Efficient tea drying equipment for tea processing

A technology for baking tea and equipment, which is applied in tea processing before extraction, conveyor objects, transportation and packaging, etc. It can solve the problems of inability to achieve one-time drying and drying treatment, inability to continuously and efficiently make tea, and high energy consumption. Achieve the effect of reducing the time of manual preparation, improving the efficiency of tea making and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

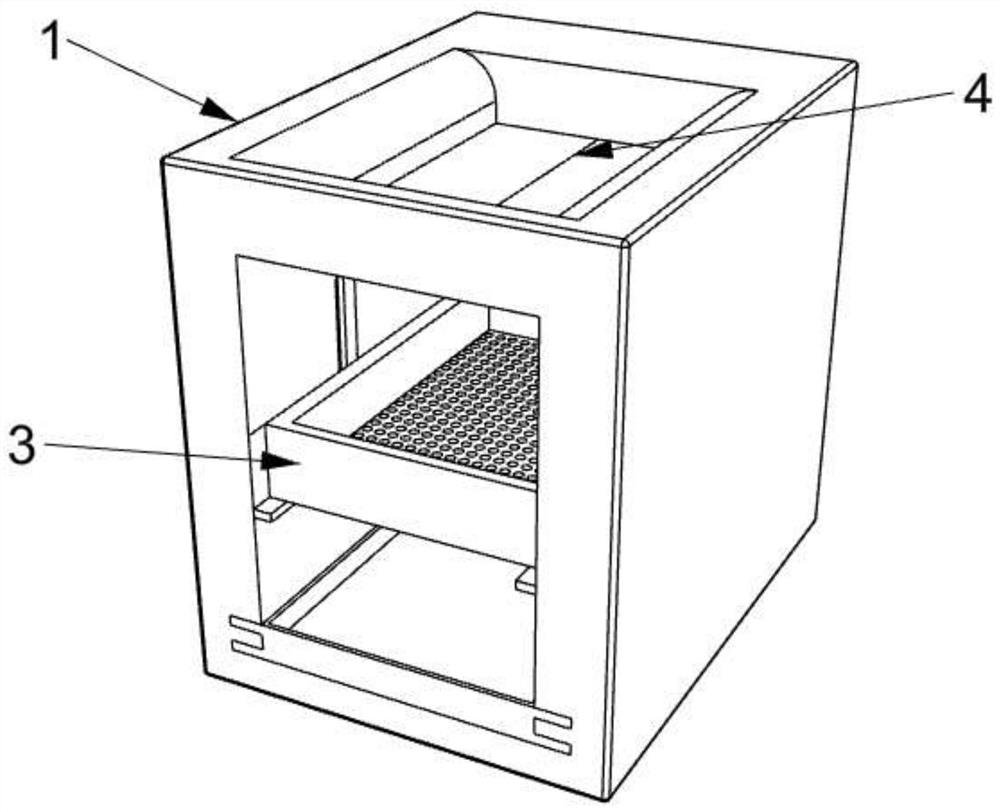

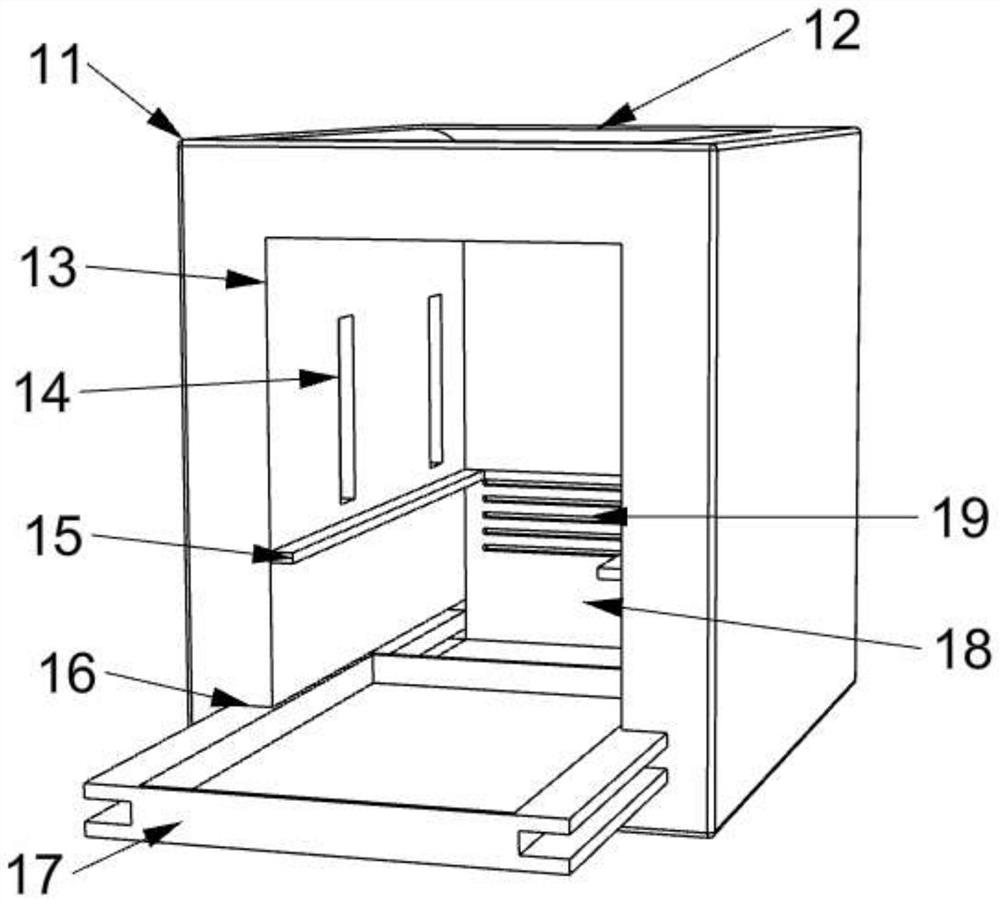

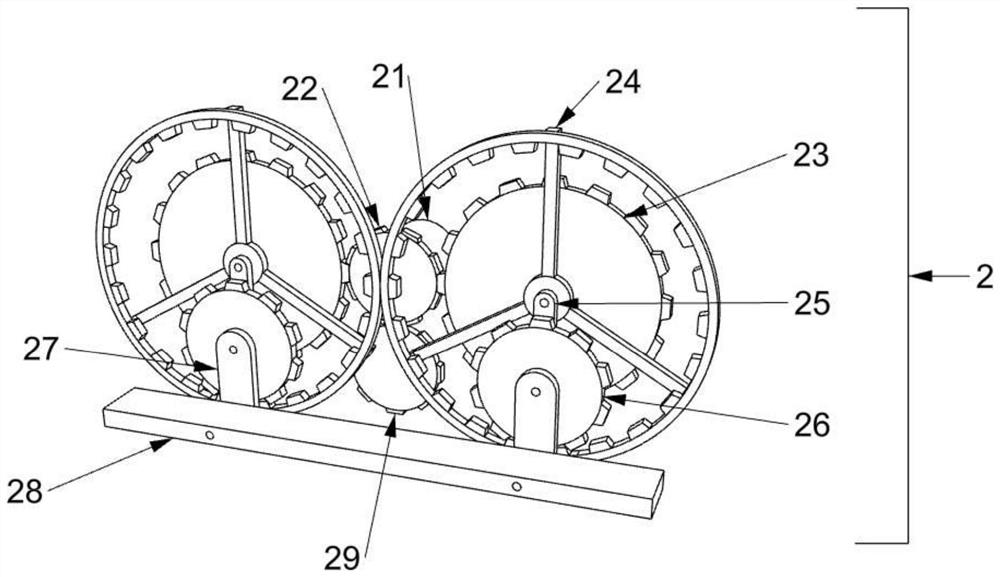

[0033] see Figure 1-5 , in an embodiment of the present invention, a high-efficiency tea-baking equipment for tea processing includes a tea-baking equipment part 1, and the tea-baking equipment part 1 includes a device body 11, a tea tank 12, a tea-baking chamber 13, a movable tank 14, a sliding Plate 15, engaging groove 16, charcoal fire insert 17, baffle plate 18 and air outlet 19;

[0034] The middle part of the upper end of the device body 11 is provided with a tea trough 12, the middle part of the device body 11 is provided with a tea-baking chamber 13, and several groups of movable grooves 14 are arranged symmetrically on the left and right sides of the tea-baking chamber 13, and the middle parts of the left and right walls of the tea-baking chamber 13 are fixed, installed and slidable Plate 15, engaging grooves 16 are symmetrically set on the left and right side walls of the lower part of the tea baking chamber 13, and a charcoal fire insert 17 is arranged between the ...

Embodiment 2

[0046] see Image 6 The difference from Example 1 is that a tea trough 319 is set on the upper side of the front end of the tea making piece 315, and the inner side of the tea trough 319 is slope-shaped, and a collecting plate 320 is arranged inside the tea making piece 315. The cross section of the collecting plate 320 is trapezoidal, and the front end of the collecting plate 320 is fixed with a connecting rod handle 321;

[0047] When in use, when the tea leaves are dried and baked, the collecting plate 320 is used to slide in the tea making piece 315, and the inclined surface at the lower end of the collecting plate 320 and the lower end of the tea outlet groove 319 are forced to limit, so that the dried tea leaves can be collected quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com