Patents

Literature

42results about How to "Not easy to scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

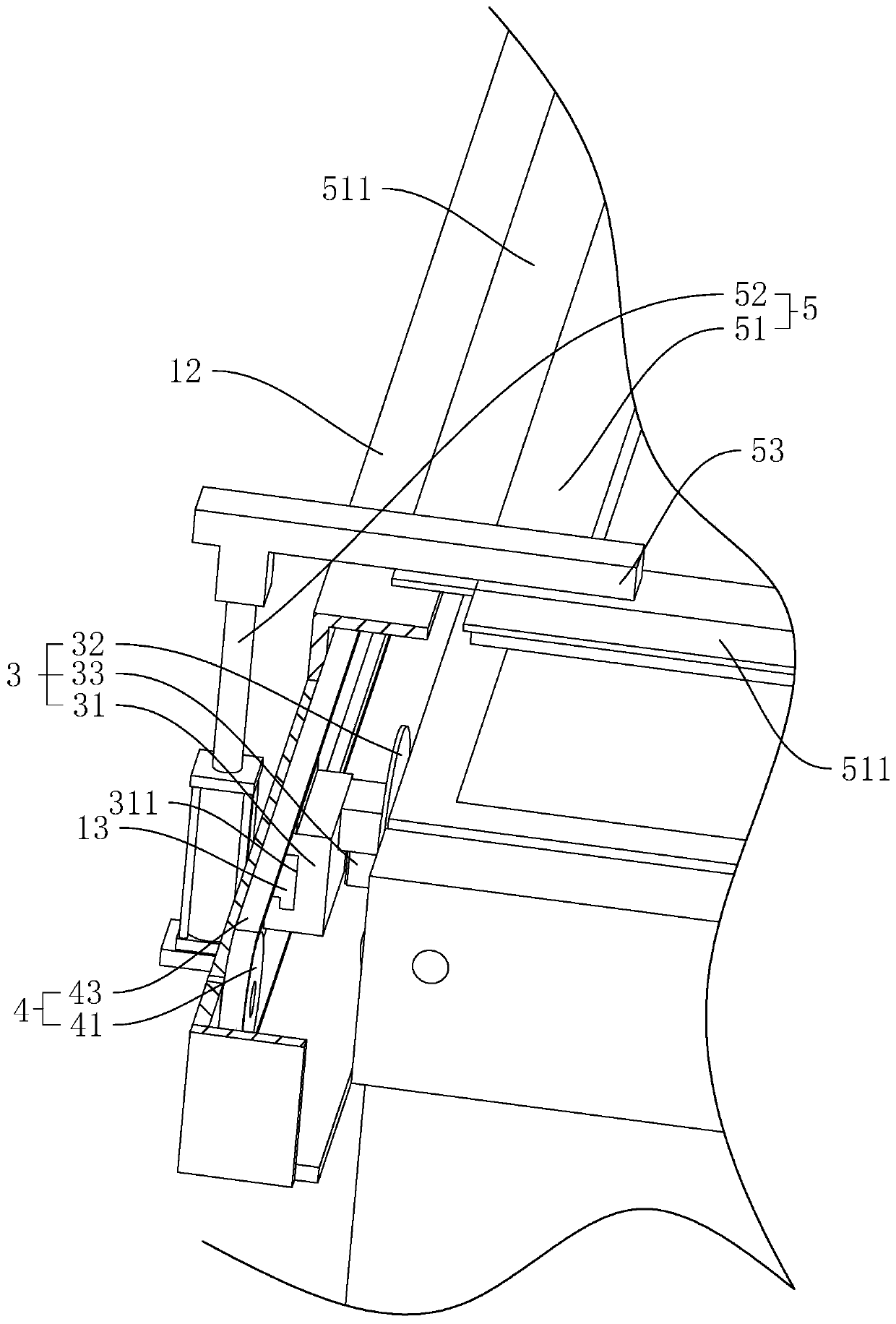

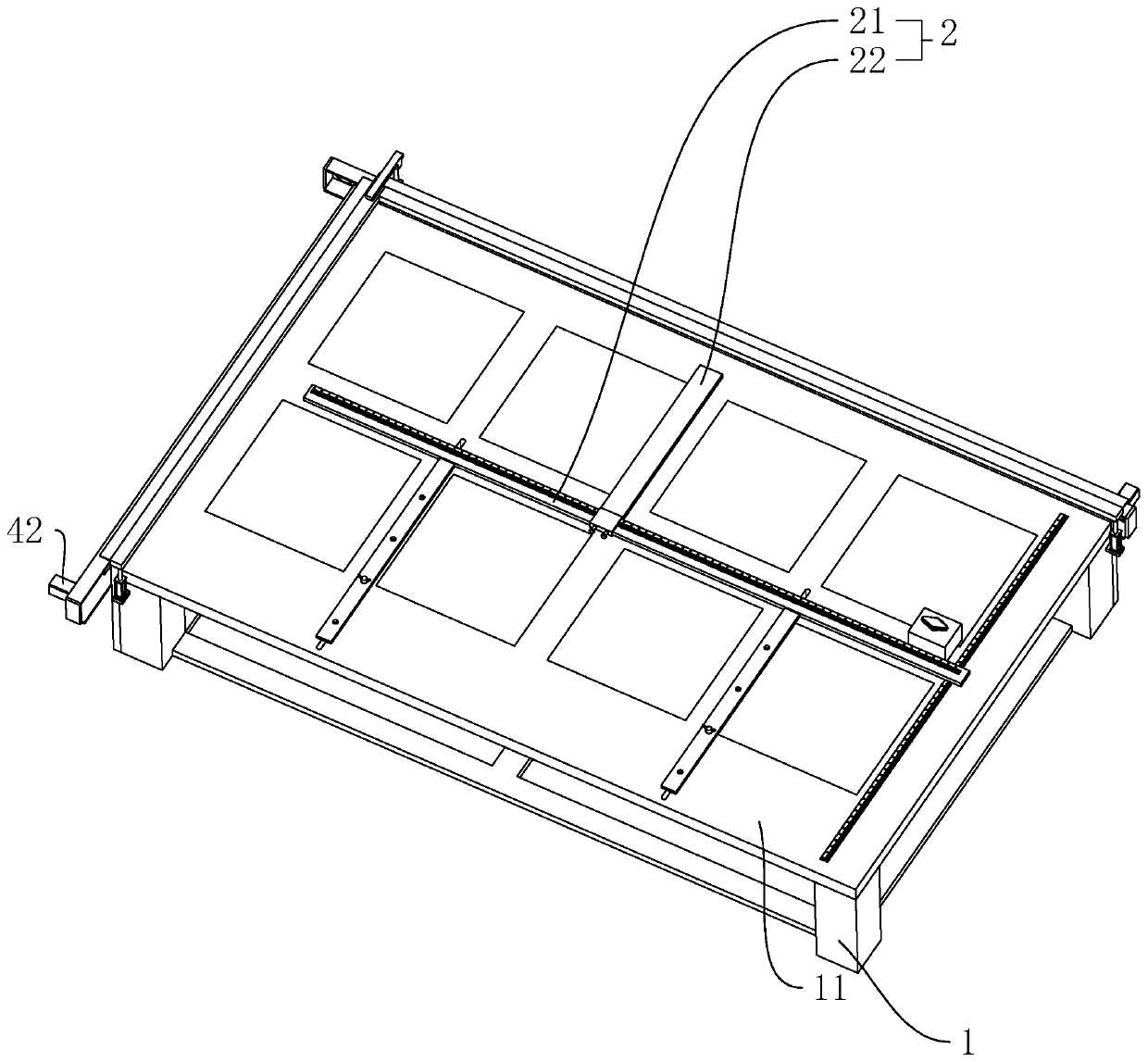

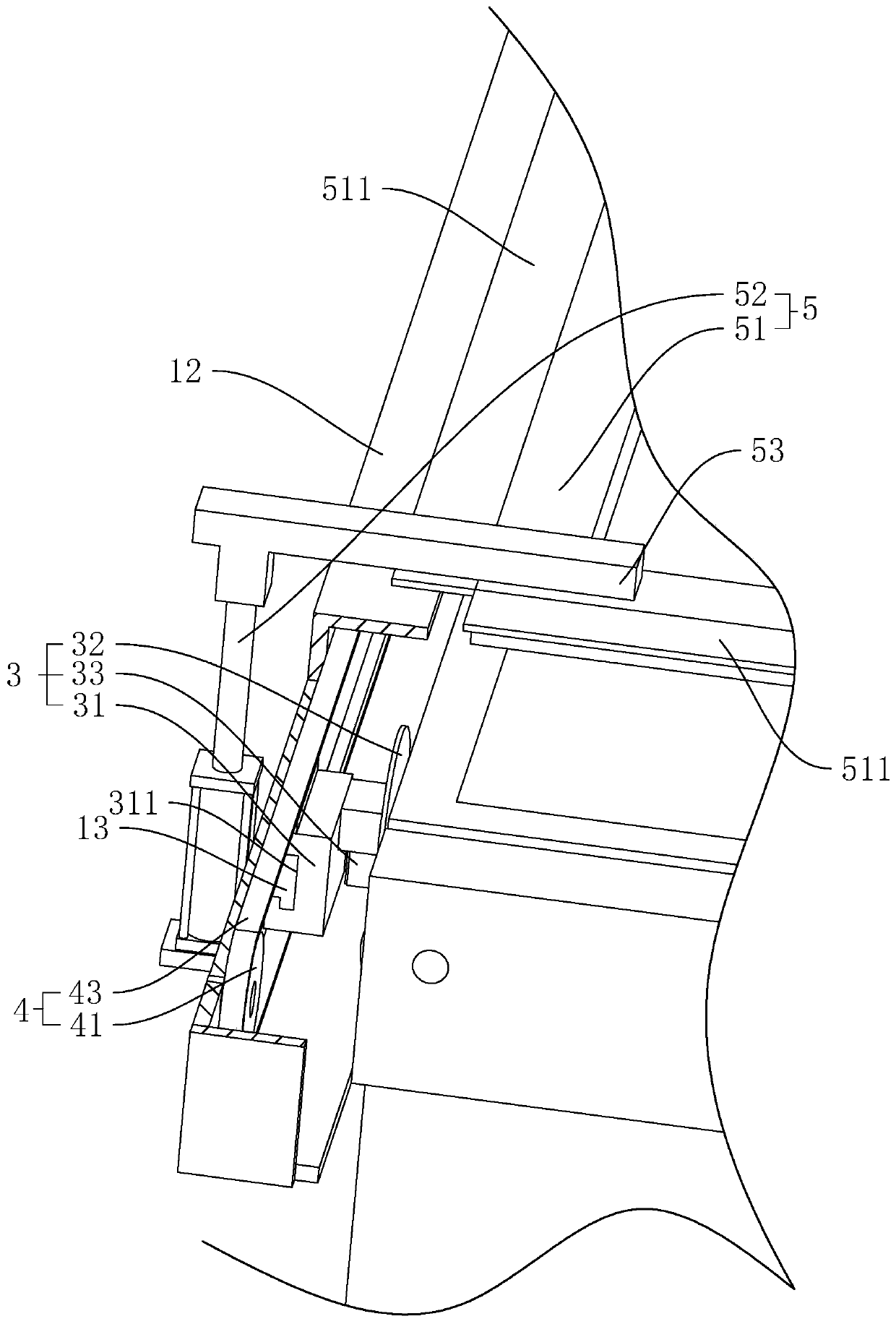

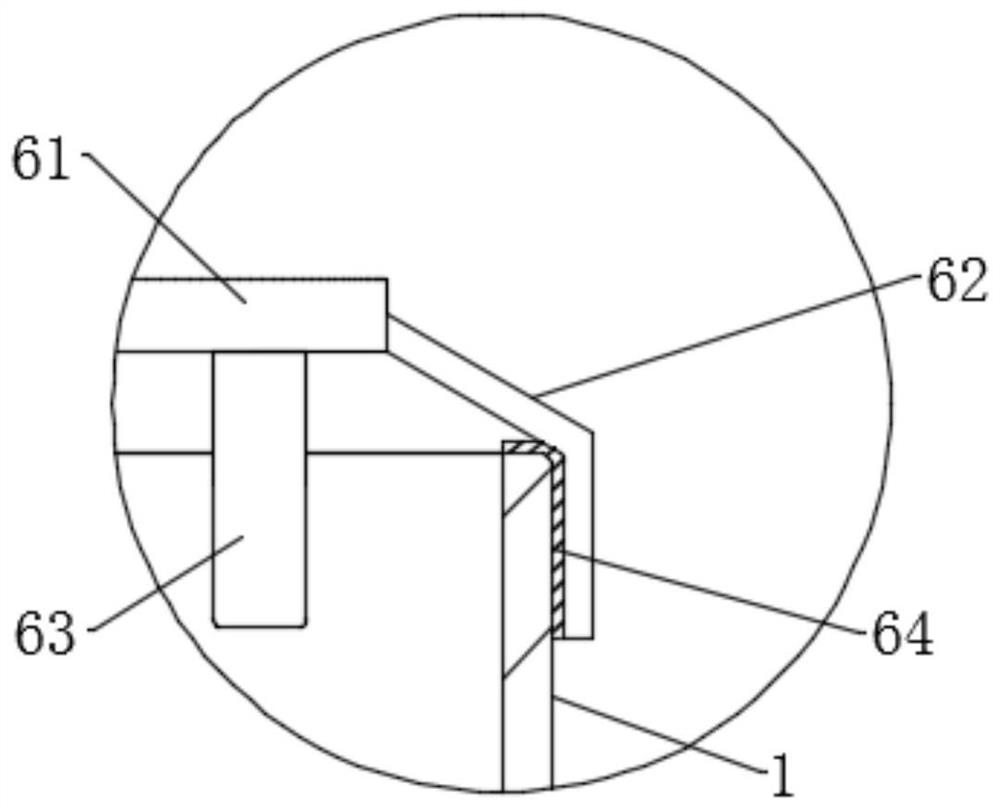

Brick cutting equipment for construction site

ActiveCN106891447AReduce riskNot easy to scrapWorking accessoriesStone-like material working toolsBrickArchitectural engineering

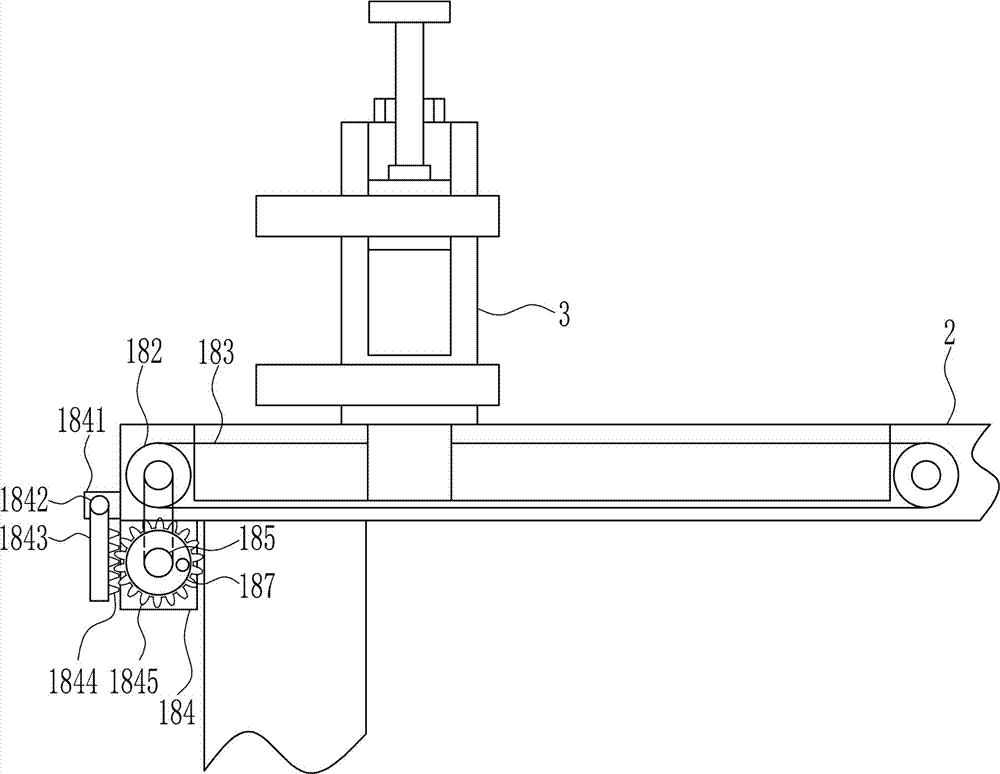

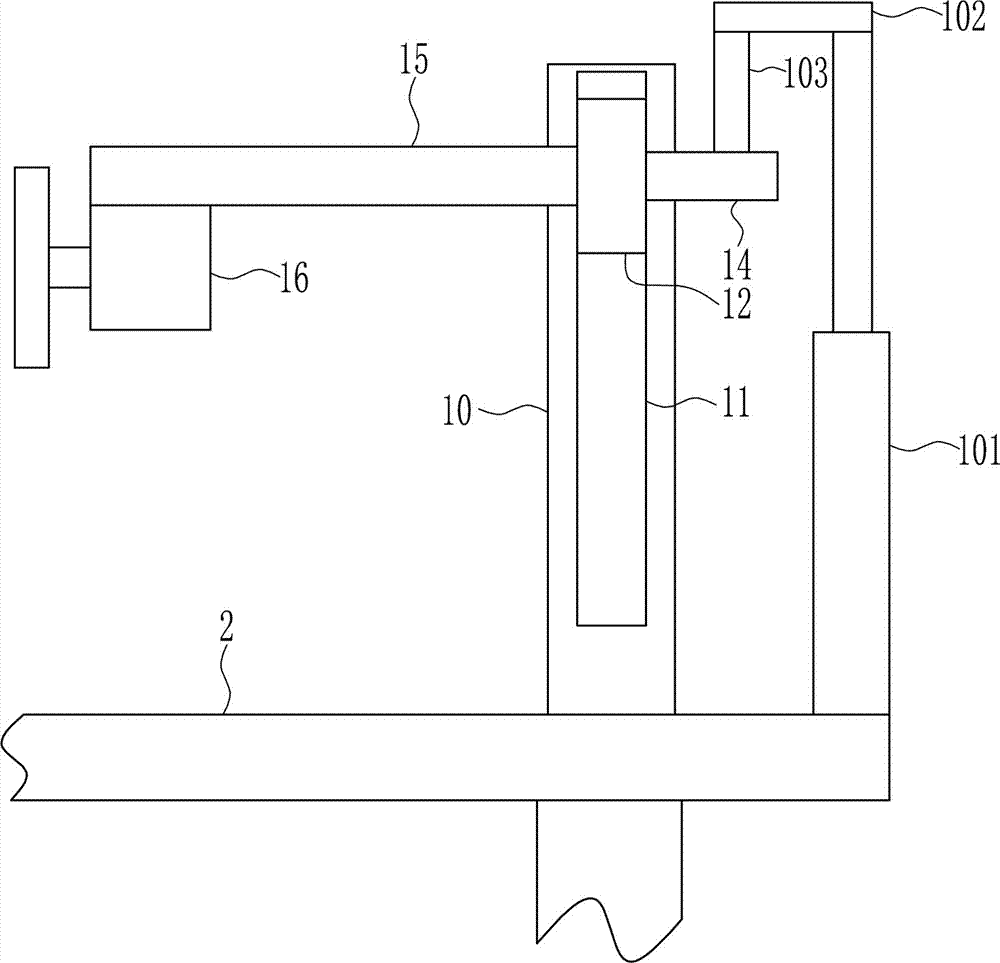

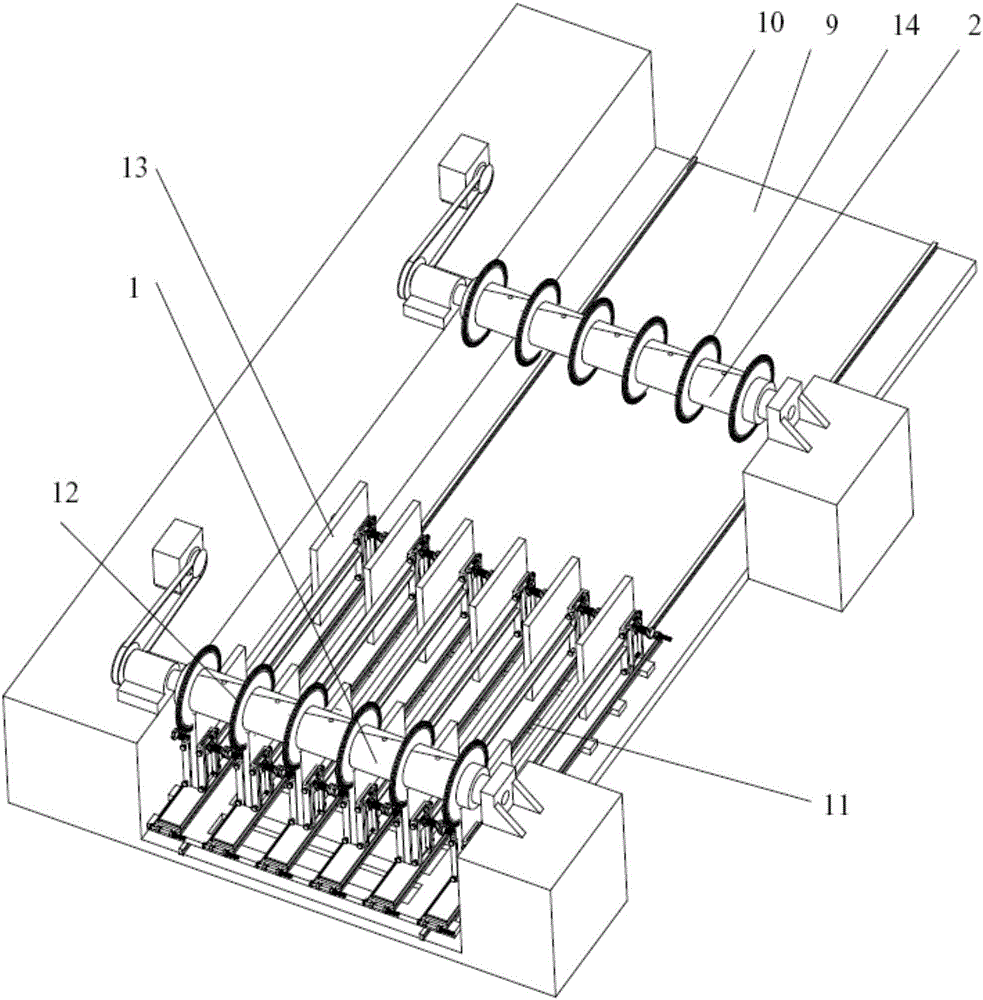

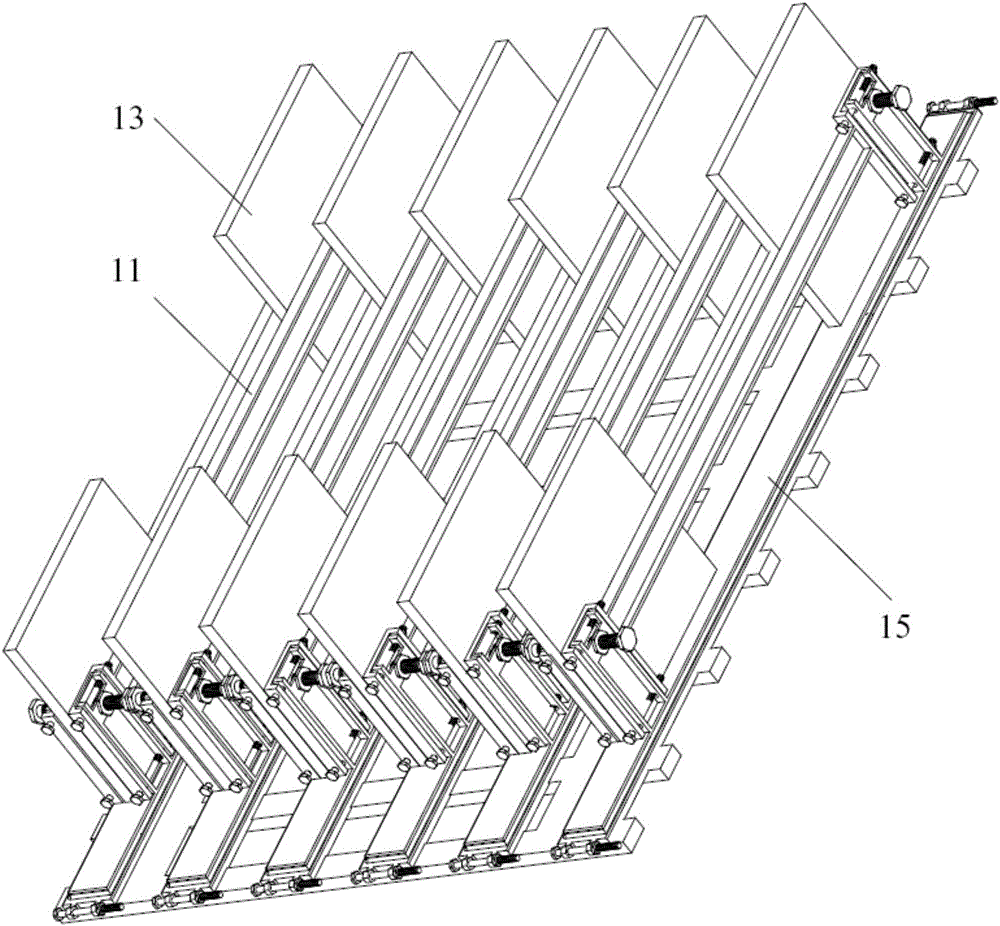

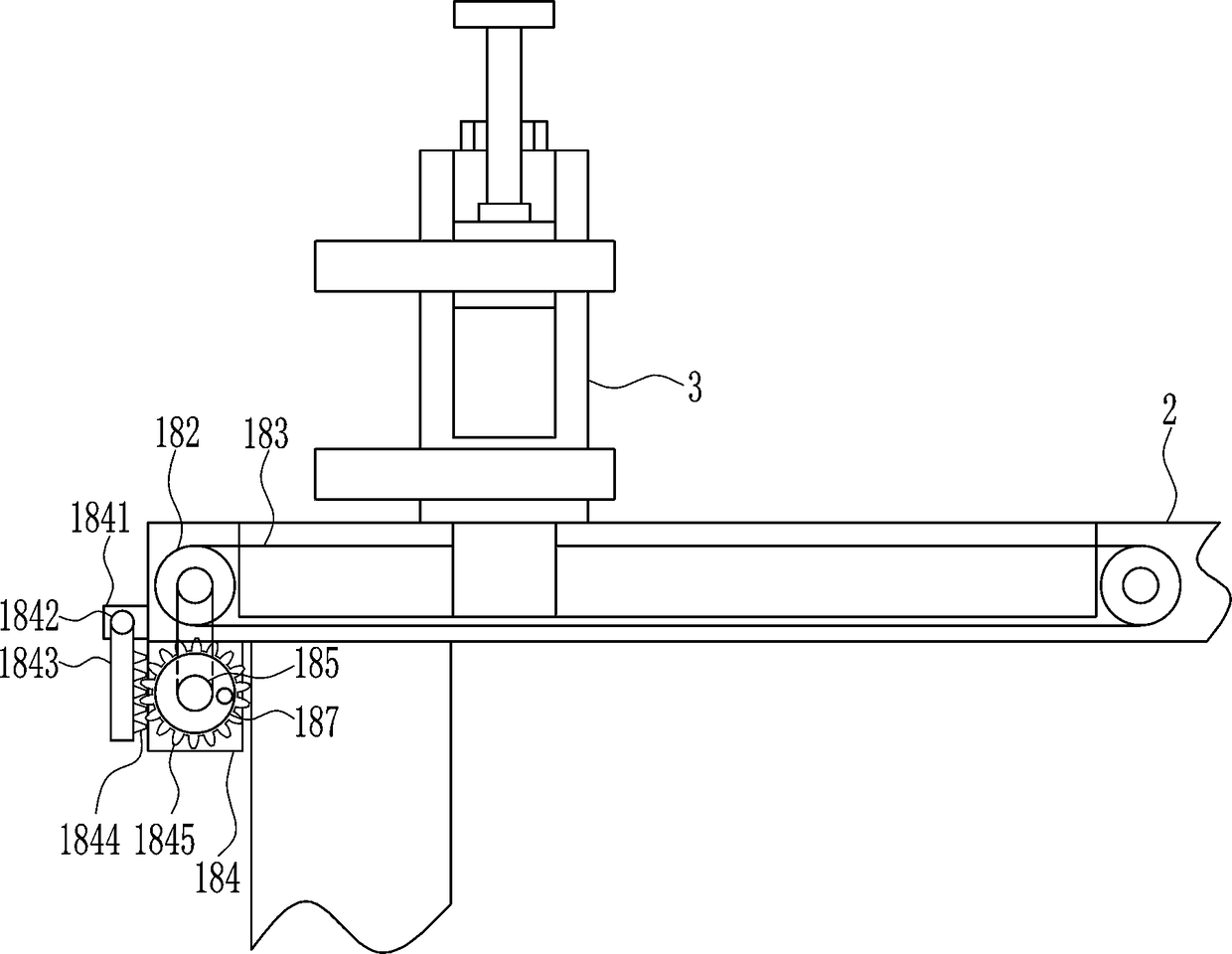

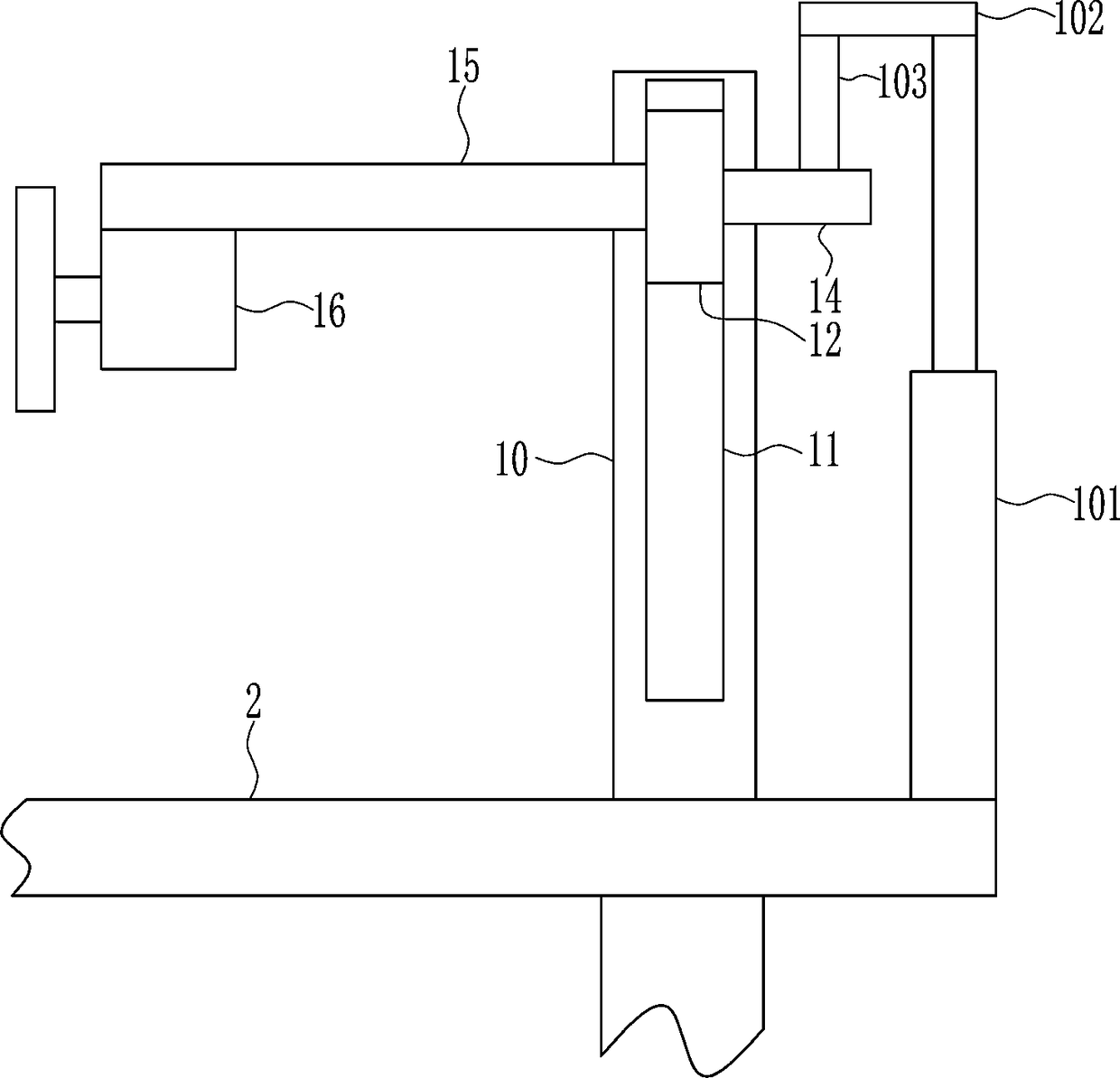

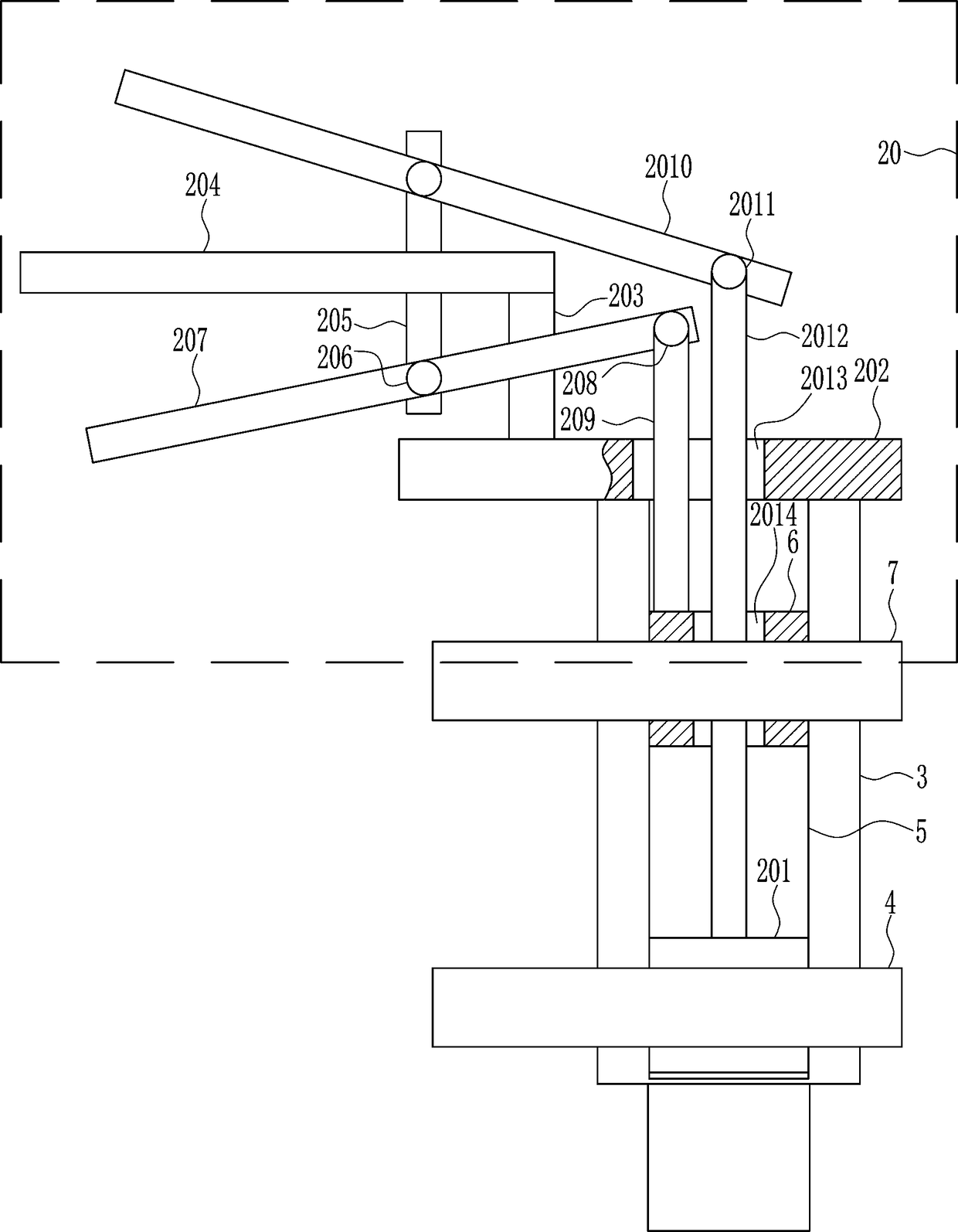

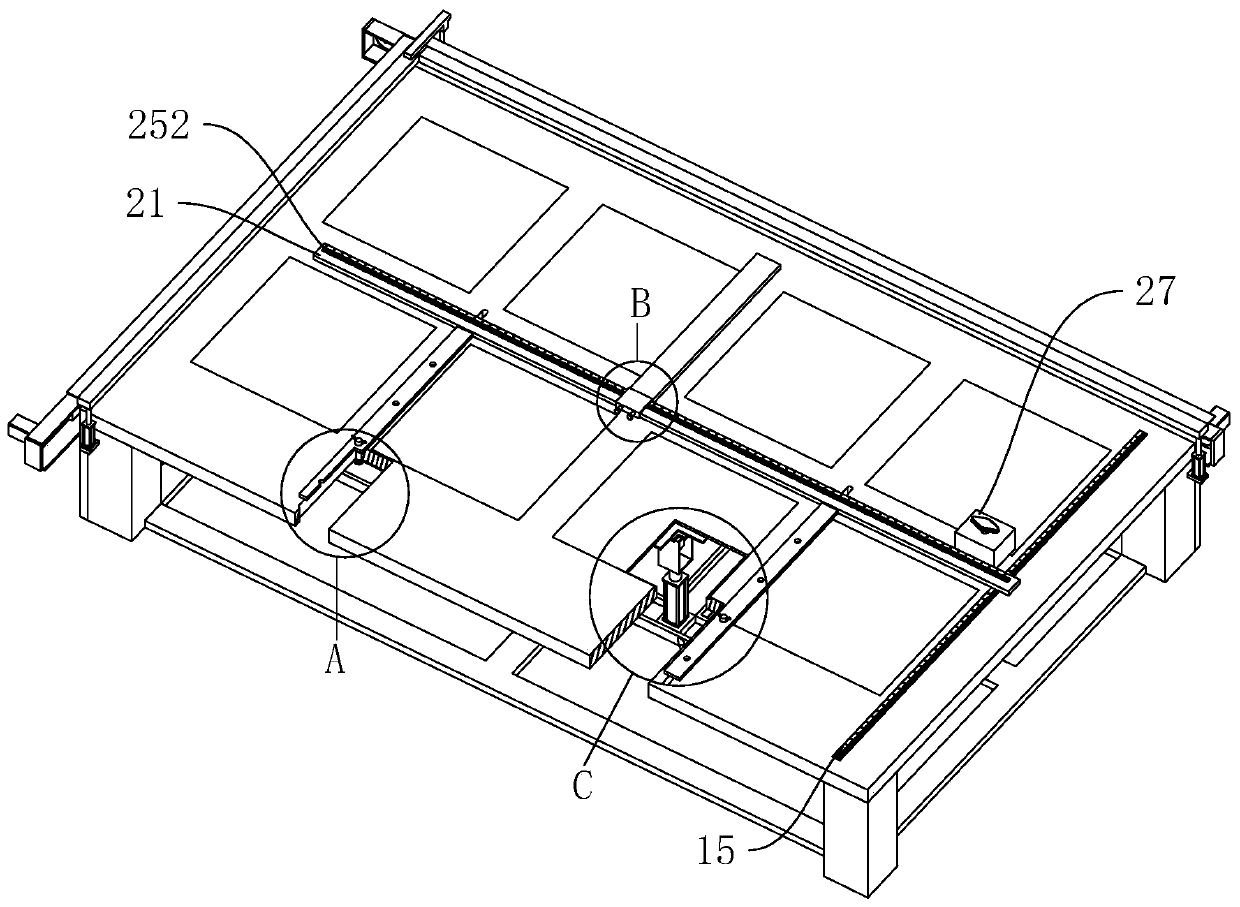

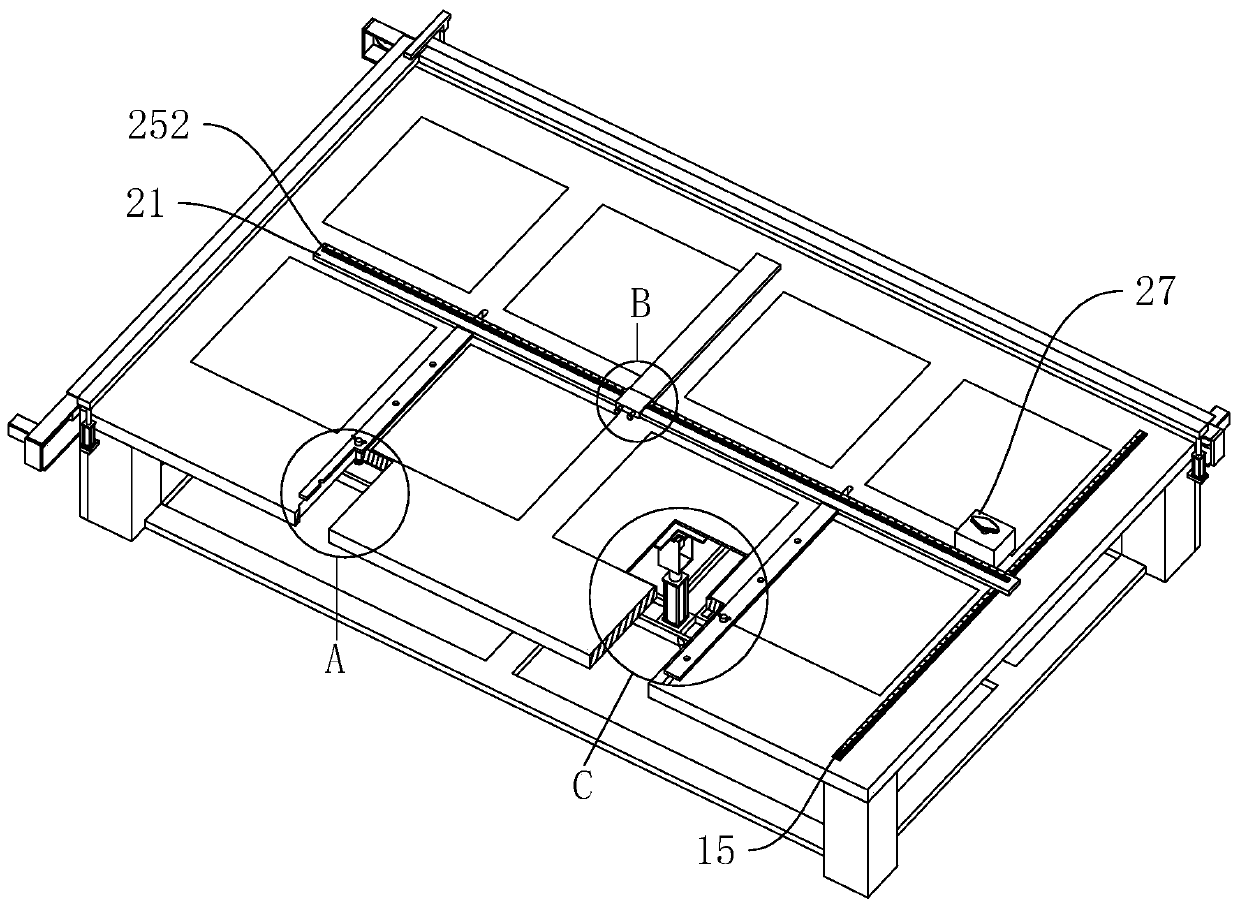

The invention relates to cutting equipment, in particular to brick cutting equipment for a construction site. The brick cutting equipment for the construction site is provided for achieving the technical effects that danger of workers is low, the equipment can conduct cutting accurately, and bricks are not likely to be scrapped. In order to achieve the technical effects, the brick cutting equipment for the construction site, provided by the invention, comprises a support, a working table, a third slide rail, a third sliding block, a fixed platform, a carrying platform, a first slide rail, a first sliding block, a pressing plate, a first nut, a first screw rod and the like. The working table is mounted at the upper end of the support in a welded mode. The third slide rail is mounted on the inner left side of the working table in a bolt connection mode. The third sliding block is connected into the third slide rail in a sliding mode. The brick cutting equipment for the construction site achieves the effects that danger to workers is small, the equipment can conduct accurate cutting, and bricks are not likely to be scrapped. Bricks are moved through a moving device.

Owner:福建省裕景建筑工程有限公司

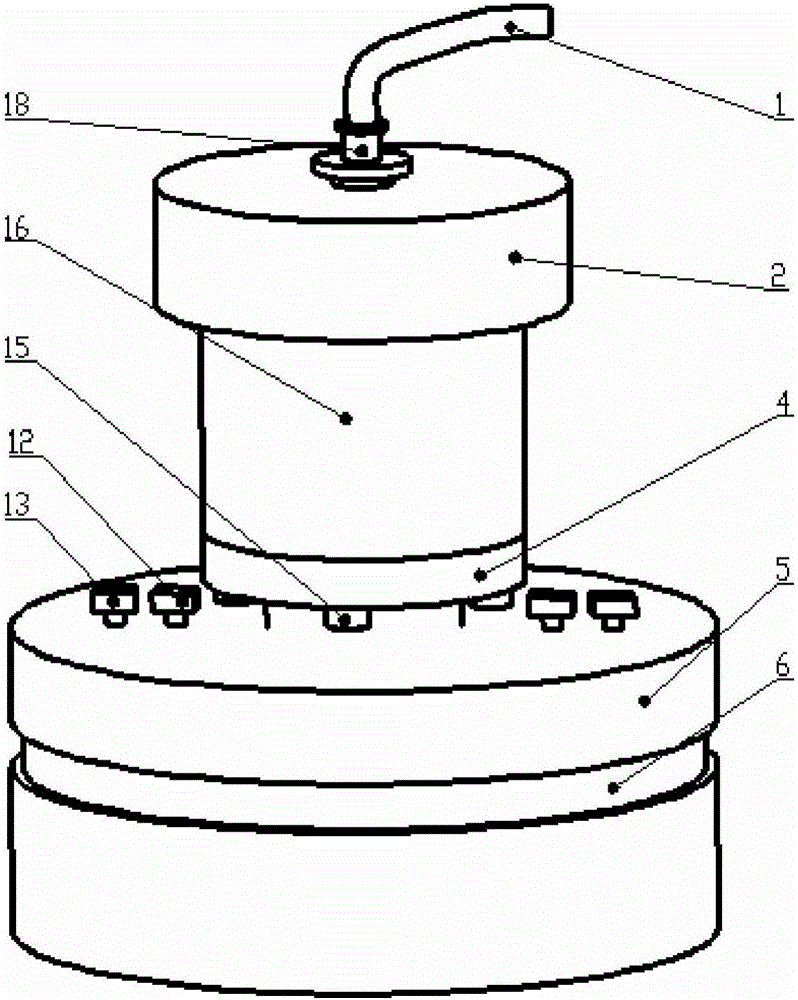

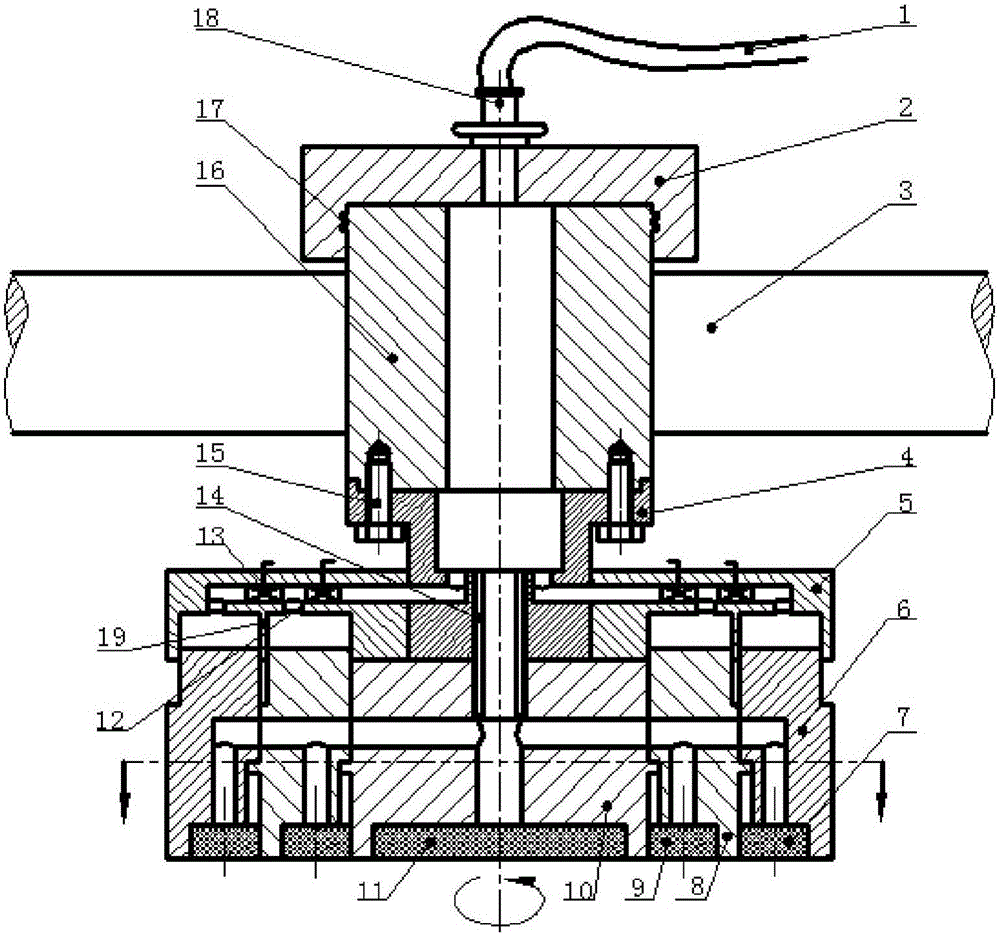

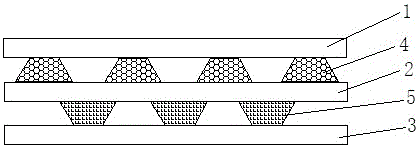

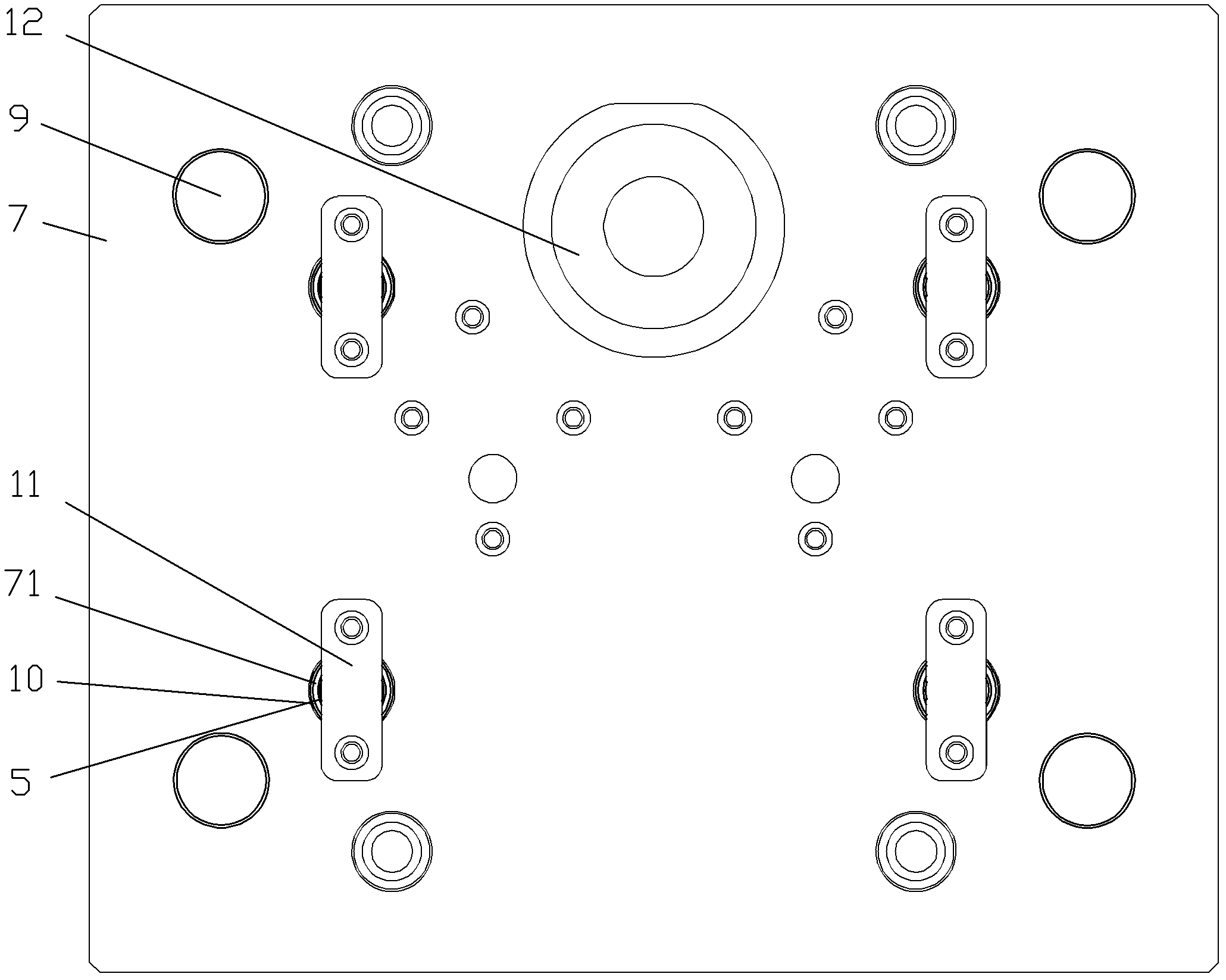

Multistage vacuum adsorption device for polishing of magnetorheological plane and machining method of multistage vacuum adsorption device

ActiveCN106041729ARealization of vacuum adsorptionNot easy to scrapGrinding work supportsMagnetorheological fluidProcess engineering

The invention discloses a multistage vacuum adsorption device for polishing of a magnetorheological plane and a machining method of the multistage vacuum adsorption device. The device comprises a vacuum adsorption generating device, a conversion device for different stage numbers and a vacuum adsorption device; the vacuum adsorption generating device comprises an air guiding pipe, a rotary connector, a base body, a main shaft and an air guiding connector; the conversion device for different stage numbers comprises a connection sleeve, an end cover, a manual ball valve and a connection pipe; and the vacuum adsorption device comprises a third-stage fixing piece, a third-stage porous ceramic disk, a second-stage fixing piece, a second-stage porous ceramic disk, a first-stage fixing piece and a first-stage porous ceramic disk. Based on the magnetorheological effect, the multistage vacuum adsorption device for polishing of the magnetorheological plane can clamp optical elements in different sizes in a vacuum adsorption manner under the situation that the porous ceramic disks are not abraded, and the vacuum adsorption device is low in cost, simple in structure, reliable in adsorption, convenient, practical and capable of being applicable to ultra-smooth magnetorheological polishing of planes of the optical elements in different sizes.

Owner:GUANGDONG UNIV OF TECH

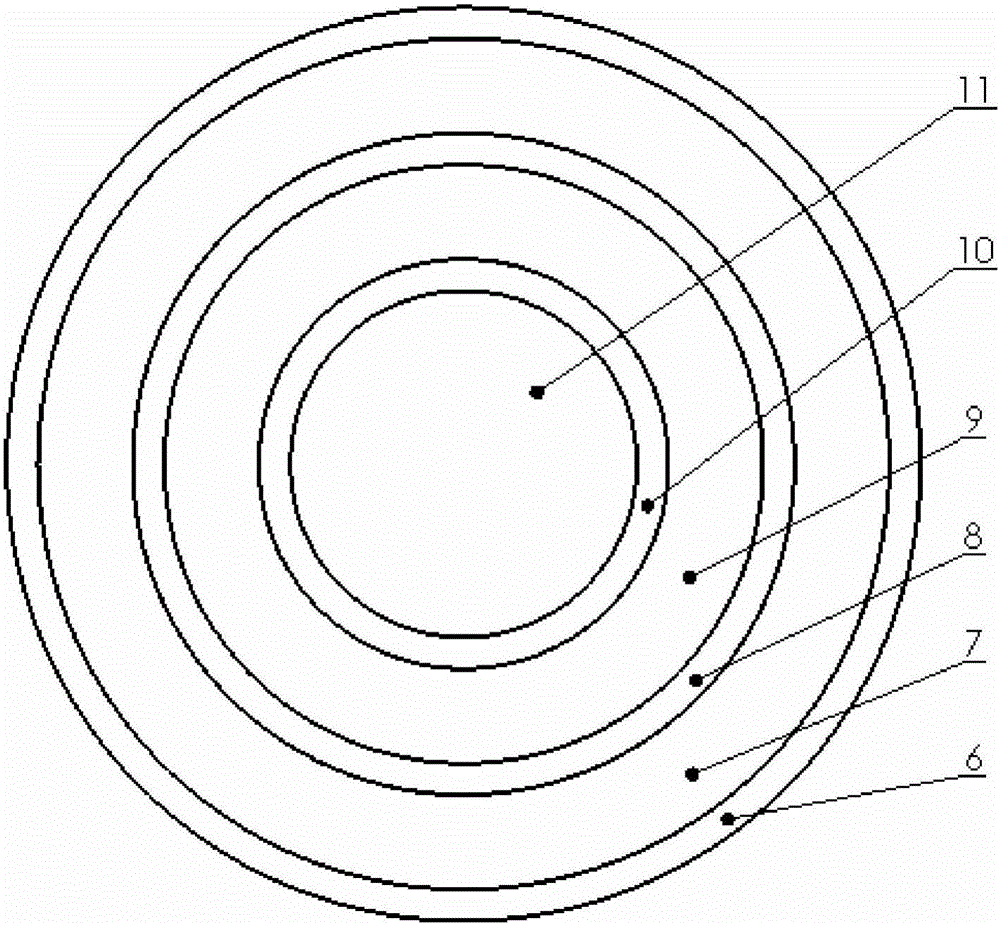

Concentrating photovoltaic circuit substrate fixing base

InactiveCN102881745APhenomenon that is not easy to deviateImprove qualityFinal product manufacturePhotovoltaic energy generationConcentrator photovoltaicPhotovoltaic power generation

The invention relates to a concentrating photovoltaic circuit substrate fixing base, and belongs to the technical field of solar photovoltaic power generation. The fixing base comprises a base body and concentrating photovoltaic circuit substrate grooves, and is characterized in that the concentrating photovoltaic circuit substrate grooves are formed on the base body by carving. The fixing base has the advantages that a unified technique is adopted by personnel, product quality is improved, and production efficiency is obviously improved; the phenomenon that a product is poor or scrapped because the product is easily influenced by external force when moved and placed is avoided; and the phenomenon that a cell chip deviates because the cell chip is easily vibrated by external force when the product is moved and heated is avoided.

Owner:成都聚合科技有限公司

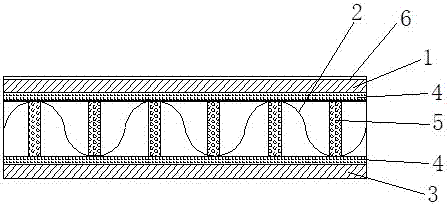

High-intensity corrugated paper board

InactiveCN103306166AHigh strengthEasy to carrySpecial paperPaper/cardboardFiberPulp and paper industry

The invention relates to a high-intensity corrugated paper board. The high-intensity corrugated board comprises corrugated paper, inner paper and surface paper, wherein the inner paper and the surface paper are respectively positioned at the inner side and the outer side of the corrugated paper; a plurality of reinforce boards are longitudinally connected between the inner paper and the surface paper, and penetrate through the trough of the corrugated paper. The high-intensity corrugated paper board provided by the invention improves the integral intensity of the corrugated paper board through the arrangement of the plurality of fiber boards, ensures that the corrugated paper board is not deformed easily, is beneficial to goods transportation, and is difficult to scrap.

Owner:KUNSHAN SANDA PACKAGING

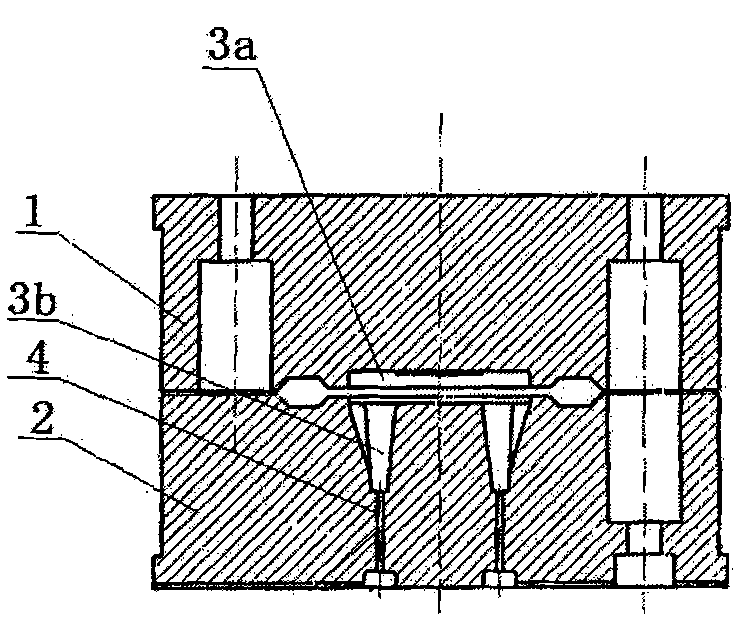

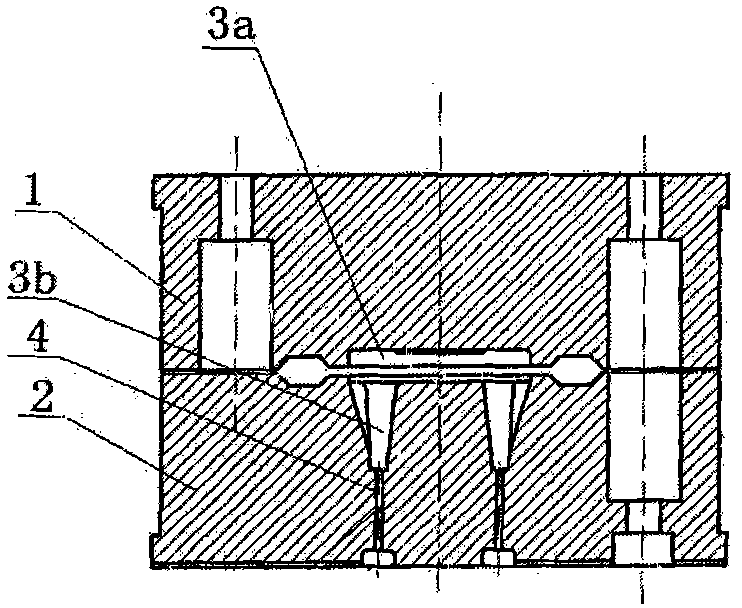

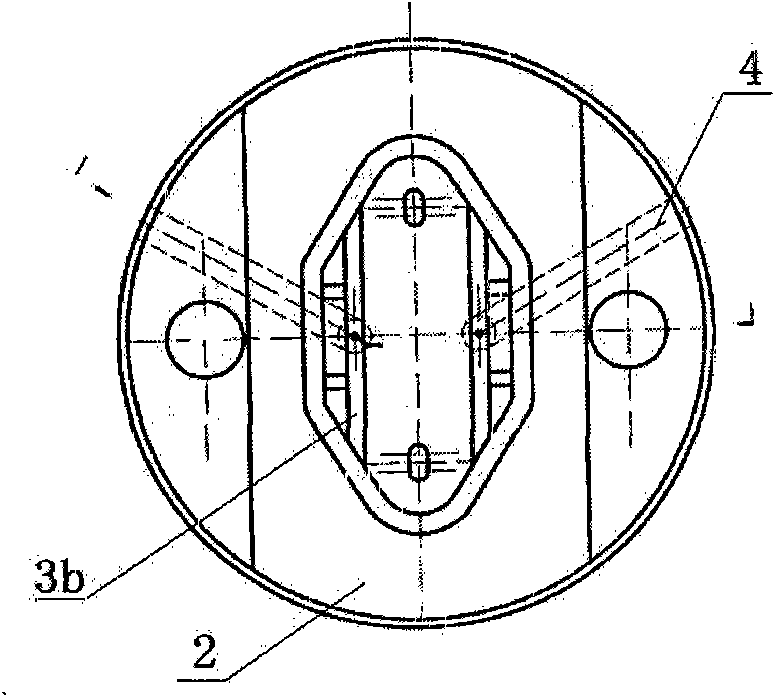

Forging mold for cantilever type hardware fitting base of electrified railway contact network parts

InactiveCN101947626ASmall tonnageIncrease contact areaRailway componentsForging/hammering/pressing machinesContact networkMetallurgy

The invention relates to a forging mold for a cantilever type hardware fitting base of electrified railway contact network parts, comprising an upper mold and a lower mold, wherein the cavities of the upper mold and the lower mold are combined to form a mold cavity of the hardware fitting base, the mold cavity comprises a base and lug parts symmetrically arranged on both sides of the base, and the conicity of the middle inner side face of each lug part is 1-2 degrees; and the inner wall of the mold cavity is provided with an exhaust channel communicated with the outside. When forging the hardware fitting base, the lower mold is arranged on a workbench of a friction press, the upper mold is arranged on a sliding block, and the upper mold and the lower mold are closed through the sliding block to extrude a forged material into the hardware fitting base. Because the exhaust channel is arranged on the inner wall of the mold cavity, the hardware fitting base is easier to be punched and molded and difficult to be scrapped, the tonnage of the friction press is greatly reduced, and thus the manufacture cost is greatly reduced. Due to the arrangement of the exhaust channel, when the conicity of the middle inner side face of each lug part is 1-2 degrees, the molds can be successfully lifted, the contact area between the double lugs parts of the hardware fitting base and a connecting piece is enhanced during assembly, and the stress effect is good.

Owner:RUGAO DASHENG LINE EQUIP

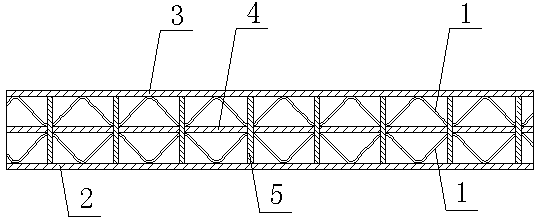

High-strength corrugated paperboard used as package material

InactiveCN107160804AHigh strengthImprove toughnessFlexible coversWrappersPuncture resistancePaperboard

The invention discloses a high-strength corrugated cardboard for packaging materials, which includes face paper, core paper and inner paper. The core paper is arranged between the face paper and the inner paper, and also includes a grid fiber layer and reinforcing ribs. The mesh fiber layers are respectively arranged on the inner side of the surface paper and the inner paper on both sides of the core paper, the cross section of the core paper is in a wave structure, and the reinforcing ribs are respectively vertically arranged on the flute of the core paper. Shaped protruding part and is connected with described face paper or inner paper. Through the above method, the high-strength corrugated cardboard used for packaging materials of the present invention improves the toughness of the corrugated cardboard, has the characteristics of strong tear resistance and good puncture resistance, strengthens the overall strength of the corrugated cardboard, and makes it difficult to deform. It is conducive to the handling of goods, and at the same time has the characteristics of waterproof and is not easy to be scrapped.

Owner:SUZHOU YONGCHUANGDA ELECTRONICS

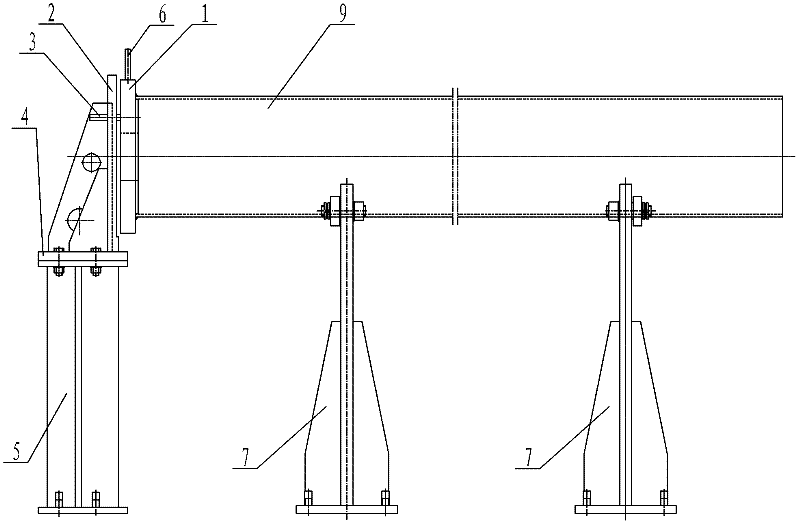

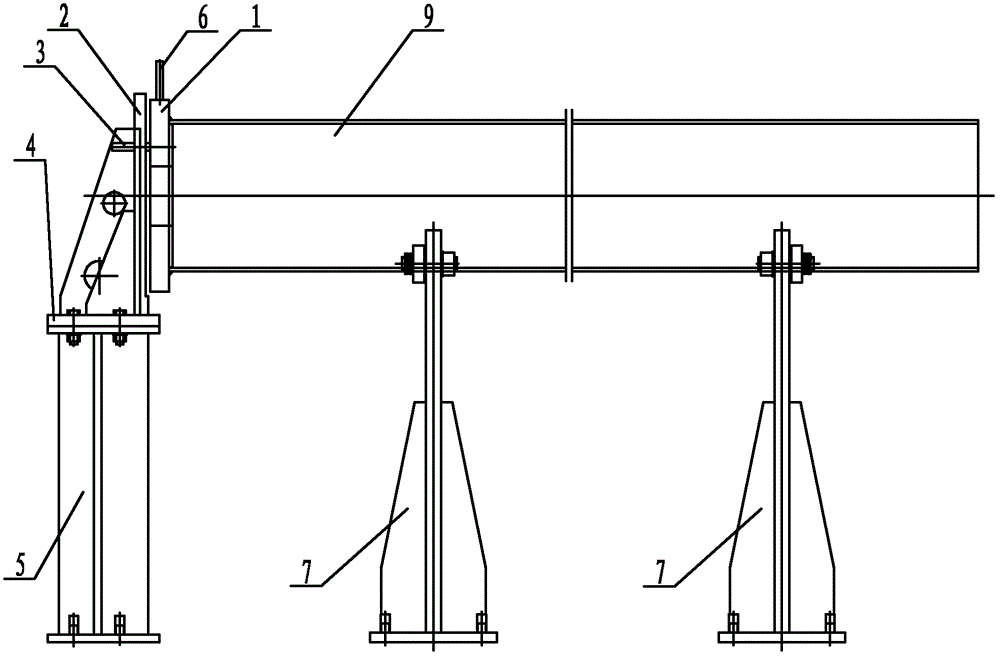

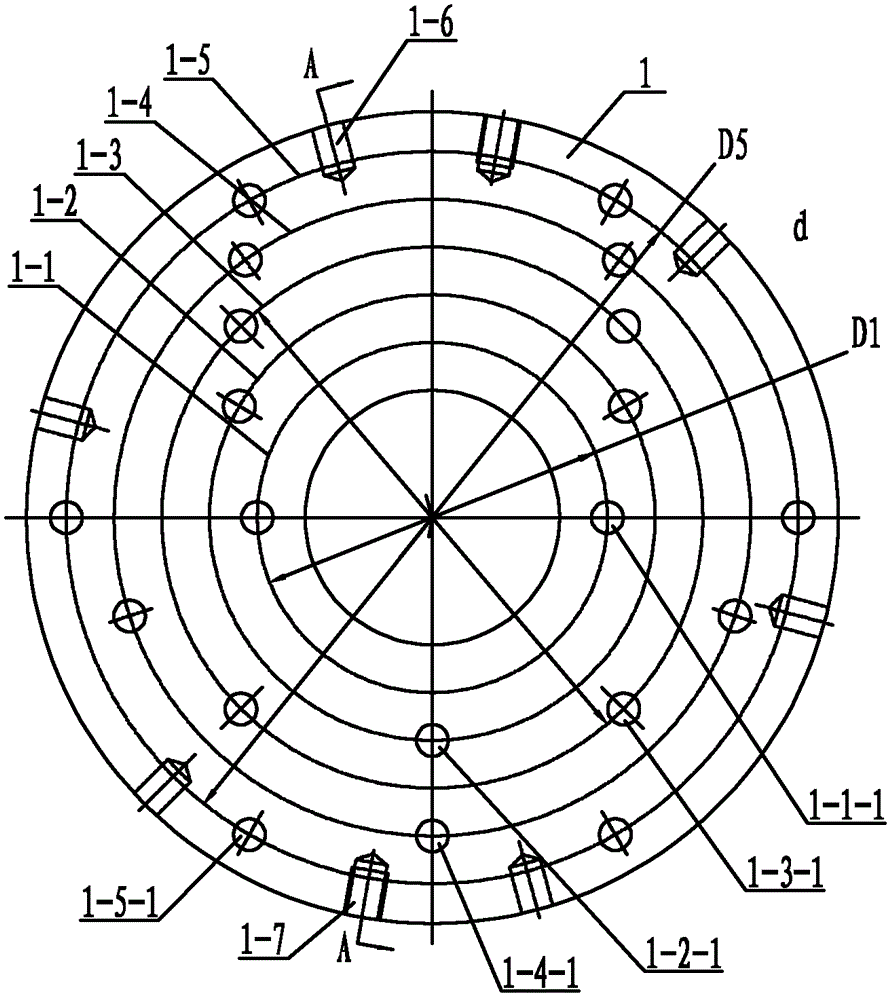

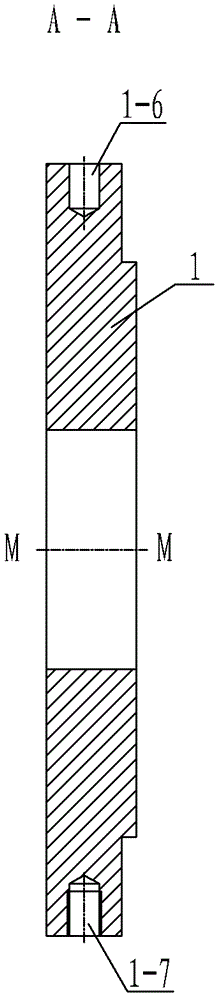

Tooling for machining steam turbine condenser air extraction pipe

ActiveCN102294503ANot easy to scrapPrecise positioningPrecision positioning equipmentBoring/drilling machinesDrill holeEngineering

The invention discloses a tool for processing an air extracting pipe of a condenser of a turbine, which relates to an auxiliary tool for processing the air extracting pipe of the condenser of the turbine and aims to solve the problems that a processed pipe is supported by two pieces of V-shaped iron, air extracting holes are directly drilled on a radial drill, the positions of the drilled holes are inaccurate and the drilled holes have low precision in the conventional tool for processing the air extracting pipe of the condenser of the turbine. A rotating rod is arranged in an installation hole; a positioning plate and an indexing disk are arranged in parallel; the center line of the positioning plate is opposite to the center line of the indexing disk; two long holes are formed between afirst positioning pitch circle and a second positioning pitch circle on the positioning plate; the width of each long hole is equal to the diameter of an indexing hole; an included angle between the two long holes is 90 degrees; positioning pins are arranged in the long holes and the indexing holes; the lower end of the positioning plate is connected with a bearing seat by a seat plate; the indexing disk, the positioning plate, the components of the bearing seat and two support frames are sequentially arranged along a longitudinal direction; and the vertical center lines of frame bodies and the center line of the indexing disk are positioned in the same plane. The tool is used for processing the air extracting pipe of the condenser of the turbine.

Owner:HARBIN TURBINE +1

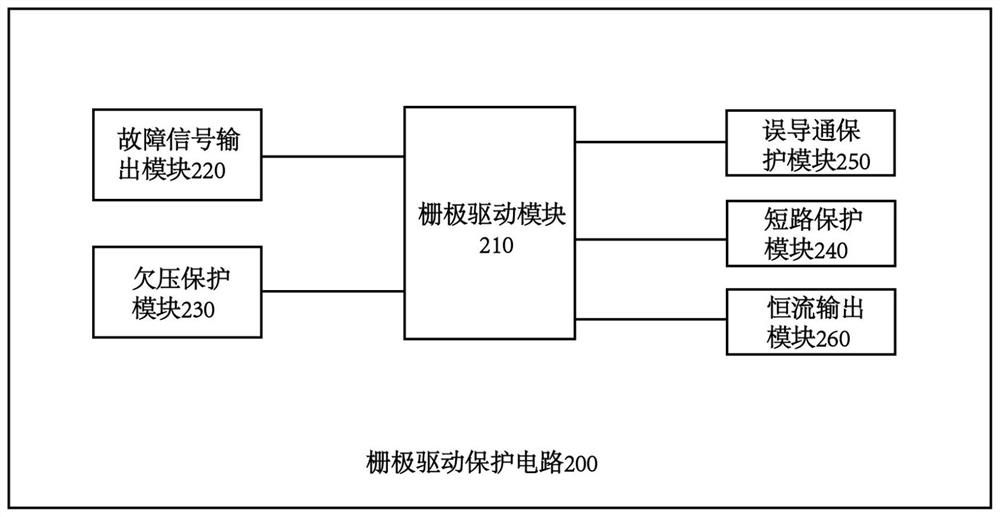

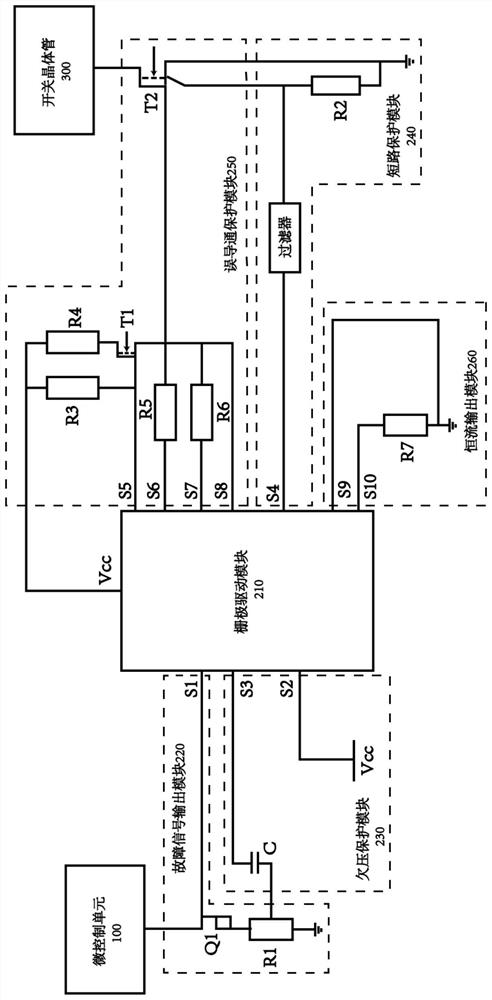

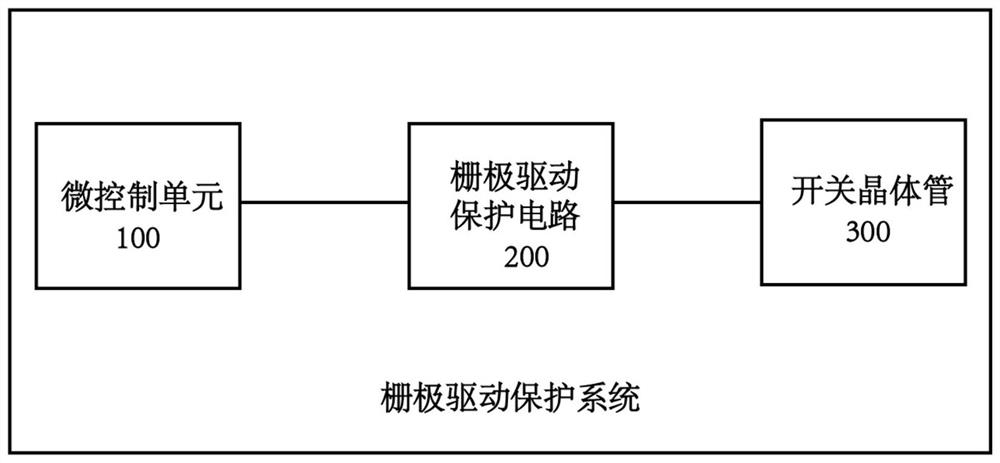

Grid driving protection circuit, grid driving protection system and vehicle-mounted inverter system

PendingCN114204834ANot easy to damageNot easy to scrapAc-dc conversionArrangements responsive to excess currentIn vehicleControl cell

The invention relates to a gate drive protection circuit and system and a vehicle-mounted inverter system. The gate drive protection circuit comprises a gate drive module, a fault signal output module, an under-voltage protection module, a short-circuit protection module, a misconduction protection module and a constant-current output module. The gate driving module comprises a driving chip; the fault signal output module is electrically connected with the driving chip and the micro-control unit and is used for outputting a fault signal; one end of the under-voltage protection module is electrically connected with the driving chip, the other end of the under-voltage protection module is electrically connected with the fault signal output module, and the under-voltage protection module is used for carrying out under-voltage protection on the input voltage of the driving chip; the short-circuit protection module is electrically connected with the driving chip and is used for performing short-circuit protection on the driving chip; the mis-conduction protection module is electrically connected with the driving chip and is used for preventing mis-conduction of the switching transistor; the constant current output module is electrically connected with the driving chip and is used for outputting stable current; therefore, the circuit system is higher in stability and more optimized in performance, and the circuit is not easy to damage and scrap.

Owner:智新控制系统有限公司

Multilayer high-pressure-resistant corrugated board for packaging material

InactiveCN107175850AHigh strengthEasy to carryPaper/cardboard layered productsDomestic containersEngineeringHigh pressure

The invention discloses a multi-layer high pressure-resistant corrugated cardboard for packaging materials, comprising a first corrugated board, a second corrugated board, a third corrugated board, a first reinforcing rib and a second reinforcing rib, the first reinforcing rib The ribs are evenly arranged between the first corrugated board and the second corrugated board, the second reinforcing ribs are evenly arranged between the second corrugated board and the third corrugated board, and the first reinforcing ribs and The second reinforcing ribs are arranged in a staggered position, the first reinforcing ribs have a trapezoidal structure, and the second reinforcing ribs have an inverted trapezoidal structure and a mirror image structure with the first reinforcing ribs. Through the above method, the multi-layer high pressure-resistant corrugated cardboard used in the packaging material of the present invention has relatively high compressive resistance and impact resistance to puncture, strengthens the overall strength of the corrugated cardboard, makes it difficult to deform, and is beneficial to the handling of goods , not easy to scrap.

Owner:SUZHOU RUINAIJIE ELECTRONICS SCI & TECH NEW MATERIAL

Efficient bisecting and sawing device for stone panel

InactiveCN105690573AImprove efficiencyAvoid crackingWorking accessoriesStone-like material working toolsCar drivingEngineering

The invention discloses a high-efficiency split sawing device for stone slabs, which comprises a wheel saw device, a clamping device for stone slabs; a linear guide device; There is a track, on which there is no less than one frame car that is driven by a synchronous device; the wheel saw device is a set of wheel saw groups with equal shaft lengths installed along the rail above the track, and the wheel saw group A plurality of circular saw blades are set at equidistant intervals along the axial coaxial axis, the number of circular saw blades on each wheel saw group is equal, and the corresponding circular saw blades on each wheel saw group The diameter of the circular saw blade on the wheel saw group gradually increases, and the radius of the circular saw blade on the last wheel saw group is equal to the height of the sawing surface of the stone slab; Adjustable pair of splints equal to the number of circular saw blades on a single wheel saw group. High yield, low processing cost and high efficiency.

Owner:福建省新达保温材料有限公司

A kind of brick cutting equipment for construction site

ActiveCN106891447BReduce riskNot easy to scrapWorking accessoriesStone-like material working toolsBrickArchitectural engineering

The invention relates to cutting equipment, in particular to brick cutting equipment for a construction site. The brick cutting equipment for the construction site is provided for achieving the technical effects that danger of workers is low, the equipment can conduct cutting accurately, and bricks are not likely to be scrapped. In order to achieve the technical effects, the brick cutting equipment for the construction site, provided by the invention, comprises a support, a working table, a third slide rail, a third sliding block, a fixed platform, a carrying platform, a first slide rail, a first sliding block, a pressing plate, a first nut, a first screw rod and the like. The working table is mounted at the upper end of the support in a welded mode. The third slide rail is mounted on the inner left side of the working table in a bolt connection mode. The third sliding block is connected into the third slide rail in a sliding mode. The brick cutting equipment for the construction site achieves the effects that danger to workers is small, the equipment can conduct accurate cutting, and bricks are not likely to be scrapped. Bricks are moved through a moving device.

Owner:福建省裕景建筑工程有限公司

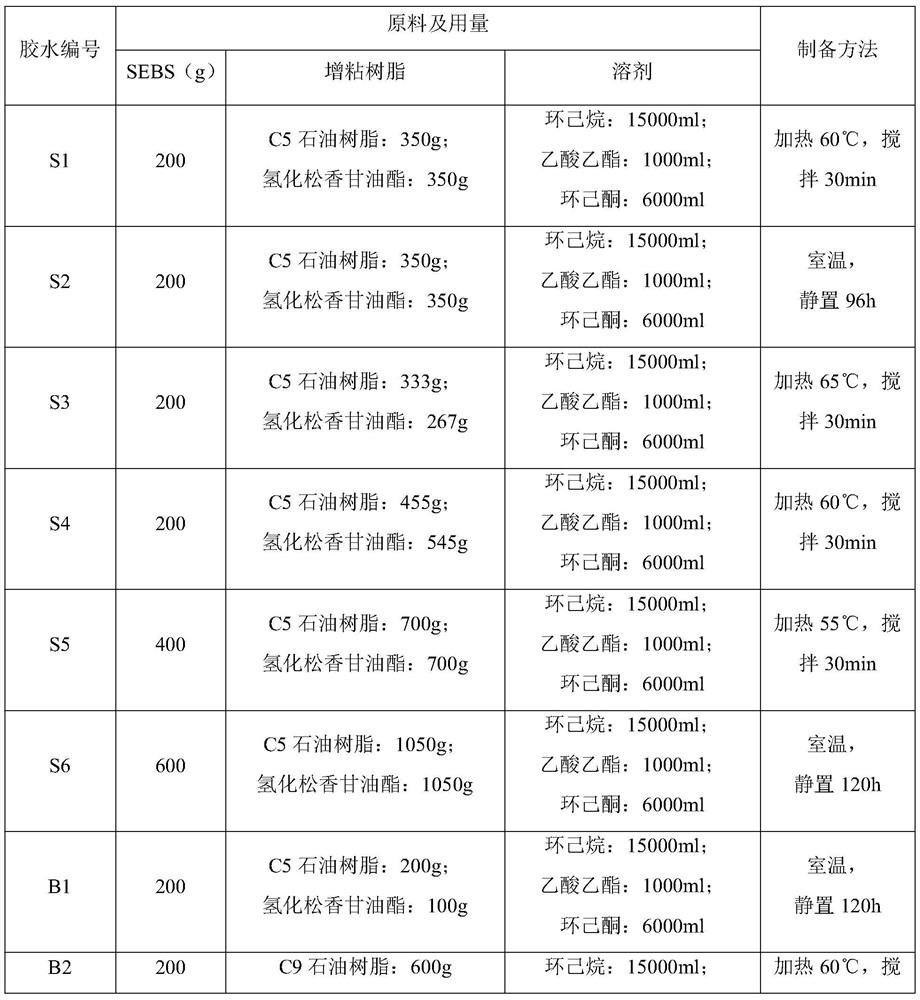

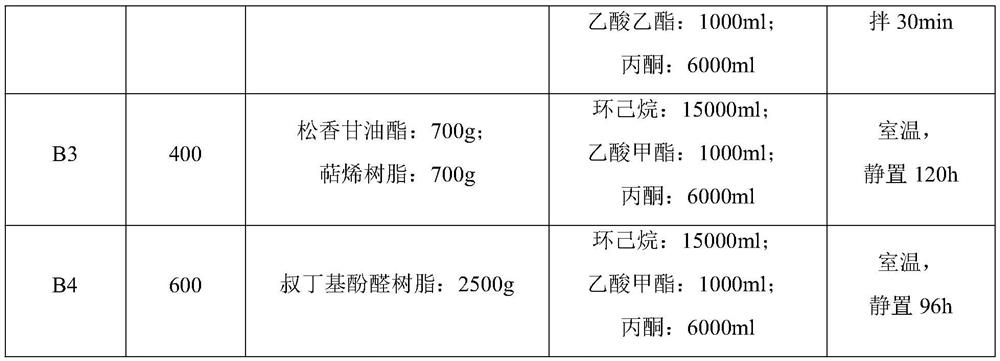

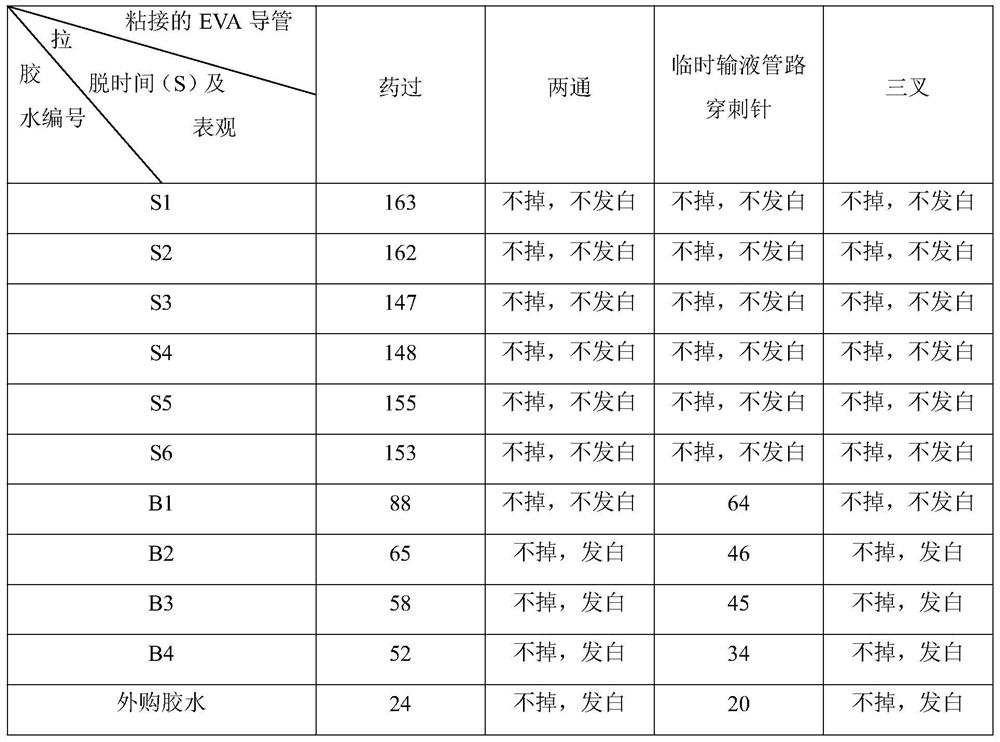

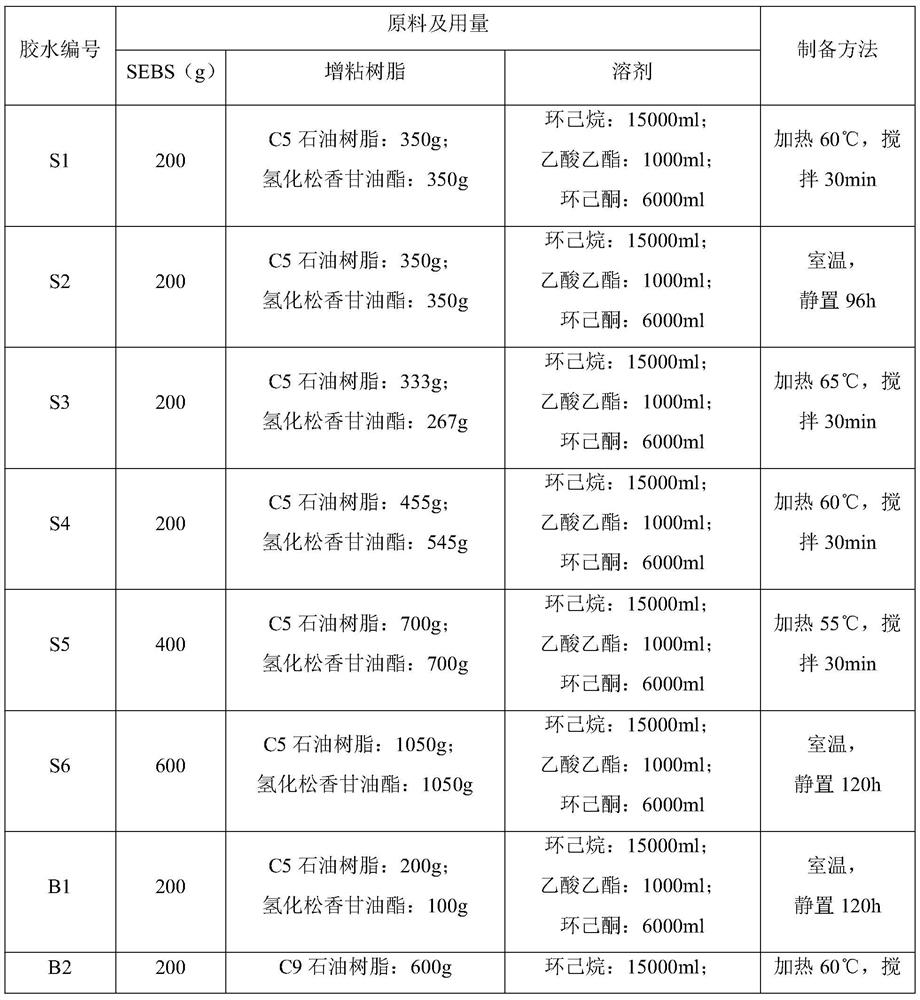

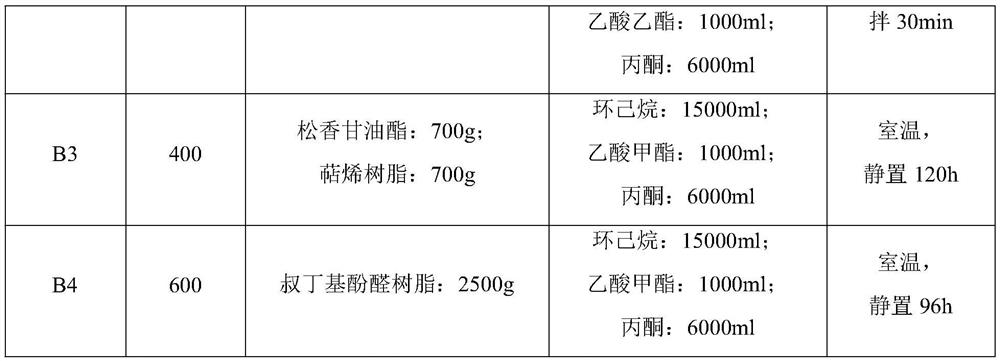

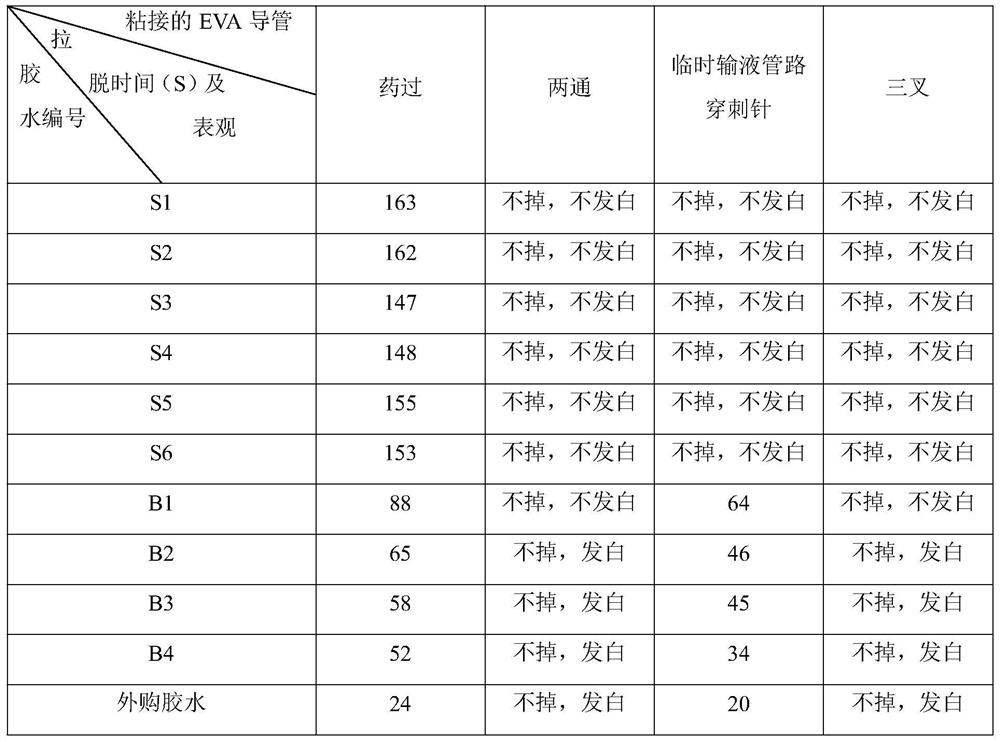

Medical catheter bonding glue and preparation method thereof

ActiveCN113278394AHigh bonding strengthSolve the problem of whiteningMineral oil hydrocarbon copolymer adhesivesRosin adhesivesCyclohexanoneHuman body

The invention discloses a medical catheter bonding glue and a preparation method thereof, which belong to the technical field of medical instrument glue production. The raw materials of the glue comprise, by mass, 1.03-2.86% of SEBS, 3.14-10% of tackifying resin, and the balance a solvent. The tackifying resin comprises C5 petroleum resin and hydrogenated rosin glyceride, and the solvent comprises cyclohexane, ethyl acetate and cyclohexanone. Proper tackifying resin types are selected in the glue, so that the bonding strength of the glue is improved; cyclohexanone is added into the solvent, so that the lubricity of the medical catheter is improved; the solvent which volatilizes slowly is selected, so that the working life of the glue is greatly prolonged; meanwhile, the solvent selected in the glue has small side effects on human bodies and small harm to bodies of workers.

Owner:JIANGSU KANGJIN MEDICAL INSTR

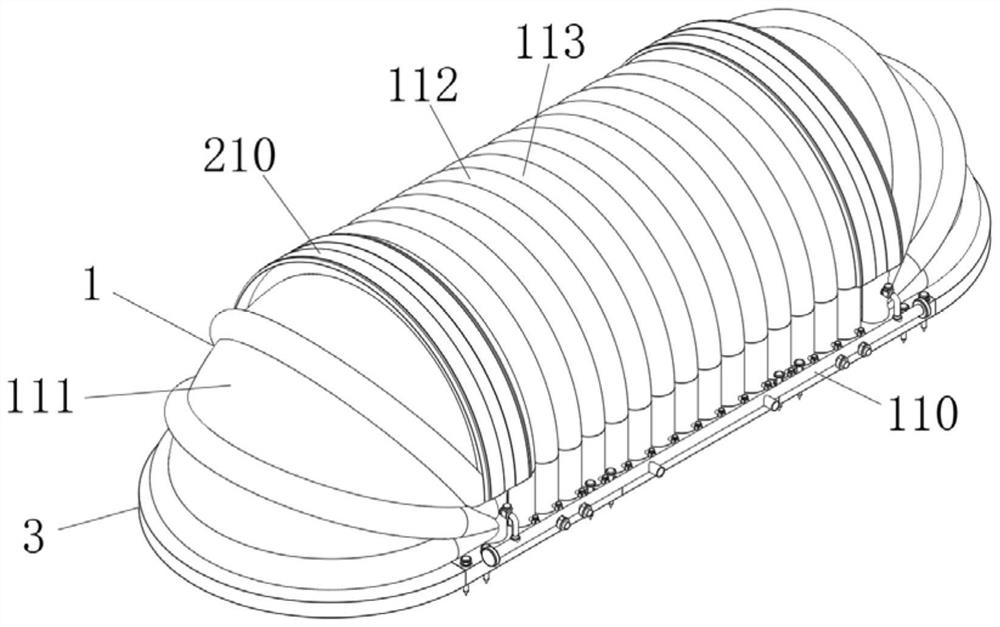

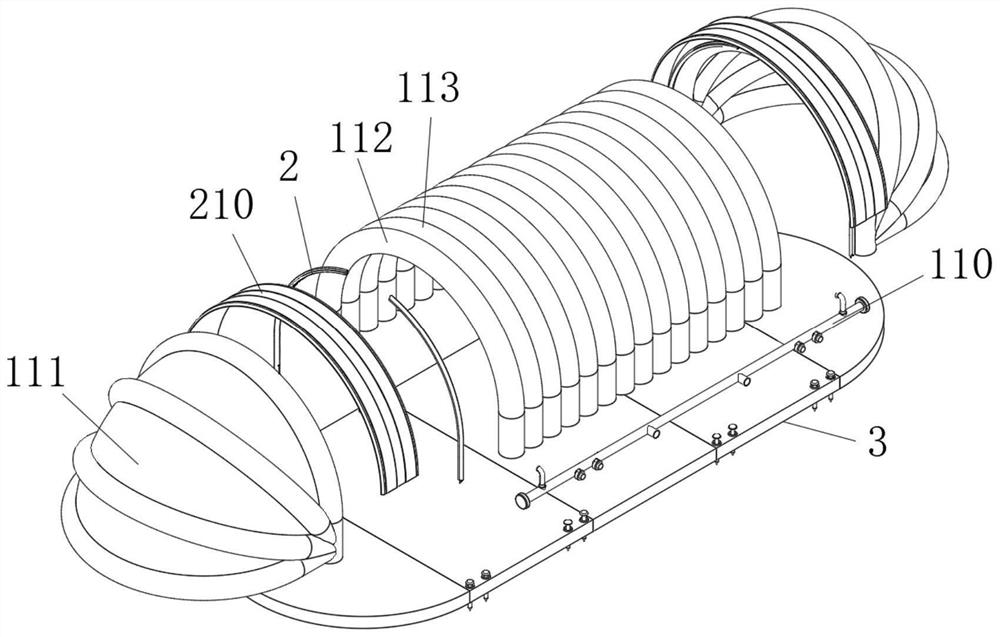

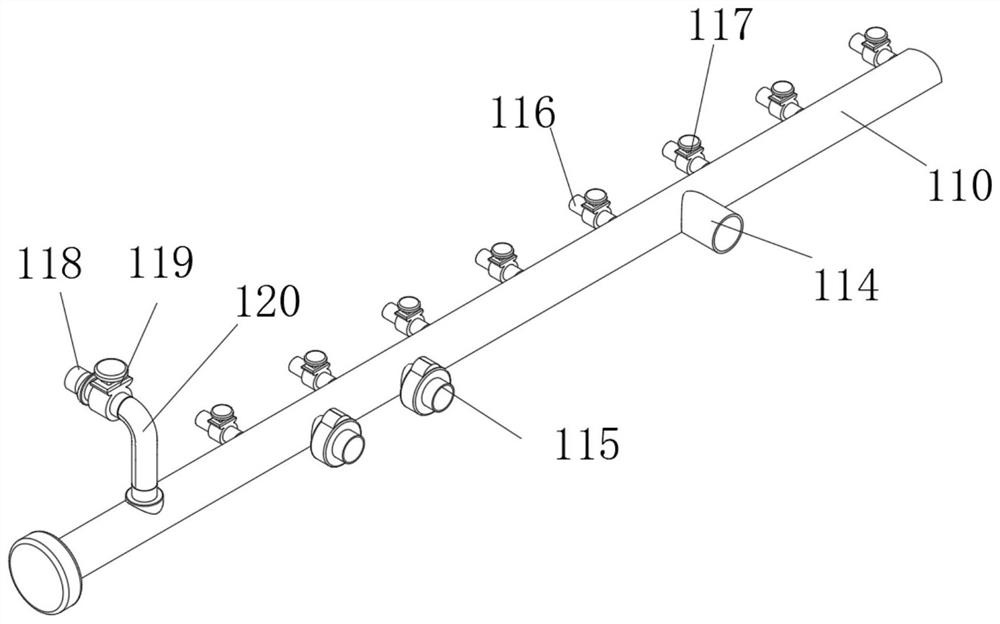

Independent pressure regulating hangar

The invention relates to the technical field of inflatable hangars, and particularly relates to an independent pressure regulating hangar. The independent pressure regulating hangar comprises a device body, wherein the device body comprises a main inflation pipeline, and PVC reinforced air bags are uniformly arranged on one surface of the main inflation pipeline. According to the independent pressure regulating hangar, column inflation pipelines, column electric control valves, gate inflation pipelines, gate electric control valves and the main inflation pipeline are arranged, so that the two gate inflation pipelines and the plurality of column inflation pipelines are used for independently inflating the PVC reinforced air bags, light air bags and hangar gate bodies of the hangar, the pressure is controlled by the column electric control valves and the gate electric control valves, the air inlet and the air outlet of each single air bag are controlled, the pressure balance can be effectively controlled, the situation that the hangar gate bodies do not reach a set value when the pressure of the hangar column bodies reaches the maximum value in the building process is prevented, and the safety of the air bags can be better guaranteed by the independent control according to various data of the air bags at different parts.

Owner:北京博奥瑞科技有限公司

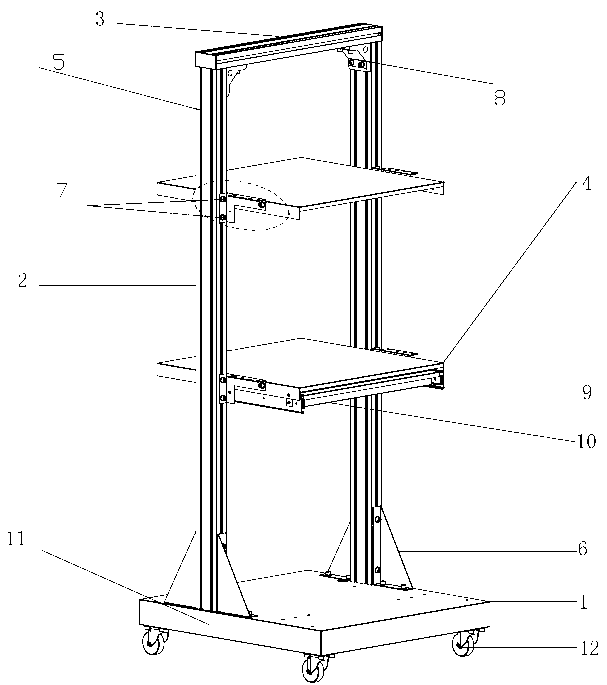

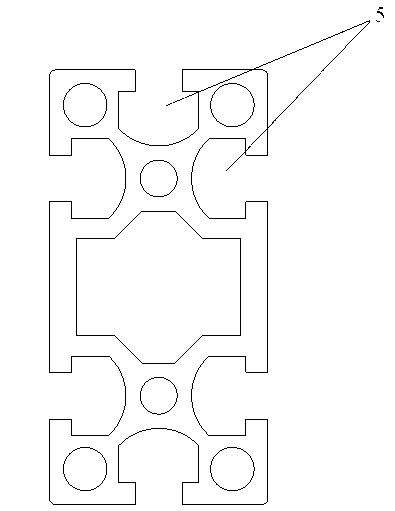

Multifunctional rack

ActiveCN102711408AFlexible structureConvenient to increase or decrease at willRack/frame constructionEngineering

The invention provides a multifunctional rack, which comprises a base, a beam, two upright posts and more than one platen, wherein bottom ends of the two upright posts are fixedly arranged on the base, the top ends of two upright posts and both ends of the beam are connected to form a door type frame, each upright post is respectively provided with four lateral surfaces, at least two non-adjacent lateral surfaces are provided with a reverse T-shaped groove, the upper end of the T shape in the T-shaped groove is located at the bottom of the groove, the lower end of the T shape is located on the lateral surfaces of the upright post, the T-shaped groove is used for containing more than one T-shaped bolt, the platen is located between the two upright posts, and the platen are in threaded connection with the upright posts through the T-shaped bolts. The multifunctional rack, provided by the invention, has the advantages of simple structure, convenience for assembly and disassembly, flexible use and strong expandability.

Owner:GUANGZHOU NANTIAN COMP SYST +1

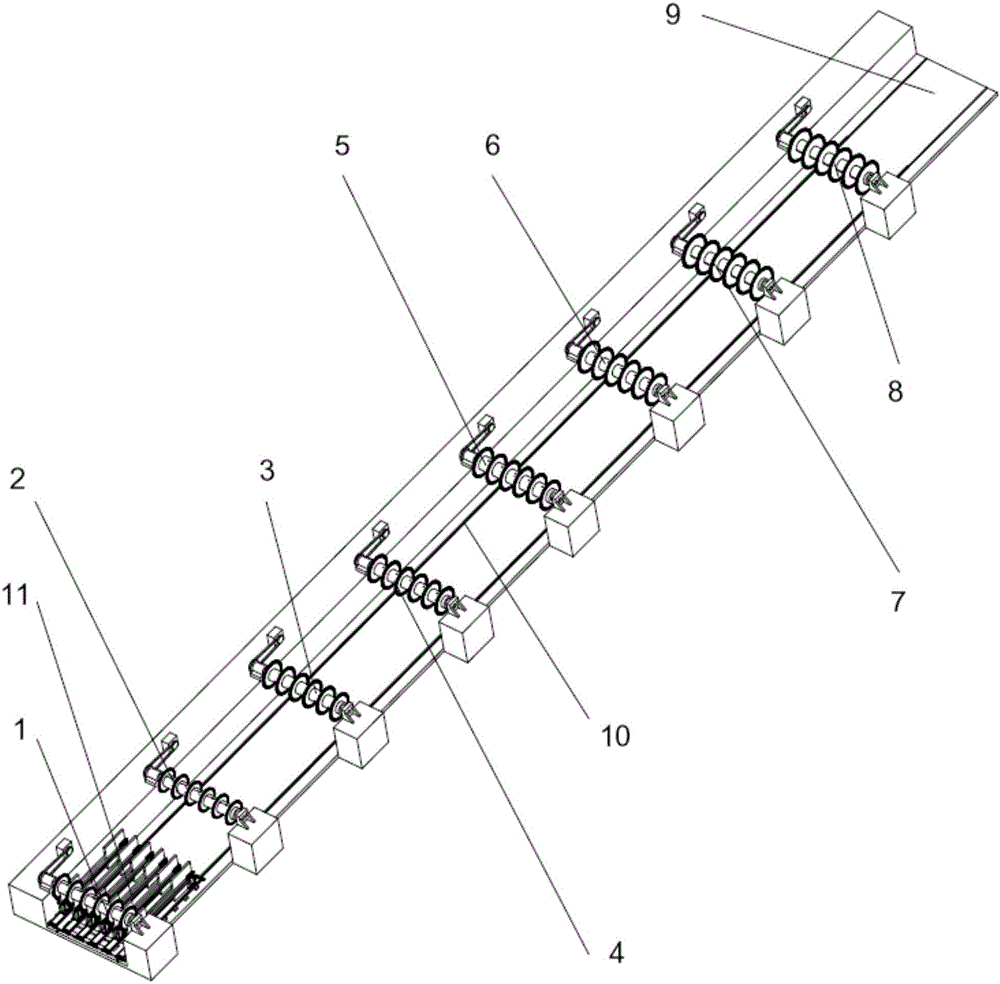

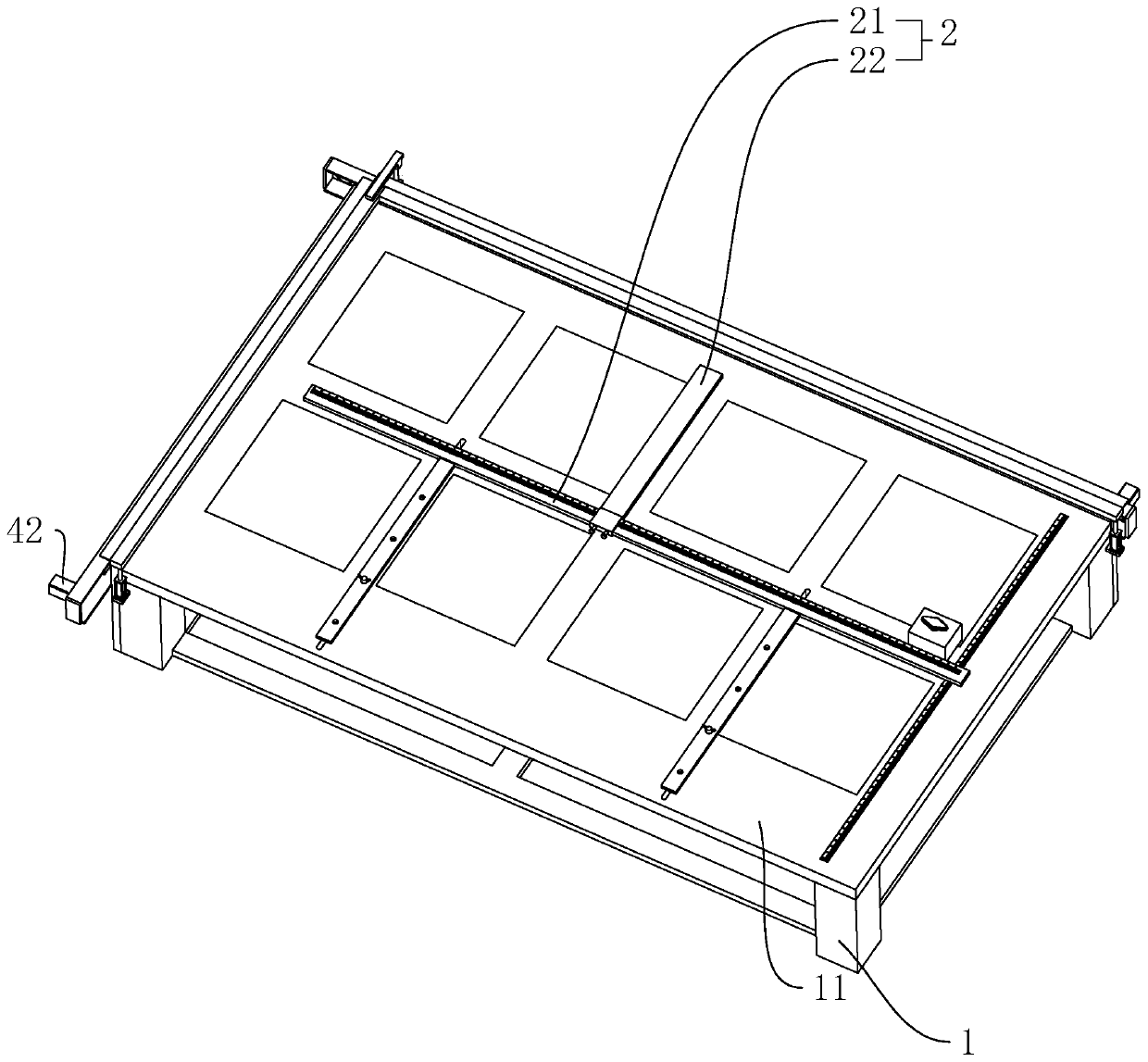

Formed honeycomb core cutting device

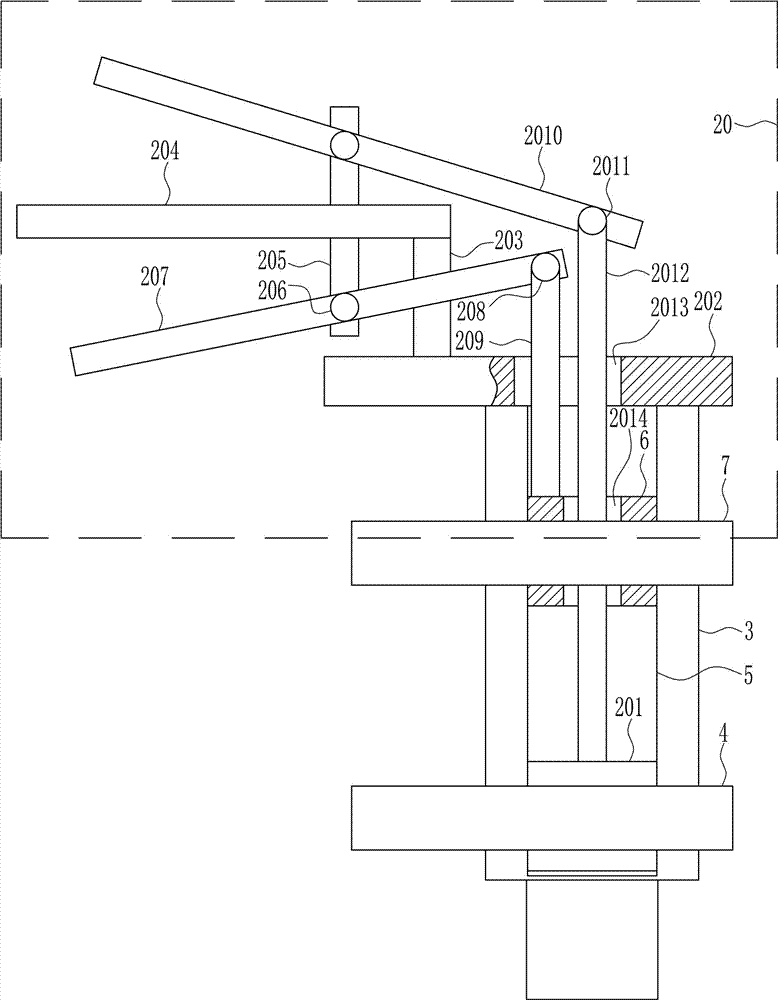

ActiveCN110142464ASmall sizeNot easy to scrapPositioning apparatusMetal-working holdersHoneycombEngineering

The invention discloses a formed honeycomb core cutting device. According to the technical scheme, the formed honeycomb core cutting device is characterized in that the formed honeycomb core cutting device comprises a rack and an installing plate fixed to the upper end of the rack, and a positioning mechanism is arranged at the upper end of the installing plate and comprises a positioning rod anda measuring rod; the two adjacent side walls of the installing plate are each connected with a cutting mechanism, and each cutting mechanism comprises a cutting base, a cutter and a cutting motor, wherein the upper end of the cutter is higher than the upper end face of the installing plate; and a compressing mechanism used for fixing a honeycomb core is connected to the upper end of the installingplate, the compressing mechanism comprises two compressing blocks and a plurality of compressing air cylinders used for driving the compressing blocks to vertically move, and the two compressing blocks are perpendicular to each other and close to the side walls, connected with the cutting mechanisms, of the installing plate. According to the formed honeycomb core cutting device, the structure isreasonable, the position of the honeycomb core is limited through the positioning mechanism, therefore, the size of the honeycomb core is more precise in the cutting process, and the machined honeycomb core is not prone to scrapping.

Owner:嘉善翔洲蜂窝制品有限公司

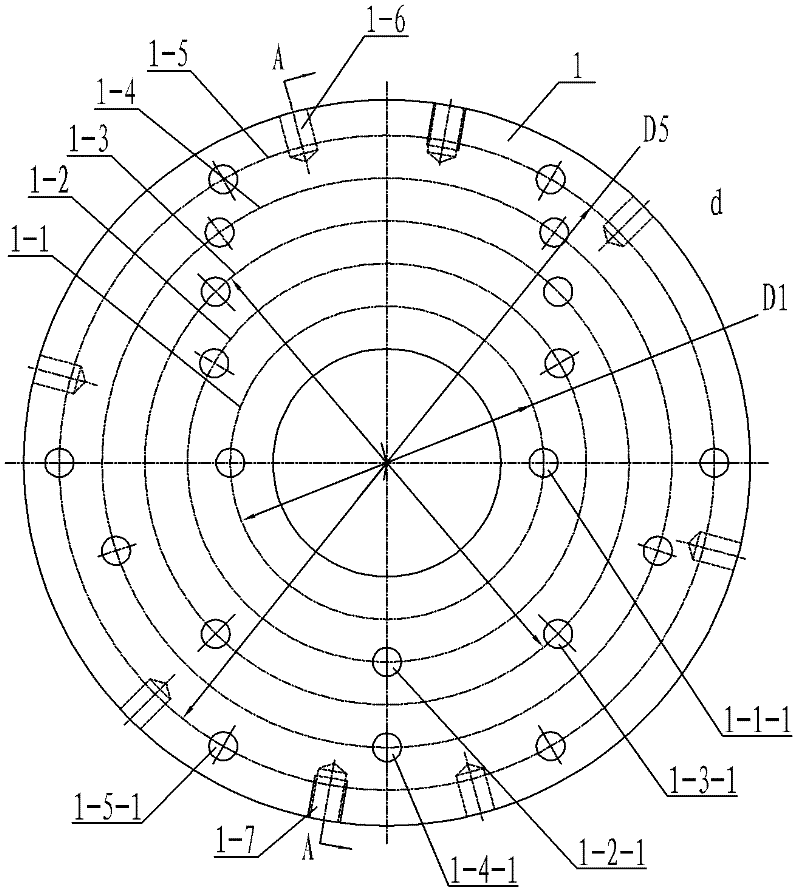

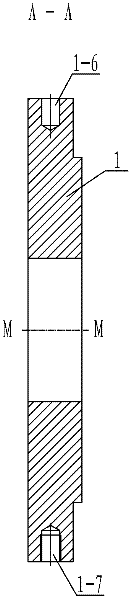

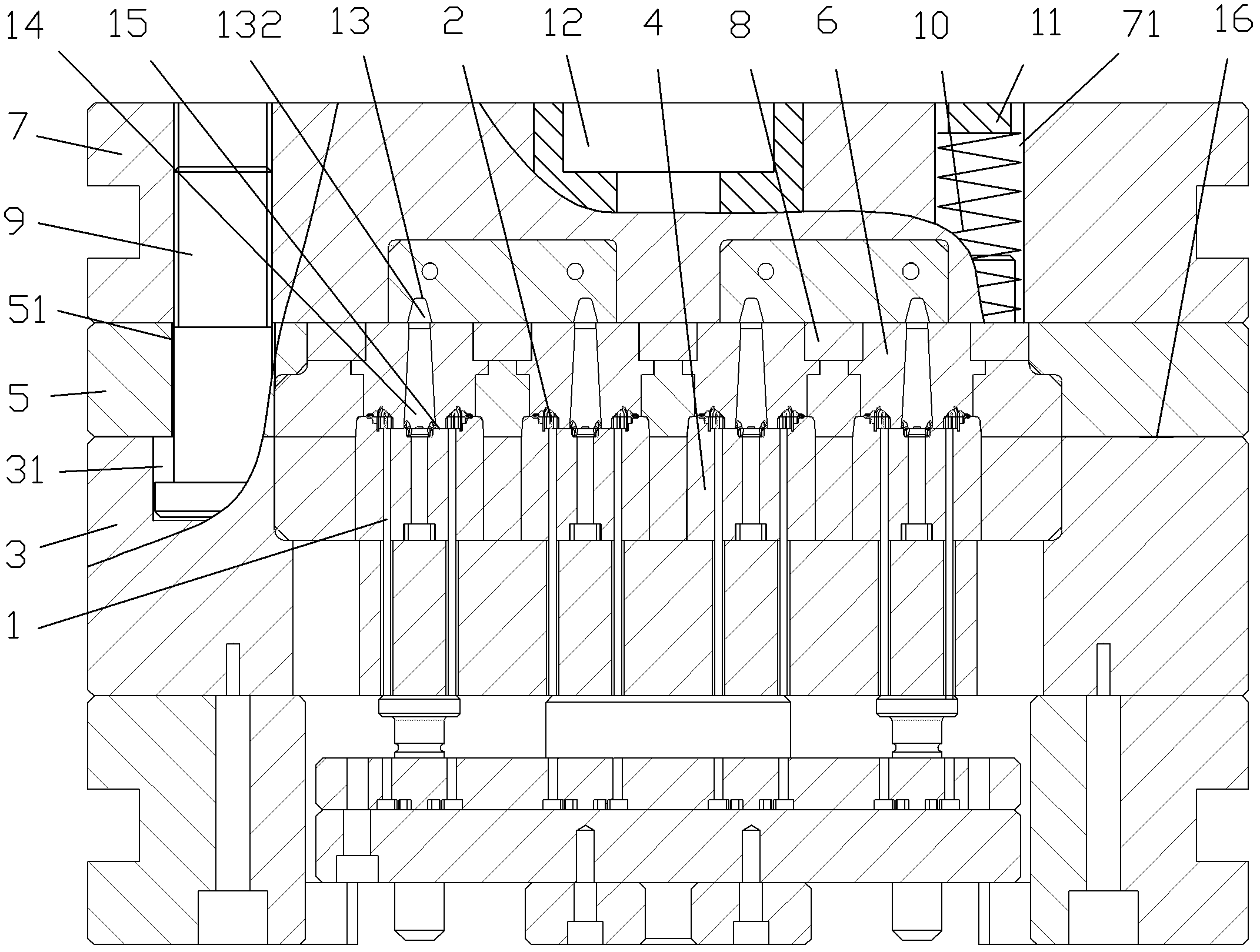

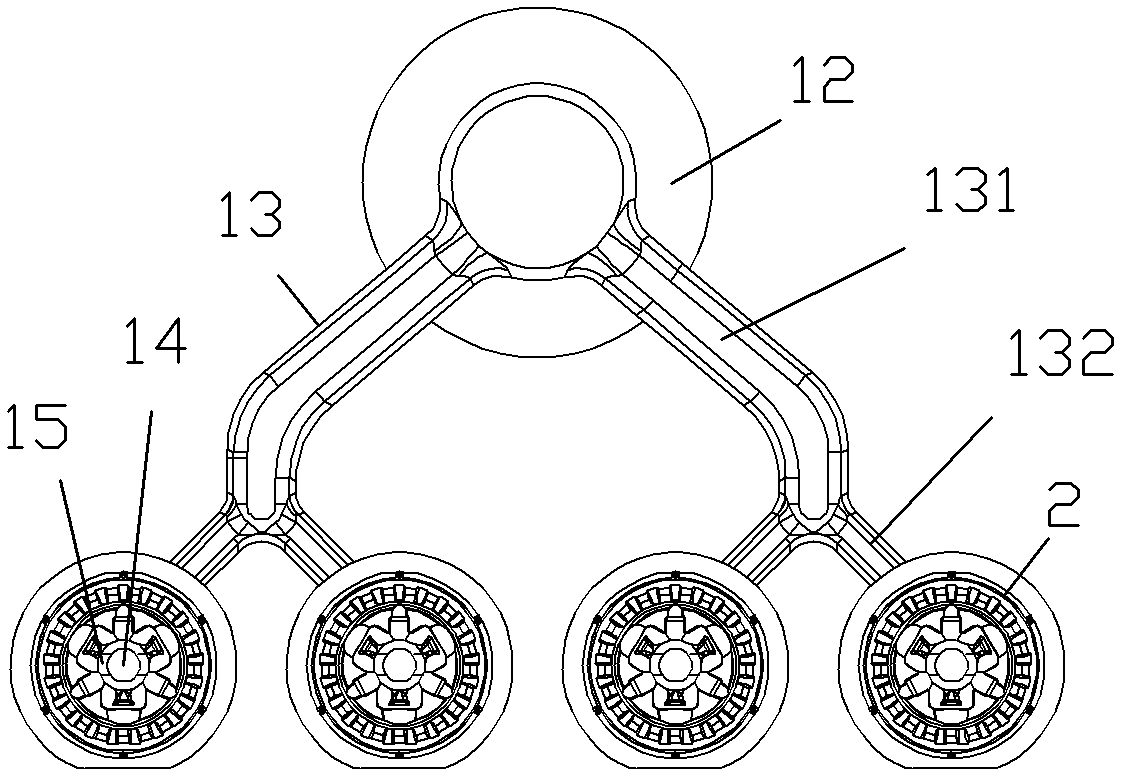

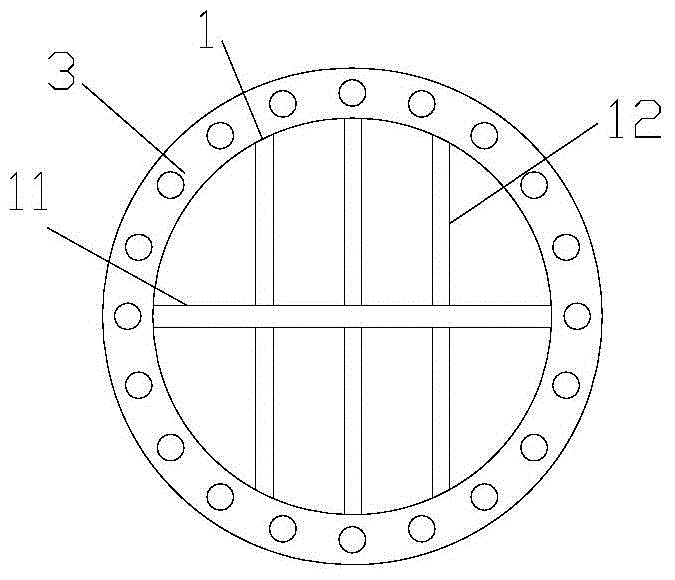

Center feeding die-casting mold

The invention relates to the field of die-casting molds and aims at providing a center feeding die-casting mold enabling a die-casting piece to be close in strength in all directions and not apt to deform or discard. The center feeding die-casting mold comprises a fixed mold, a moving mold, a runner system and a plurality of ejector rods located at the position of the moving mold. The fixed mold and the moving mold are enclosed to form a plurality of annular mold cavities. The runner system comprises a material barrel, cross runners and feeding runners with the same number as the mold cavities. At least two feeding ports evenly distributed in the circumferential directions are arranged outside the feeding runners which are coaxial with the mold cavities, the feeding ports are communicated with the inner circumferences of the mold cavities, and the material barrel is communicated with the feeding runners through the cross runners. The center feeding die-casting mold enables the die-casting piece to be close in strength in all directions and not apt to deform or discard.

Owner:宁波环亚机械制造有限公司

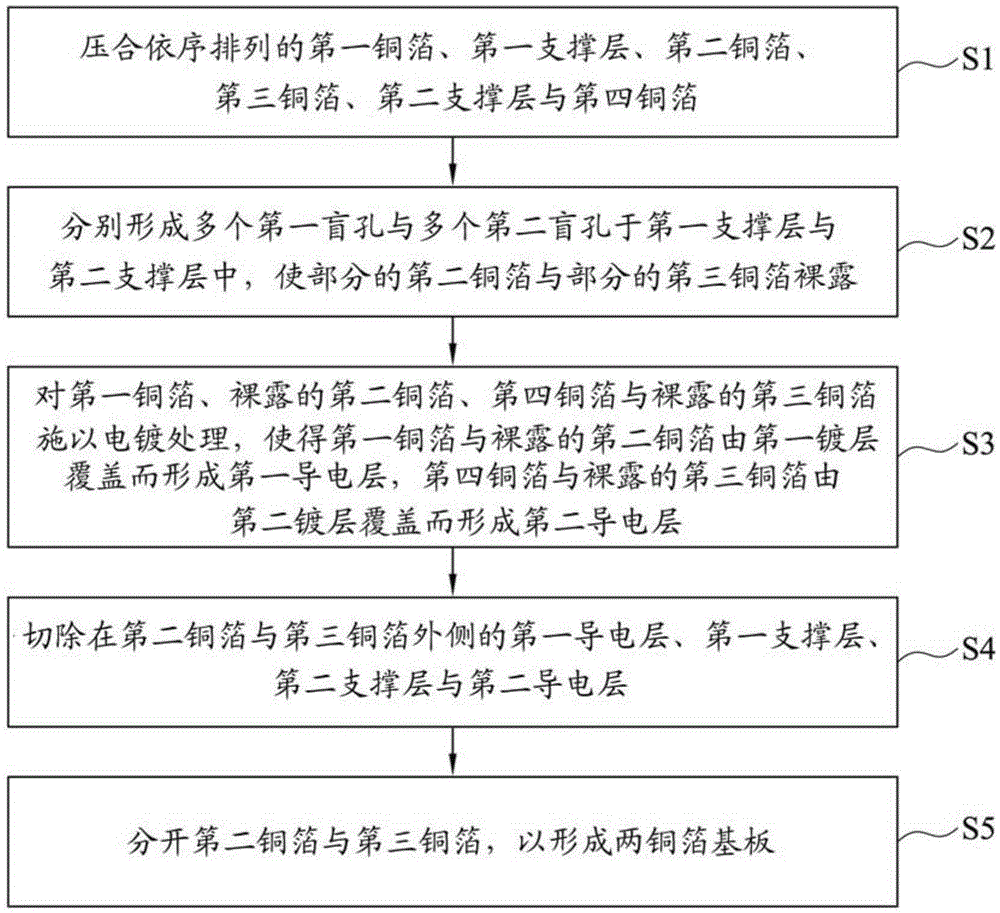

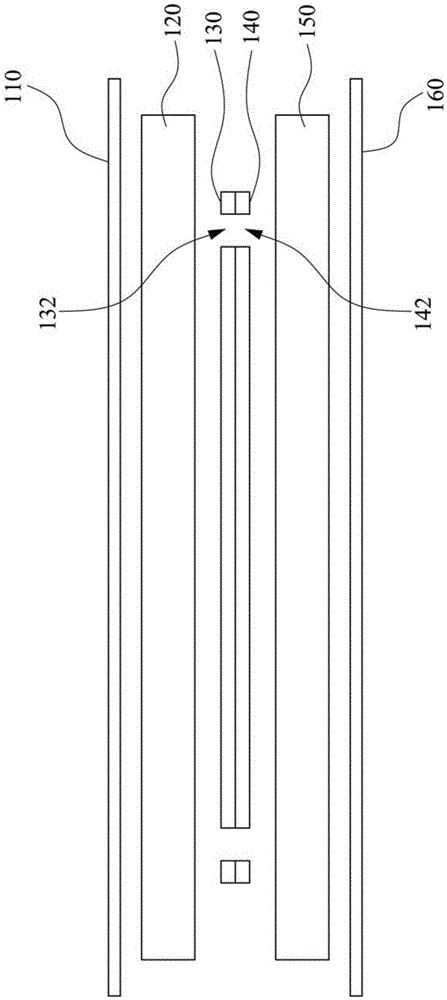

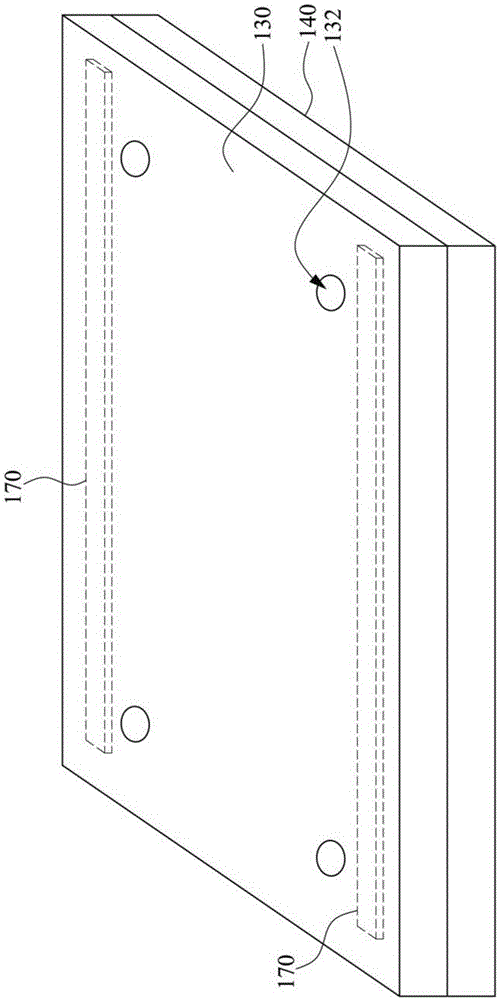

Copper foil substrate manufacturing method

ActiveCN106604545ALow costIncrease production capacityPrinted circuit simultaneous processingCopper foilElectroplating

The invention discloses a copper foil substrate manufacturing method. The copper foil substrate manufacturing method comprises the steps of: laminating first copper foil, a first supporting layer, second copper foil, third copper foil, a second supporting layer and fourth copper foil; forming a plurality of first blind holes in the first supporting layer, and forming a plurality of second blind holes in the second supporting layer, so that part of the second copper foil and part of the third copper foil are exposed; carrying out electroplating treatment on the first copper foil, the exposed second copper foil, the fourth copper foil and the exposed third copper foil, so that the first copper foil and the exposed second copper foil are covered by a first plating layer to form a first conductive layer, and the fourth copper foil and the exposed third copper foil are covered by a second plating layer to form a second conductive layer; cutting off the first conductive layer, the first supporting layer, the second supporting layer and the second conductive layer on the outer sides of the second copper foil and the third copper foil; and separating the second copper foil from the third copper foil.

Owner:TRIPOD WUXI ELECTRONICS

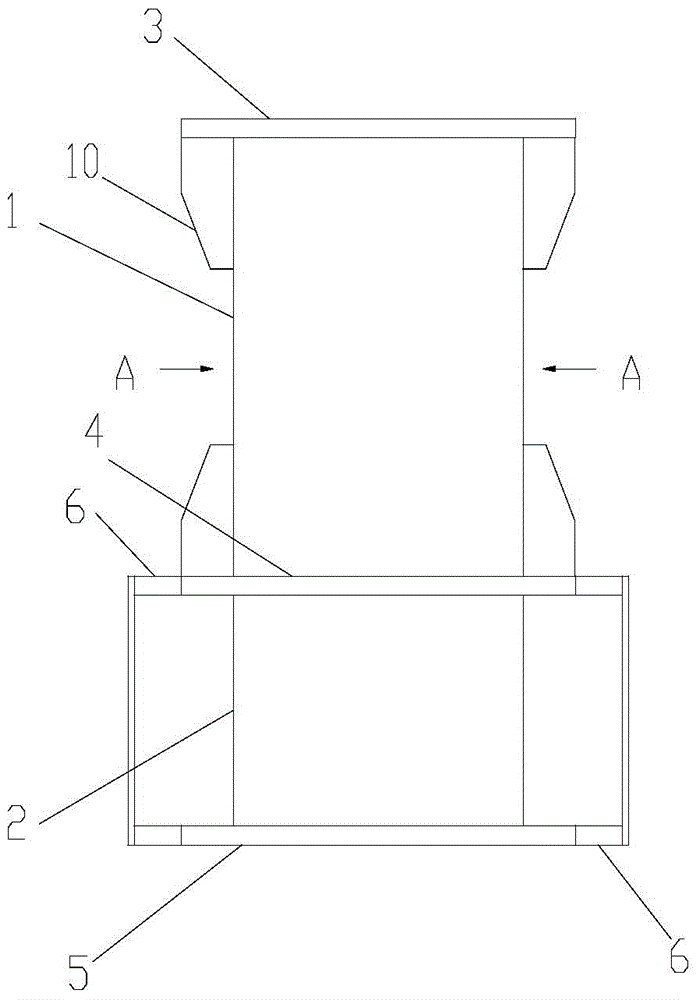

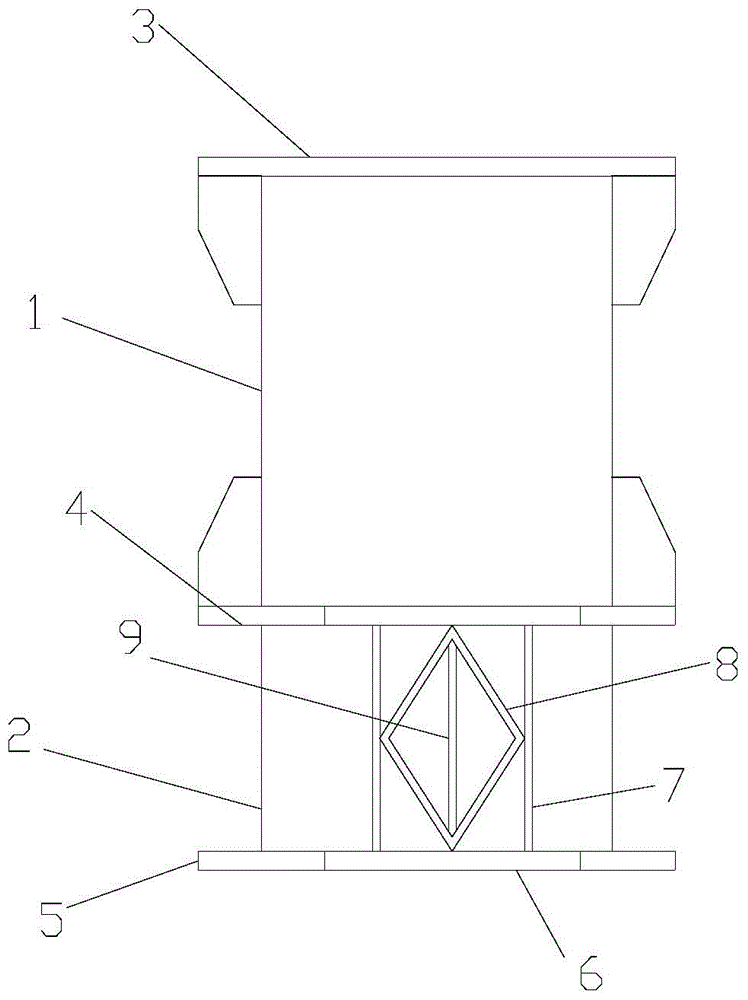

Fixing end of steel support

InactiveCN104452774AImprove affordabilityImproved for stabilityArtificial islandsExcavationsEngineeringStressed state

The invention relates to a fixing end of a steel support. The fixing end comprises a steel tube body and a connecting section. A first flange and a second flange are connected to the two ends of the steel tube body respectively, a central reinforcing plate and an inner reinforcing plate perpendicular to the central reinforcing plate are further welded in the steel tube body, the connecting section is connected with the second flange, a bottom plate is connected to the bottom of the connecting section, the diameter of the bottom plate is large than the diameter of the connecting section, lengthening plates are symmetrically arranged on the second flange and the bottom plate which are arranged on the two sides of the connecting section, a plurality of parallel supporting plates are arranged between the lengthening plates, and a diamond reinforcing plate is further arranged between the supporting plates. The fixing end of the steel support has the advantages of being capable of improving the stress state, stable in structure and the like.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

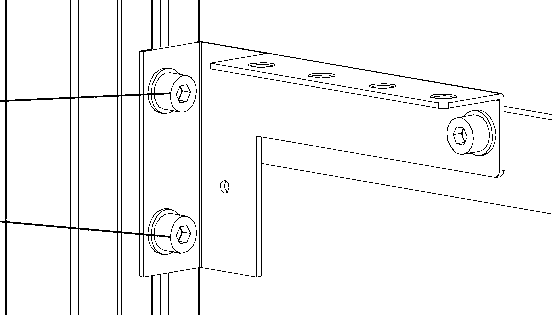

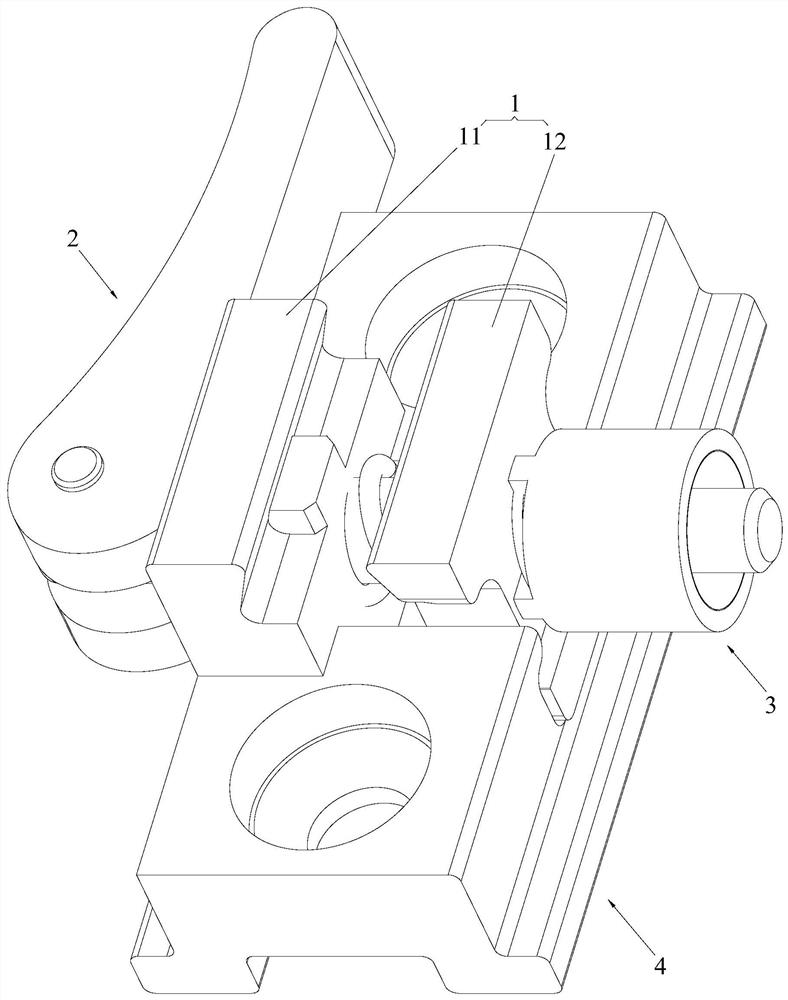

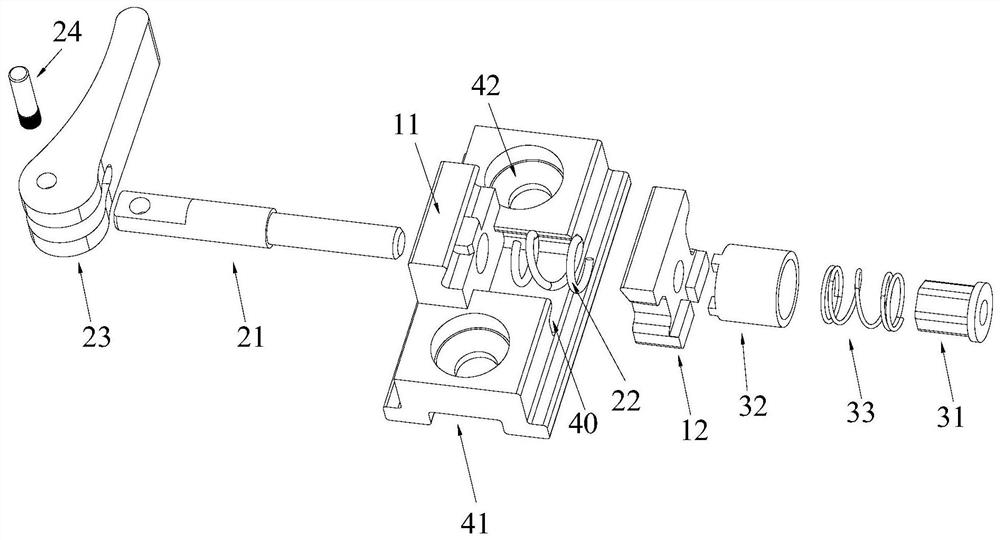

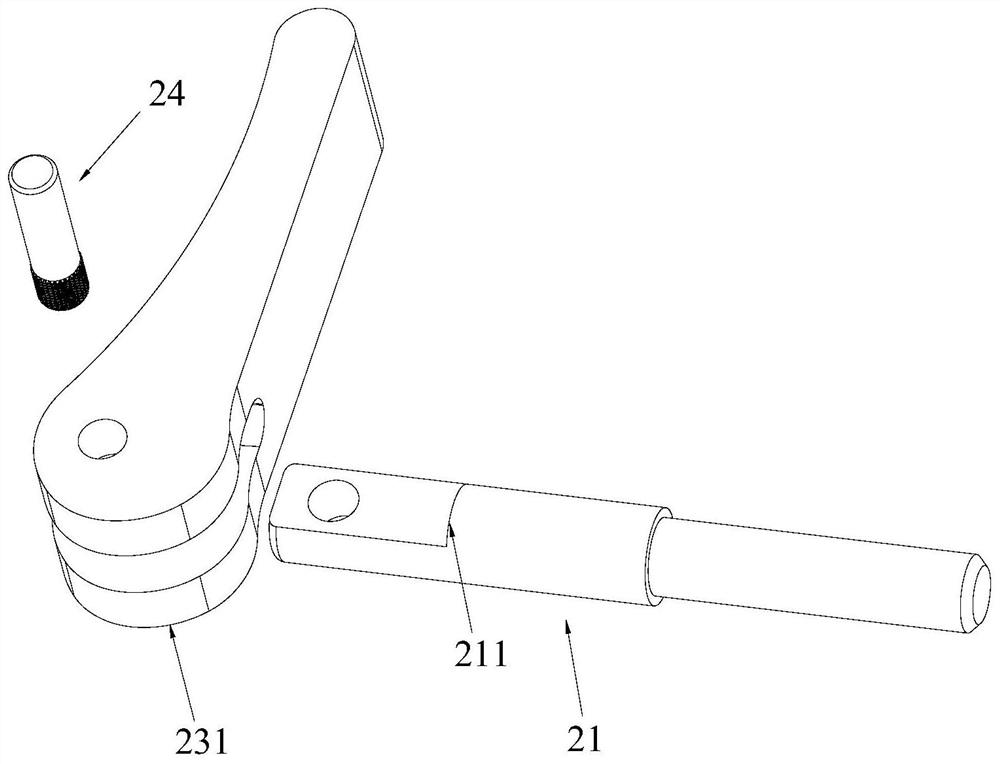

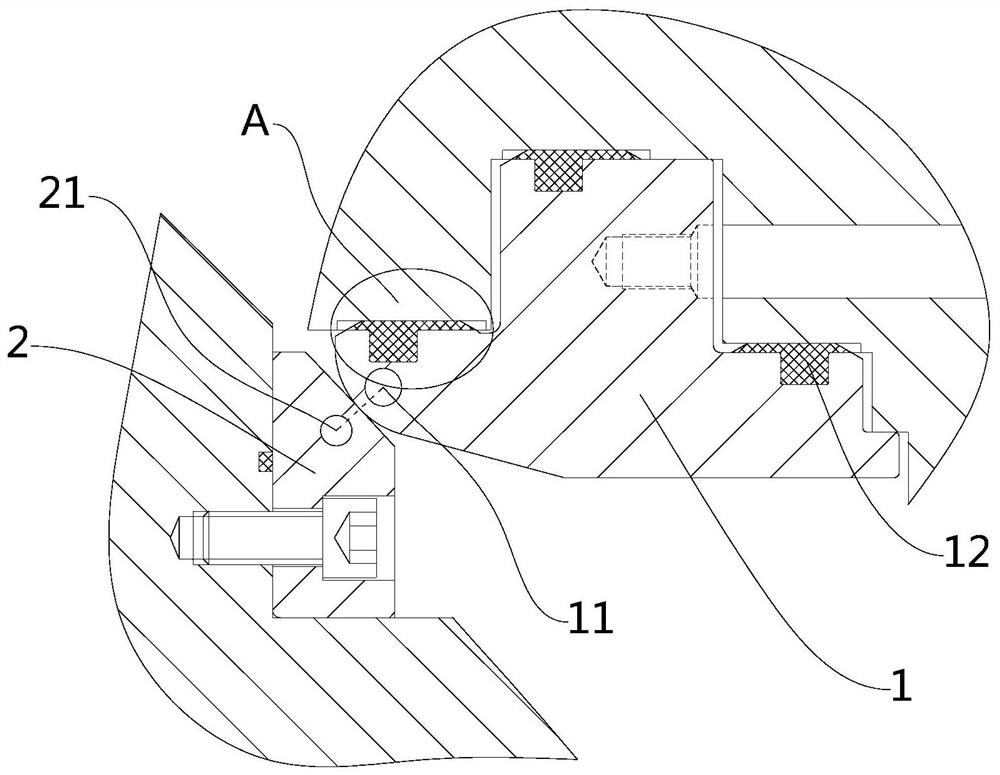

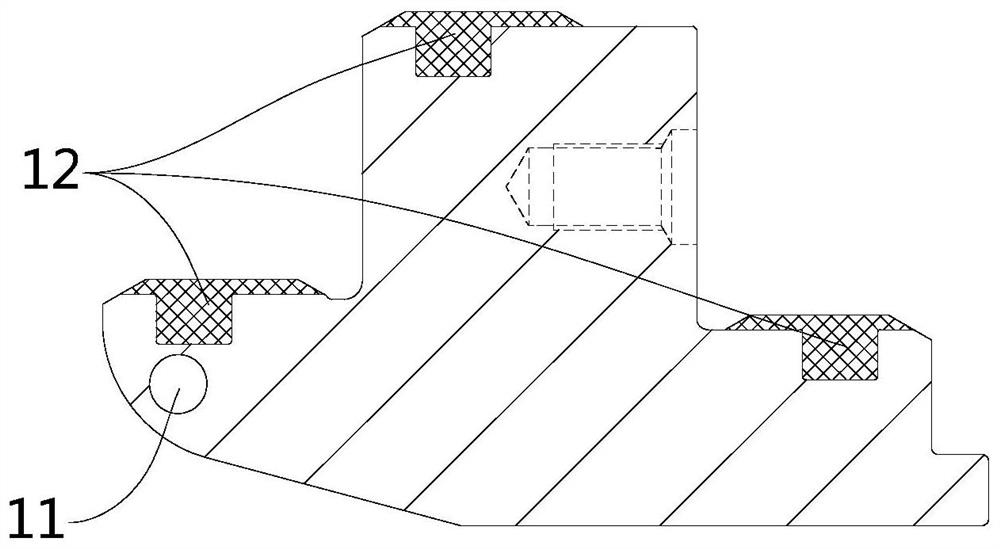

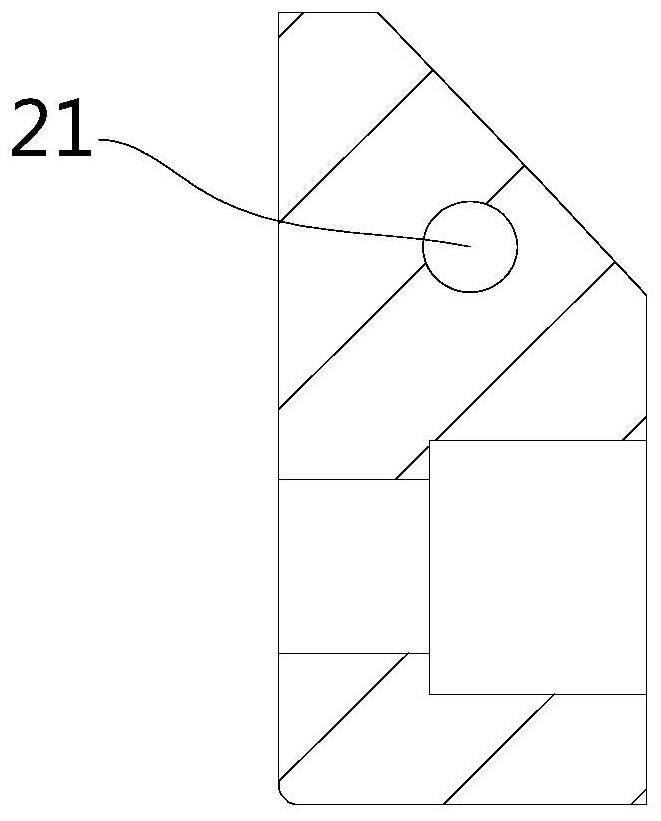

Quick-install structure and tactical lights

ActiveCN110530199BReduce scrap ratePreventing InconsistenciesLighting support devicesWeapon componentsMechanical engineeringElectrical and Electronics engineering

The invention provides a fast assembly structure, comprising: a clamping assembly, including a first clamping plate and a second clamping plate, the first clamping plate is fixedly arranged; a quick drive assembly, connected with the second clamping plate, and The second clamping plate can be driven to move to the first position, and the second clamping plate can form a clamping opening for clamping external equipment with the first clamping plate at the first position; the fine adjustment component is connected with the fast drive component and the A second clamping plate is attached and used to fine-tune the size of the clamping opening. A tactical light includes a light body and a quick-installation structure, the quick-installation structure is used to clamp the light body and install the light body on a rifle, and the light body is clamped between a first clamping plate and a second clamping plate. The quick assembly structure provided by the present invention can fine-tune the size of the clamping opening between the first clamping plate and the second clamping plate, can effectively improve the insufficient clamping force caused by manufacturing tolerances, and reduce the wear of the quick assembly structure Scrap rate.

Owner:深圳市海洋王绿色照明技术有限公司 +3

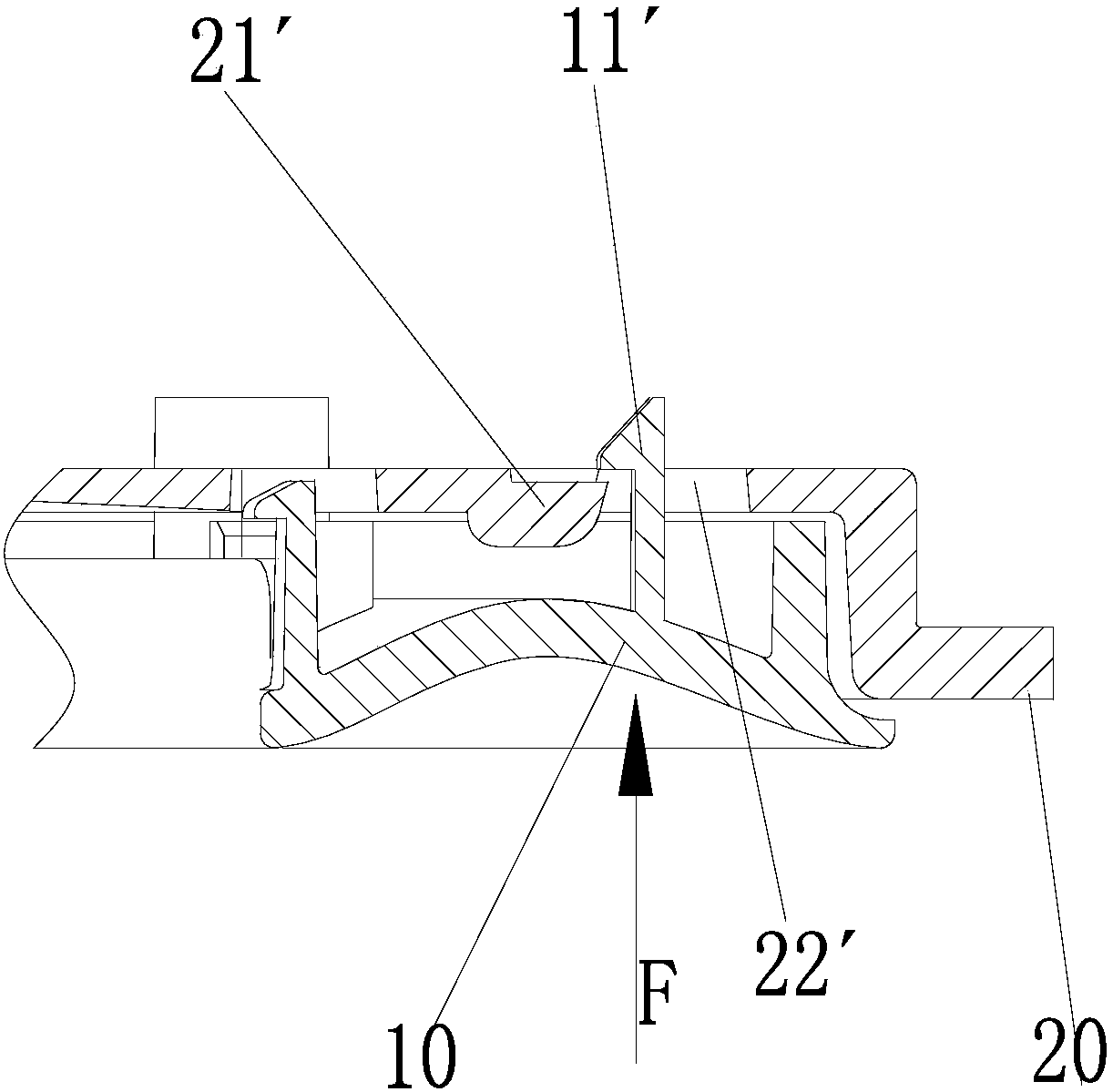

A ball valve working sealing assembly with an elastic central hole

The invention discloses a working sealing assembly of a ball valve with an elastic central hole, comprising a movable sealing ring (1) movably connected with a ball valve body and a fixed sealing ring (2) fixed on a ball valve valve, the movable sealing ring The inside of (1) is provided with the first central hole (11) of annular penetration, and the interior of the fixed sealing ring (2) is provided with the second central hole (21) of annular penetration; the first central hole ( 11) and the second center hole (21) are formed with two circles on the cross-section of the central axis of the movable seal ring (1), and the line connecting the centers of the two circles passes through the movable seal ring (1) and the fixed seal ring (2) contact parts. The invention has the advantages of good sealing performance and long service life.

Owner:STATE GRID CORP OF CHINA +2

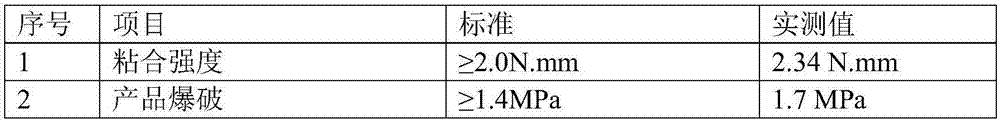

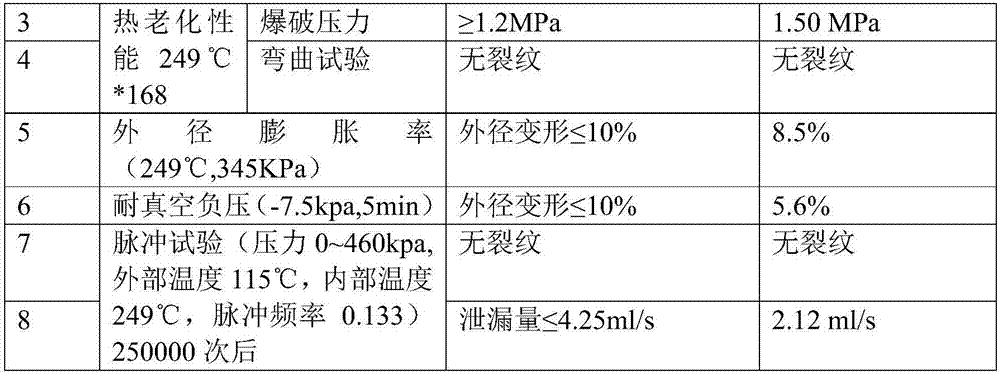

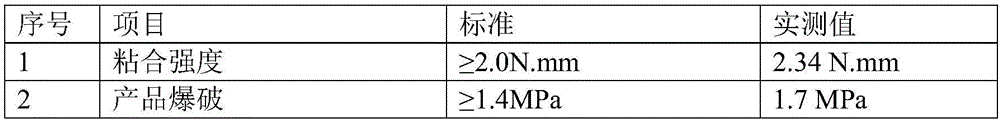

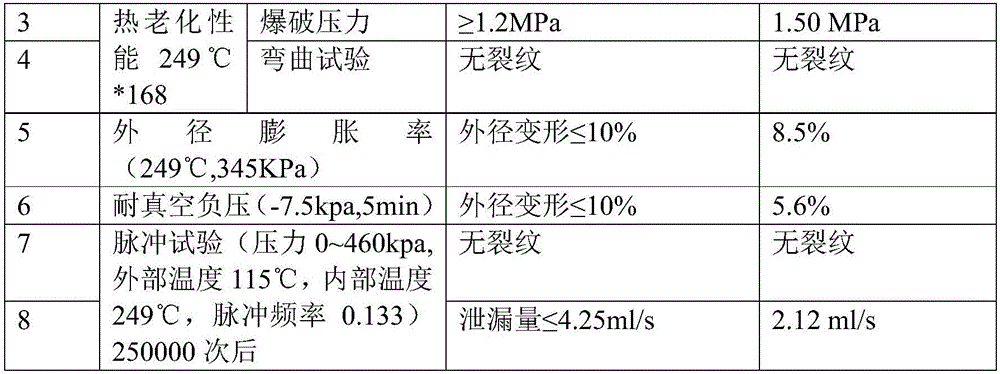

A production process of an automobile turbocharger intake hose

Owner:NINGBO FENGMAO FAR EAST RUBBER

Production process of air inlet rubber tube of automobile turbocharger

The invention discloses a production process of an air inlet rubber tube of an automobile turbocharger. The production process comprises the following steps: raw material preparation; mixing; rolling; fabric cutting; coiling; sleeving; sizing; and vulcanization. A prevulcanization step is additionally arranged between rolling and fabric cutting, wherein the prevulcanization temperature is 190+ / -5 DEG C, and the time is 8-10min. The production process disclosed by the invention improves the percent of pass of production while improving the product performance, thereby reducing the production cost of a product.

Owner:NINGBO FENGMAO FAR EAST RUBBER

Tool for processing air extracting pipe of condenser of turbine

ActiveCN102294503BNot easy to scrapPrecise positioningPrecision positioning equipmentBoring/drilling machinesEngineeringTurbine

The invention discloses a tool for processing an air extracting pipe of a condenser of a turbine, which relates to an auxiliary tool for processing the air extracting pipe of the condenser of the turbine and aims to solve the problems that a processed pipe is supported by two pieces of V-shaped iron, air extracting holes are directly drilled on a radial drill, the positions of the drilled holes are inaccurate and the drilled holes have low precision in the conventional tool for processing the air extracting pipe of the condenser of the turbine. A rotating rod is arranged in an installation hole; a positioning plate and an indexing disk are arranged in parallel; the center line of the positioning plate is opposite to the center line of the indexing disk; two long holes are formed between afirst positioning pitch circle and a second positioning pitch circle on the positioning plate; the width of each long hole is equal to the diameter of an indexing hole; an included angle between the two long holes is 90 degrees; positioning pins are arranged in the long holes and the indexing holes; the lower end of the positioning plate is connected with a bearing seat by a seat plate; the indexing disk, the positioning plate, the components of the bearing seat and two support frames are sequentially arranged along a longitudinal direction; and the vertical center lines of frame bodies and the center line of the indexing disk are positioned in the same plane. The tool is used for processing the air extracting pipe of the condenser of the turbine.

Owner:HARBIN TURBINE +1

A kind of medical catheter bonding glue and preparation method thereof

ActiveCN113278394BHigh bonding strengthSolve the problem of whiteningMineral oil hydrocarbon copolymer adhesivesRosin adhesivesCyclohexanoneEthyl acetate

Owner:JIANGSU KANGJIN MEDICAL INSTR

A shaped honeycomb core cutting device

ActiveCN110142464BSmall sizeNot easy to scrapPositioning apparatusMetal-working holdersHoneycombElectric machinery

The invention discloses a formed honeycomb core cutting device. According to the technical scheme, the formed honeycomb core cutting device is characterized in that the formed honeycomb core cutting device comprises a rack and an installing plate fixed to the upper end of the rack, and a positioning mechanism is arranged at the upper end of the installing plate and comprises a positioning rod anda measuring rod; the two adjacent side walls of the installing plate are each connected with a cutting mechanism, and each cutting mechanism comprises a cutting base, a cutter and a cutting motor, wherein the upper end of the cutter is higher than the upper end face of the installing plate; and a compressing mechanism used for fixing a honeycomb core is connected to the upper end of the installingplate, the compressing mechanism comprises two compressing blocks and a plurality of compressing air cylinders used for driving the compressing blocks to vertically move, and the two compressing blocks are perpendicular to each other and close to the side walls, connected with the cutting mechanisms, of the installing plate. According to the formed honeycomb core cutting device, the structure isreasonable, the position of the honeycomb core is limited through the positioning mechanism, therefore, the size of the honeycomb core is more precise in the cutting process, and the machined honeycomb core is not prone to scrapping.

Owner:嘉善翔洲蜂窝制品有限公司

Anti-dropping assembly structure and refrigerator

InactiveCN110440508APrevent disengagementEasy to installLighting and heating apparatusDomestic refrigeratorsStructural stabilityRefrigerated temperature

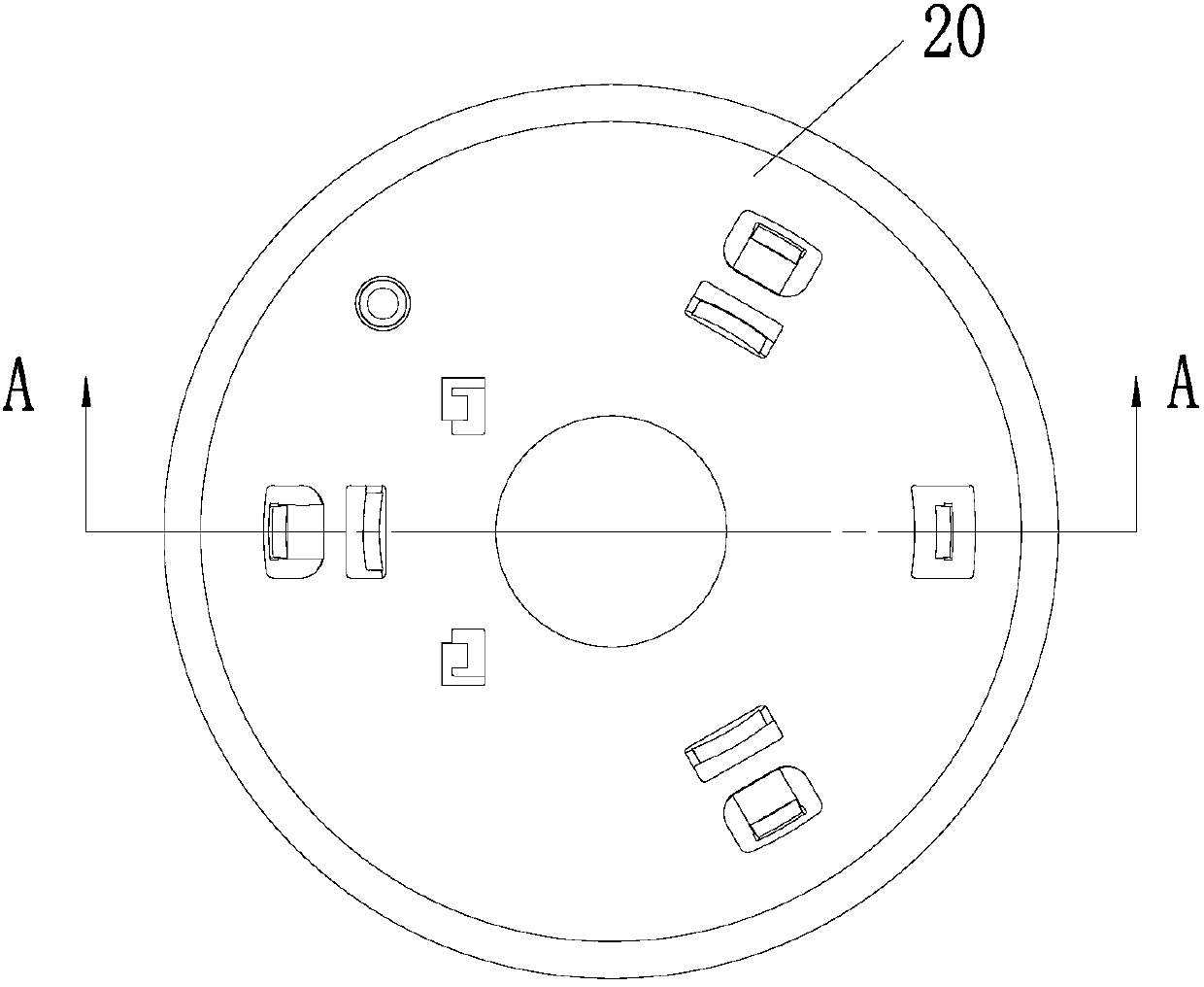

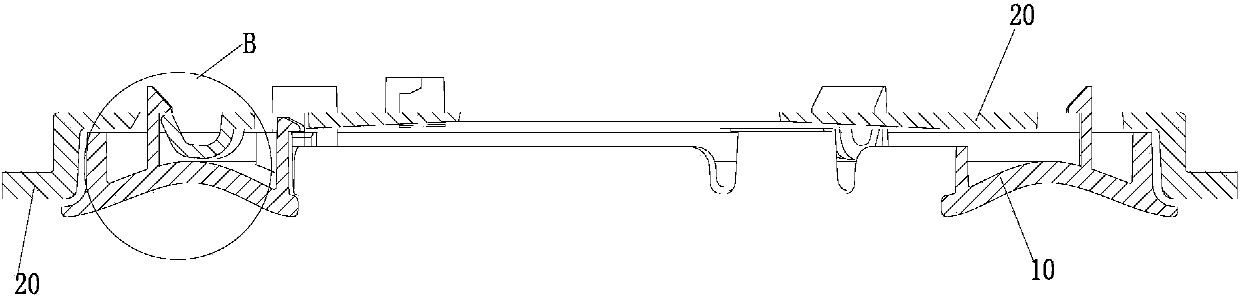

The invention relates to the field of anti-dropping assembling between two parts, and discloses an anti-dropping assembly structure and a refrigerator. The anti-dropping assembly structure comprises afirst assembly part (10) and a second assembly part (20), wherein the first assembly part is provided with a clamping part (11), the second assembly part is provided with an inclined elastic stop part (21), the clamping part is clamped on the elastic stop part by deforming the elastic stop part, the difference value between the length (X) of the elastic stop part and the length (L) of projectionof the elastic stop part in the horizontal direction is larger than the matching size (L1) between the clamping part and the elastic stop part, and the matching size is the size of contacting betweenthe clamping part, in the direction where the clamping part drops off from the elastic stop part, and the elastic stop part. According to the anti-dropping assembly structure, the first assembly partcan be conveniently assembled and fixed to the second assembly part, structural stability is good, dropping and scrapping are not prone to cause, and the production efficiency is high.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

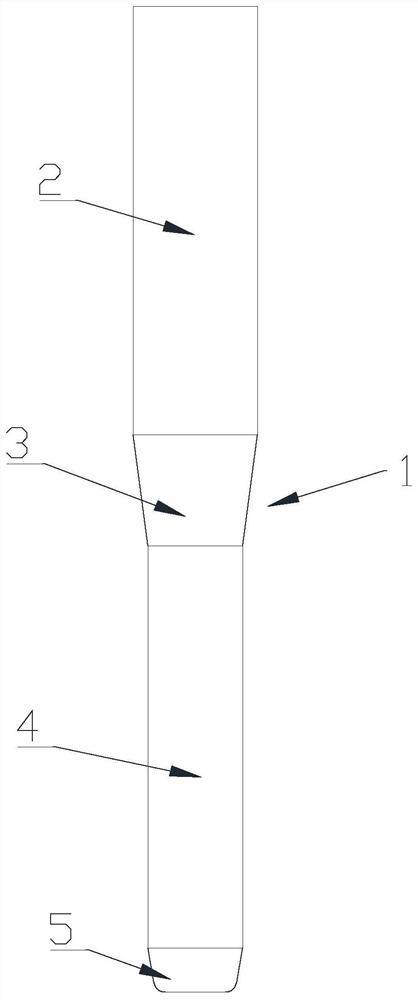

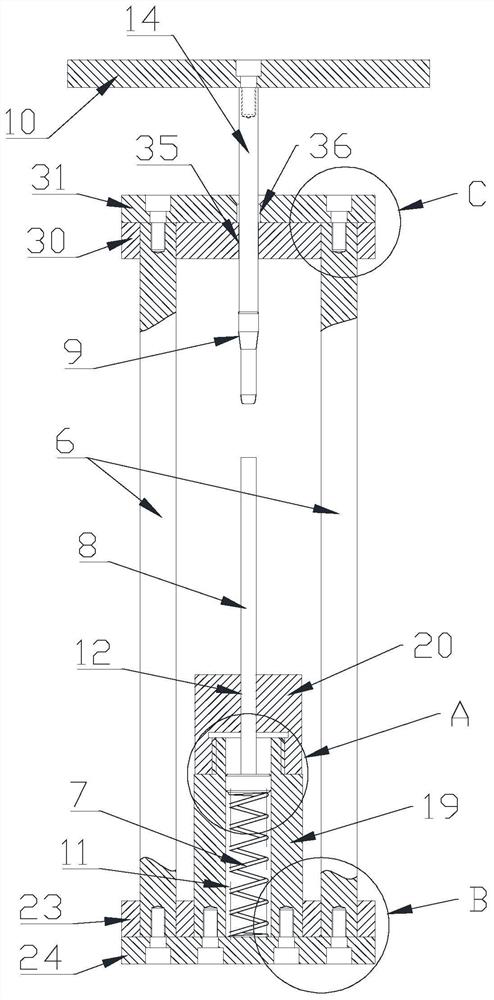

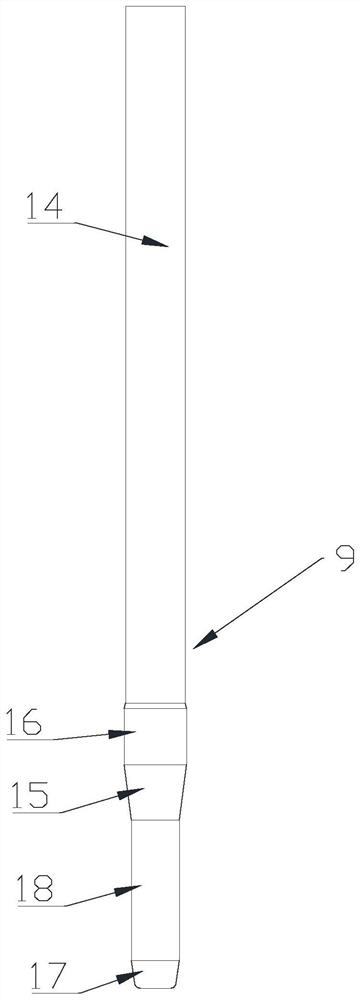

Oil seal transition sleeve and opening expanding tool for machining oil seal transition sleeve

The invention relates to the field of transition sleeves, in particular to an oil seal transition sleeve which is of a thin-wall hollow structure. The oil seal transition sleeve comprises a connecting pipe, a transition pipe and a guide pipe, the connecting pipe is arranged at one end of the transition pipe, the guide pipe is arranged at the other end of the transition pipe, the diameter of the connecting pipe is larger than that of the guide pipe, and the transition pipe is in a circular truncated cone shape. The invention further relates to an opening expanding tool for machining the oil seal transition sleeve, the opening expanding tool for machining the oil seal transition sleeve comprises a lower die lower base, a lower die upper base, a supporting column, a positioning base, a spring, a positioning rod, the opening expanding die and an upper die bottom plate moving up and down, structural design is reasonable, and the connecting pipe and the transition pipe can be conveniently formed through opening expanding machining. According to the oil seal transition sleeve and the opening expanding tool for machining the oil seal transition sleeve, the oil seal transition sleeve is reasonable in structural design and convenient to machine and manufacture, the opening expanding tool is reasonable in structural design, the oil seal transition sleeve meeting actual requirements can be efficiently machined, oil seal transition sleeves of different specifications can be conveniently machined after the tool is replaced. In this way, actual machining requirement can be better met.

Owner:浙江亚之星汽车部件有限公司

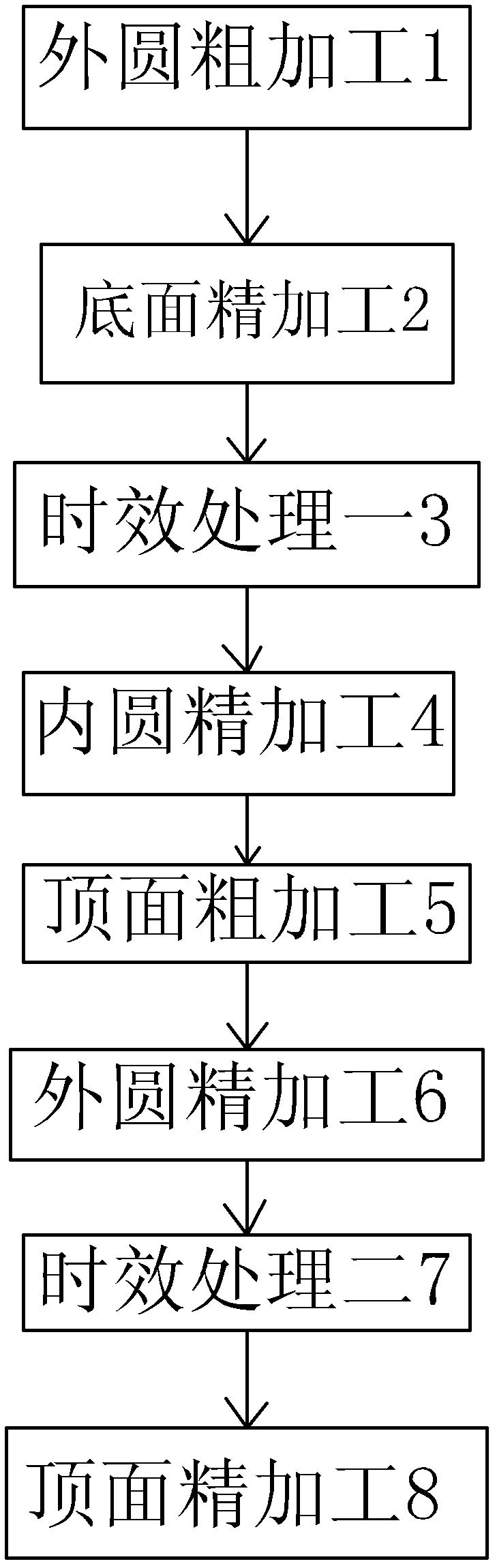

Machining method for stainless steel seal rings in large valves

ActiveCN102649164BMeet the precision requirementsReduce deformation rateTurning machinesEngineeringMachining process

Owner:浙江坤博精工科技股份有限公司

Post production process of thin panels

The invention discloses a post production process of thin panels. The post production process includes subjecting a PANEL to preforming before a gold immersion procedure, subjecting the preformed PANEL to gold immersion, integral panel testing and final check and verification, and integral panel surface treatment procedure sequentially, subjecting the PANEL subjected to the integral panel surface treatment to second SET panel forming and screwing, subjecting SET panels to secondary check and verification, package and delivery. The preforming treatment step includes screwing shape of each SET panel on the PANEL before gold immersion, connection parts are reserved among the SET panels, and blue adhesive layers are attached on two plate surfaces of the integral PANEL after the PANEL is subjected to preforming. By producing the thin plates by the post production process, quality of PCBs (printed circuit boards) of the thin panels can be effectively improved, and rejection rate is decreased.

Owner:南通胜宏科技有限公司

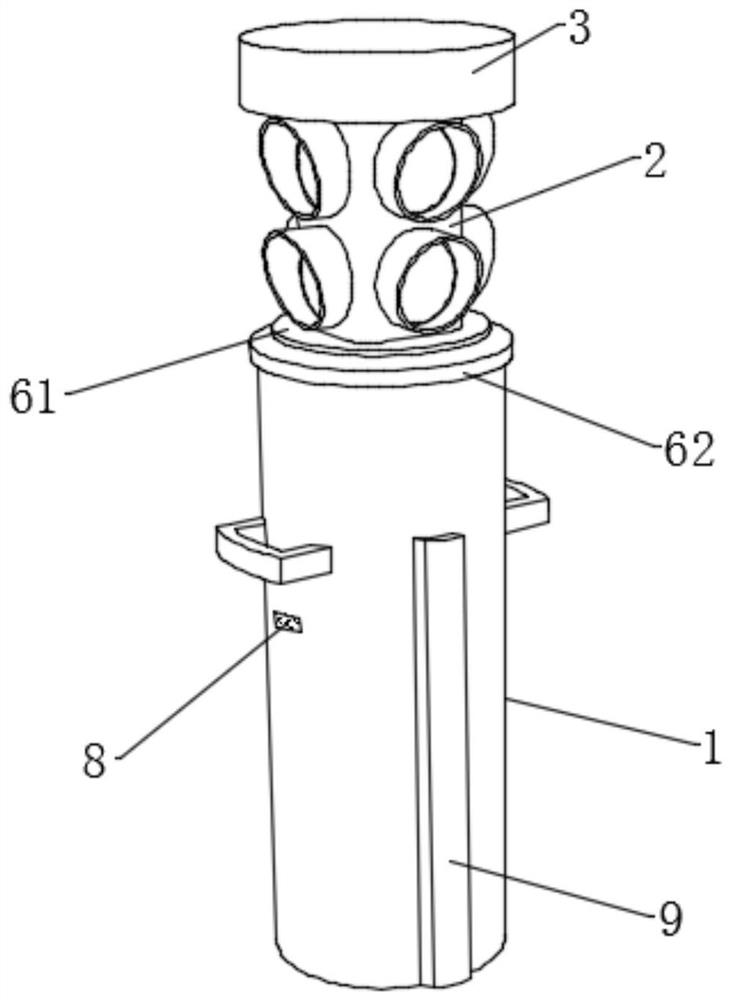

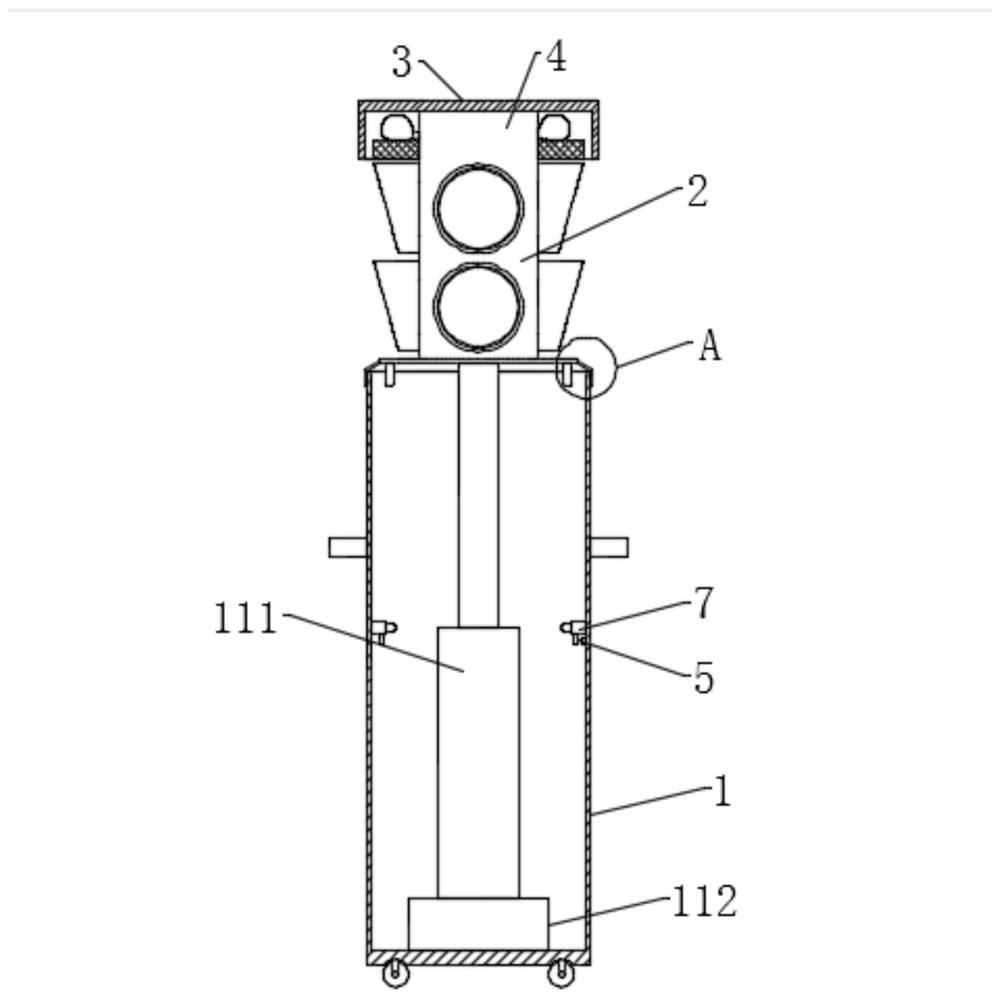

A protective mobile traffic signal light

ActiveCN111047888BRealize monitoringAchieve protectionRoad vehicles traffic controlMachines/enginesTraffic signalLiquid level measurement

The invention discloses a protective mobile traffic signal lamp, which belongs to the field of photoelectric products. A protective mobile traffic signal lamp comprises an outer shell, a liquid level measuring instrument is installed at the outer end of the outer shell, and a liquid level measuring instrument is installed at the inner bottom end of the outer shell. There is a battery, the upper end of the battery is connected with a telescopic cylinder, the upper end of the output shaft of the telescopic cylinder is fixedly connected with a positioning plate, the upper end of the positioning plate is fixedly connected with the main lamp body, the upper end of the main lamp body is fixedly connected with a top cover, and the inner end of the top cover Installed with a sealing structure, it is convenient to monitor the liquid level through the liquid level measuring instrument, so that the protection of the main lamp body can be realized when the liquid level is high, and the gas in the sealing structure can be exchanged between the storage bag and the sealing bag , strengthen the sealing between the outer shell and the top cover, so that the main lamp body is not easy to be scrapped due to water ingress when soaked in water, and at the same time lock the connection between the top cover and the outer shell when not in use, reducing the probability of the top cover being opened, so that the inside Parts are not easy to lose.

Owner:杭州昕华信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com