Extractor hood with function of reducing vibration and noise

A technology of range hood and range hood is applied in the field of machinery, which can solve the problems of noise, inability to absorb shock, and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

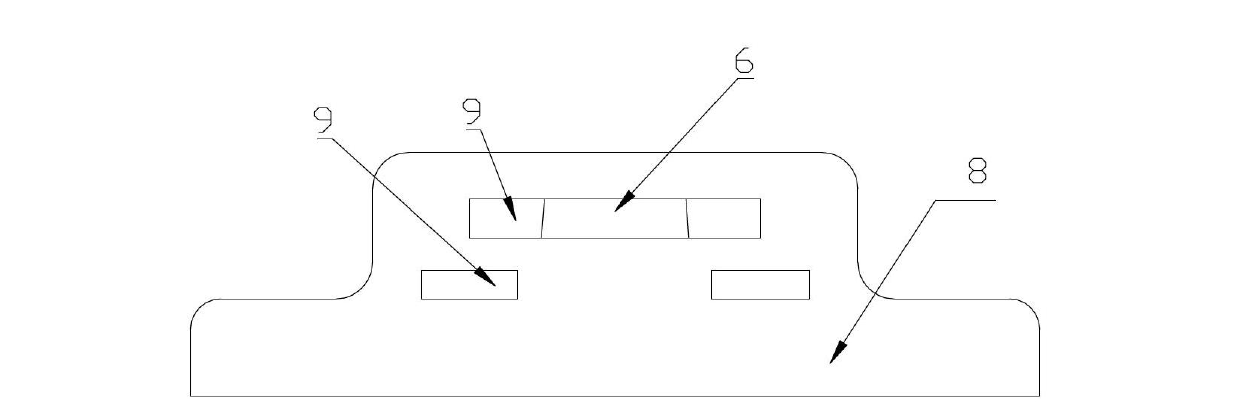

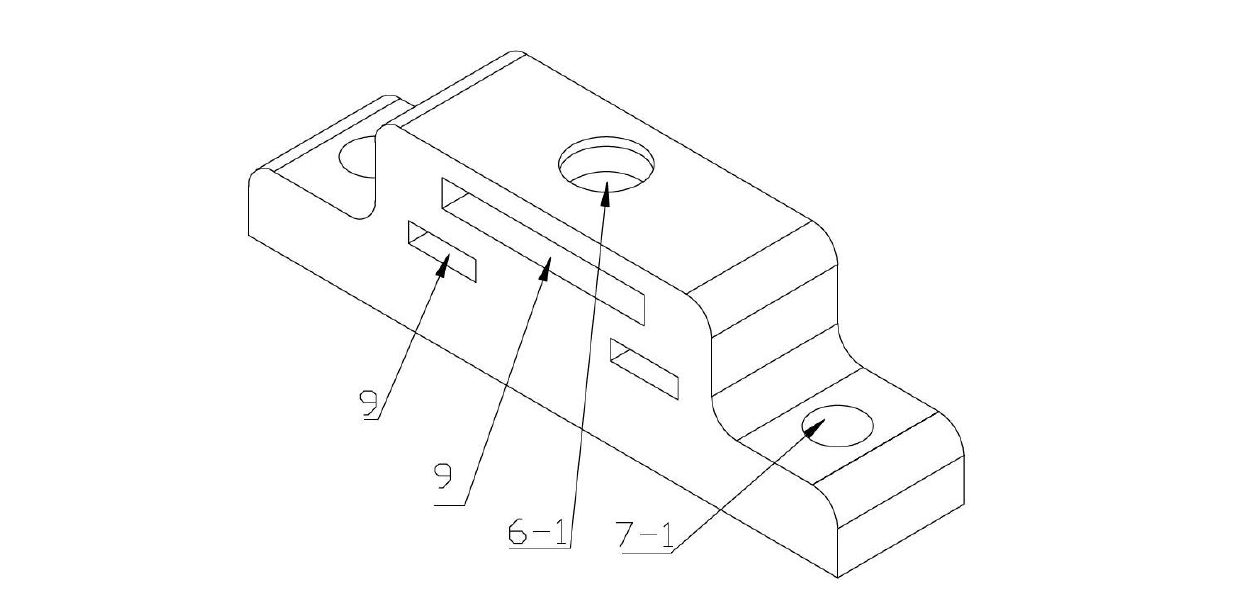

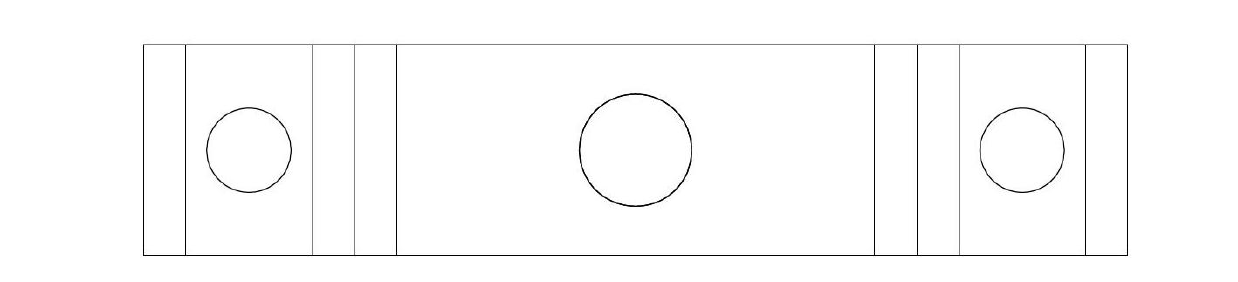

[0026] The present invention will be further described now in conjunction with accompanying drawing.

[0027] see Figure 1 to Figure 12 In the present invention, where the volute 4 of the turbine assembly and the range hood casing 3 are connected by screws, the combined connection of the noise reduction and shock absorbing device 1 and the screws is used instead. That is, the connecting surface between the volute 4 of the turbine assembly and the range hood casing 3 is connected by a noise reduction and shock absorption device 1; the noise reduction and shock absorption device 1 adopts a stepped convex rubber body with upper and lower platforms , and in the middle of the stepped convex structure rubber body, a cylindrical groove is longitudinally provided downward from the upper table, the bottom of the cylindrical groove is located in the lower table, and a metal threaded connector 6 is embedded in the cylindrical groove. The threaded connector 6 is a cylinder with an annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com