Cooling electronic devices in a data center

A technology for data center cooling and electronic equipment, which is applied in the field of cooling electronic equipment in data centers, and can solve problems such as areas that are difficult to cool, insufficient cooling, and unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

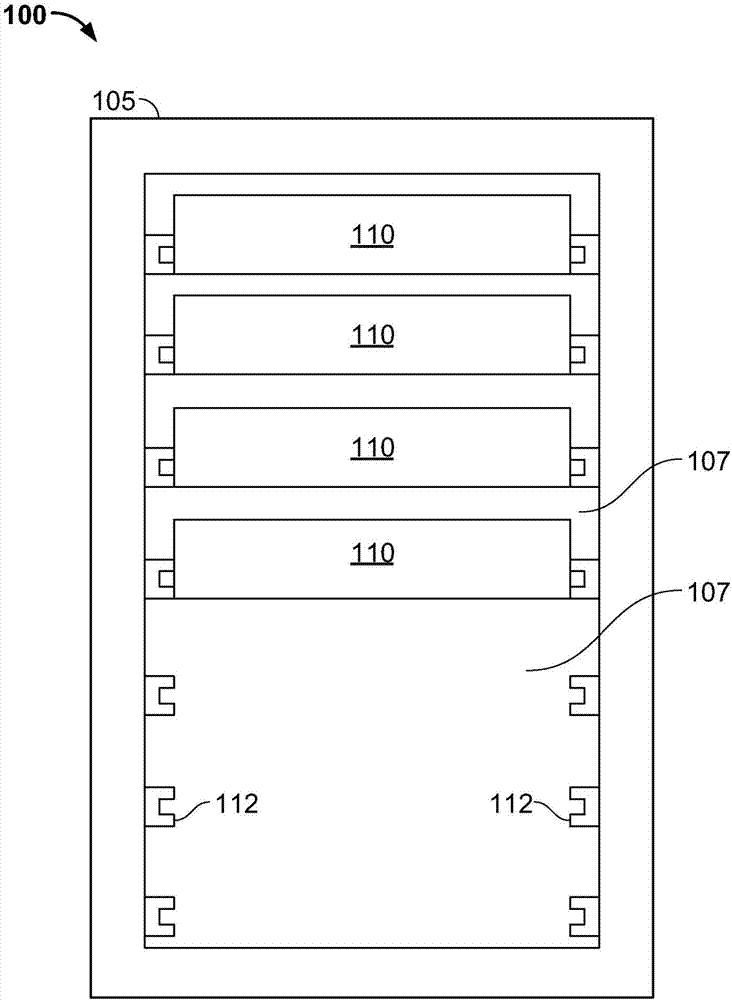

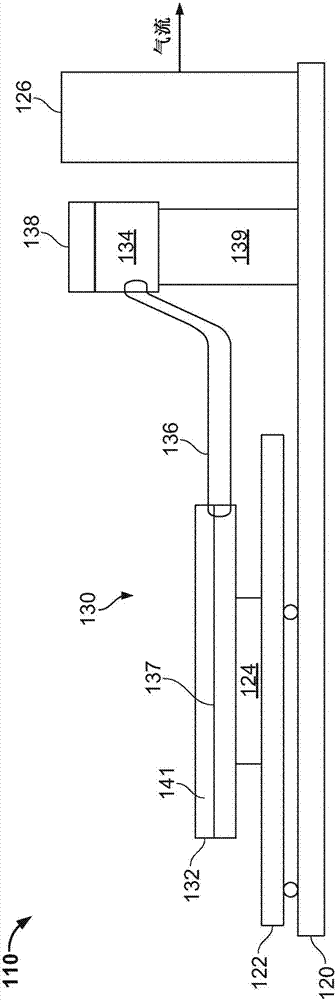

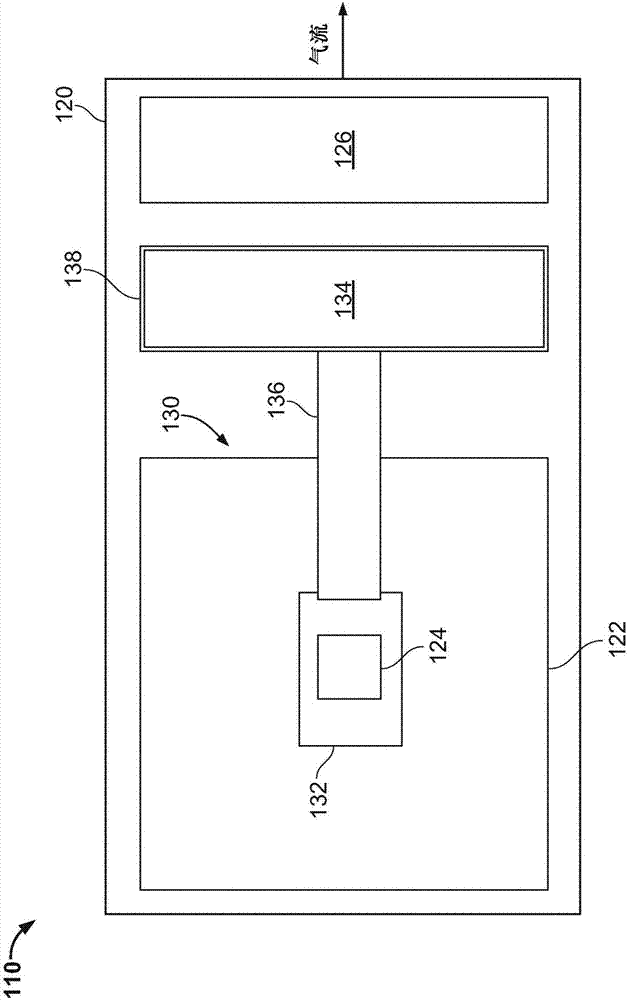

[0039] This document discloses a modular heat sink operable to cool one or more electronic heat generating devices, such as devices located on server rack subassemblies (eg, server trays) in a data center. In some embodiments, modular heat sinks can provide hot spot cooling and three-dimensional distribution of heat generated by these devices to handle high heat fluxes. In some embodiments, a modular heat sink according to the present disclosure includes an evaporator, a transfer tube, and a condenser.

[0040]In some embodiments of a modular heat sink according to the present disclosure, the evaporator comprises a small copper block with a heat transfer surface (eg, a fin structure). The fins in the fin construction can be machined or cut, or they can be welded or brazed to the evaporator small copper block as a separate part. The fins can be plate fins or pin fins and can be coated with copper porous particles to increase evaporation rate and reduce thermal resistance. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com