Electric motor

A technology of motors and rotors, applied in the field of motors, can solve problems such as huge investment, and achieve the effect of uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

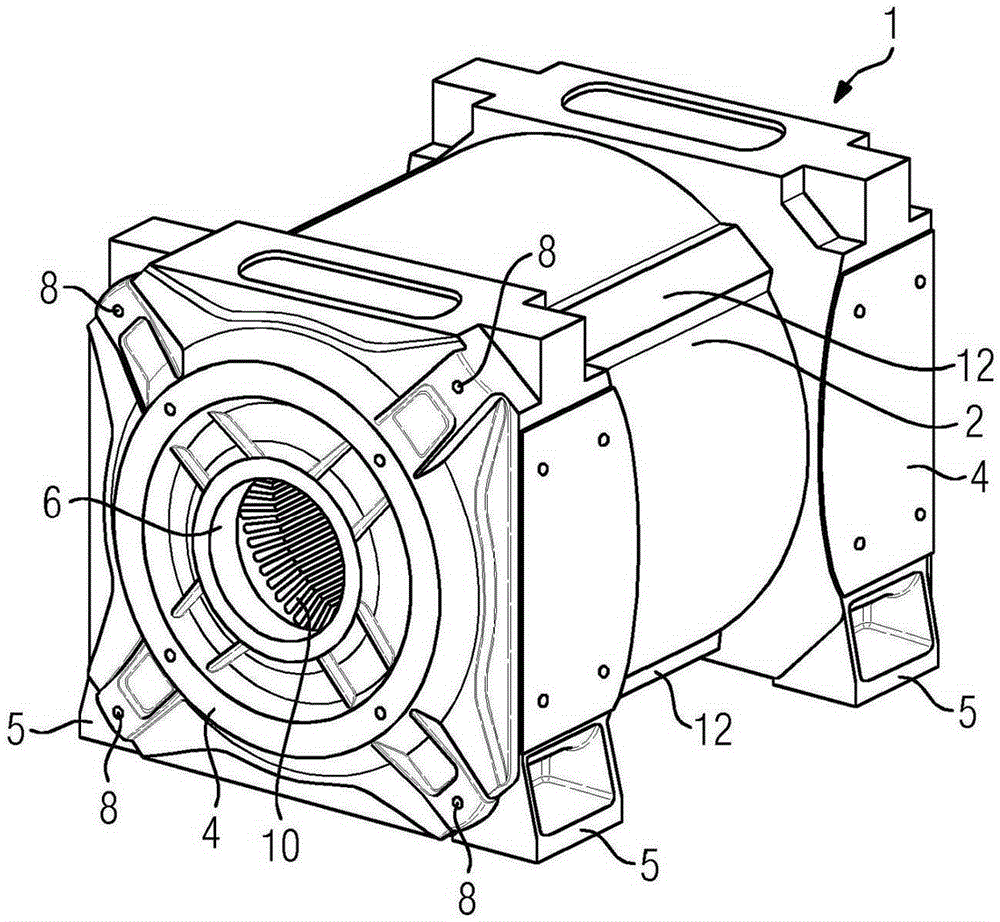

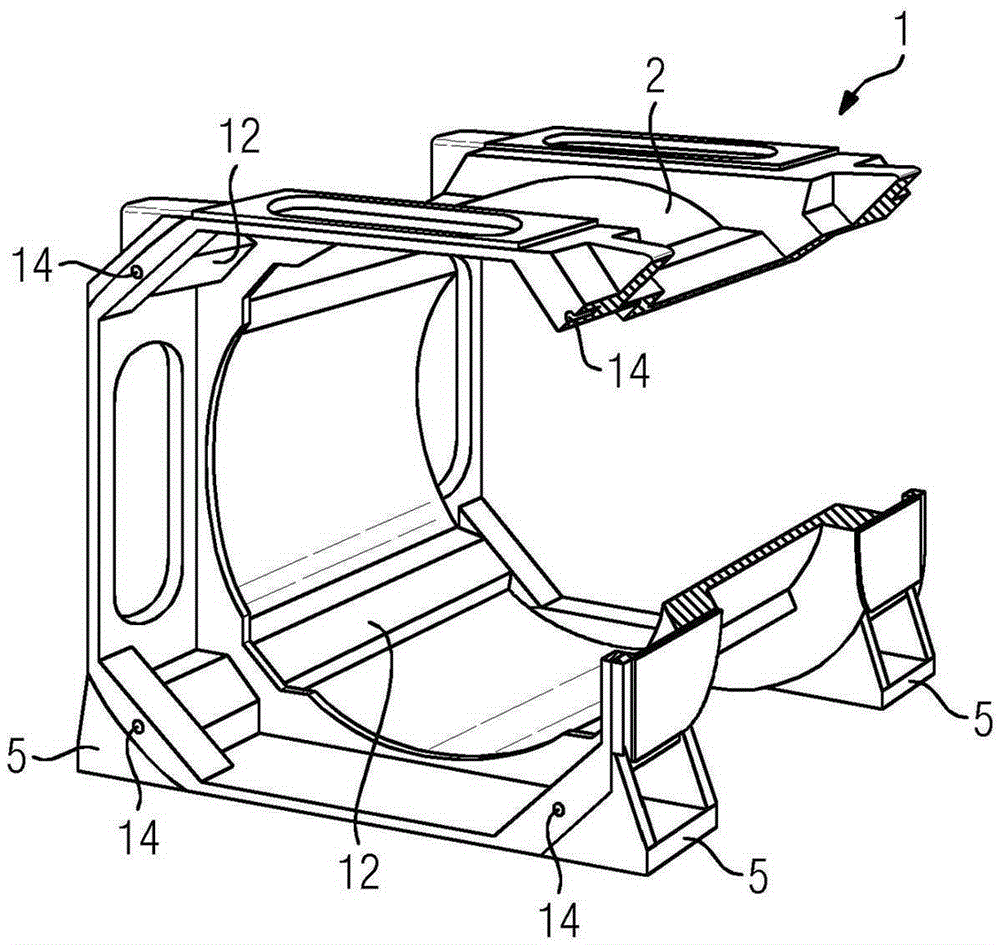

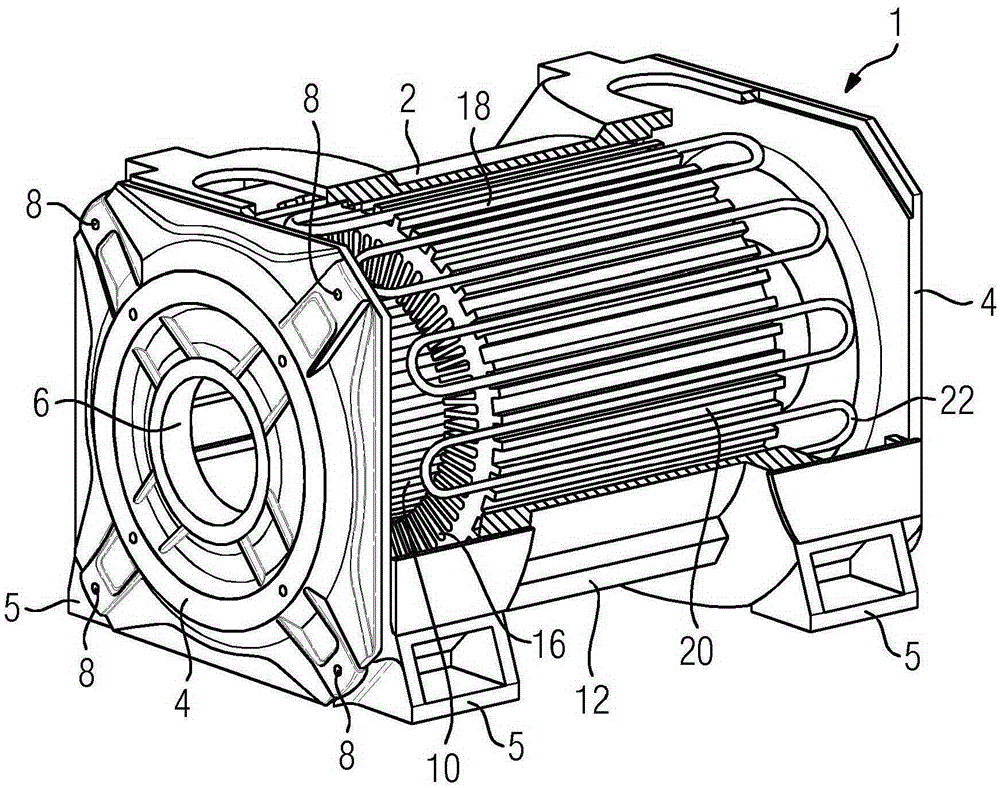

[0029] figure 1 The housing 1 for the electric motor is shown in plan view. The housing 1 is produced as a cast part, but can alternatively also be produced from steel. It comprises a single-walled housing 2 which is designed essentially in the shape of a cylindrical circumference. At the axial ends of the cylinder are arranged bearing caps 4 which form the top and bottom faces of the cylinder. In the axial edge region, the housing 2 merges into a square in order to secure the end shield 4 . In this case, the side lengths of the square axial end regions in cross section exceed the circumference of the cylinder of the housing.

[0030] In this case, the side surfaces of the axial end regions form the mounting edge, on which the housing stands. For this purpose, four feet 5 are additionally provided on the bottom in the region of the two-sided edges. The endshield 4 includes a central, circular opening 6 for supporting the not shown rotor of the electric motor. In the regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com