Means, method and system for heat exchange

A heat exchange surface and heat technology, applied in the field of heat exchange devices and systems, can solve the problems of inability to achieve high-efficiency heat exchange, reduce the overall coefficient of performance of heat pumps, and deteriorate the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

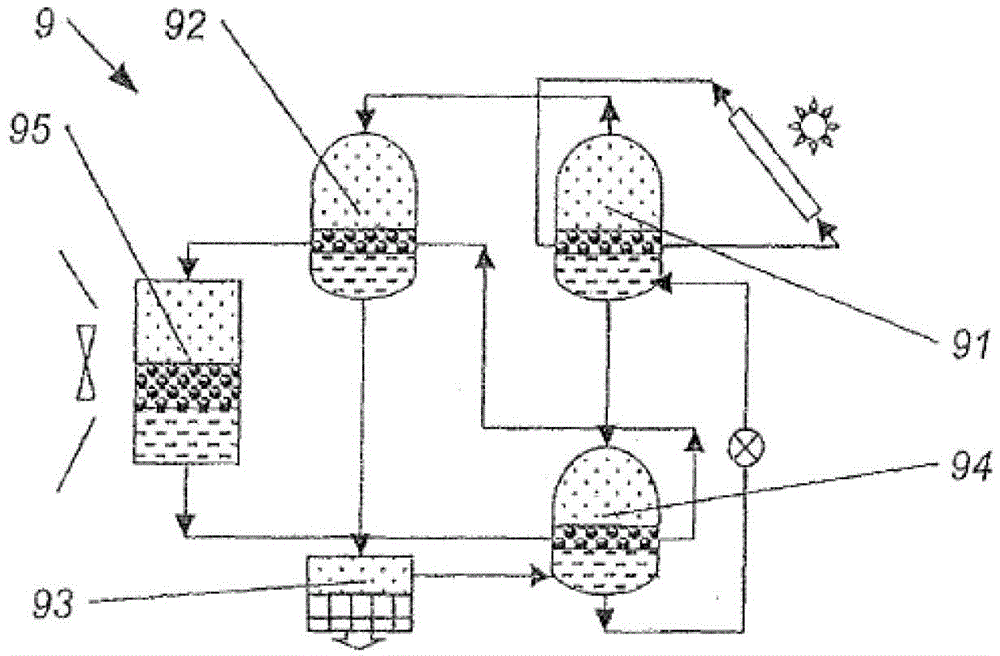

[0063] figure 1A schematic diagram of an absorption refrigeration system 9 with a solar power supply is shown. An aqueous solution of ammonia, for example, can be contained in a solvent evaporator 91 designated as an ejector of the absorption refrigeration system. In this case, the solution is heated indirectly by, for example, steam or hot water from a thermal solar system. As an alternative to thermal solar systems, other suitable heat sources that can provide the necessary evaporation temperatures can be used. Ammonia vapor is then exhausted from the solvent evaporator 91 . In most cases, the vapor then passes through a separation or rectification column ( figure 1 not shown in ) are separated from the water residue and then flow into the liquefier 92. The liquid ammonia is then stored in a high pressure collector ( figure 1 not shown in). For conditioning, the air stream from the connected refrigeration customer is sent to heat exchanger 93 where the cooled ammonia i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com