Measurement method of sticking-welding grating stripping force

A test method and technology of peeling force, which is applied in the field of peeling force testing of stick-welded grids, to achieve the effect of preventing unfair competition and profit-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

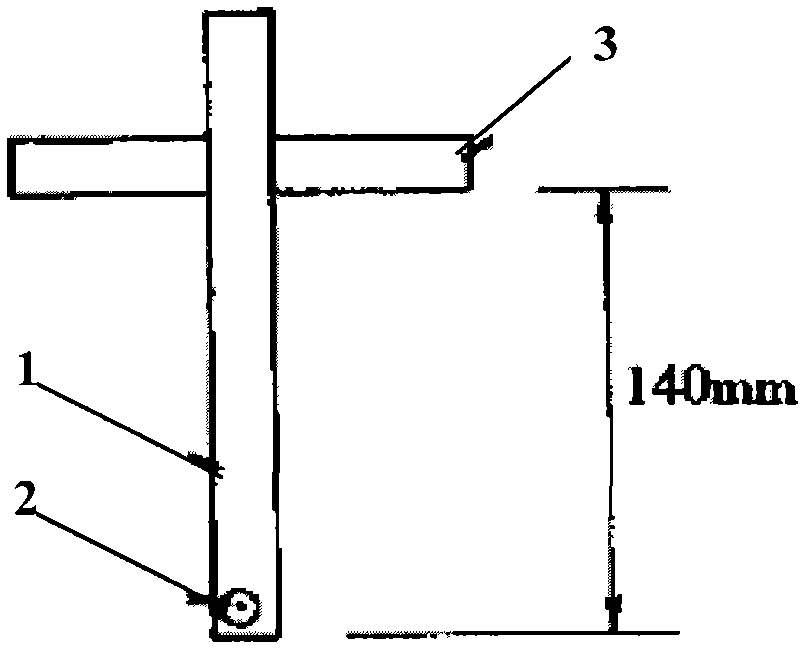

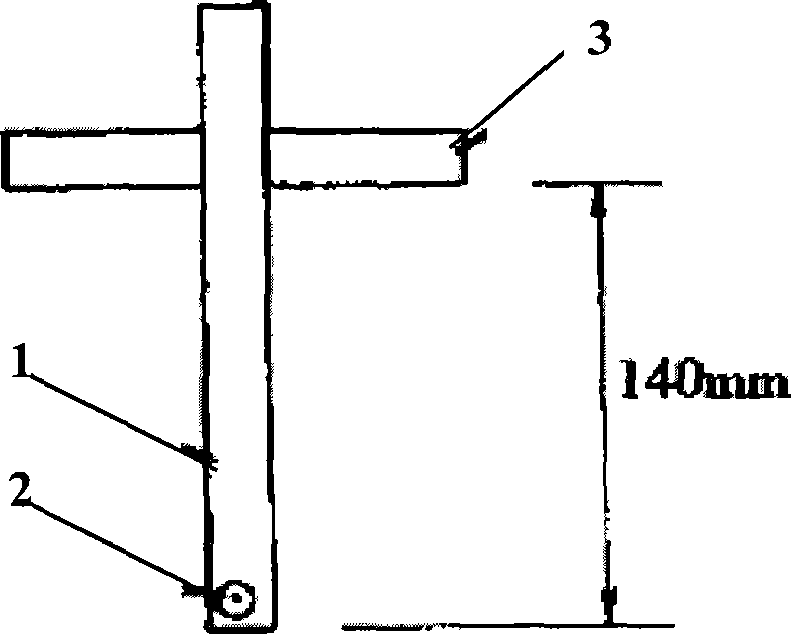

[0008] According to the sampling method of the geosynthetic material test, samples are taken at the sticky welding points of the sticky welded geogrid. Place the sample horizontally on the plane of the tensile machine, with the longitudinal rib 1 on top and the transverse rib 3 on the bottom. The transverse ribs 3 on both sides of the longitudinal ribs are clamped and firmly fixed, and then the stretching end of the tension machine is firmly tightened to the free end 2 of the longitudinal ribs. Start the tension machine, slowly pull up the longitudinal reinforcement strip 2, and read the tension value of the tension machine continuously until the welded joints are completely peeled off. Select the maximum pulling force value as the peeling force value of the adhesive-welded grid.

[0009] When utilizing the bonding grid peeling force test method of the present invention to detect, at first it should be randomly intercepted from the extracted batch samples, five peeling sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com