Anti-deformation control technology for two-way stainless steel plate jointing

A stainless steel, anti-deformation technology, applied in the field of welding assembly, can solve the problems of stainless steel plate costing a lot of manpower and material resources, increasing the risk of cutting damage to the mother board, increasing local deformation, etc., to achieve stress reduction, good control, and uniform heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

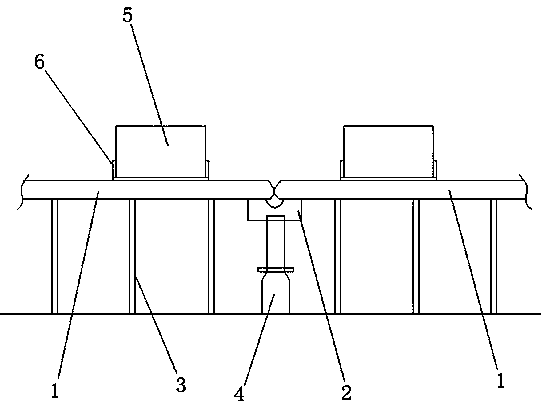

[0022] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] An anti-deformation control process for two-way stainless steel panels of the present invention is firstly based on a tool for anti-deformation tooling for two-way stainless steel panels, including several support columns 7, and two stainless steel panels 1 are placed on several support tools 3 , the lower part of the butt joint edge of two stainless steel jigsaw panels 1 is provided with a support block 2, the cross section of the support block 2 is U-shaped, and two stainless steel jigsaw panels 1 are respectively placed on a support point of the U-shaped support block 2; the support block 2. The lower part has a jack 4 for adjusting the height of the support; the stainless steel assembly 1 is provided with a briquetting block 5.

[0024] A process for anti-deformation control of two-way stainless steel panels, comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com