3D printer nozzle structure

A 3D printer and nozzle technology, applied in the field of 3D printing, can solve the problems of temperature rise, influence effect, melting of nozzle silk, etc., and achieve the effects of stable thermal insulation, improved work efficiency, and uniform heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

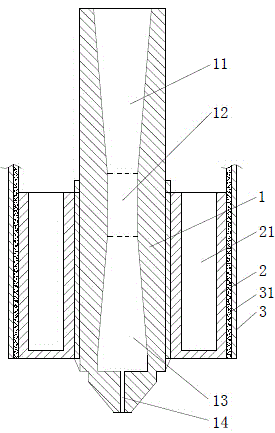

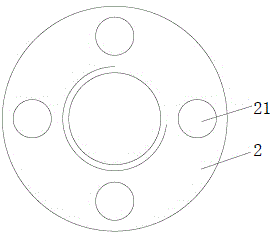

[0012] figure 1 , figure 2 The nozzle structure of the 3D printer provided by the present invention is shown, including a nozzle body 1 arranged vertically, a heating jacket 2 sleeved outside the nozzle body 1, and the nozzle body 1 protrudes from the heating jacket 2; the outer surface of the nozzle body 1 and The inner surface of the heating jacket 2 is provided with mutually matching threads; the top surface of the heating jacket 2 is provided with circumferentially uniform heating blind holes 21, and heating elements are arranged in the heating blind holes 21; the outer circular mask of the heating jacket 2 is provided with a box jacket 3 , the inner wall of the box sleeve 3 is provided with a thermal insulation layer 31; the nozzle body 1 is provided with a material hole, and the material hole is composed of the upper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com