Machining method for stainless steel seal rings in large valves

A processing method and stainless steel technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of large diameter, deformation, strict technical requirements, etc., and achieve the effect of low deformation probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

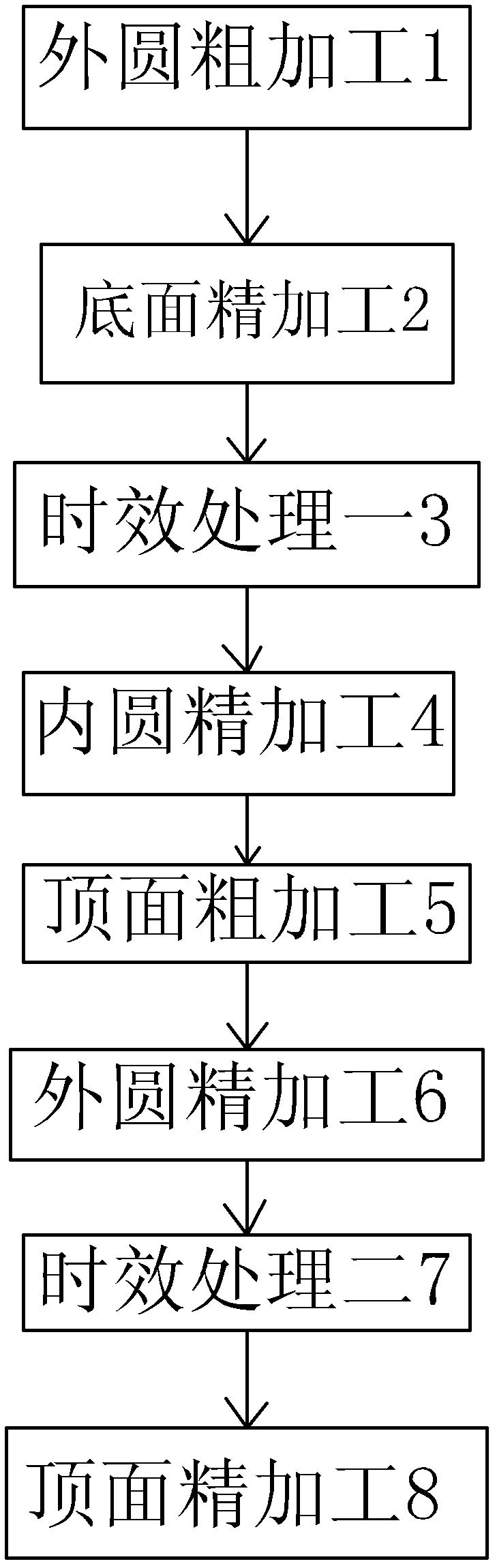

[0030] Such as figure 1 As shown, this processing method is suitable for stainless steel sealing rings in large valves, and the method includes the following steps:

[0031] Step 1. Rough machining of the outer circle 1: Place the workpiece on the lathe, clamp the workpiece with a three-jaw chuck, and leave a unilateral margin of 1.2-1.8mm for the outer circle of the rough car; as an optimal solution, the rough car in step 1 The unilateral margin left by the outer circle is preferably 1.5mm;

[0032] Step 2, bottom surface finishing 2: keep the clamping of the workpiece on the lathe unchanged, and finish the outer end surface of the workpiece;

[0033] Step 3, aging treatment 1 3: remove the workpiece from the lathe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com