Passive polarizing type three-dimensional (3D) display device

A three-dimensional display and polarizing technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as low aperture ratio and poor moiré pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

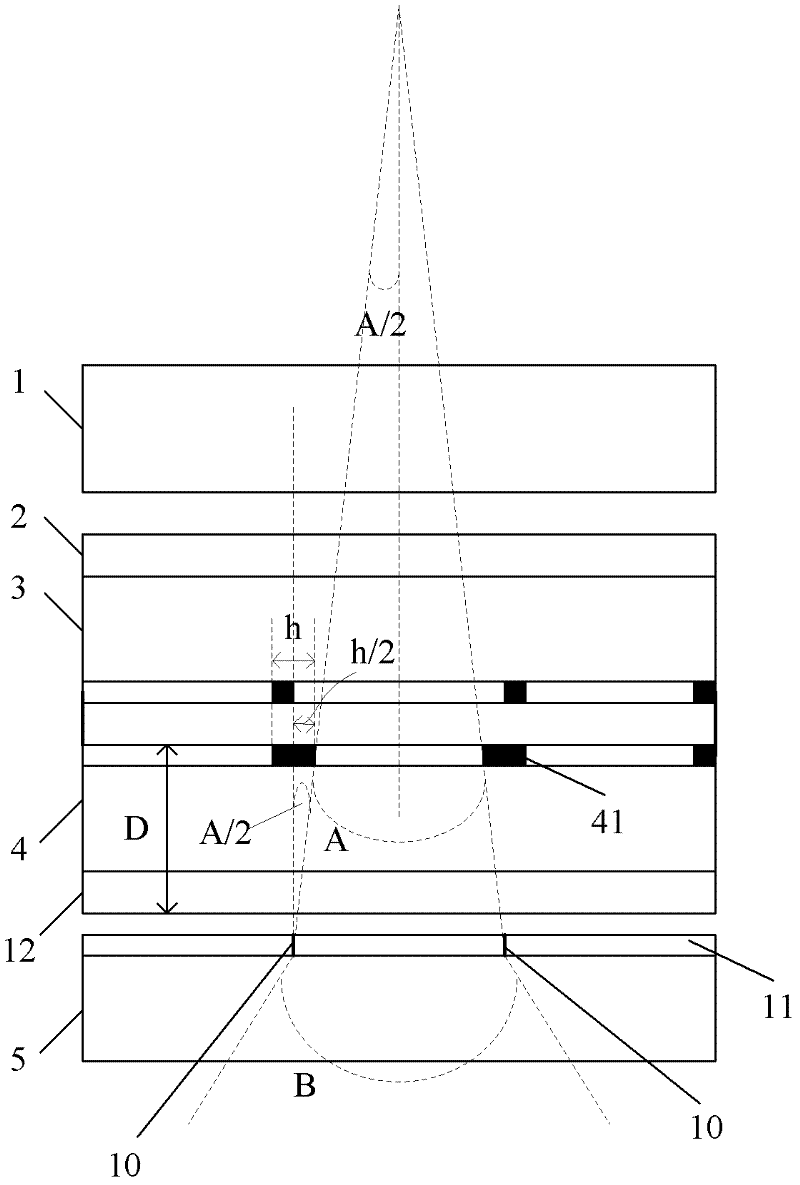

[0044] Such as Image 6 As shown, the passive polarized 3D display device using a patterned retardation film according to Embodiment 1 of the present invention includes: a backlight unit 1, a first polarizer 2, a TFT array substrate 3, a color filter substrate 4, and a second polarizer arranged in sequence. sheet 12 and pattern retardation film 5. A passive polarizing 3D display device using a patterned retardation film according to Embodiment 1 of the present invention and figure 1 The difference of the passive polarizing 3D display device using the pattern retardation film in the prior art shown is that not only matrix strips are arranged on the film surface of the color filter substrate 4, but also light-shielding strips are arranged on the back of the color filter substrate 4 8, and the light-shielding strips 8 on the back of the color filter substrate 4 have the same width and equal spacing as the matrix strips on the film surface of the color filter substrate 4, so as t...

Embodiment 2

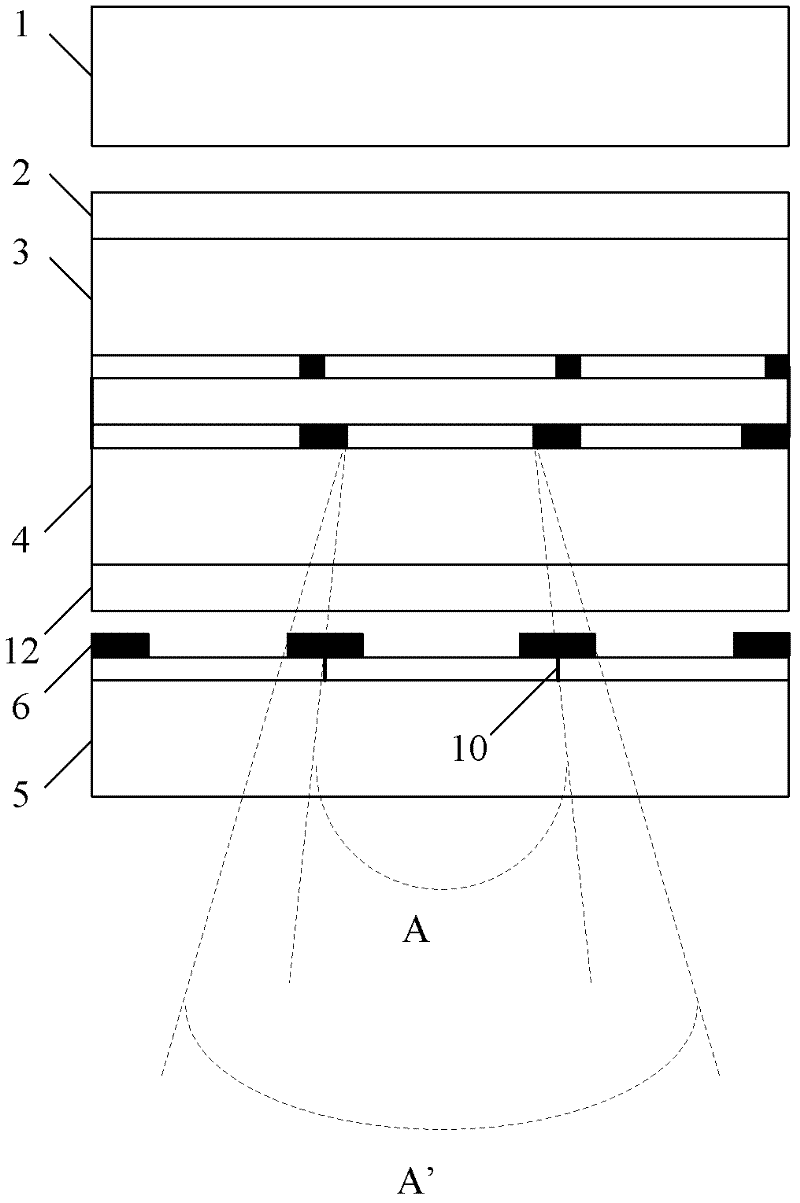

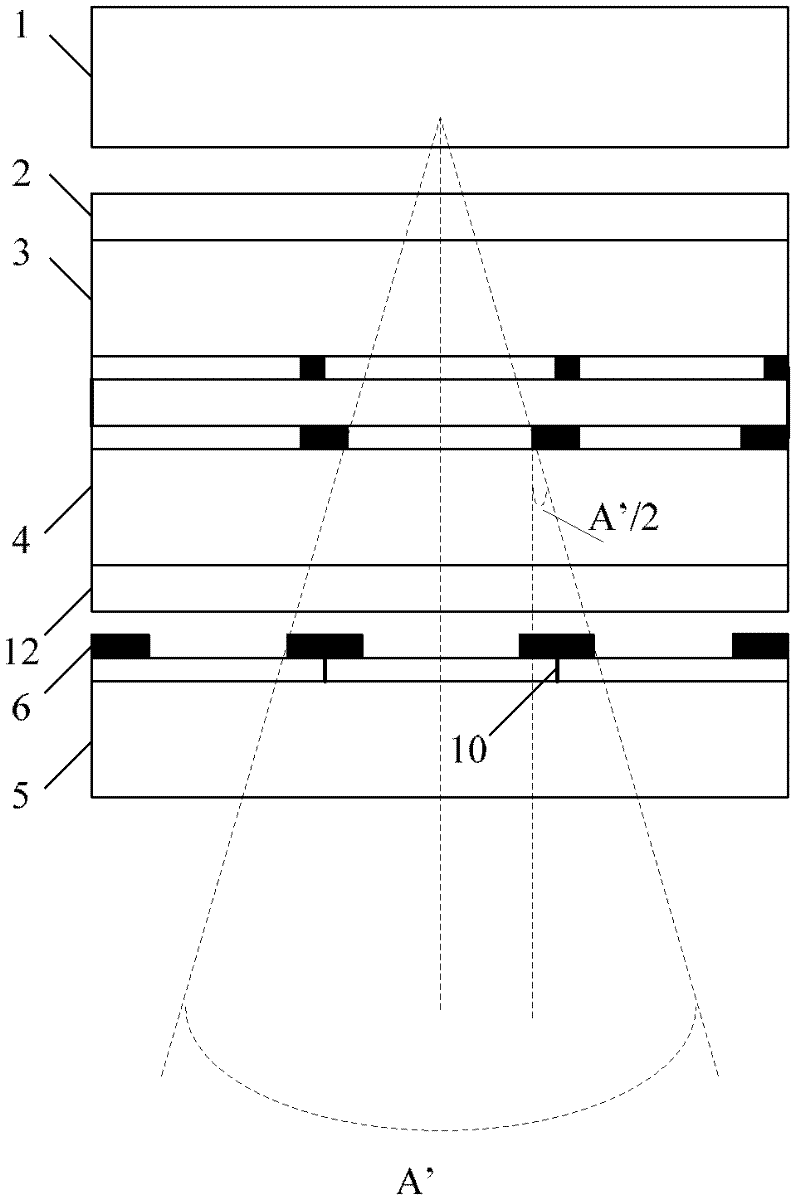

[0054] Such as Figure 7 As shown, the passive polarized 3D display device using the pattern retardation film according to Embodiment 2 of the present invention includes: a backlight unit 1, a first polarizer 2, a TFT array substrate 3, a color filter substrate 4, and a second polarizer arranged in sequence. sheet 12 and pattern retardation film 5. The passive polarized 3D display and figure 1 The difference of the passive polarizing 3D display device using the pattern retardation film in the prior art shown is that: a light-shielding strip 8 is provided on the back of the color filter substrate 4, and the corresponding position of the film surface of the color filter substrate 4 may not be provided with a matrix. strip. Wherein, the dividing line between two adjacent pattern phase difference films is opposite to the middle position of the light-shielding strip 8 on the back side of the color filter substrate 4 corresponding to the dividing line; the preferred mode of relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com