Environment-friendly energy-saving tin stove

An environmental protection, energy-saving, tin furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems that tin pots cannot meet the needs of normal processes, cannot guarantee the quality of tin immersion products, etc., and achieve guaranteed performance, high cost performance, and guaranteed products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

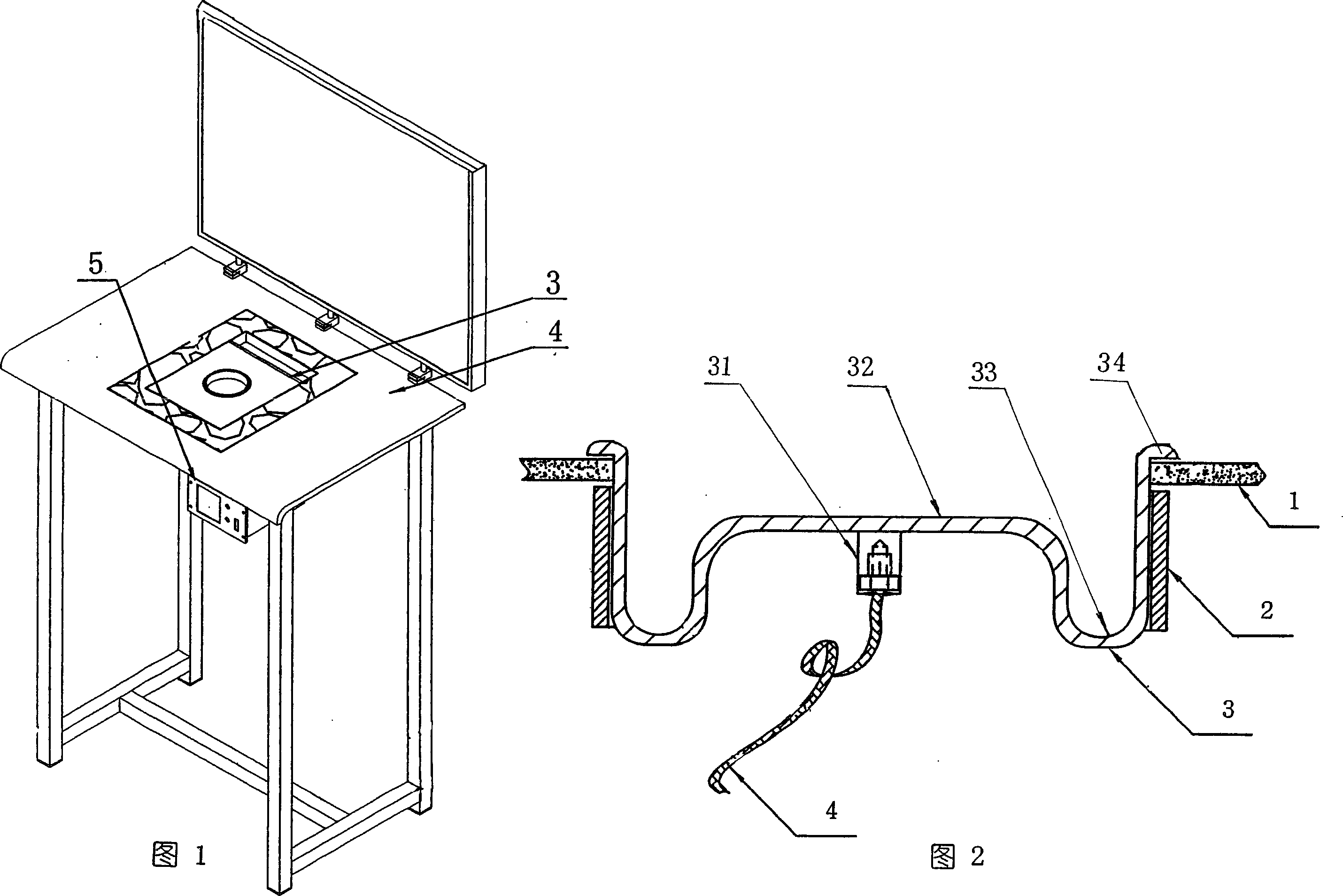

[0020] Embodiment: The environment-friendly and energy-saving tin furnace shown in Figure 1 is made up of a furnace body 4 processed and made of stainless steel, a tin pot 3 and a temperature control system 5.

[0021] In the tin pot 3 shown in Figure 2, there is a groove 33 around the bottom of the pot, and the tin dipping length is more than 8MM, and tin can be dipped in the surrounding groove. Conduction to the inner upper part; the middle of the bottom of the pot is provided with a round table 32, and the edge of the tin pot is turned outwards 34, which is an upward arc; the back of the bottom of the pot is provided with a connection port 31 for connecting the temperature measuring instrument 4, and the connection port Threaded connection is adopted with the measuring instrument; the temperature measuring instrument of this embodiment adopts a thermocouple. The tin pot is composed of two layers: the base layer of metal material, with an enamel layer on the inside of the ba...

example 1

[0022] Example 1, the outer diameter of the tin pot is 40mm, the height is 25mm, the outer diameter of the round table is 25mm, and the height from the round table to the edge is 12mm. The thickness of the steel plate is 1.5mm, and the thickness of the enamel layer is 0.4mm.

example 2

[0023] Example 2, the outer diameter of the tin pot is 120mm, the height is 40mm, the outer diameter of the round table is 80mm, and the height from the round table to the mouth is 20mm. The thickness of the steel plate is 2.5mm, and the thickness of the enamel layer is 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com