A ball valve working sealing assembly with an elastic central hole

A technology of elastic center and sealing components, which is applied to valve devices, engine components, cocks including cut-off devices, etc., can solve problems such as poor sealing performance, affecting sealing performance, and changes in contact fit, so as to optimize the sealing performance of ball valves, The effect of optimizing sealing performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

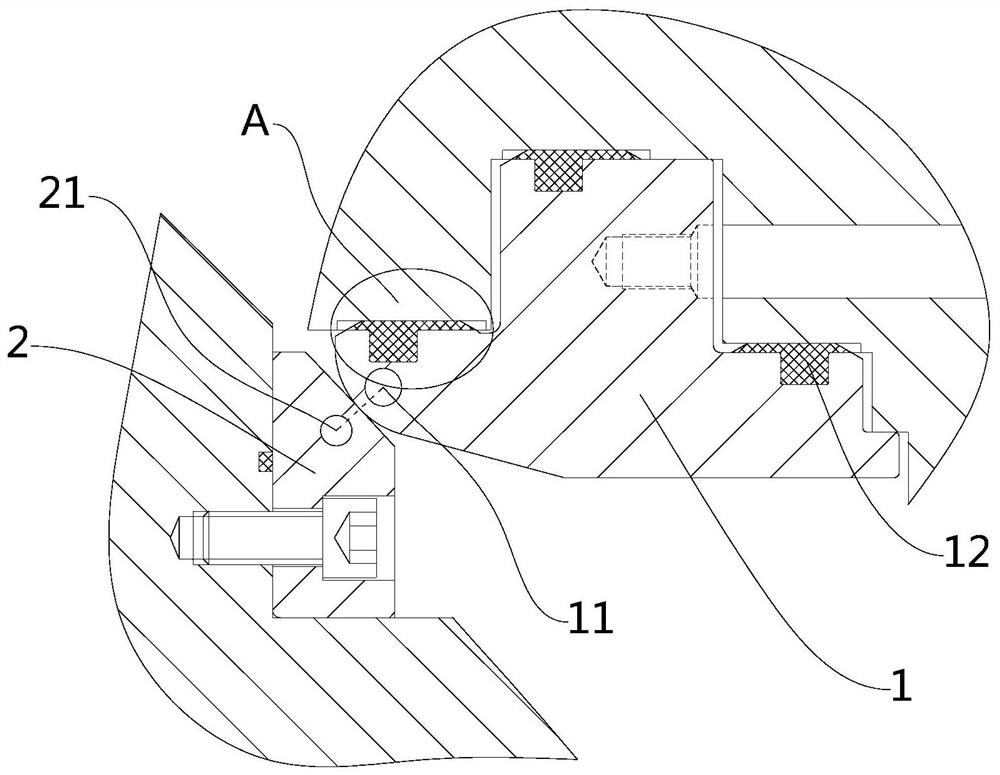

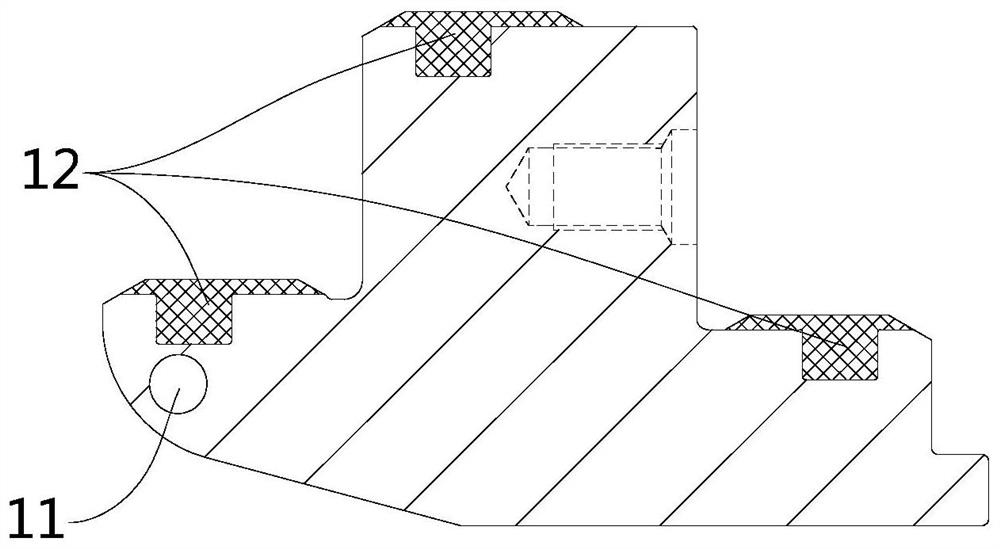

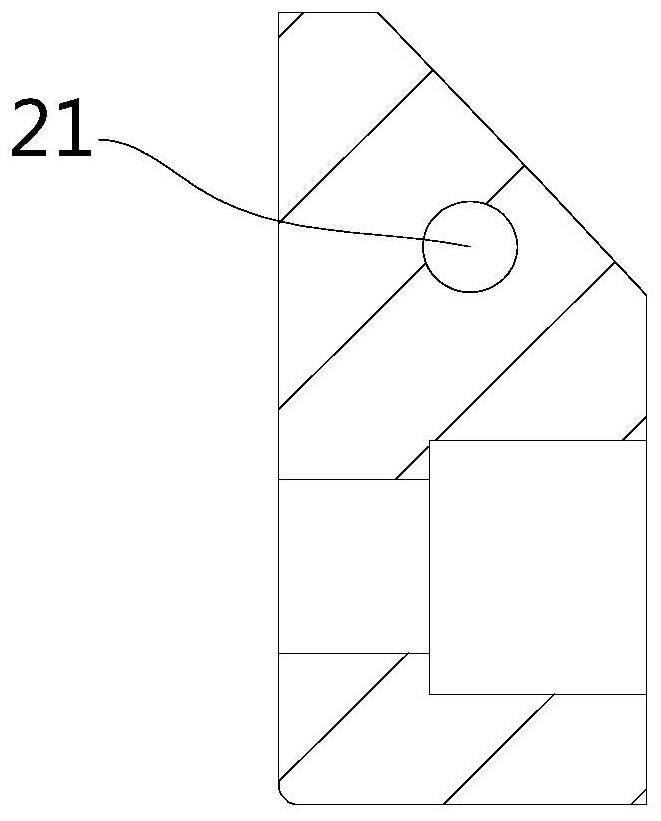

[0020] Example: a ball valve working sealing assembly with an elastic center hole, the structure is as follows Figure 1 to Figure 4 As shown in the figure, it includes a movable sealing ring 1 movably connected with the ball valve body and a fixed sealing ring 2 fixed on the valve valve of the ball valve. The inside of the sealing ring 2 is provided with a second central hole 21 that penetrates through the ring. When the materials of the movable sealing ring 1 and the fixed sealing ring 2 are deformed under the action of pressure water, the first central hole 11 and the second central hole 21 The existence of the movable sealing ring 1 and the fixed sealing ring 2 can compensate their own deformation by extruding the deformation of the two central holes, so as to effectively control the contact fit between the movable sealing ring 1 and the fixed sealing ring 2 of the ball valve, and optimize the sealing of the ball valve. For the purpose of performance, the movable sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com