Fixed bed reactor for producing maleic anhydride by benzene process with annual production capacity of 20 000 tons

A fixed bed reactor and reactor technology, applied in chemistry/physics/physical chemistry fixed reactors, organic chemistry, etc., can solve the problems of high equipment operation cost, less reaction waste heat, and large output energy consumption, etc., to achieve Improve heat exchange efficiency, reduce kinetic energy consumption, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

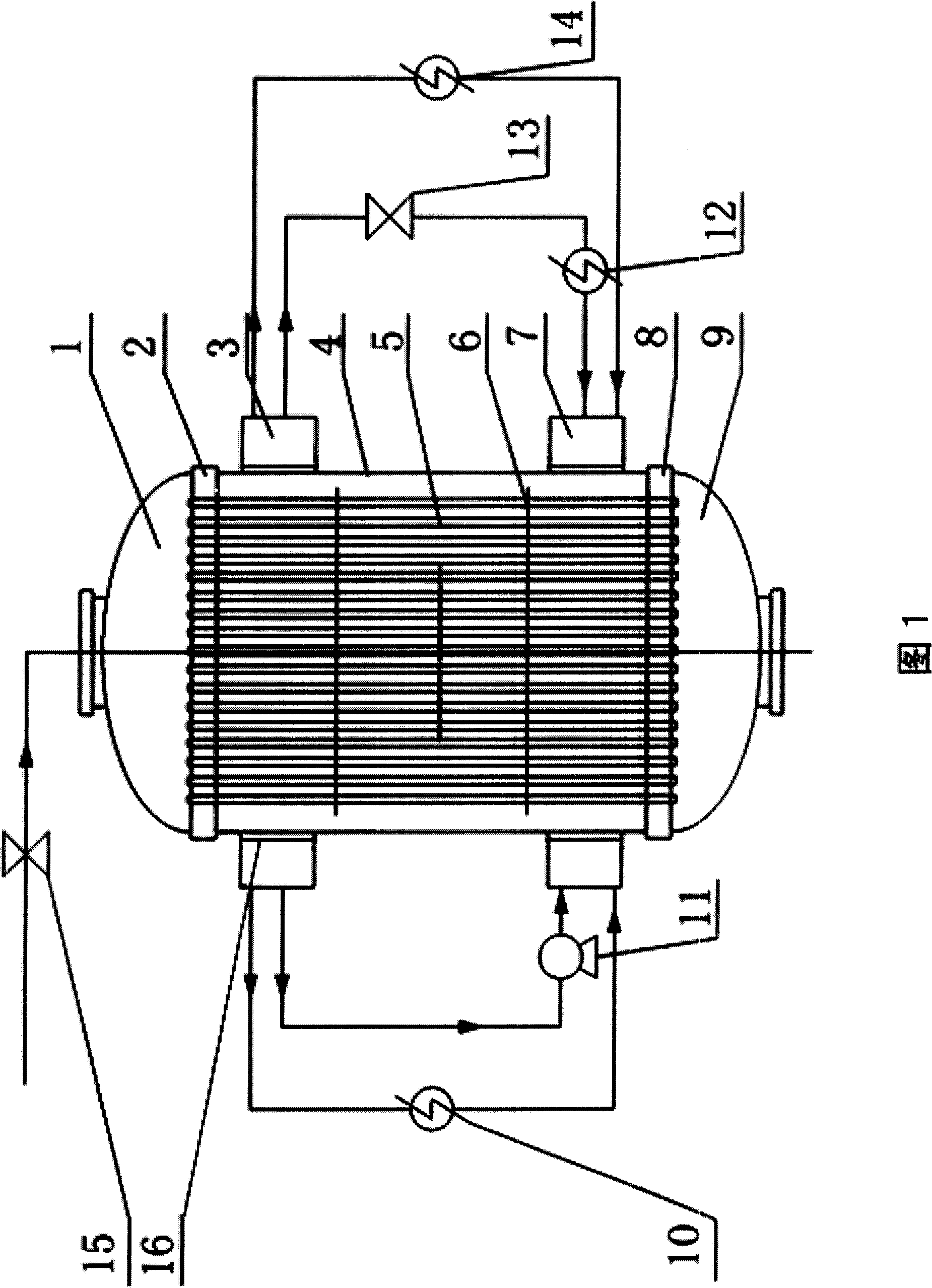

[0024] Referring to accompanying drawing 1, the structure of the embodiment of the present invention is further elaborated:

[0025] The tubular fixed bed reactor includes an upper head tube box 1, an upper tube plate 2, a shell 4, a reaction tube 5, a lower tube plate 8, and a lower head tube box 9 to form the main body of the reactor, and on the shell 4 An upper loop 3 and a lower loop 7 are provided, and two sets of circulating pumps 11 and a molten salt cooler 12 are respectively arranged between the upper loop 3 and the lower loop 7. The housings in the upper and lower loops are There are holes of different sizes on the 4, and the uniformity of the heat exchange medium flowing into the reactor is determined by designing the size of the holes; baffles 6 are installed on the upper, middle and lower parts of the shell 4, and the baffles 6 Set the small hole.

[0026] Referring to Fig. 1, the reactor of the present invention adopts double-pump circulation technology, and two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com