Long life highly effective energy-conserving type heat exchanging core

A heat exchange core, energy-saving technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient heat transfer area, large negative market impact, and narrow air ducts. Achieve the effect of prolonging heat transfer time, avoiding cross-contamination, and enhancing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

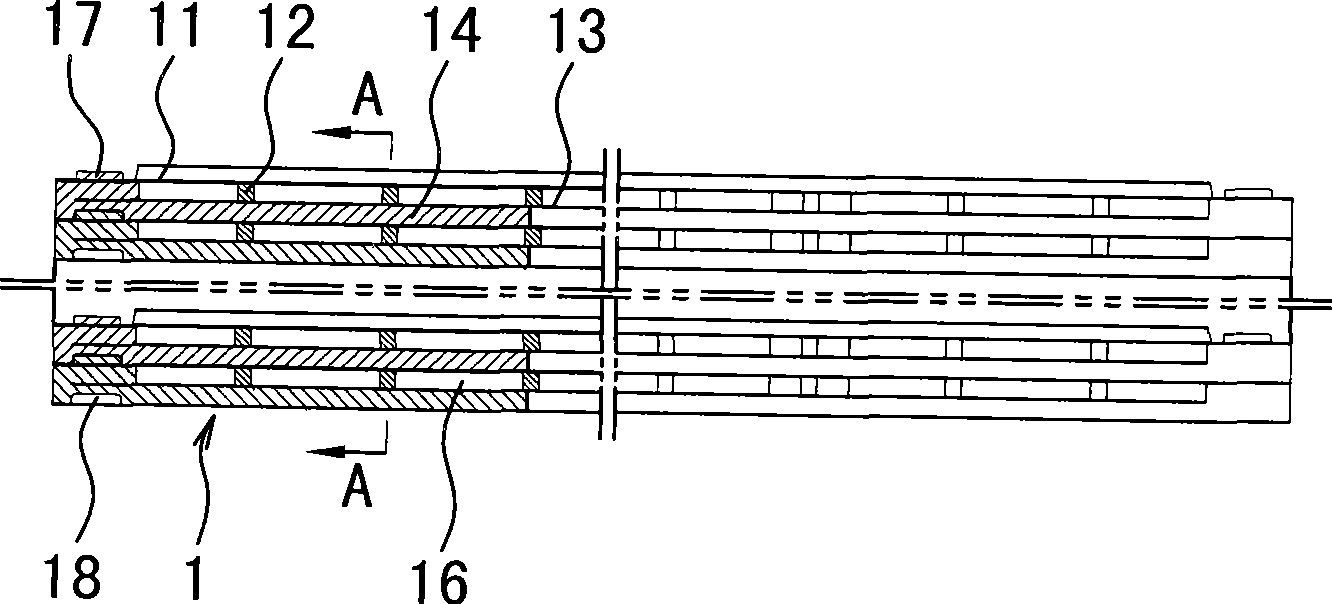

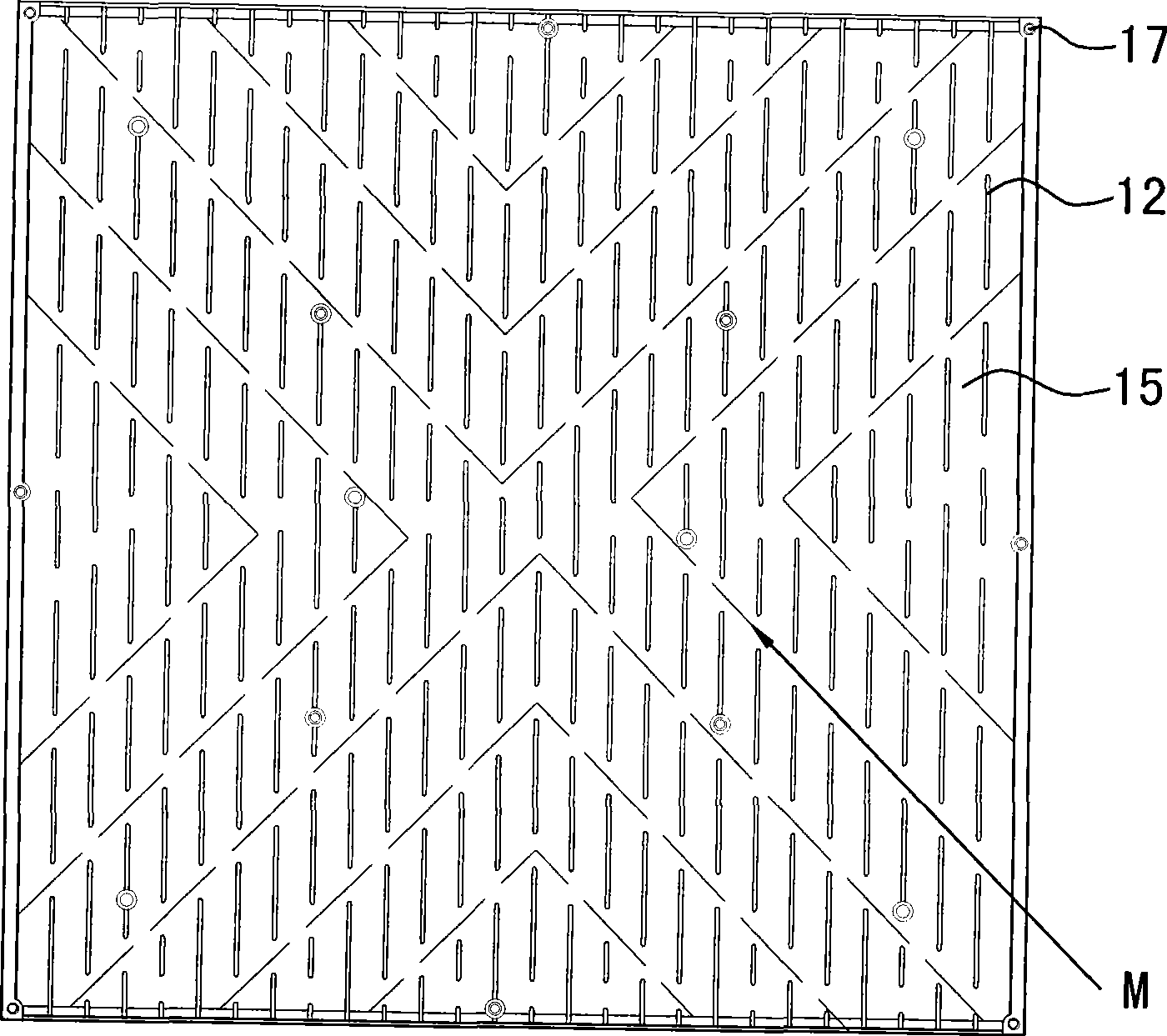

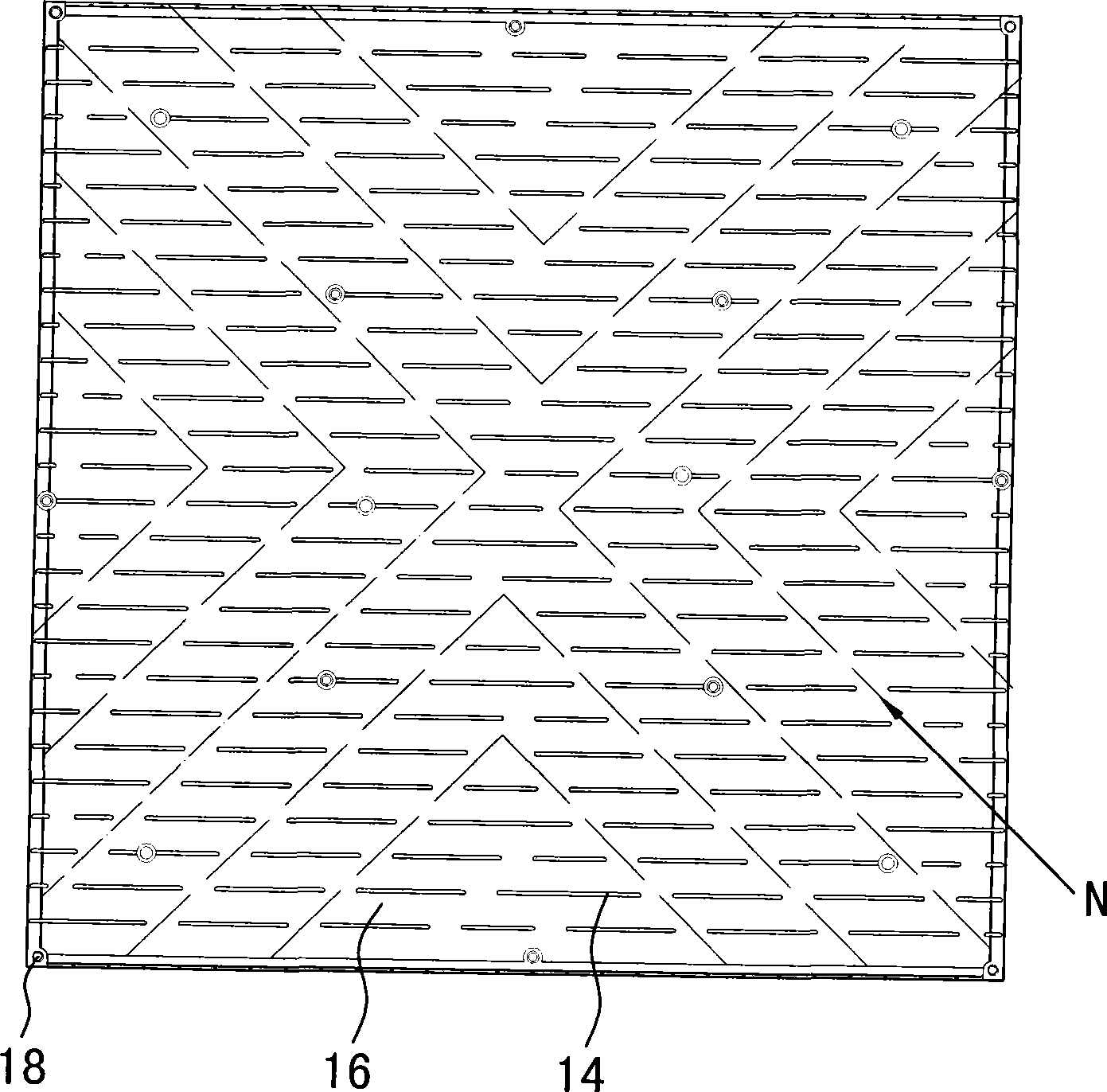

[0012] The invention discloses a long-life, high-efficiency and energy-saving heat exchange core, which is composed of a plurality of single heat exchange chips. The single heat exchange chip is composed of a keel and a heat exchange film. Road and exhaust duct, characterized in that the single heat exchange chip 1 includes four layers, such as figure 1 As shown, the first layer is the heat exchange membrane A 11, the second layer is the longitudinal keel 12, the third layer is the heat exchange membrane B 13, and the fourth layer is the transverse keel 14, the longitudinal keel 12 and the transverse keel 14 are respectively disconnected ,Such as figure 2 , image 3 As shown, the keels on this layer are not connected to each other, so that the uniform flow and pressure channels M and N are formed respectively, so that the heat transfer is more uniform and sufficient; the longitudinal keels 12 and the transverse keels 14 respectively form a rectangular transverse air duct 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com