A temperature equalizing device for dissipating heat from multi-heat source devices using a soaking plate and microchannels

A technology of micro-channel and vapor chamber, which is applied in semiconductor devices, electric solid-state devices, semiconductor/solid-state device components, etc., can solve the problems of temperature gradient affecting chip stability, inability to dissipate heat evenly in electronic devices with multiple heat sources and high heat flux density, etc. , to avoid excessive heat load, ensure sealing performance, and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

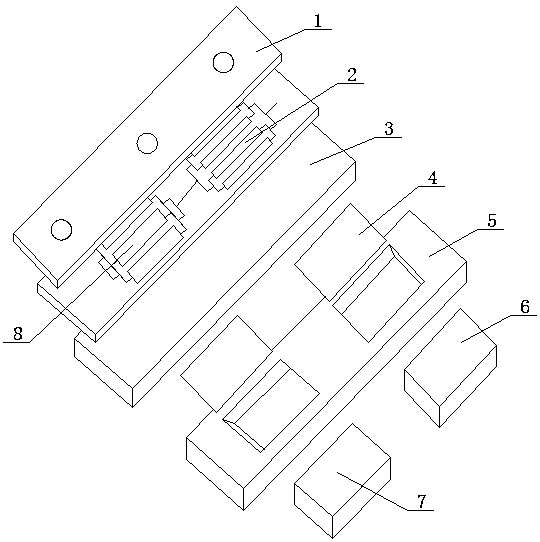

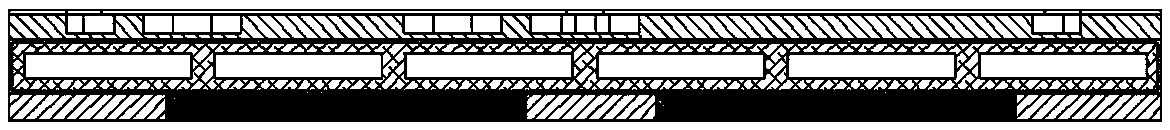

[0036] The temperature equalizing device of this embodiment adopts a vapor chamber and a microchannel to dissipate heat from a multi-heat source device, including an LTCC substrate, at least two heat sources are packaged in the LTCC substrate, and a vapor chamber is installed above the LTCC substrate, so that Microchannels with the same number as the heat source are arranged above the vapor chamber, the inlet of each microchannel communicates with an external cooling liquid source through an inlet, and the outlet of each microchannel communicates with an external liquid collection tank.

Embodiment 2

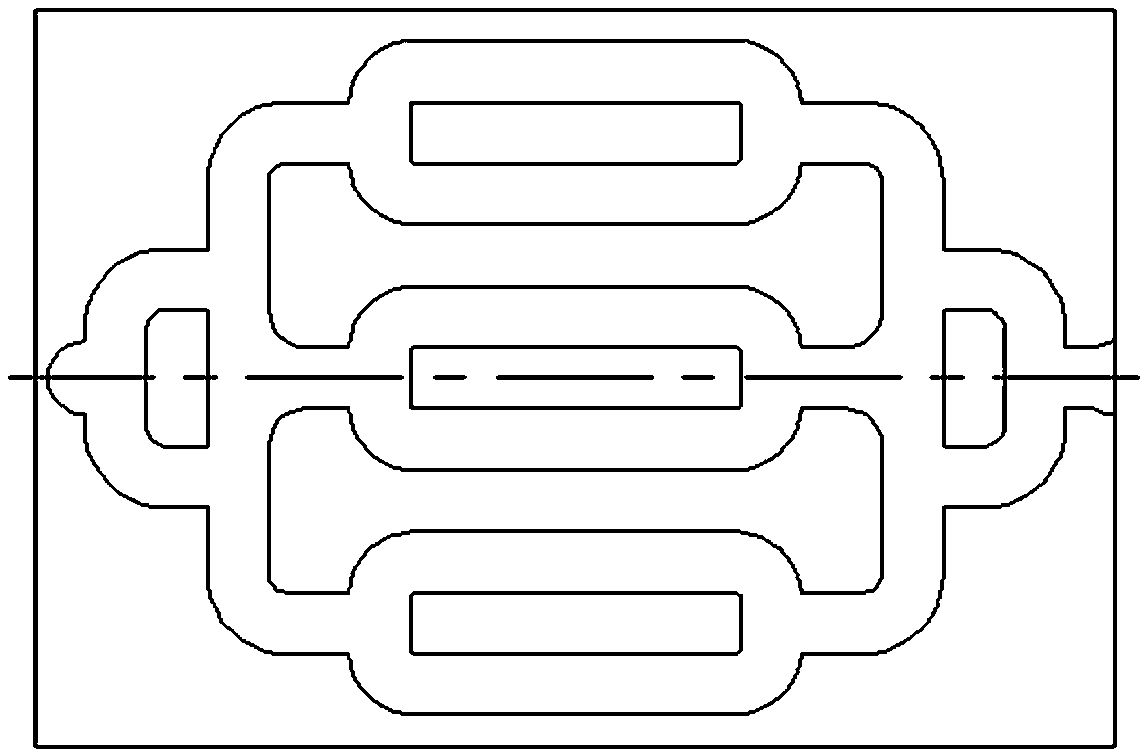

[0038] The temperature equalizing device of this embodiment adopts a vapor chamber and a microchannel to dissipate heat from a multi-heat source device, including an LTCC substrate, at least two heat sources are packaged in the LTCC substrate, and a vapor chamber is installed above the LTCC substrate, so that The top of the vapor chamber is provided with the same number of micro-channels as the number of heat sources, the inlet of each micro-channel communicates with an external cooling liquid source through an inlet, and the outlet of each micro-channel communicates with an external liquid collection tank; The channels have the same or different number of runners.

Embodiment 3

[0040] The temperature equalizing device of this embodiment adopts a vapor chamber and a microchannel to dissipate heat from a multi-heat source device, including an LTCC substrate, at least two heat sources are packaged in the LTCC substrate, and a vapor chamber is installed above the LTCC substrate, so that The top of the vapor chamber is provided with the same number of micro-channels as the number of heat sources, the inlet of each micro-channel communicates with an external cooling liquid source through an inlet, and the outlet of each micro-channel communicates with an external liquid collection tank; The channels have the same or different numbers of channels; the channels of the microchannels are arranged side by side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com