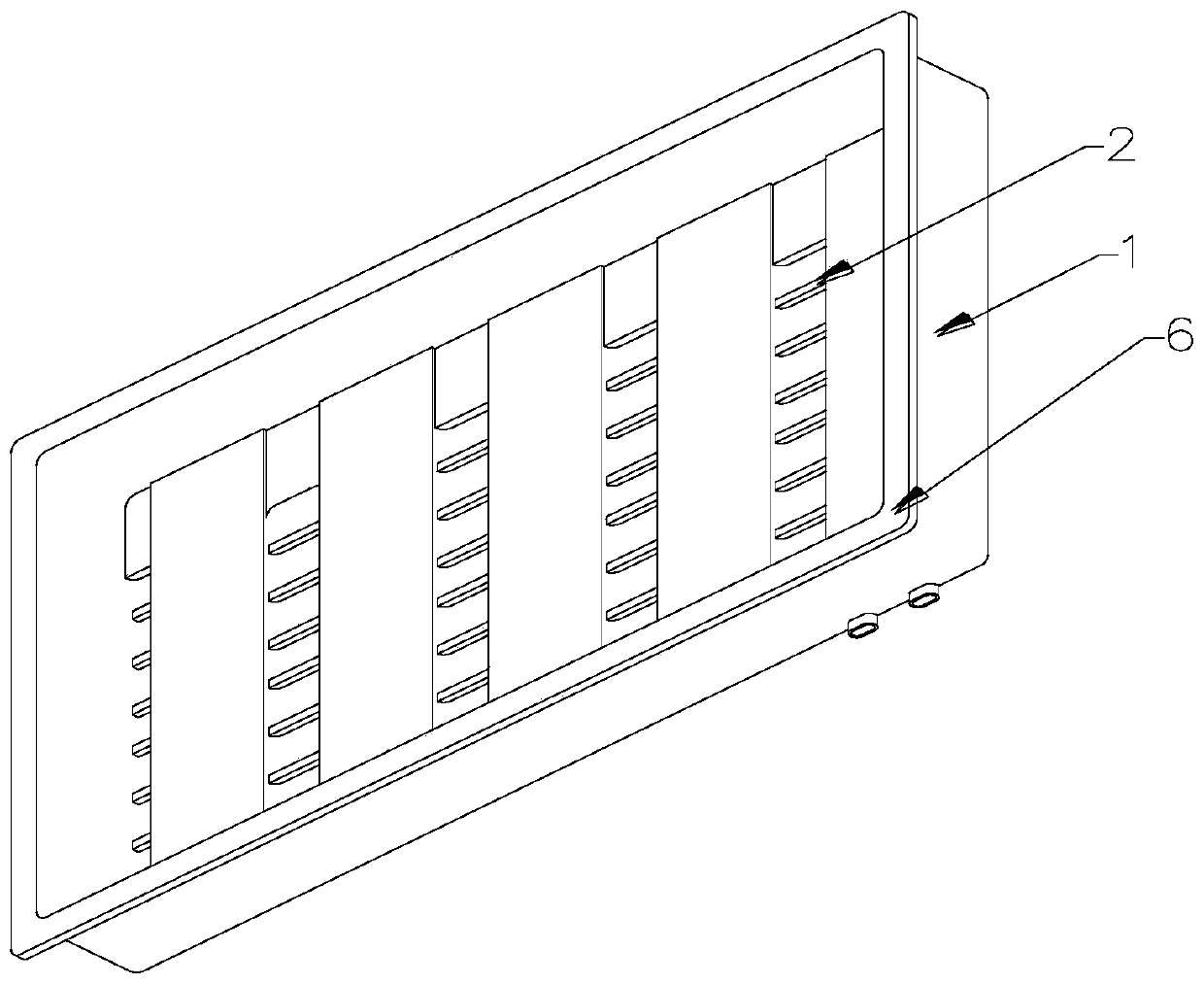

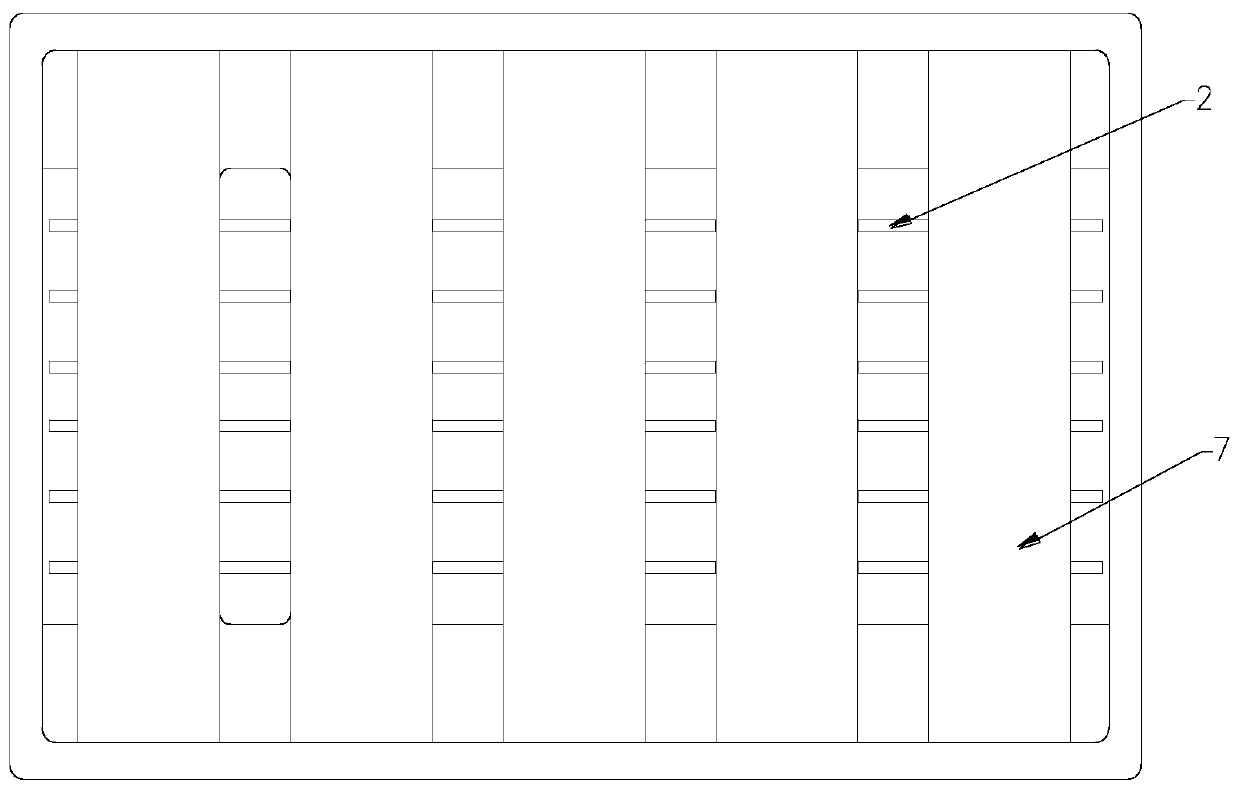

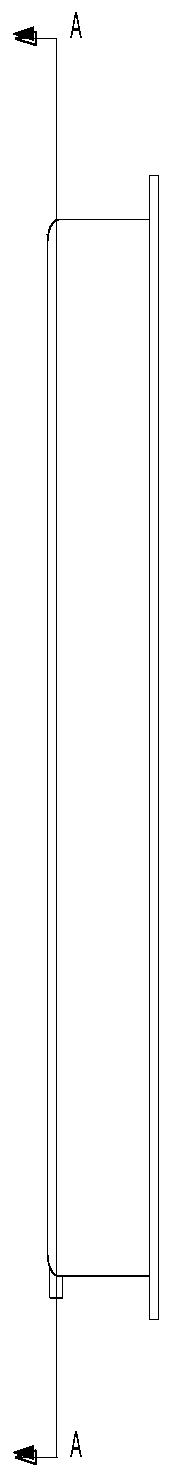

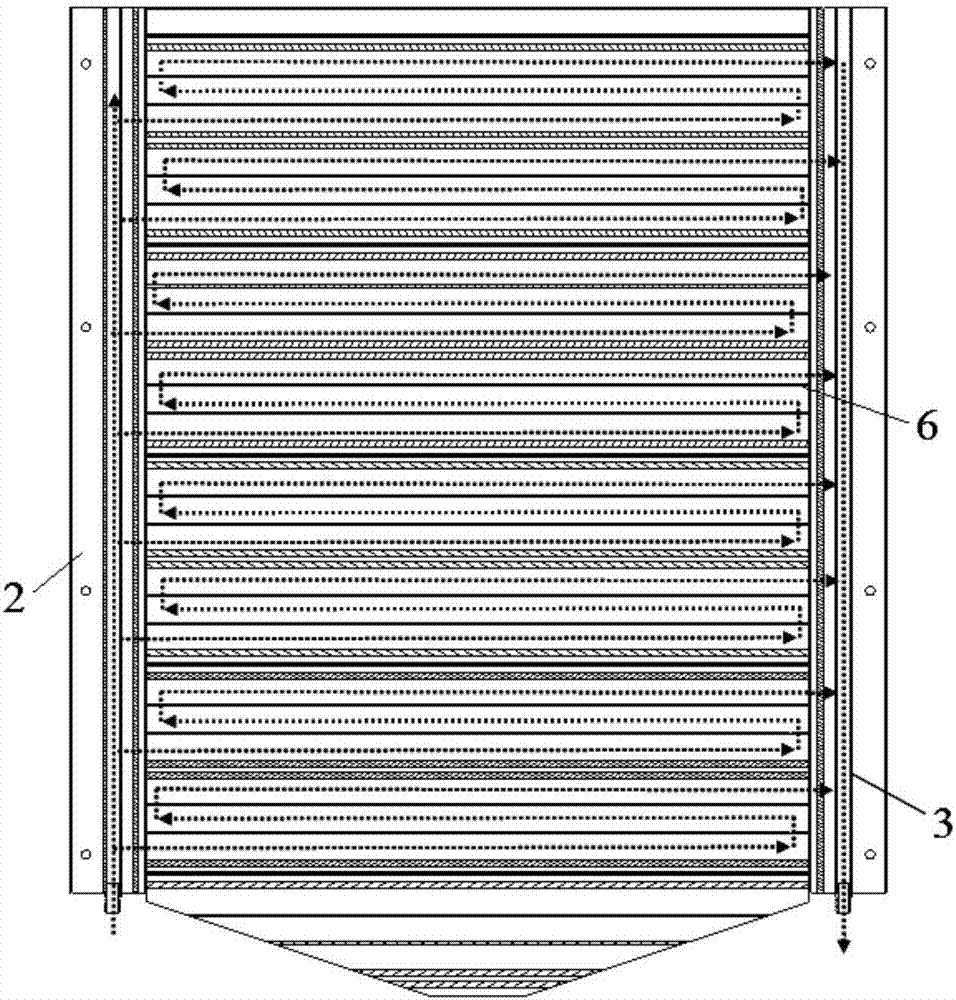

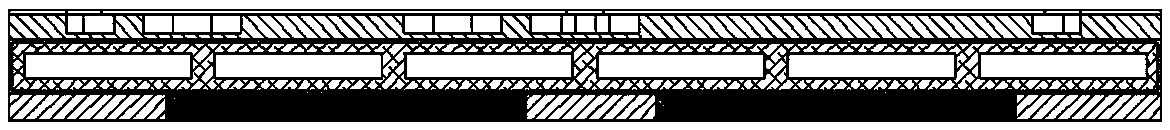

A kind of electric vehicle power battery water cooling box

ActiveCN106229582BImprove consistencyExtended service lifeSecondary cellsPower batteryElectric vehicle

The invention relates to a power battery water-cooling box for an electric vehicle, relates to the field of power battery cooling, and aims at solving the problems that a power battery box is high and uneven in temperature, and meanwhile, a traditional cooling method is poor in effect. The power battery water-cooling box for the electric vehicle comprises a box body and a cooling liquid pipeline; the cooling liquid pipeline is laid in a rectangular bottom plate of the box body; a water inlet and a water outlet of the cooling liquid pipeline extend outwards through the side wall of the box body; an upper groove is arranged in an area, in which no cooling liquid pipeline is laid, on the bottom plate of the box body; a plurality of vertical ribs are arranged in the upper groove; and the upper surfaces of the vertical ribs do not exceed the upper surface of the bottom plate of the box body. The power battery water-cooling box is suitable for cooling a power battery.

Owner:江苏和中普方新能源科技有限公司

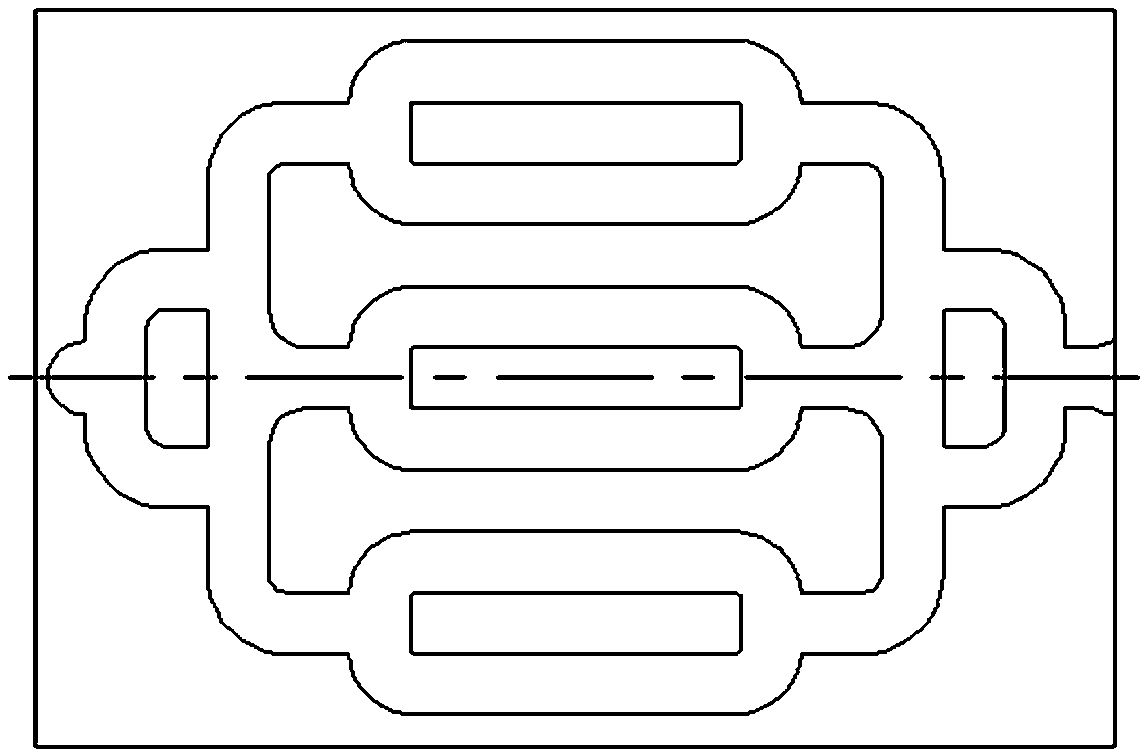

Water-cooling heat dissipation device of new energy automobile battery pack

InactiveCN107196015AEven heat transferImprove cooling effectSecondary cellsBatteriesEngineeringBattery cell

The invention discloses a water-cooling heat dissipation device of a new energy automobile battery pack. The water-cooling heat dissipation device comprises a water inlet pipe, a water outlet pipe and a water-cooling plate, wherein the water inlet pipe is used for allowing cooling water to enter, the water outlet pipe is used for allowing the cooling water to flow out, the water-cooling plate is connected with the water inlet pipe and the water outlet pipe and is used for being in contact with a battery cell of the battery pack, a water inlet passage is arranged in the water inlet pipe, a water discharge passage is arranged in the water outlet pipe, and a cooling water channel is arranged in the water-cooling plate, communicates with the water inlet passage and the water discharge passage, is used for allowing the cooling water in the water inlet passage to enter the water discharge passage and is S-shaped. In the water-cooling heat dissipation device of the new energy automobile battery pack, the S-shaped cooling water channel is arranged in the water-cooling plate, heat transfer is more balanced, so that the heat dissipation efficiency is improved; and moreover, the water-cooling heat dissipation device is more compact in structure, lighter in weight and low in manufacturing cost.

Owner:安徽天鑫能源科技有限公司

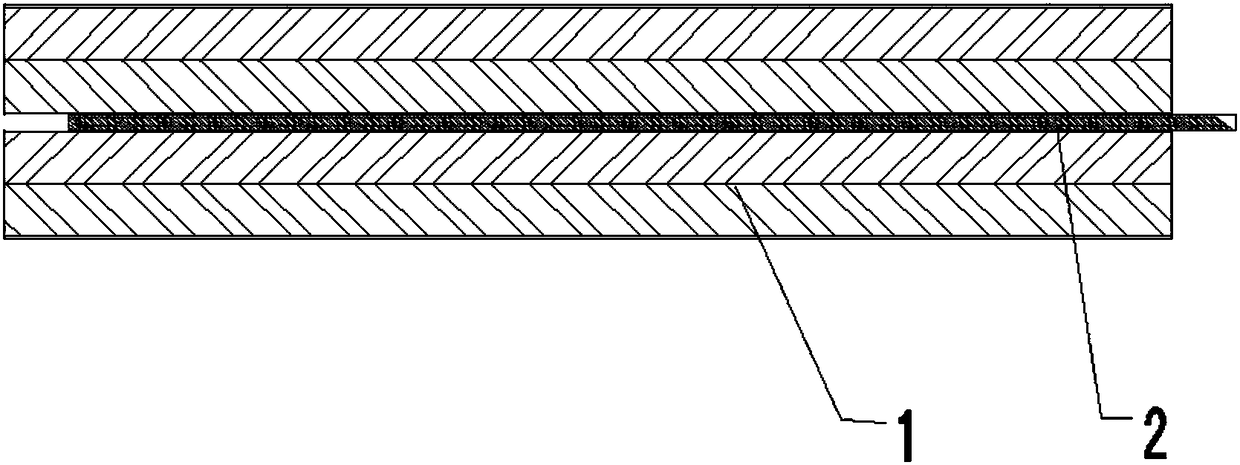

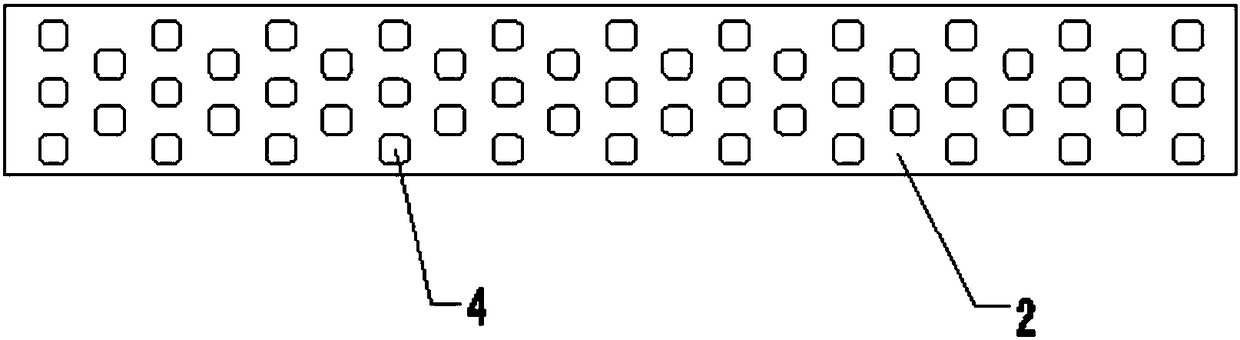

Production technology of deformation-preventing composite ground heating floor

InactiveCN108060763AHigh dimensional accuracyReduce surface roughnessCovering/liningsLamination ancillary operationsPunchingHigh intensity

The invention discloses a production technology of a deformation-preventing composite ground heating floor. The production technology comprises the following steps that a, a metal plate is made through a press-rolling method, then a plurality of punching holes are evenly formed in the metal plate through die opening and punching, and the punching holes penetrate through the metal plate; and the adopted metal steel plate is low in cost, and high-strength performance of the metal steel plate can maintain stability and durability of wooden plates; b, the wooden plates adopt mechanical profiling and are made into the wooden plates with a plurality of positioning protrusions, and the positioning protrusions are matched with the punching holes in the step (a); and c, glue is applied to the two sides of the metal plate and the protruding sides of the wooden plates, the wooden plates are inserted into the punching holes in the corresponding positions of the metal plate through the positioningprotrusions correspondingly on the two sides of the metal plate, so that the composite ground heating floor is formed through splicing. The steel-wood composite ground heating floor is durable, uniform in heat transfer and not prone to being deformed and cracking; the production process, installation process and subsequent maintenance and replacement are simplified, the simple and quick effects are achieved, and the production technology is simple.

Owner:浙江绿城联合设计有限公司

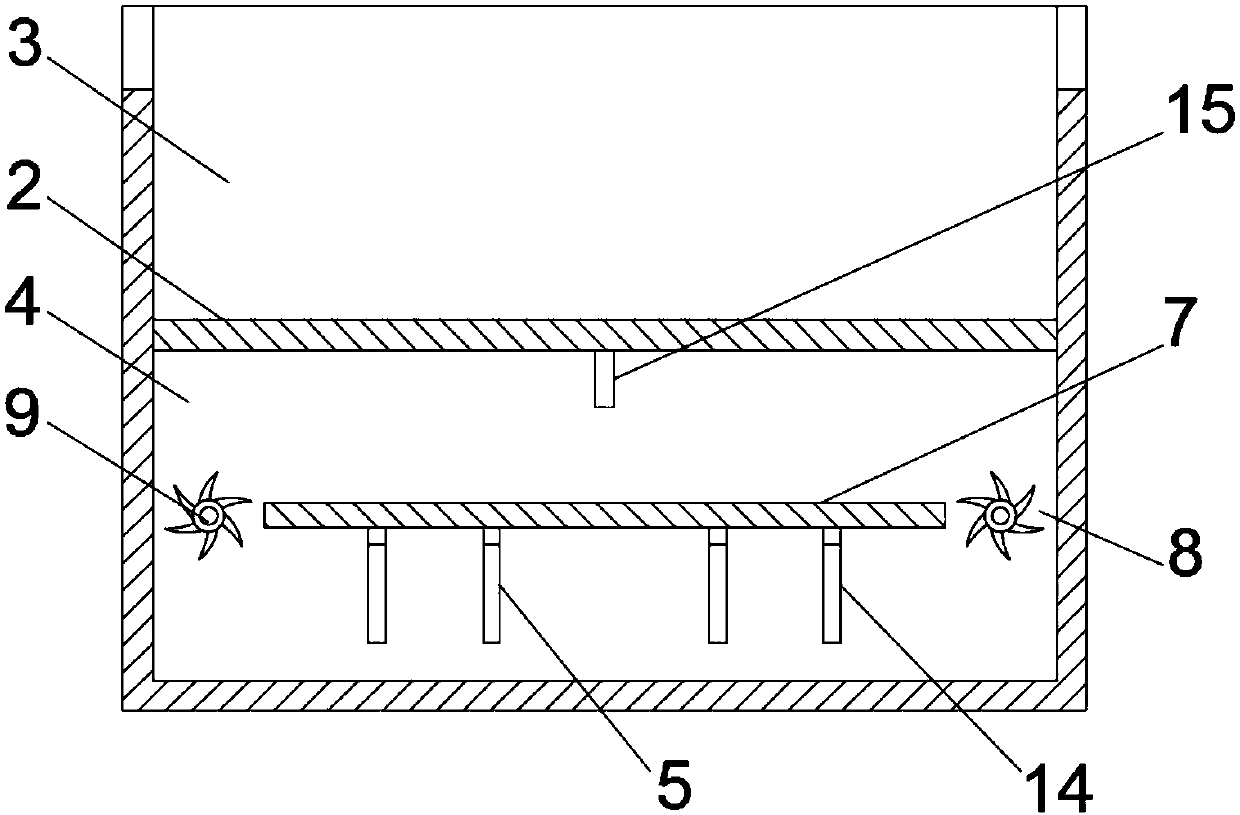

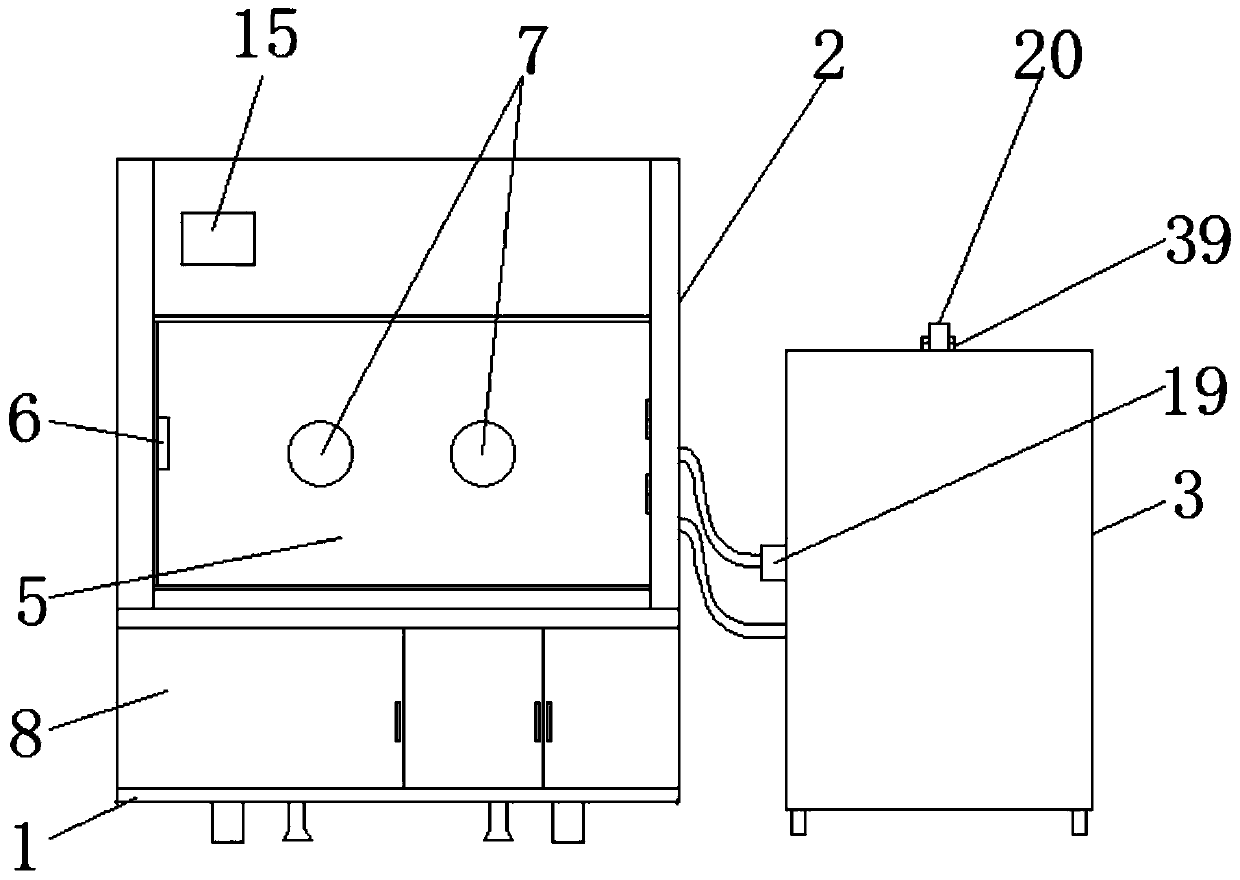

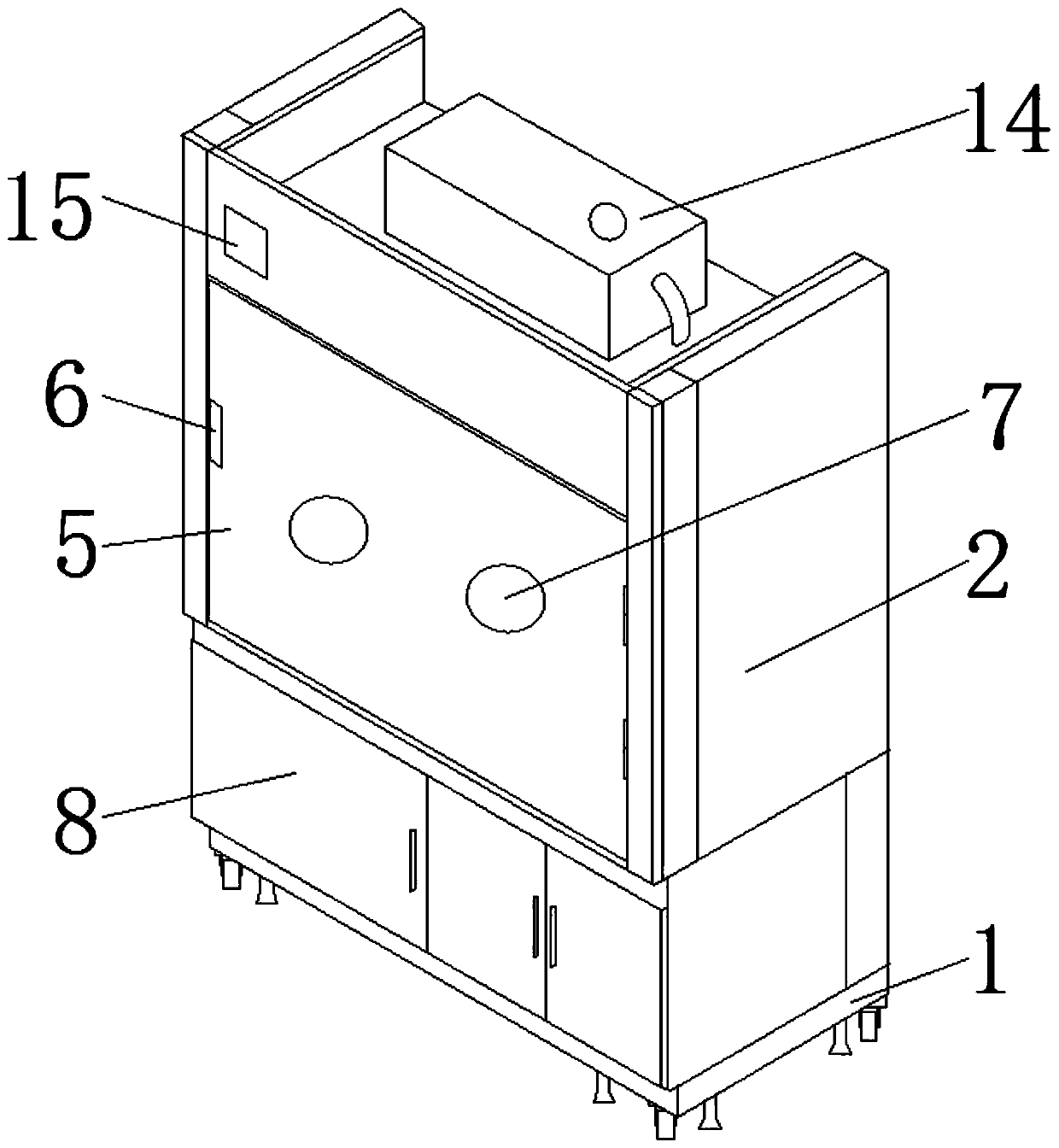

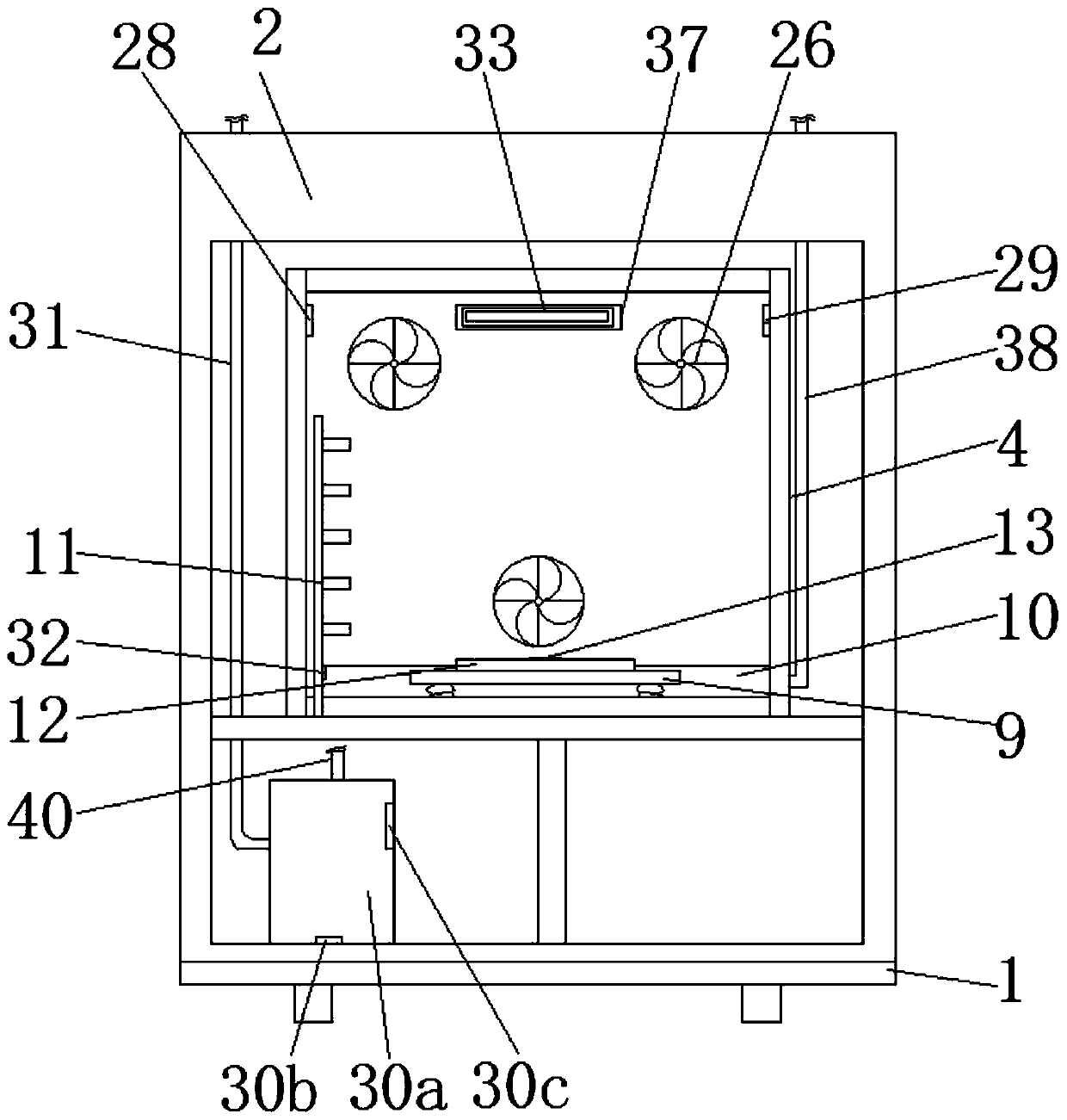

Environment-friendly high-precision constant-temperature and constant-humidity weighing device

InactiveCN111256793AUniform temperatureReduce the temperatureWeighing apparatus for materials with special property/formMaterial weighingCondenser (heat transfer)Heat transmission

The invention discloses an environment-friendly high-precision constant-temperature and constant-humidity weighing device. The environment-friendly high-precision constant-temperature and constant-humidity weighing device includes a base, a housing, a constant temperature box and an operation box, the housing is provided with at least two lower cabinet chambers below the operation box; a water supplementing tank is fixed at the top of the housing; the operation box is of a rectangular frame structure with an opening facing a moving door, and the rectangular frame structure is composed of a left constant-temperature plate, a right constant-temperature plate, a rear constant-temperature plate, an upper constant-temperature plate and a lower constant-temperature plate. Three circulating fansare arranged on the rear constant-temperature plate; heating coils are arranged on the left constant temperature plate, the right constant temperature plate, the rear constant temperature plate, the upper constant-temperature plate and the lower constant-temperature plate; a steam inlet is formed in the upper end of the rear constant-temperature plate; a condenser is arranged on the steam inlet, adamping table and a sample frame are fixed to the lower constant-temperature plate, a weighing balance is fixed to the upper end of the damping table, a humidifier is fixed into one lower cabinet chamber, water with large specific heat capacity serves as a heat conduction medium to heat an operation box connecting pipe through five-face type heat exchange, and heat transfer is more uniform.

Owner:山东宜维检测有限公司

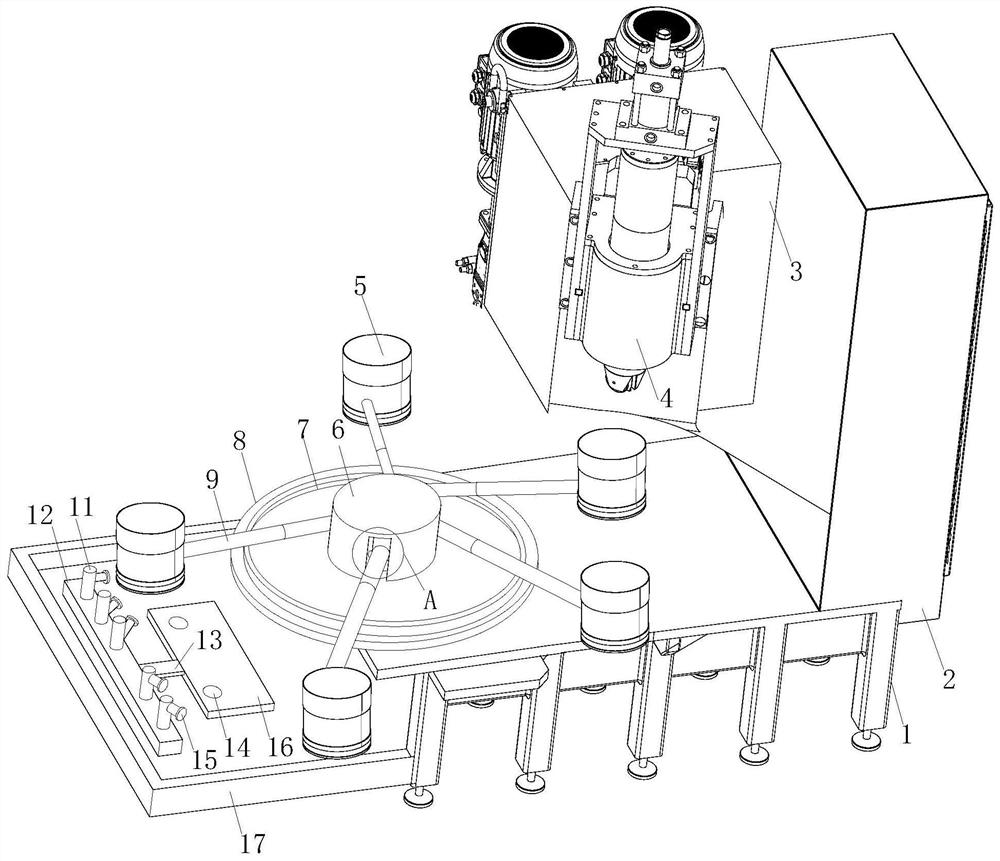

Aluminum alloy cast ingot automatic production line

ActiveCN112756568AFast molding speedImprove cooling forming efficiencyIngot casting plantsMould handling equipmentsProduction lineWater storage

The invention relates to the field of aluminum alloy machining, in particular to an aluminum alloy cast ingot automatic production line. The line comprises a workbench, a liquid injection pipe and a plurality of forming cylinders. A storage box is installed on the side face of one end of the top of the workbench. The liquid injection pipe is vertically installed on one side of the storage box and in through connection with the interior of the storage box. After a water storage bag is extruded, cooling water in the water storage bag is sprayed outwards from spray heads, then the cooling water is sprayed to the forming cylinders at the two ends above a water storage tank, and after the cooling water is sprayed to the forming cylinders about to enter the water storage tank and the outer walls of the forming cylinders just separated from the interior of the water storage tank, the cooling forming efficiency of an aluminum alloy solution can be improved.

Owner:鹤山市胜达金属有限公司

Environment-friendly energy-saving tin stove

InactiveCN101059311AMeets the highest environmental standardsLow costCrucible furnacesSlagMetallic materials

The present invention discloses a new environment-friendly energy-saving tin stove. It includes tin pan which outer surface is equipped with electric heating ring and its temperature measuring and controlling device. Said tin pan is shallow circular body, the circumference of pan bottom is equipped with a ring of groove, the centre of pan bottom is equipped with circular platform, the bead of tin pan is flanged out, the back of pan bottom is equipped with connecting mouth which is used for connecting temperature measuring device; the tin pan is composed by three layers: basic layer in metal materials and two enamel layers on the two sides of basic layer. The melt tin in the invention fits the ROHS forth highest environment-friendly standards requirements, and the melt tin color is bright, tin is not be bonded, the high temperature oxidation film is less and the heating transfer is uniform; the products cost is low and the rate of performance to price is high; the foreign materials on tin pieces can be eliminated completely under the action of high temperature; the tin melting speed is fast and it saves energy; the interfacial tension of melt tin upper part and the tin pan contacting position is large, the tin slag is easy to be used and stripped and the melt tin is not easy to spillover.

Owner:朱建焕 +1

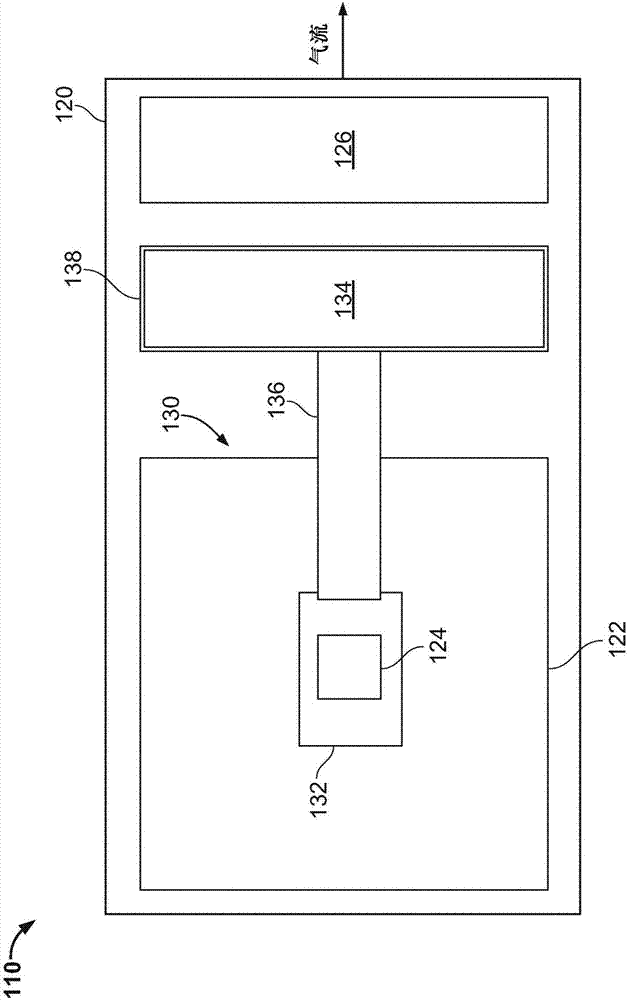

Cooling electronic devices in a data center

ActiveCN107302839ACooling capacity can be limitedEven heat transferDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidData center

A data center cooling system includes a modular heat sink and a working fluid. The modular heat sink includes an evaporator configured to thermally contact a heat-generating electronic device to receive heat from the data center heat-generating electronic device; a condenser coupled to the evaporator and configured to transfer the heat from the heat-generating electronic device into a cooling fluid; and a plurality of transport tubes that fluidly couple the evaporator and the condenser, at least one of the plurality of transport tubes including an open end positioned in the evaporator and a closed end positioned in the condenser. The working fluid vaporizes in the evaporator based on receipt of the heat from the heat-generating electronic device, and circulates, in vapor phase, from the evaporator to the condenser in the transport member, and circulates, in liquid phase, from the condenser to the evaporator.

Owner:GOOGLE LLC

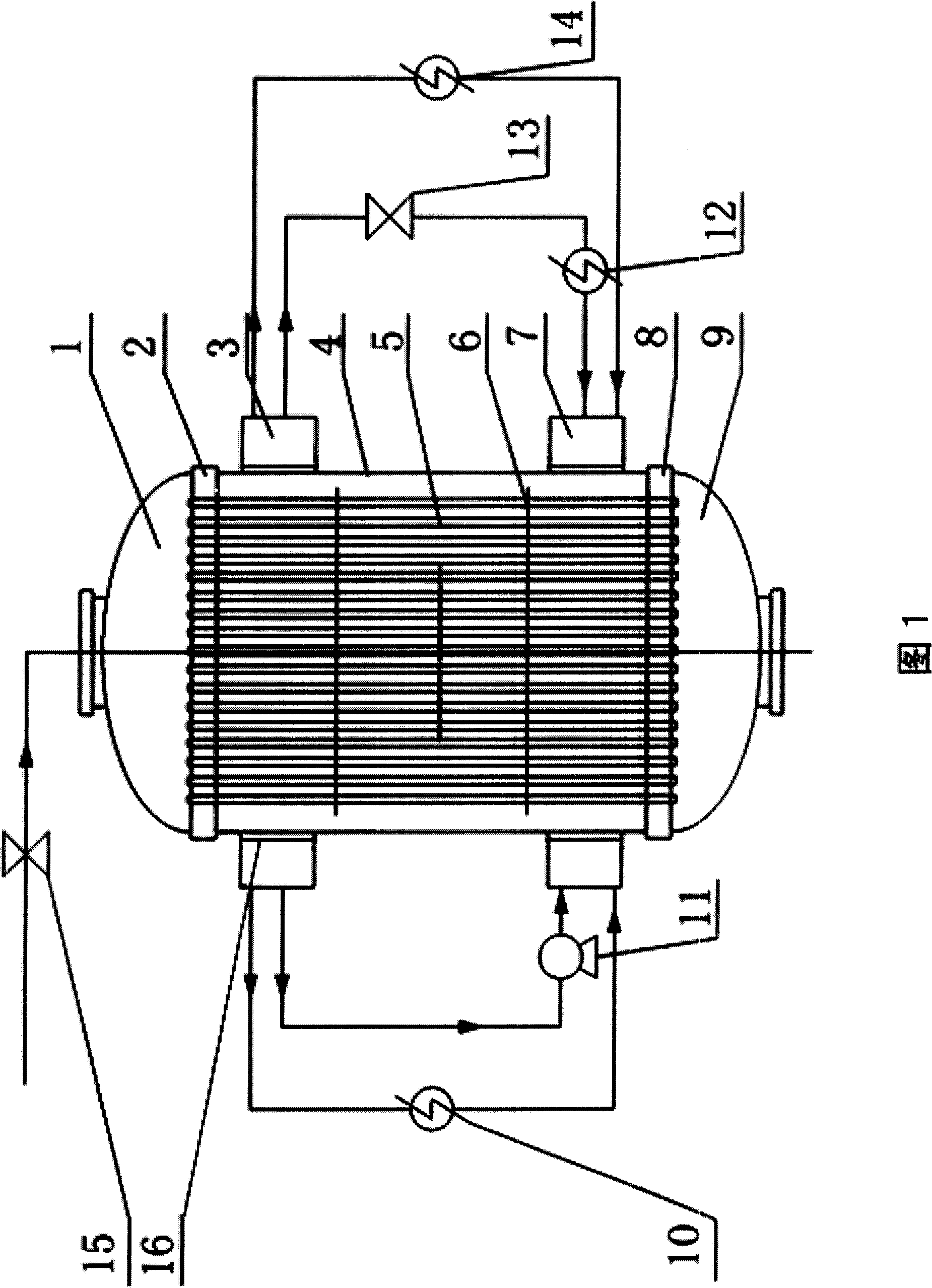

Fixed bed reactor for producing maleic anhydride by benzene process with annual production capacity of 20 000 tons

InactiveCN101182316AEven heat transferUniform accessOrganic chemistryChemical/physical/physico-chemical stationary reactorsFixed bedAnnual production

The present invention relates to a chemical reactor group using benzene as a raw material for maleic anhydride production, and the annual production capacity of the chemical reactor group is twenty thousand tons of the maleic anhydride. In China, the maximum annual production capacity of a single piece of the device using the benzene as the raw material for the maleic anhydride production is ten thousand tons per year, and a salt-melting cycling pump used for moving heat is all adopted in one piece. The reactor group in ten thousand tons per year has the problems as follows: firstly, the production capacity of the single piece of device is limited, which can not meet the requirement of the market development; secondly, when the device is used, the energy consumption of unit output is large, the effective utilization rate is low, and the equipment operation cost is high; thirdly, one piece of salt-melting cycling pump is used for moving heat, which causes that the heat concentrated and can be hardly moved out; fourthly, the reaction waste heat is too little, which can not be used completely.

Owner:西安航天华威化工生物工程有限公司 +1

Anti-deformation control technology for two-way stainless steel plate jointing

The invention discloses an anti-deformation control technology for two-way stainless steel plate jointing. The anti-deformation control technology for two-way stainless steel plate jointing comprises the steps that two-way chamfering is conducted on welded edges of stainless steel plates jointed; then levelling is conducted by utilizing a jack; and the stainless steel plates jointed are welded finally, and in the welding process, pressing blocks are placed on the stainless steel plates jointed. Compared with the prior art, by means of the anti-deformation control technology for the two-way stainless steel plate jointing, good control over deformation of the stainless steel plates jointed is achieved; it is guaranteed that the steel plates are welded in a free state; stress is effectively released, and stress concentration is reduced; the cost of stainless steel protection is lowered; and in addition, the risk of base metal damage caused by cutting is evaded.

Owner:南通象屿海洋装备有限责任公司

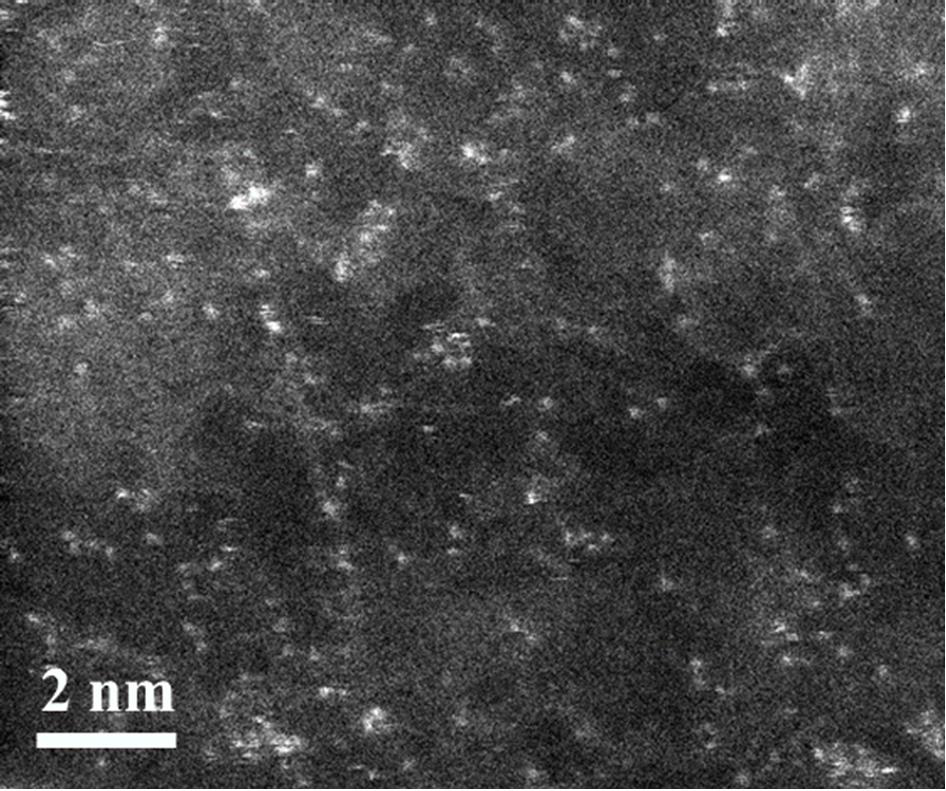

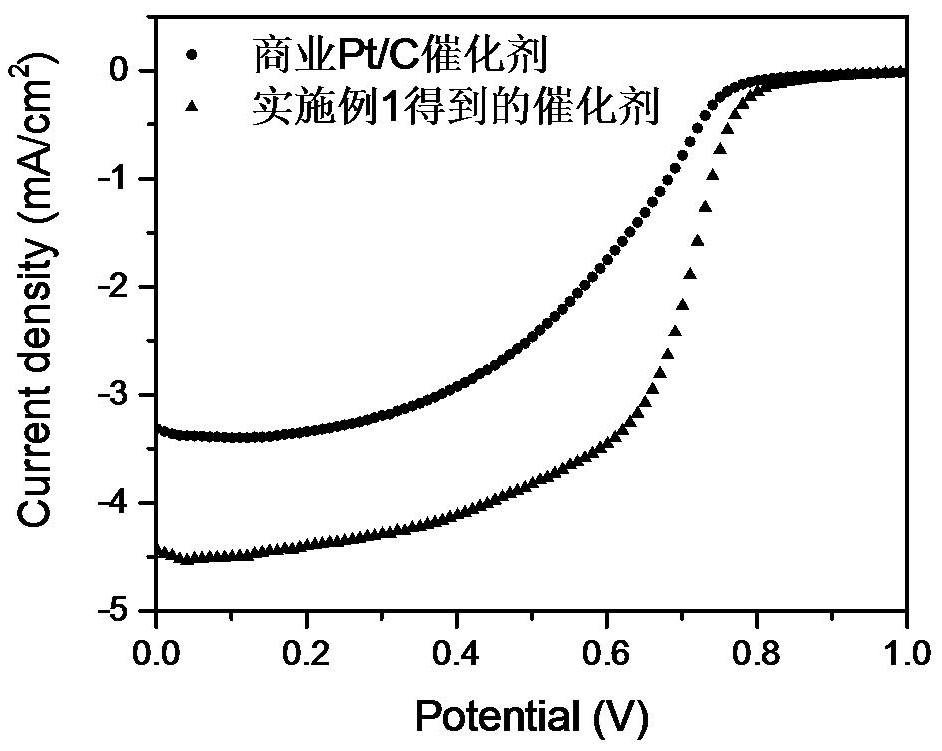

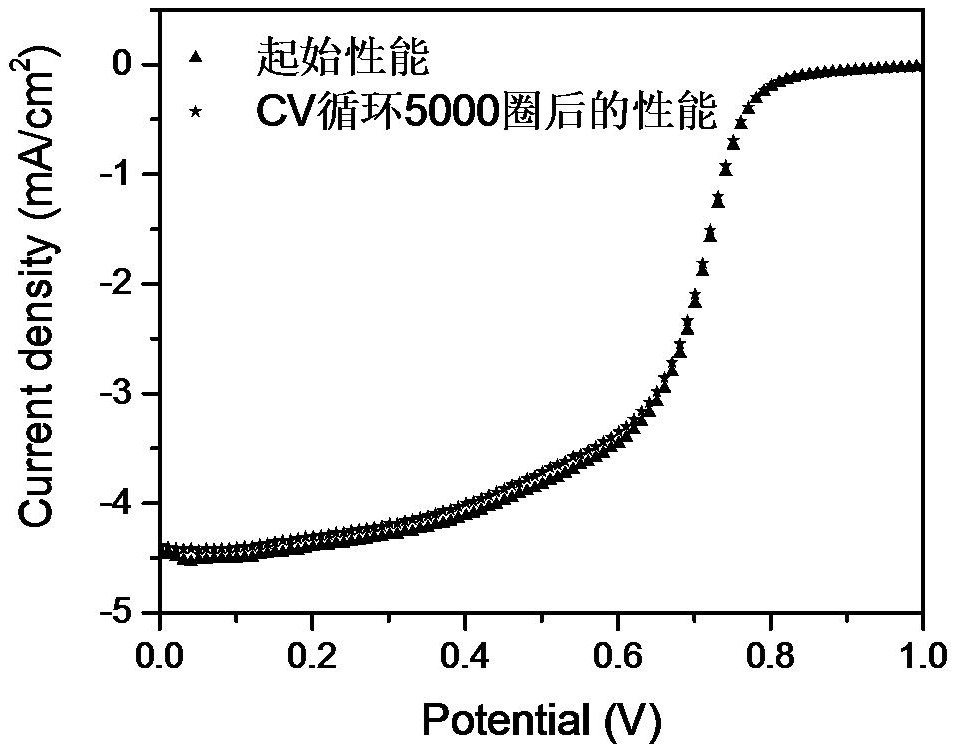

Composite material based on metal single atoms and graphene as well as preparation method and application of composite material

ActiveCN113921833AIncrease loadLarge specific surface areaCell electrodesPotassium hydroxideGraphite

The invention relates to a composite material based on metal single atoms and graphene as well as a preparation method and application of the composite material. The preparation method of the composite material based on metal single atoms and graphene comprises the steps of mixing graphene, a metal oxide and an etching agent (water or potassium hydroxide) to prepare a mixture; carrying out microwave heat treatment on the mixture to prepare a graphene-loaded metal monatomic precursor; and carrying out water washing treatment on the graphene-loaded metal monatomic precursor. The high temperature generated by microwaves can enable water or potassium hydroxide to etch graphene to form carbon defects and increase the specific surface area of graphene on the one hand, and can enable metal oxide to form steam which is uniformly distributed in graphene and reduced by carbon to be doped into the carbon defects in the form of metal single atoms on the other hand, so that the metal single atoms are doped into the graphene, the metal single atoms are high in loading capacity and not prone to agglomeration, and when the metal single atoms are applied to the electrochemical oxygen reduction reaction, the catalytic activity is high, and the stability is good.

Owner:北京石墨烯技术研究院有限公司

A temperature equalizing device for dissipating heat from multi-heat source devices using a soaking plate and microchannels

InactiveCN105118811BReduce total pressure dropExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesHeat flowElectrical devices

The invention discloses a temperature equalizing device adopting a vapor chamber and microchannels for radiating a multi-heat-source device. The temperature equalizing device is used for solving the problems that the existing radiating device cannot be used for radiating multi-heat-source high heat flux electrical devices evenly, and the stability of a chip is affected due to a high temperature gradient formed since temperature rises quickly along flow directions when the existing parallel microchannels are in use. The temperature equalizing device comprises an LTCC substrate, wherein at least two heat sources are packaged inside the LTCC substrate, the vapor chamber is installed on the LTCC substrate, the microchannels with the same number as the heat sources are formed above the vapor chamber, an entrance of each microchannel is communicated with an external cooling liquid source through an inlet, and an exit of each microchannel is communicated with an external liquid collecting box.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

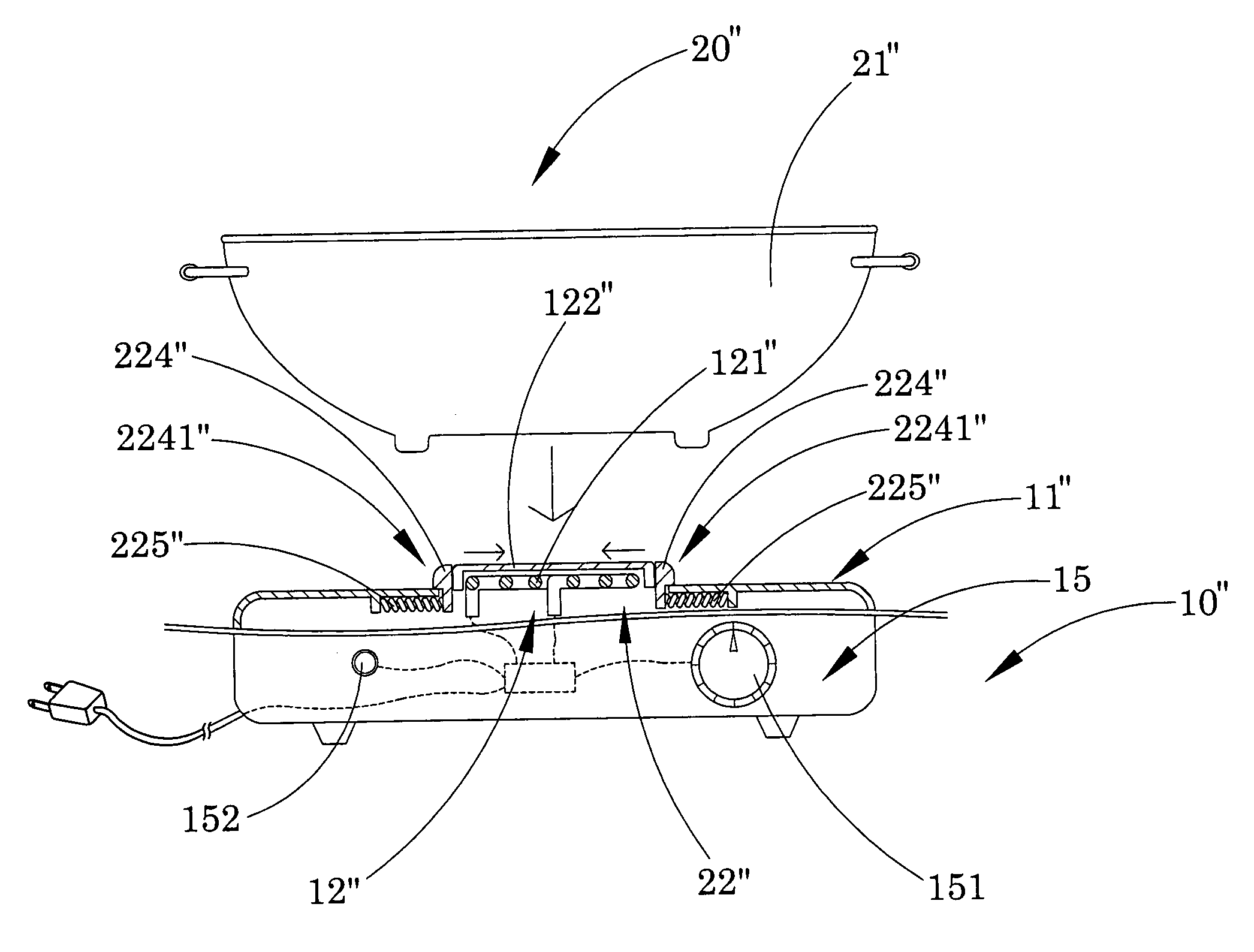

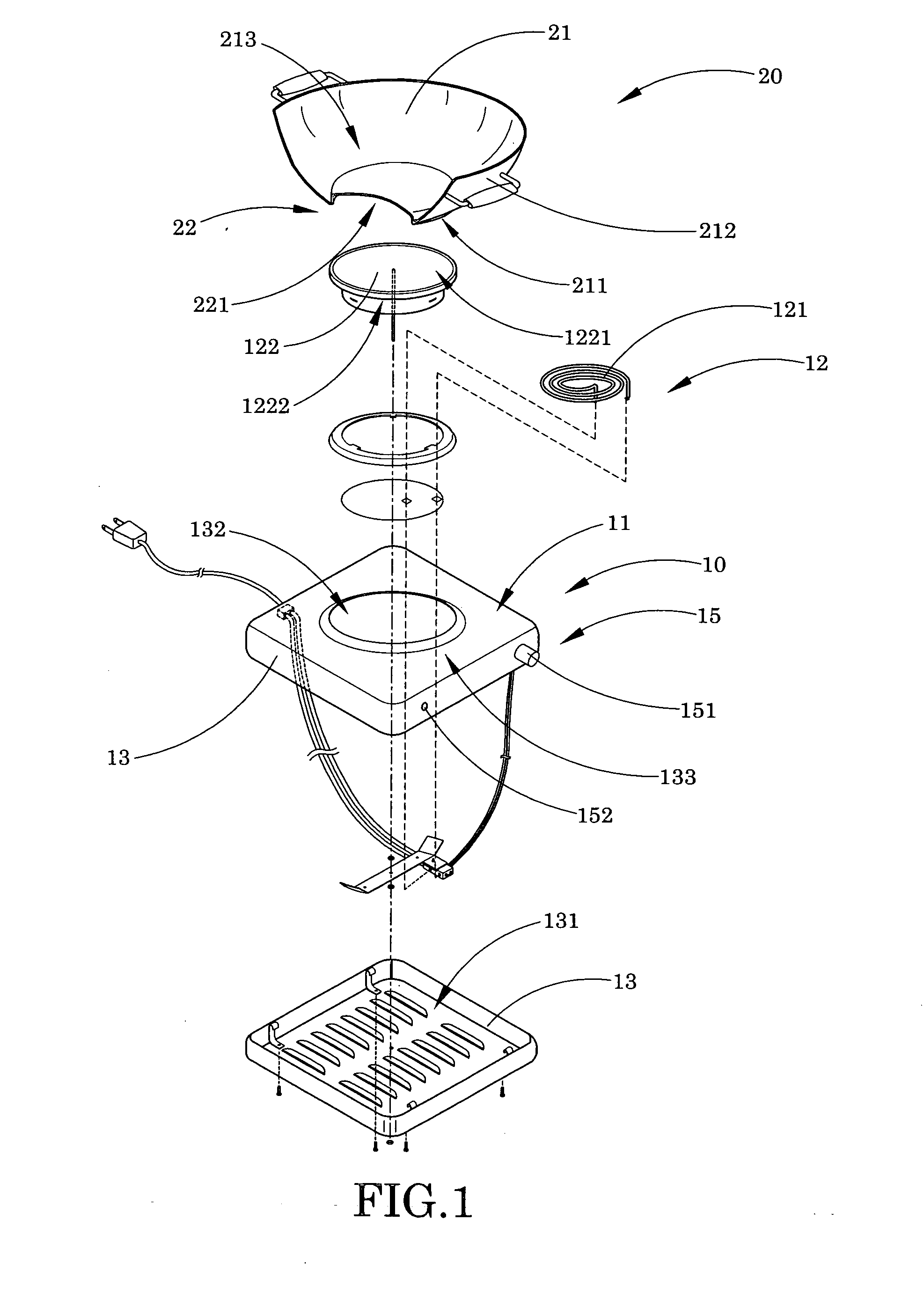

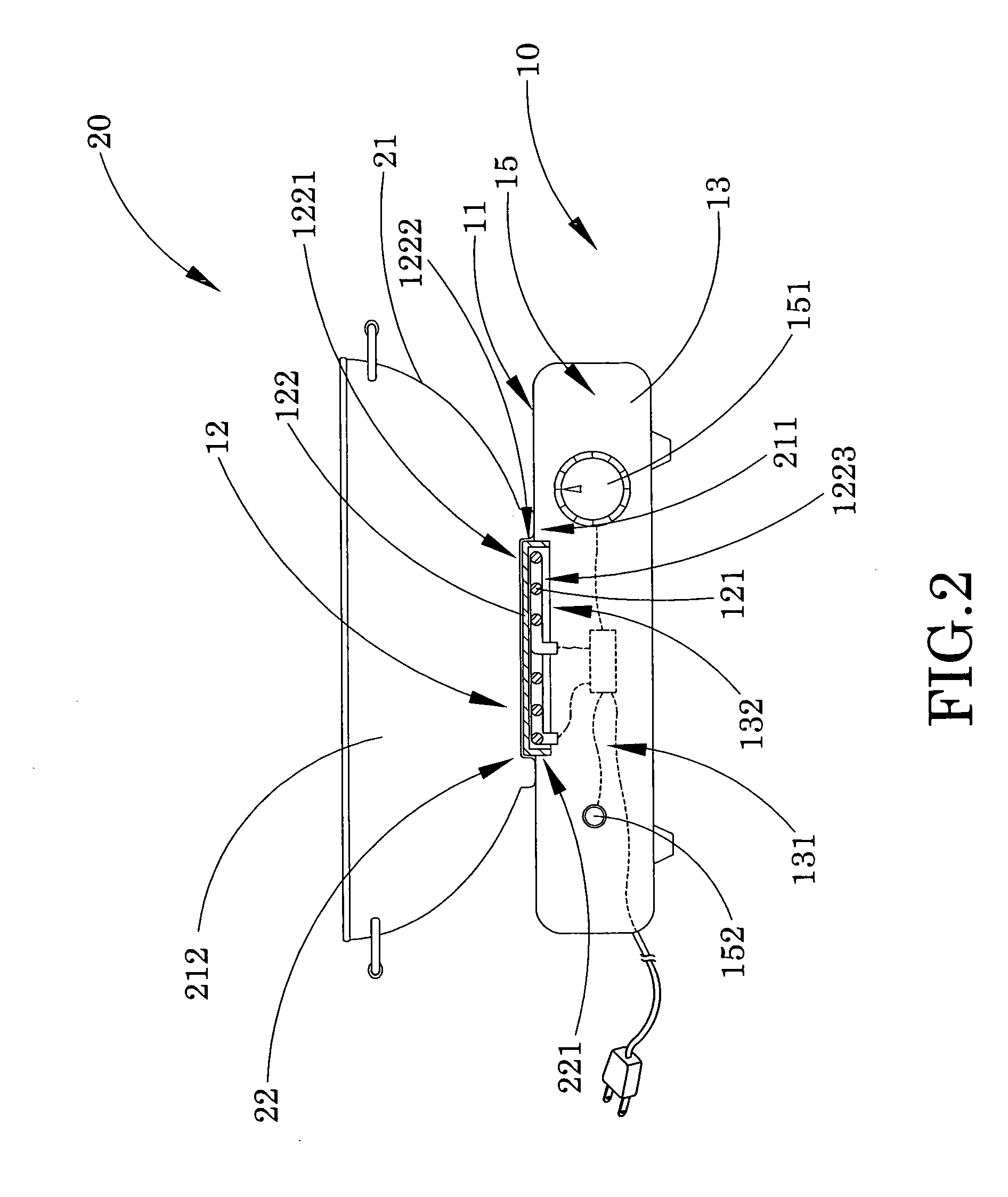

Container and cooker

InactiveUS20080135540A1Efficient heat transferSmooth transmissionHot plates heating arrangementsOhmic-resistance heating detailsEngineeringCooker

Owner:HUARUN APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com