Gear set

A technology of gear sets and gears, applied in the field of gear sets, can solve problems such as unbalanced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

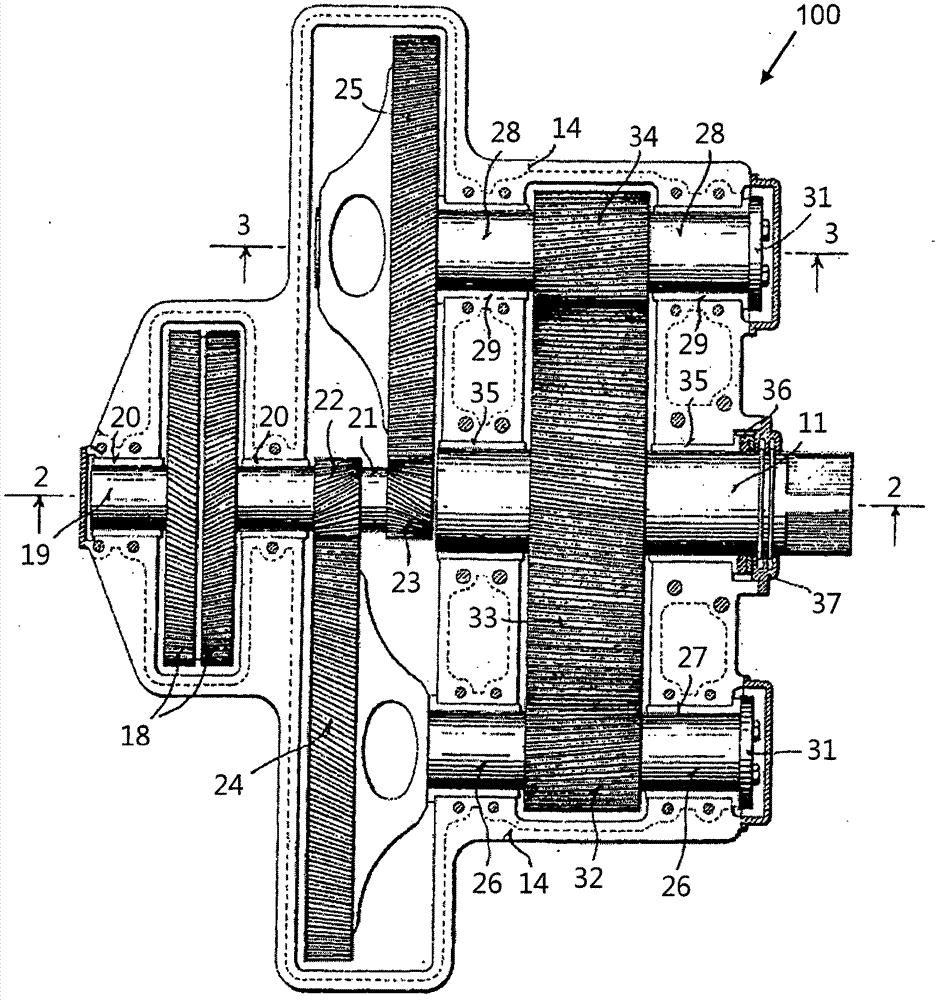

[0057] figure 1 The existing gear set of patent document US1759689 is described, which has been described in the background of the invention above.

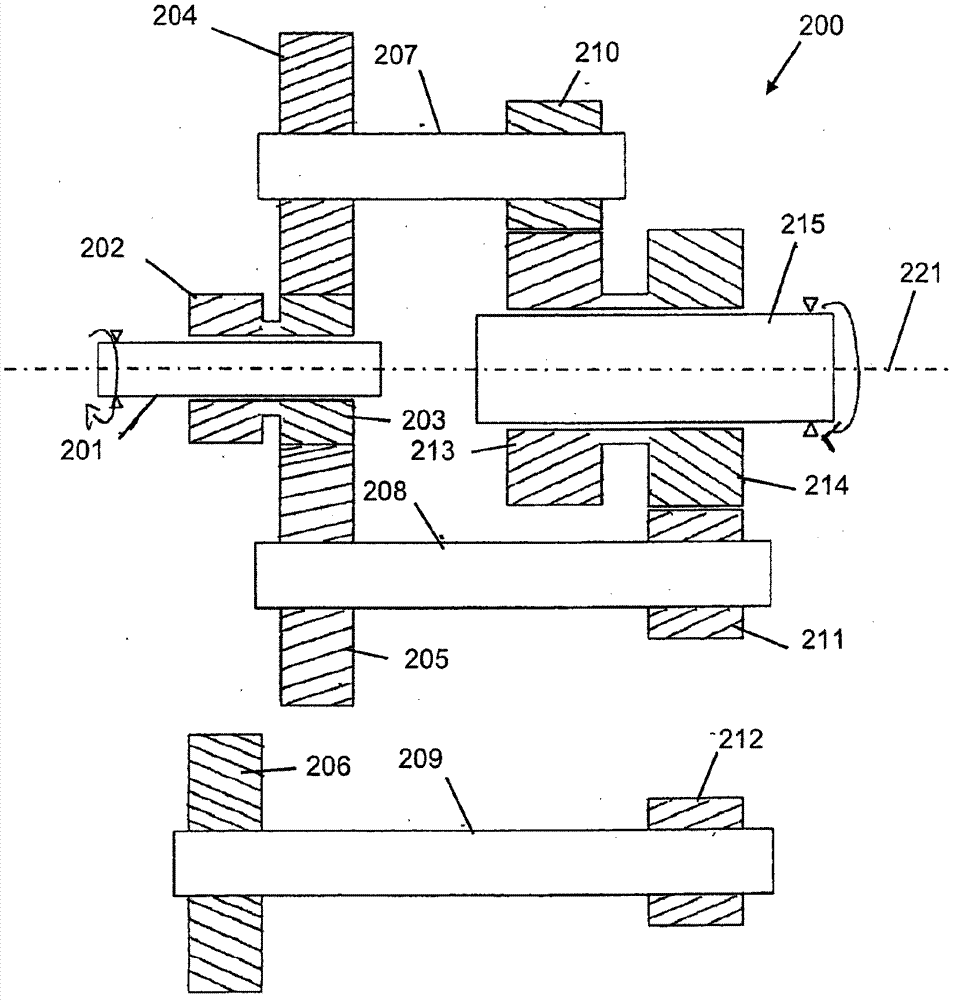

[0058] figure 2 Shown is a gear set 200 having three layshafts 207 , 208 , 209 . Each layshaft has an input gear 204 , 205 , 206 which meshes with one of a pair of helical input gears 202 , 203 mounted on the input shaft 201 . The pair of helical input gears 202 , 203 are configured to rotate together with the input shaft 201 . The helical input gears 202, 203 are fixed relative to each other, for example by being formed as a single unit, but mounted so as to allow some axial movement of the pair of gears. This is achieved by helical input gears 202 , 203 slidable along an axis 221 of the input shaft 201 , which preferably coincides with the axis of the output shaft 215 of the gear set 200 .

[0059] Each of the layshafts 207 , 208 , 209 also has an output gear 210 , 211 , 212 which meshes with one of a pair of helical outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com