Experiment method for simulating impact type rock burst

An experimental method, rockburst technology, applied in the field of rock mass mechanics and geotechnical engineering research in deep mine engineering, can solve problems such as short research time, no experimental method, and shallow understanding of rockburst occurrence rules, so as to ensure smooth progress , The effect of maintaining construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

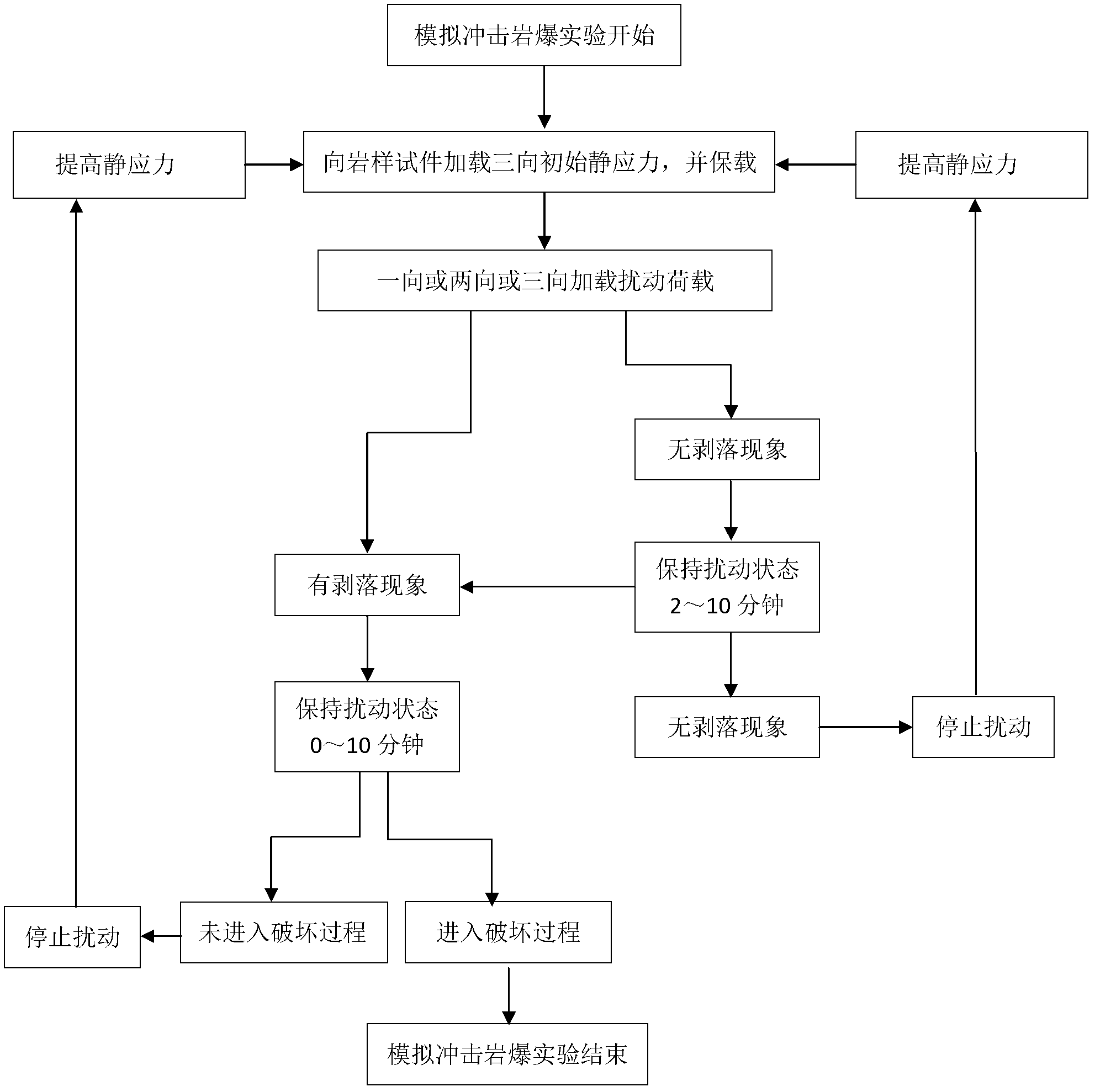

[0039] Such as figure 1 As shown, the first embodiment of the experimental method of the simulated impact type rockburst of the present invention comprises the following steps:

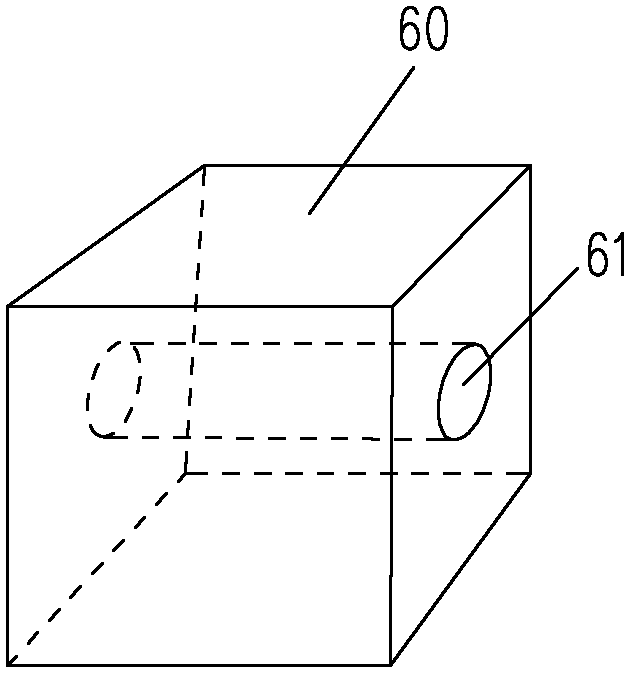

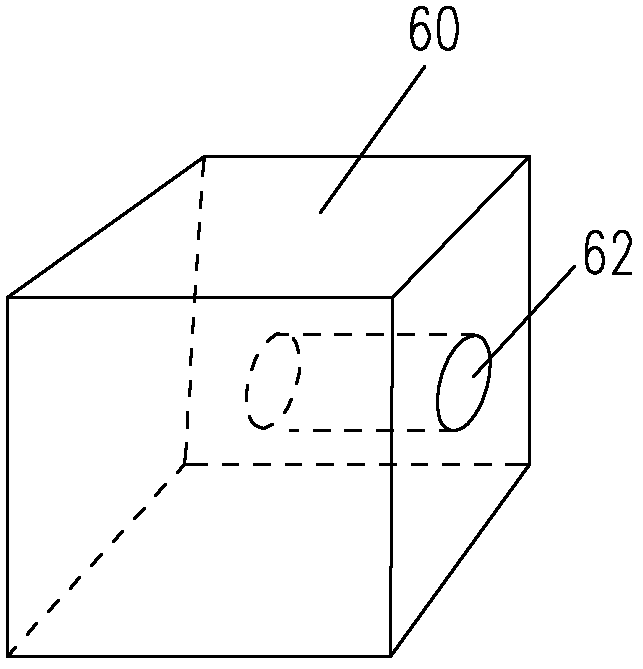

[0040] S1, making the rock sample test piece 60, the rock sample test piece 60 center has a circular through hole 61 in section (see Figure 2A) or a circular half hole 62 (see Figure 2B ) or a horseshoe-shaped through hole 63 (see Figure 2C ) or a horseshoe-shaped half hole 64 (see Figure 2D ). The holes in the rock sample 60 are mainly through holes and half holes, but the cross-sectional shapes of the holes can be various, not limited to circular or horseshoe. The rock sample can be made in the laboratory, or it can be taken from the rock mass at the proposed excavation site. Using the rock mass at the proposed excavation site can not only study the mechanism of rockburst, but also be used for the actual site. Excavation and blasting play a guiding role.

[0041] S2. Load the three-dimensi...

experiment example 1

[0052] see image 3 , Figure 4A to Figure 4F . Using the experimental method of simulating impact rockburst in the first embodiment above, the rock sample specimen is a sandstone rock mass collected at the proposed excavation site, which is a cube of 110×110×110mm, which has a circular shape with a diameter of 50mm. through the hole. The uniaxial strength of the rock sample specimen is 68MPa. In step S2, the three-way initial static load stress loaded on the rock sample specimen is respectively: X-direction static stress FX: 30kN, Y-direction static stress FY: 290kN, Z Static stress FZ: 50kN, when the force loading method is adopted, the loading rate is 0.5kN / s, the type of disturbance load in step S3 is square wave (amplitude 0.1mm, frequency 0.05HZ), only in the Y direction disturbance, disturbance After the load is applied for 3 minutes, there is no peeling phenomenon in the hole through which the rock sample penetrates, and the disturbance is stopped; the static stress...

Embodiment 2

[0058] Such as Figure 6 As shown, the steps of the second embodiment of the experimental method of simulating impact rockburst of the present invention are basically the same as the steps of the first embodiment, the only difference is that in steps S4 and S5 of the first embodiment, when the rock sample When no rock burst occurs in the specimen, after increasing the three-way static stress value loaded on the rock specimen specimen, repeat the remaining experimental steps (i.e. repeat steps S2 and the following experimental steps); and in the steps of the second embodiment In S4 and S5, when the rock burst does not occur in the rock sample, after increasing the disturbance load loaded on the rock sample, repeat the remaining experimental steps (that is, repeat the experimental steps of step S3 and below), and finally succeed cause rockbursts. Other parts of the second embodiment that are the same as those of the first embodiment will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com