High-accuracy frequency measurement system

A high-precision, frequency measurement technology, applied in the field of instrument systems, can solve problems such as the impact of test accuracy, achieve the effect of reducing impact and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

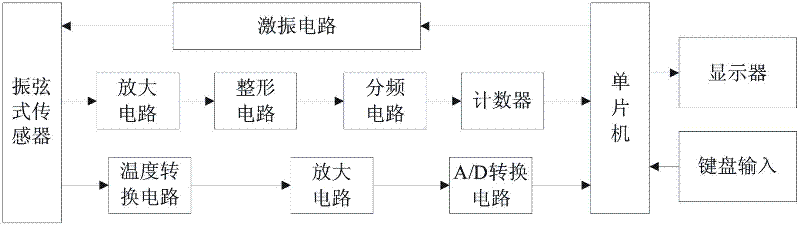

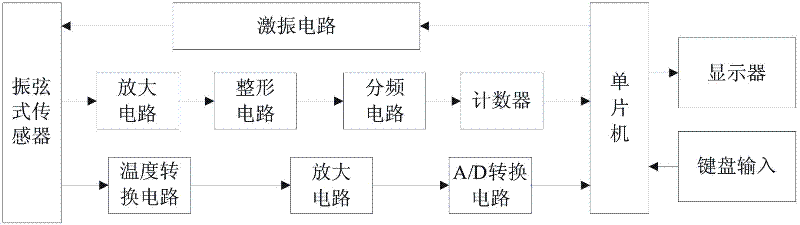

[0010] Such as figure 1 Shown is a high-precision frequency measurement system, including an excitation circuit, a vibrating wire sensor, a sensor vibration measurement circuit and a temperature compensation circuit. The sensor vibration measurement circuit is composed of an amplifier circuit, a shaping circuit, a frequency division circuit and a counter connection , the temperature compensation circuit is composed of a temperature conversion circuit, an amplification circuit and an A / D conversion circuit.

[0011] The system controls the excitation circuit to excite the string through the single-chip microcomputer, so that the vibrating wire sensor outputs a frequency signal, and the I / O port of the single-chip microcomputer sends out a pulse, and uses a high-frequency transformer and a voltage doubler circuit to boost the voltage to generate a high-voltage pulse to excite the vibrating wire. vibration.

[0012] The vibrating wire sensor is a frequency sensor, and its coil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com