HRB500E Nb-Ti microalloy high-strength aseismic reinforcement bar and production process

A technology of anti-seismic steel bar and production process, which is applied in the field of metallurgy to achieve the effects of reducing crack sensitivity, reducing billet defects, and reducing the density of reinforcing bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

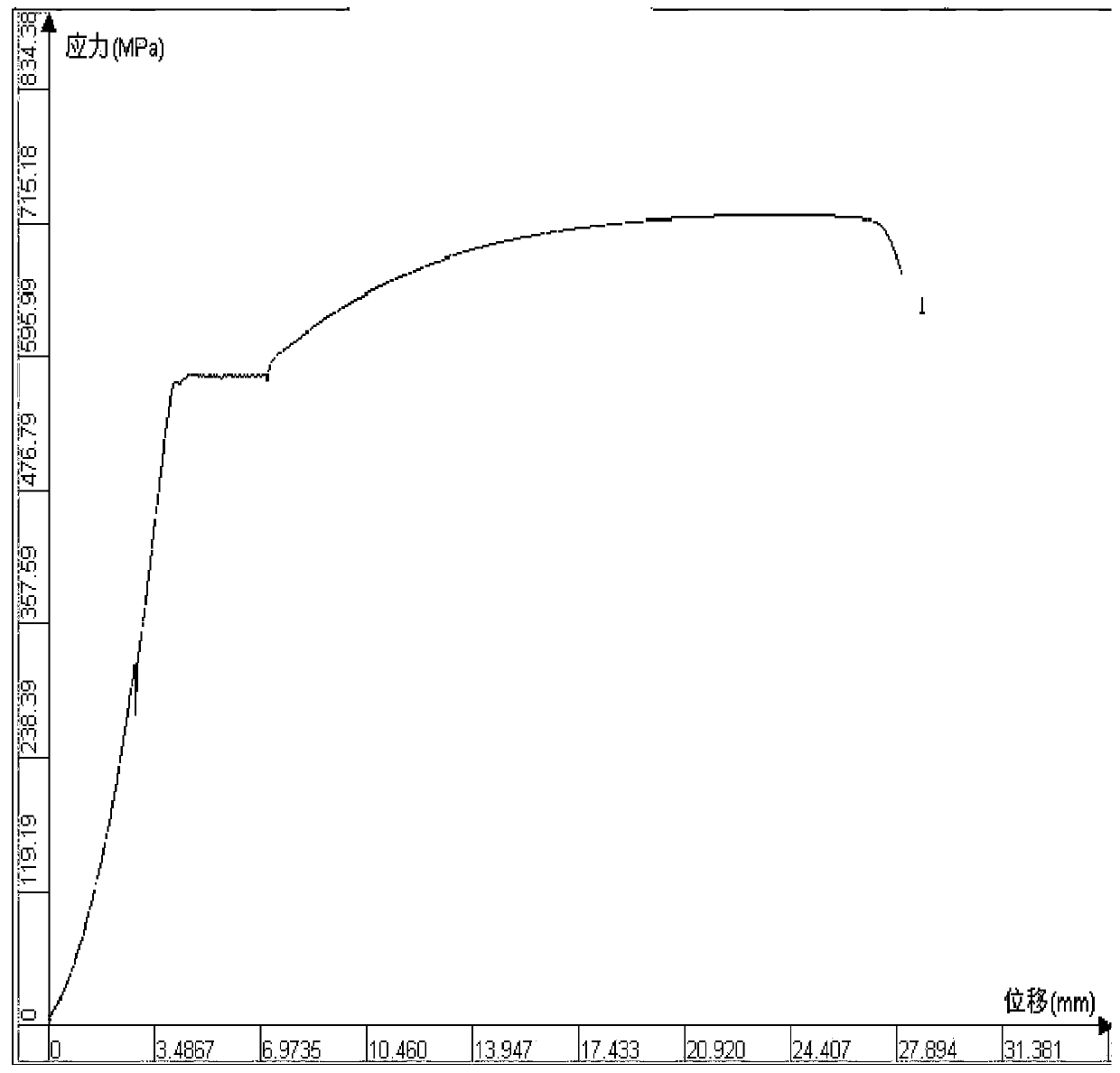

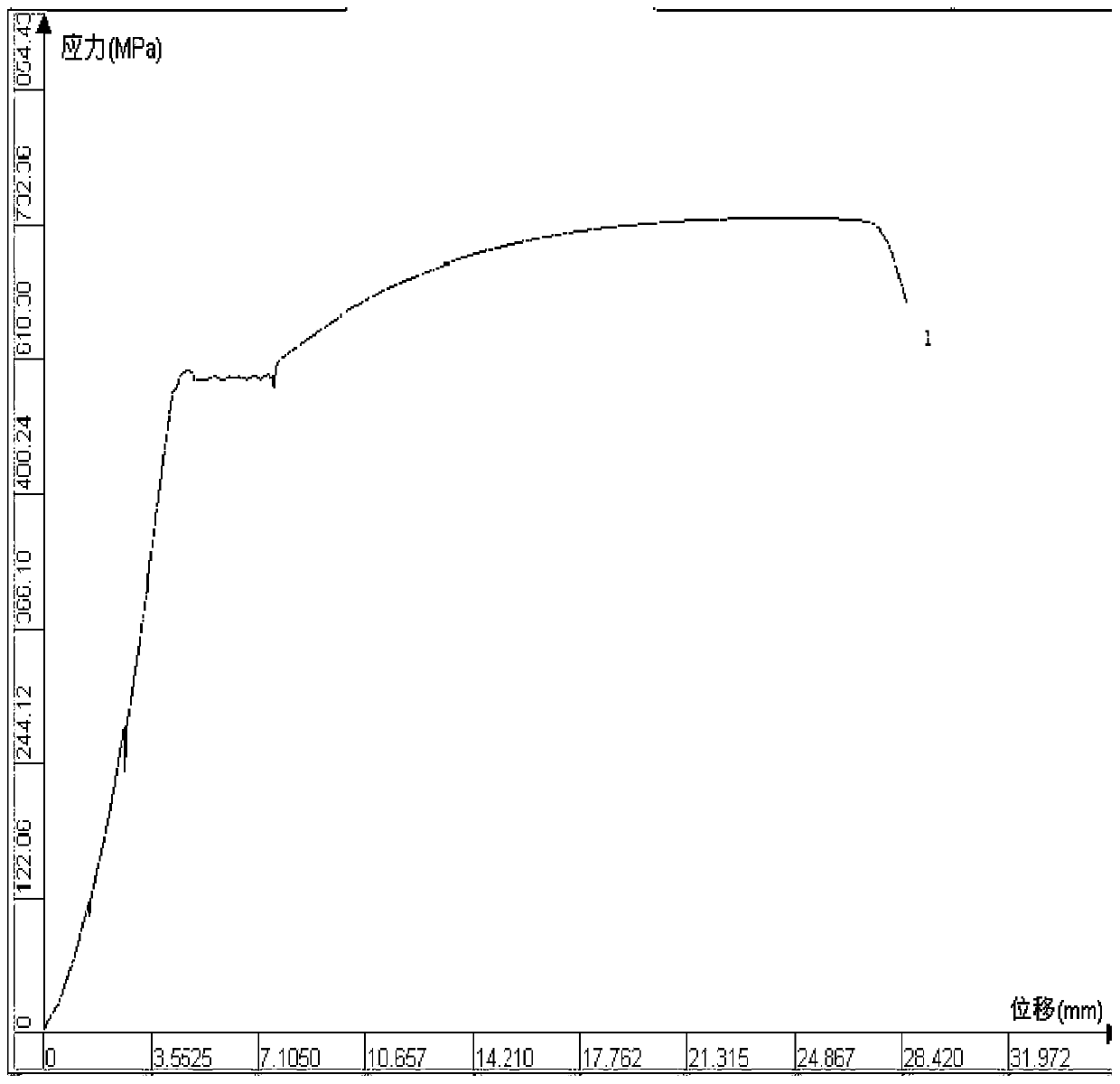

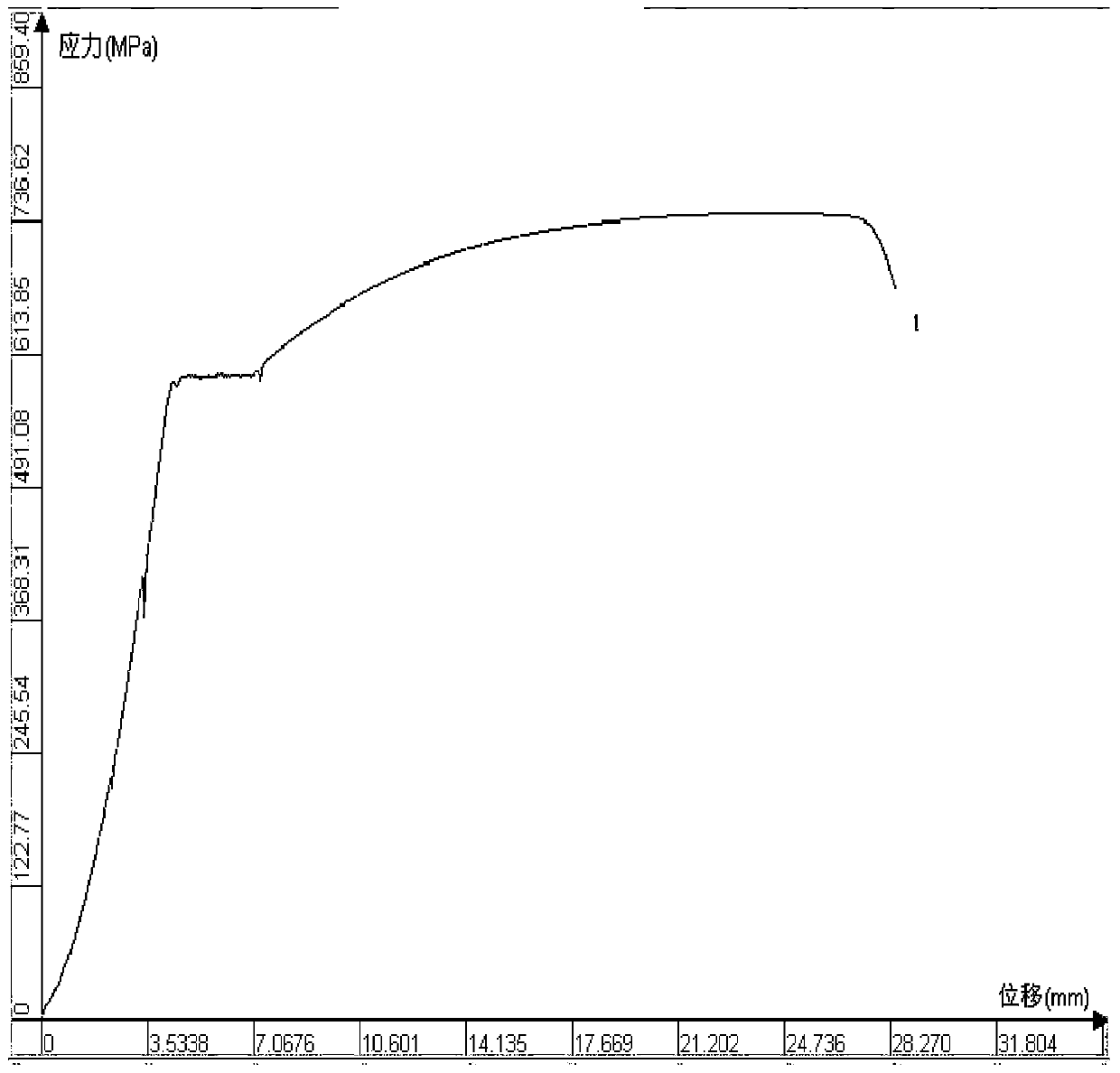

Image

Examples

Embodiment 1

[0035] The production process of the HRB500E niobium-titanium microalloy high-strength anti-seismic steel bar of the present invention comprises the following steps:

[0036] Step 1, converter smelting process:

[0037] Add molten iron and scrap steel at a ratio of 9:1, the total amount of molten iron and scrap steel is 80t; blowing 10min, heating rate is 36°C / min, control end point temperature is 1660°C, add 22kg ferrosilicon and 7.4kg silicon during tapping Manganese alloy and 0.4kg ferro-niobium are deoxidized and alloyed, 340L / min air volume is blown at the bottom for 3 minutes, then adjusted to a small air volume of 34L / min, temperature is measured and sampled, after the composition is qualified, 0.82kg of titanium iron is added, and air volume is blown at the bottom Stir for 40 seconds to make it melt quickly, then adjust to 20L / min and softly blow air for 6 minutes. After the furnace temperature is 1568°C, turn off the argon gas and send it to continuous casting;

[00...

Embodiment 2

[0045] The production process of the HRB500E niobium-titanium microalloy high-strength anti-seismic steel bar of the present invention comprises the following steps:

[0046] Step 1, converter smelting process:

[0047] Add molten iron and scrap steel at a ratio of 9:1, the total amount of molten iron and scrap steel is 80t, blow for 12min, the heating rate is 31°C / min, the control end temperature is 1670°C, add 23kg of ferrosilicon and 7.6kg of silicon during tapping Manganese alloy and 0.5kg ferro-niobium are deoxidized and alloyed, 360L / min air volume is blown at the bottom for 4 minutes, then the air volume is adjusted to 37L / min, temperature is measured and sampled, after the composition is qualified, 0.85kg of titanium iron is added, and air volume is blown at the bottom for 45s , Stir to make it melt quickly, then adjust to a small gas volume of 18L / min and blow softly for 7 minutes. After the furnace temperature is 1575°C, turn off the argon gas and send it to continuo...

Embodiment 3

[0054] The HRB500E niobium-titanium microalloy high-strength anti-seismic steel bar production process of the present invention comprises the following steps:

[0055] Step 1, converter smelting process:

[0056] Add molten iron and scrap steel at a ratio of 9:1, the total amount of molten iron and scrap steel is 80t, blow for 10min, the heating rate is 37°C / min, the control end temperature is 1668°C, add 24kg of ferrosilicon and 7.8kg of silicon during tapping Manganese alloy and 0.6kg ferro-niobium are deoxidized and alloyed, 370L / min air volume is blown at the bottom for 5 minutes, then the air volume is adjusted to 35L / min, temperature is measured and sampled, after the composition is qualified, 0.9kg of titanium iron is added, and air volume is blown at the bottom for 50s , stir to make it melt quickly, then adjust to a small gas volume of 20L / min and softly blow air for 7 minutes, after the furnace temperature is 1570°C, turn off the argon gas and send it to continuous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com