Numerical control tea leaf pinching and forming machine

A molding machine and tea technology, applied in the direction of tea processing before extraction, can solve the problems of reducing production efficiency and tea quality, high technical requirements, time-consuming and laborious, etc., achieving consistent tea quality, reducing human resources, and improving production technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

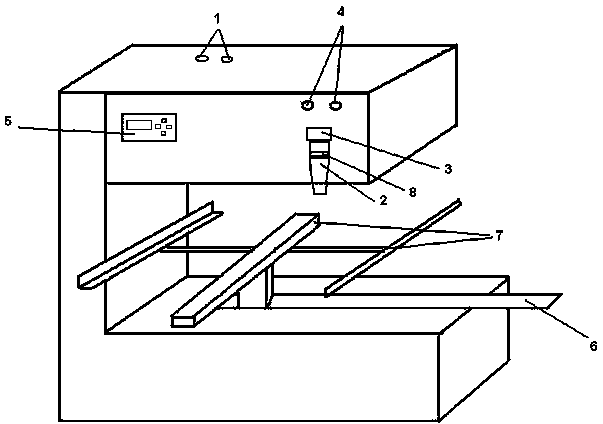

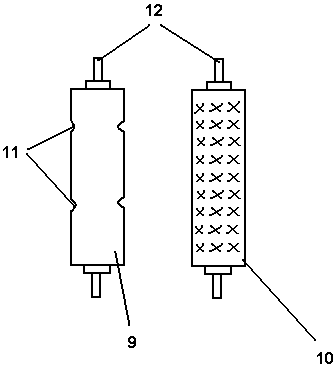

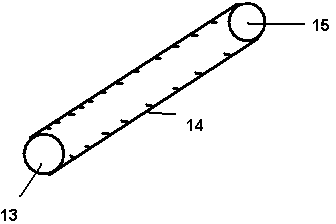

[0015] refer to figure 1 , 2 3. The present invention is a numerically controlled tea tipping machine, which mainly includes a tea feeding device, an internal tea pressing and transportation device, and an external material receiving and adjusting device, wherein the tea feeding device is composed of two external interfaces, and the internal The tea pressing and transportation device includes a pressing roller, an internal interface and a transportation device. The external material receiving and adjusting device includes a photoelectric induction system 3, a PLC controller 5 and an adjustable material receiving rack. The feeding device is installed on the top of the machine, and the internal The tea pressing and transporting device is placed inside the machine, the regulating device is installed on the surface of the machine, and the receiving rack is horizontally installed directly below the machine. Among them, the internal tea pressing equipment is mainly composed of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com