Hydraulic Vehicle Active Suspension System

An active suspension and hydraulic technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of inaccurate compound valve flow control, reduce the reliability of the suspension system, and the high price of the hydraulic system. Fuel economy, improved ride comfort and handling stability, and low price effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

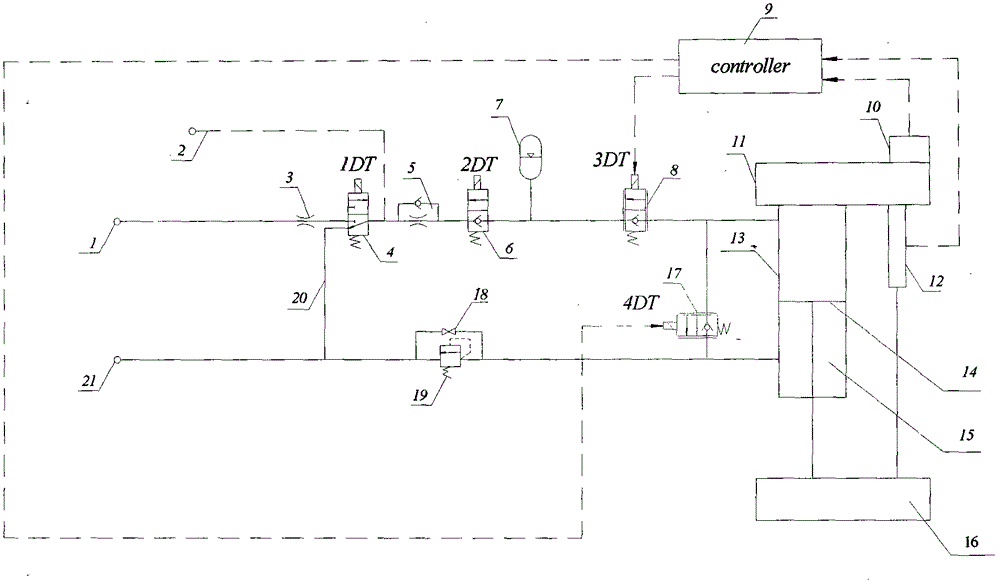

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] A hydraulic vehicle active suspension system, the suspension system consists of a hydraulic pump 1, a throttle valve 3, a two-position three-way electromagnetic reversing valve 4, a one-way throttle valve 5, a two-position two-way electromagnetic ball valve 6, Two-position two-way proportional directional valve A 8, damping hydraulic cylinder 14, overflow valve 19 and oil tank 21 are sequentially connected in series to form a closed-loop hydraulic system, and the oil outlet of hydraulic pump 1 is connected to two-position three-way One end of the electromagnetic reversing valve 4 is connected, and the other end of the two-position three-way electromagnetic reversing valve 4 is respectively connected with the oil inlet of the one-way throttle valve 5 and one end of the oil return pipeline 20, and the other end of the oil return pipeline 20 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com