Cooling roller lifting fine-adjustment positioning mechanism for printing equipment

A technology of printing equipment and positioning mechanism, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., and can solve the problems of tearing printing materials, different pressures of printing materials, and axis tilting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

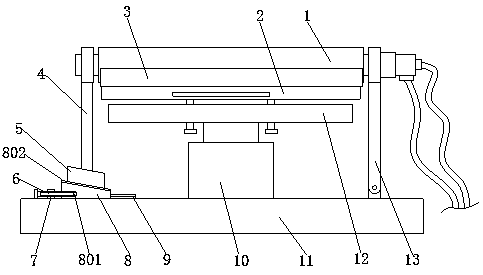

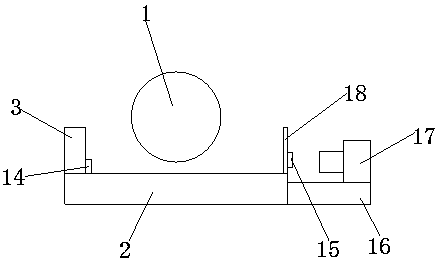

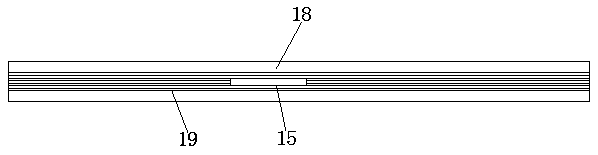

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] like Figures 1 to 3 As shown, a cooling roller lifting and fine-tuning positioning mechanism for printing equipment according to the present invention includes a cooling roller body 1, a threaded rod 6, a wedge-shaped slider 8, a guide rail 9 and a base 11; the cooling roller body 1 The two shaft heads of the cooling roller are respectively provided with a left bracket 4 and a right bracket 13; the left bracket 4 and the right bracket 13 are respectively connected to the two shaft heads of the cooling roll body 1 in rotation; the right bracket 13 is hinged with the base 11; The guide rail 9 is fixed on the surface of the base 11; the longitudinal direction of the guide rail 9 is arranged parallel to the axis of the cooling roll body 1; the wedge-shaped slider 8 is slidably connected to the guide rail 9; There is a bearing seat 7; the shaft of the threaded rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com