Large-current electric connector and component thereof

An electrical connector and high-current technology, applied in the field of high-current electrical connectors and their components, can solve problems such as easy fatigue deformation of conductive strips, and achieve the effects of eliminating poor contact, solving easy fatigue deformation, and preventing fatigue deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

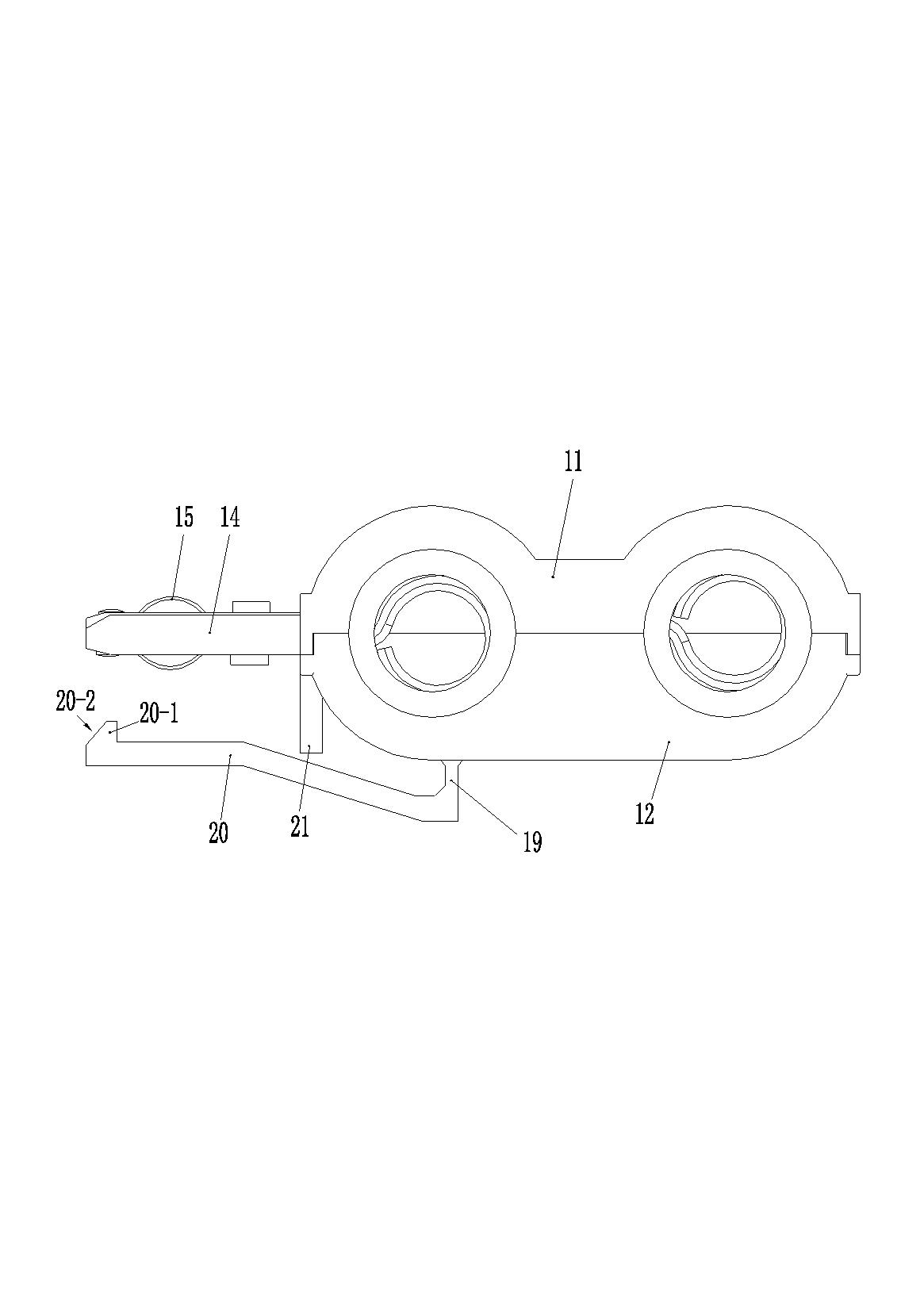

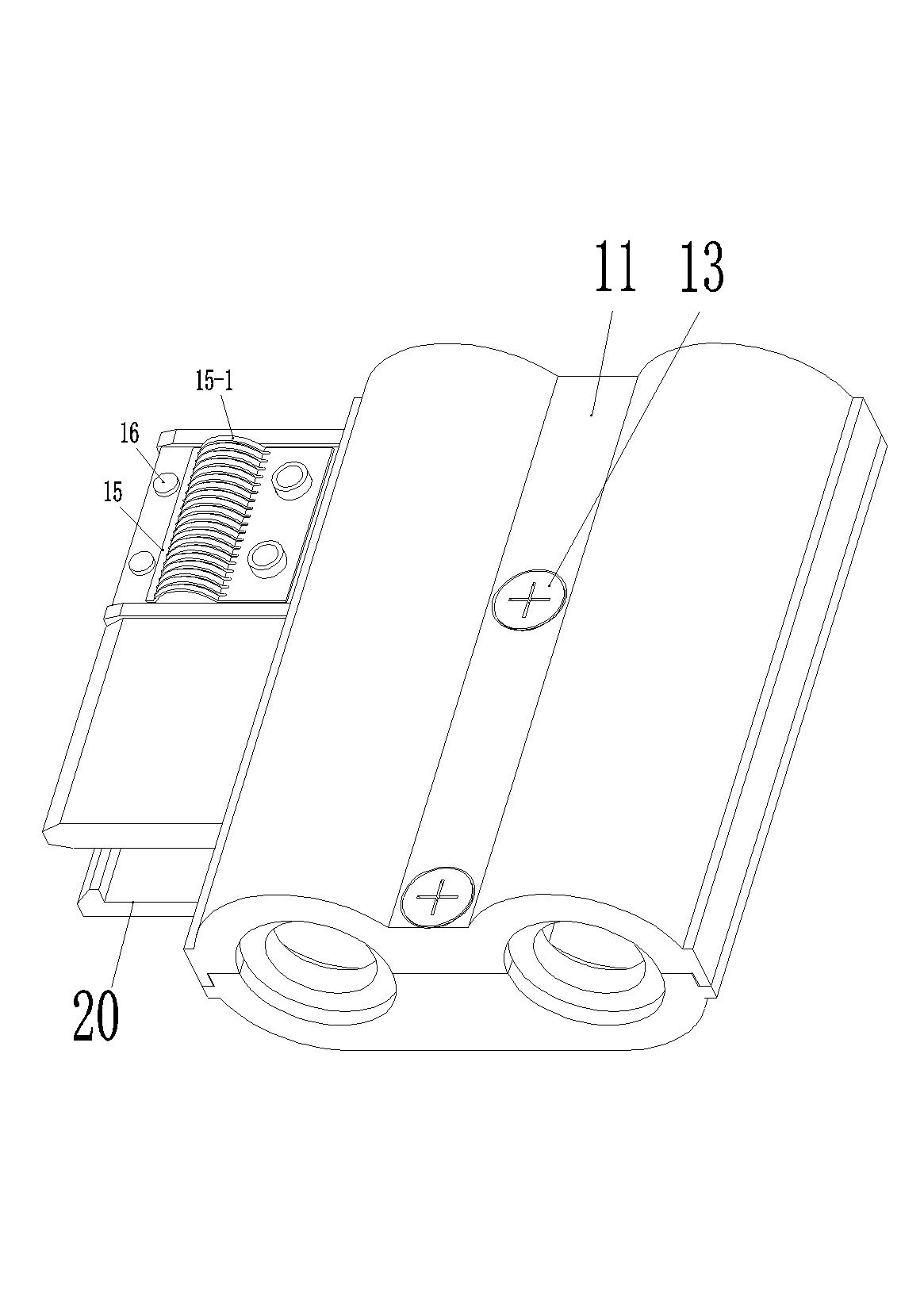

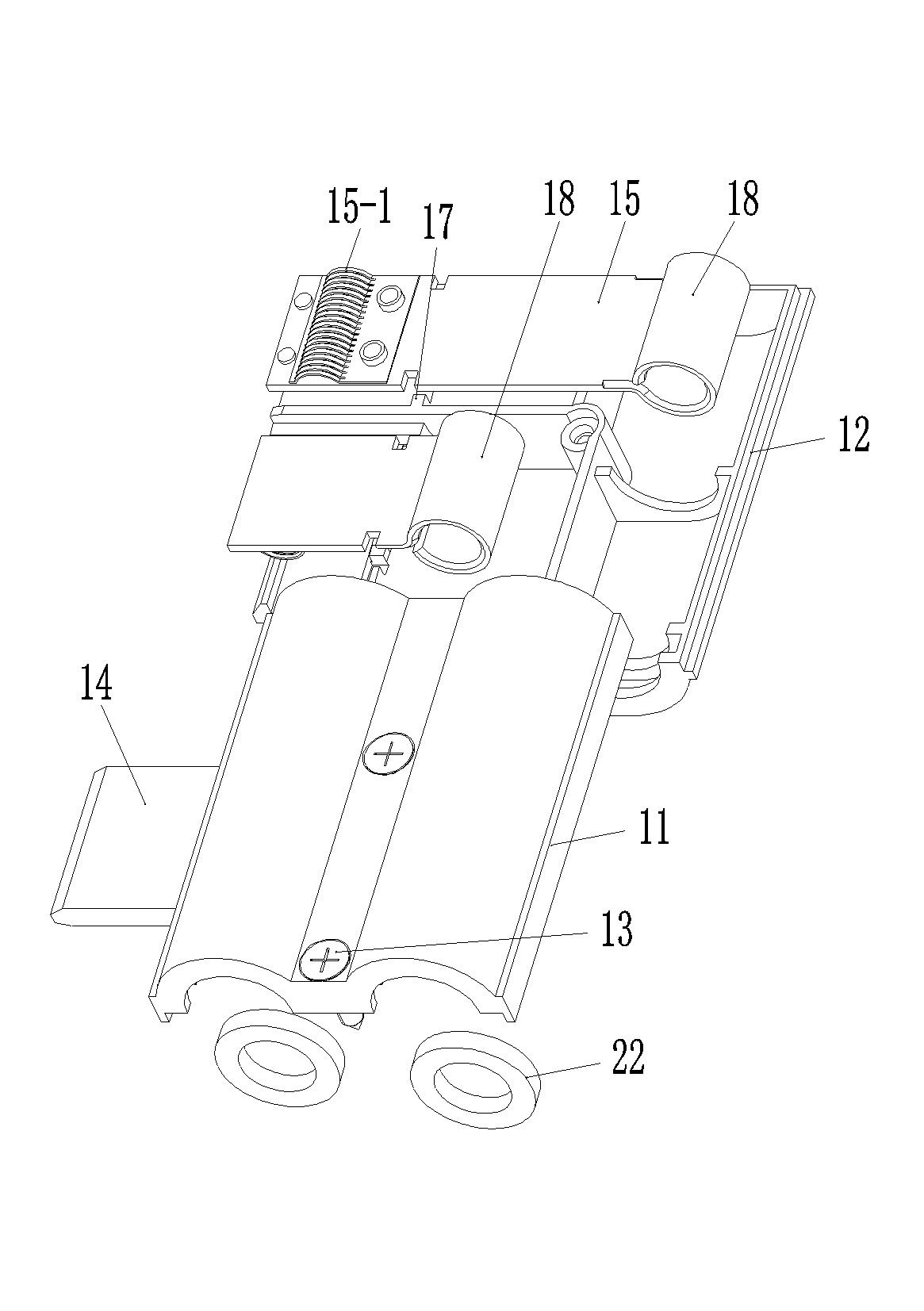

[0024] Embodiment 1 of the high-current electrical connector of the present invention, such as Figure 1-3As shown, the electrical connector uses the front end as the plug-in end, and includes an insulating shell, which is formed by buckling the cover plate 11 and the base 12, and the cover plate 11 and the base 12 are further fixed by screws 13 after buckling, The cover plate 11 and the base 12 are respectively provided with a tongue 14 extending forward at the front end, and the tongues on the cover plate 11 and the base 12 are respectively fixed with conductive sheets 15, and the two conductive sheets are arranged on the left and the right, conducting The front end of the sheet 15, that is, the part located on the corresponding tongue is provided with a conductive strip 15-1, the conductive strip 15-1 extends along the front and rear direction and has a curved and bulging direction away from the tongue between the front and rear ends. The contact part is used to contact the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com