Nozzle system for processing netted material

A technology of mesh material and nozzle, applied in heat treatment furnace, thin material treatment, heat treatment equipment, etc., can solve the problems of uneven heat treatment results and reduction of carrying capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

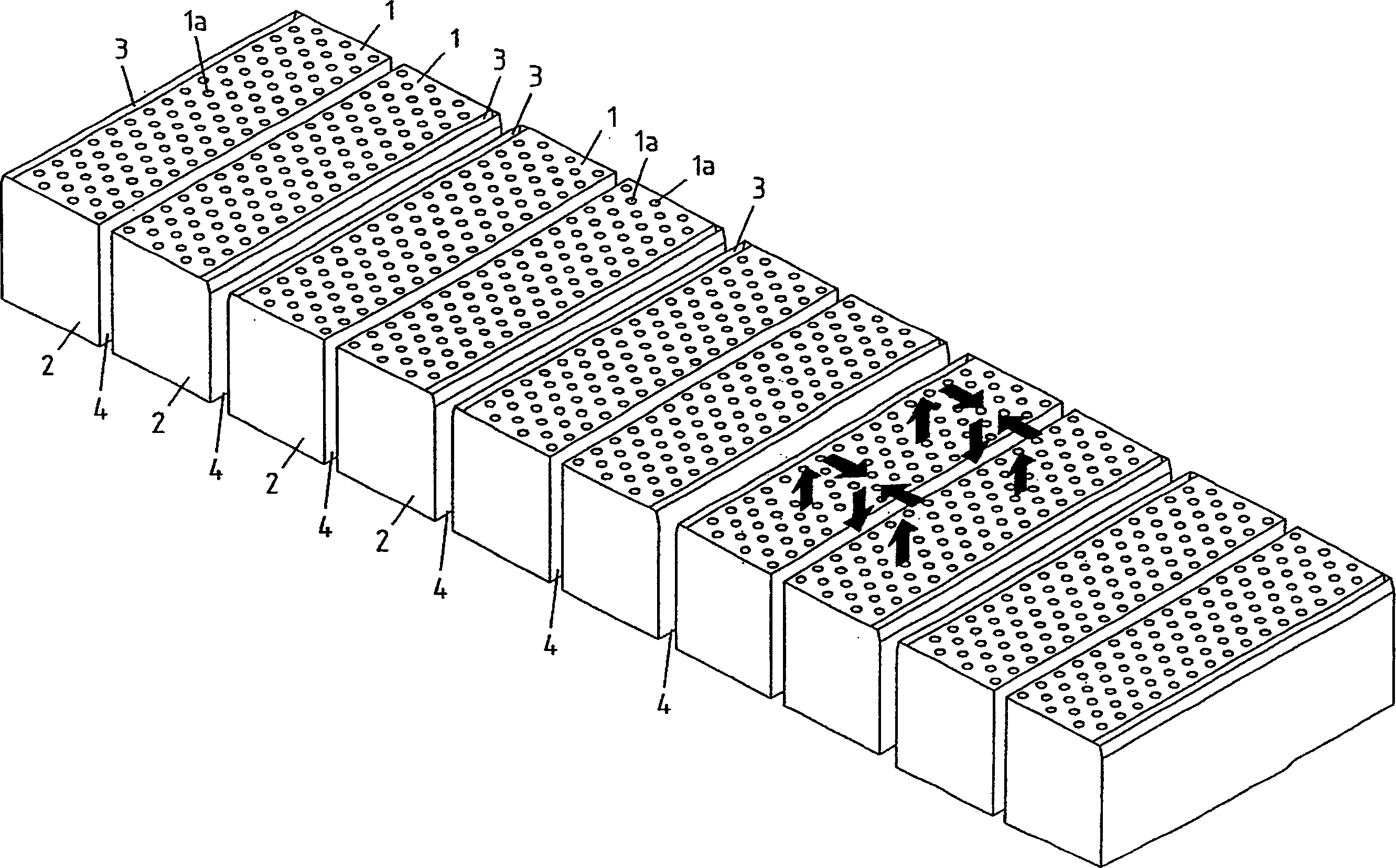

[0017] according to figure 1 The nozzle system comprises a total of ten consecutive nozzle surfaces 1 along the conveying direction (not shown) of the metal strip. A nozzle system (not shown) of the same type may be arranged above the metal strip. These nozzle surfaces 1 are each arranged on the upper side of nozzle boxes 2 , which are connected on the bottom side to a fan, not shown. The nozzle surfaces 1 also each have a plurality of, in this embodiment circular, nozzle openings 1 a through which the process gas flowing from the fan into the nozzle box 2 flows onto the metal strip. Channels 4 are formed between the nozzle boxes 2 through which the process gas flowing onto the surface of the metal strip flows out again. According to the invention, the nozzle surface 1 is divided into groups, in this embodiment into pairs, by slit-like nozzles 3 extending perpendicularly to the conveying direction of the material which is also arranged on the upper side of the nozzle box 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com