Center feeding die-casting mold

A center-feeding, die-casting mold technology, applied in the field of die-casting molds, can solve problems such as scrapping and deformation of die-casting parts, and achieve the effects of easy exhaust, convenient demoulding and material return, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

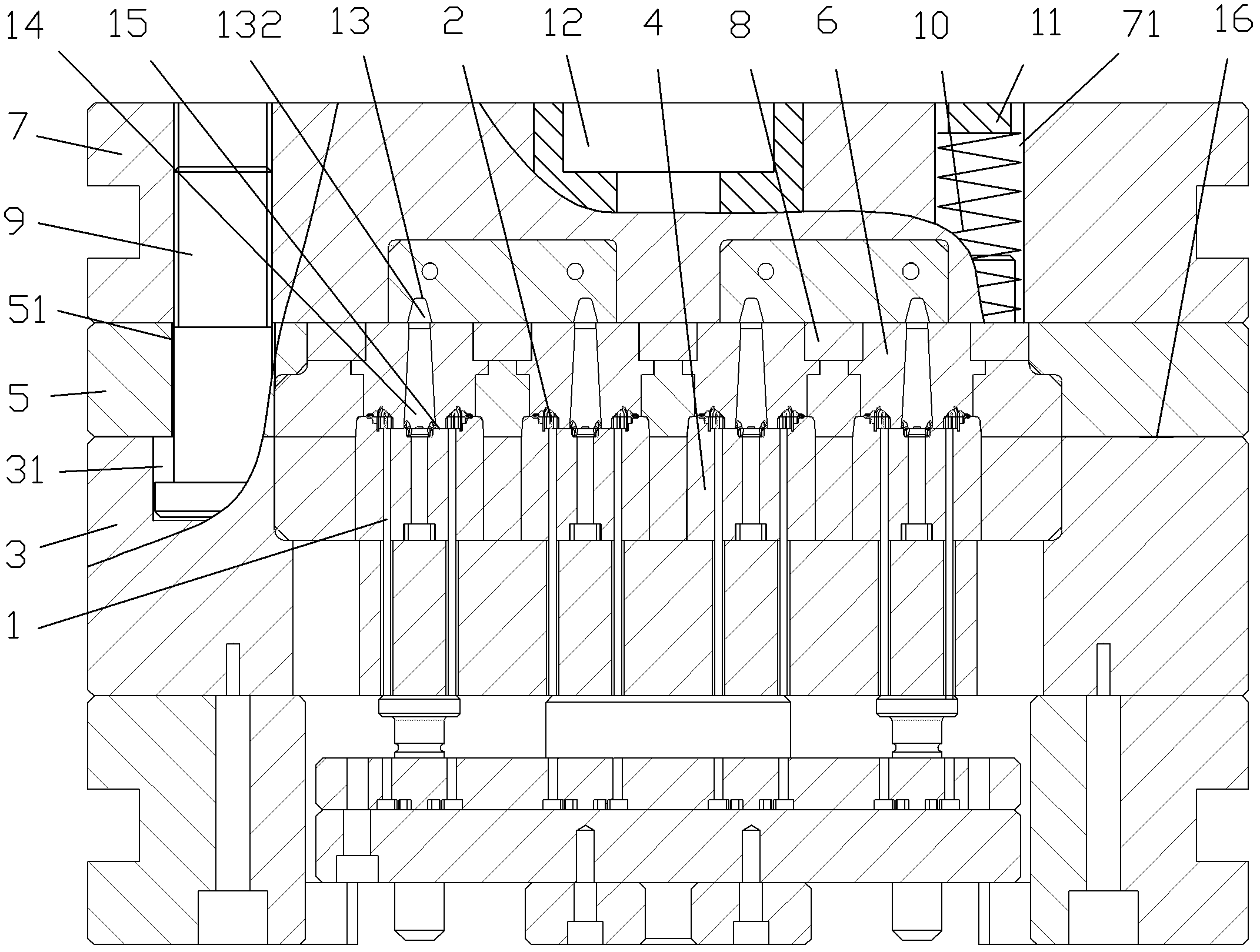

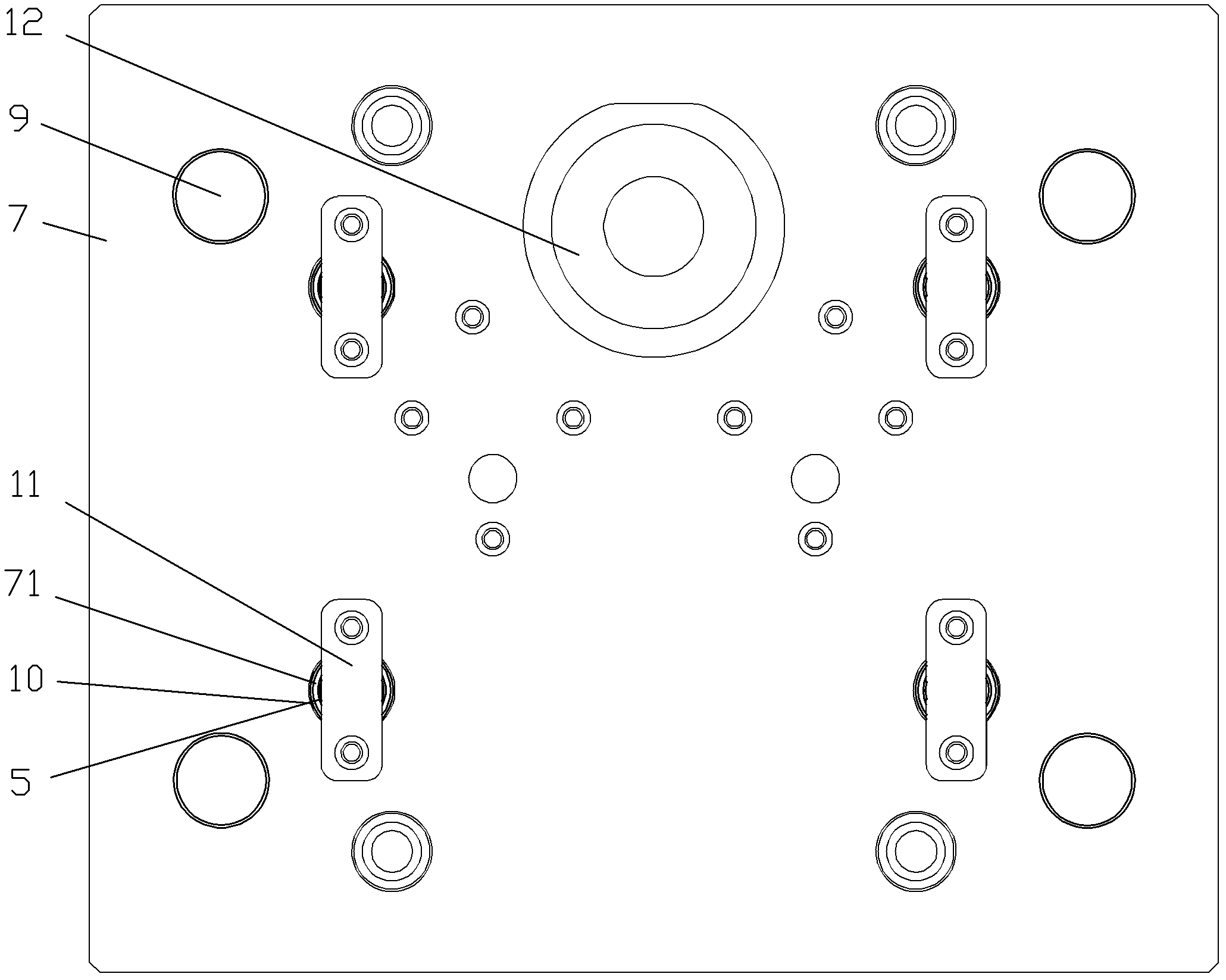

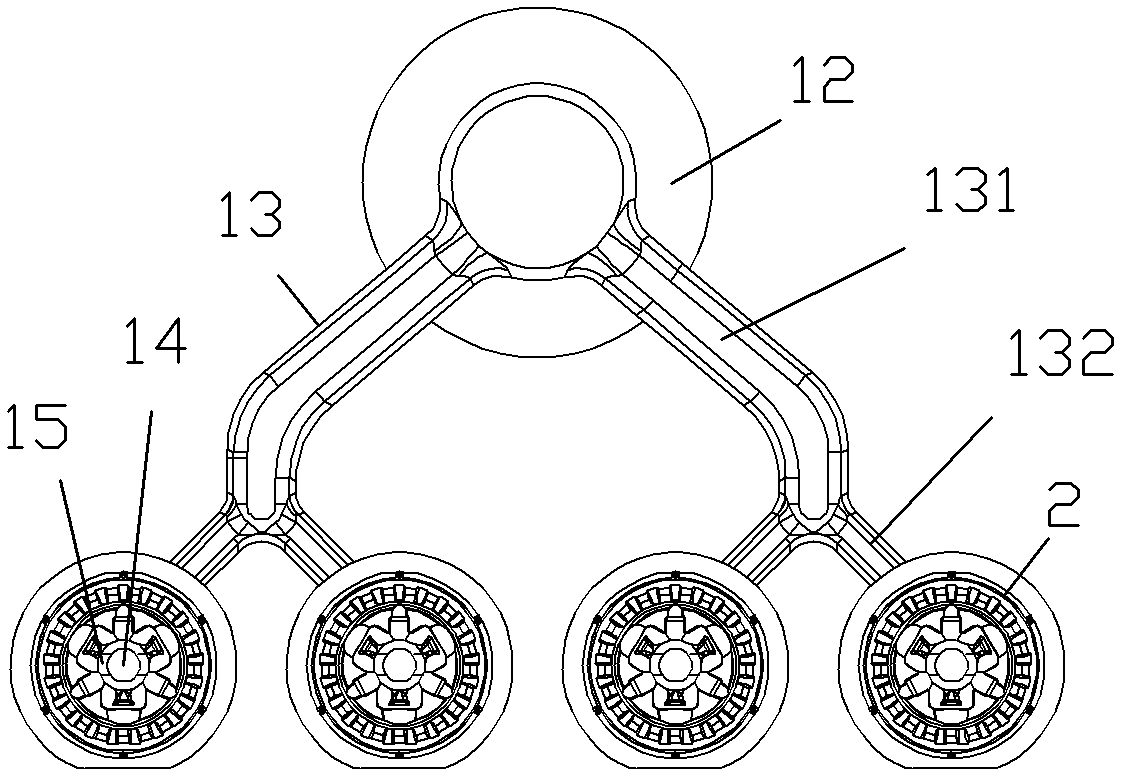

[0019] as attached figure 1 , attached figure 2 Shown: a center-feed die-casting mold, including a fixed mold, a movable mold, a runner system and eight ejector pins 1 located at the movable mold; the fixed mold and the movable mold are enclosed to form four cavities 2; The cavity 2 described is an annular cavity 2.

[0020] The movable mold includes a movable mold base 3 and four movable mold cores 4 whose number is equal to that of the cavity 2 and connected with the movable mold base 3 by screws.

[0021] The fixed mold includes a fixed template 5, four fixed mold kernels 6 equal in number to the 4 movable mold kernels, a cover plate 7, a fixed plate 8, four limit guide nails 9, four clip springs 10 and Four pressing plates 11 whose number is equal to the number of stage clips 10; the fixed mold core 6 is located in the fixed template 5 and corresponds to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com