Electric connector capable of pressing cable and assembly of electric connector

A technology of electrical connectors and connectors, which is applied to the parts, connections, and contact parts of connecting devices, can solve the problems of conductive belt fatigue deformation and other problems, and achieve the goal of eliminating poor contact, solving fatigue deformation, and preventing fatigue deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

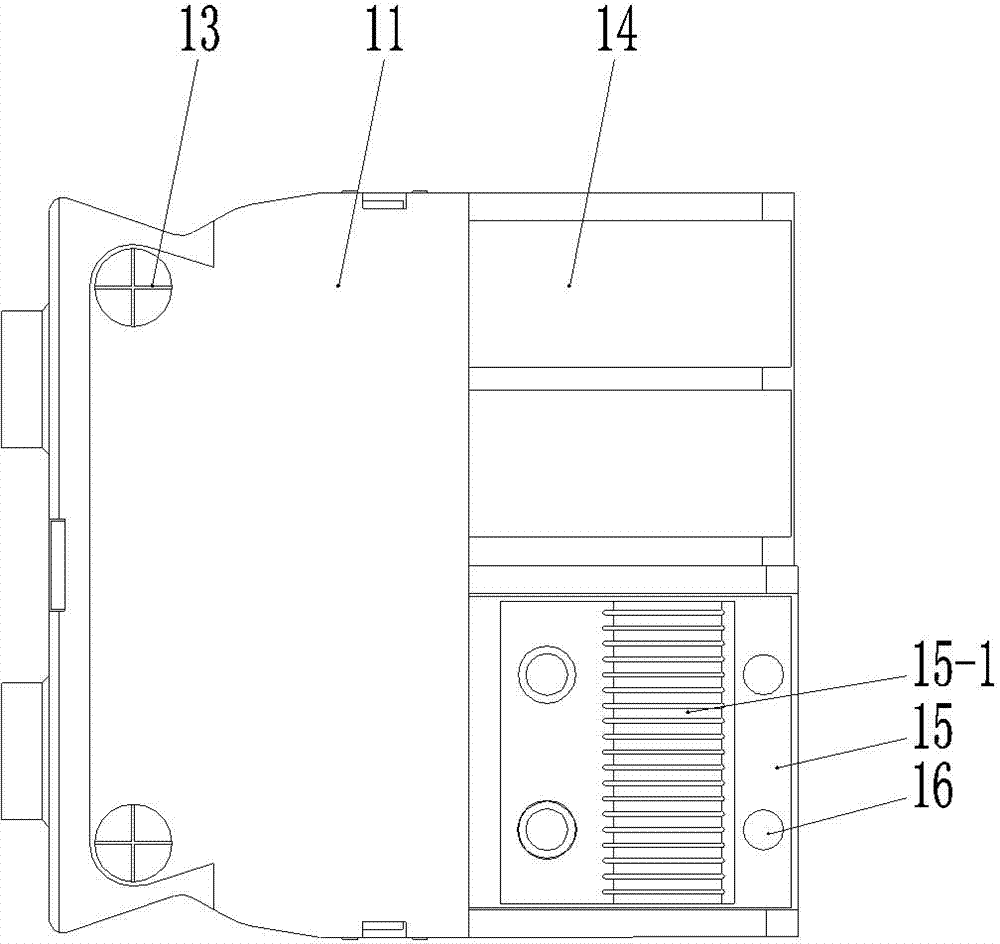

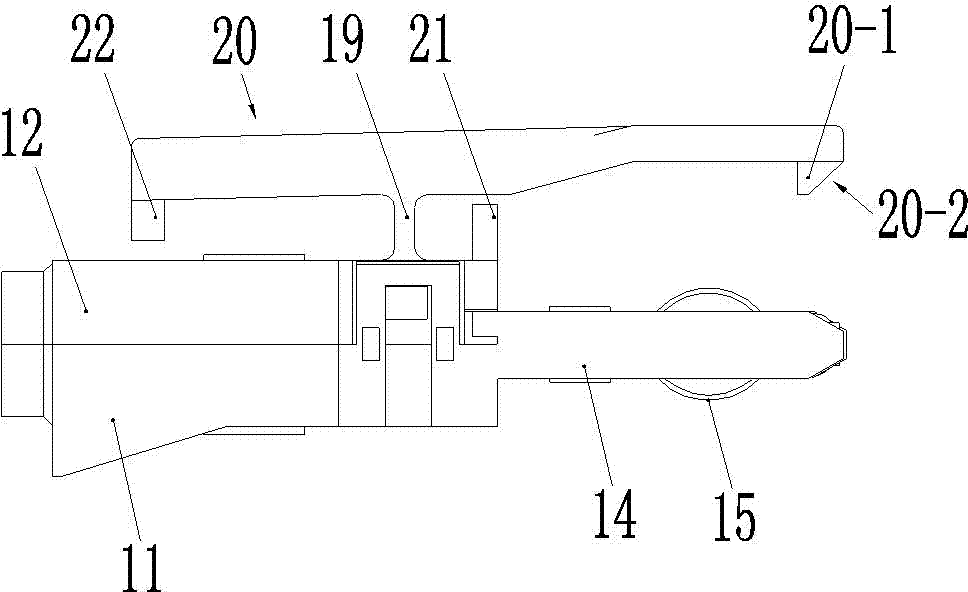

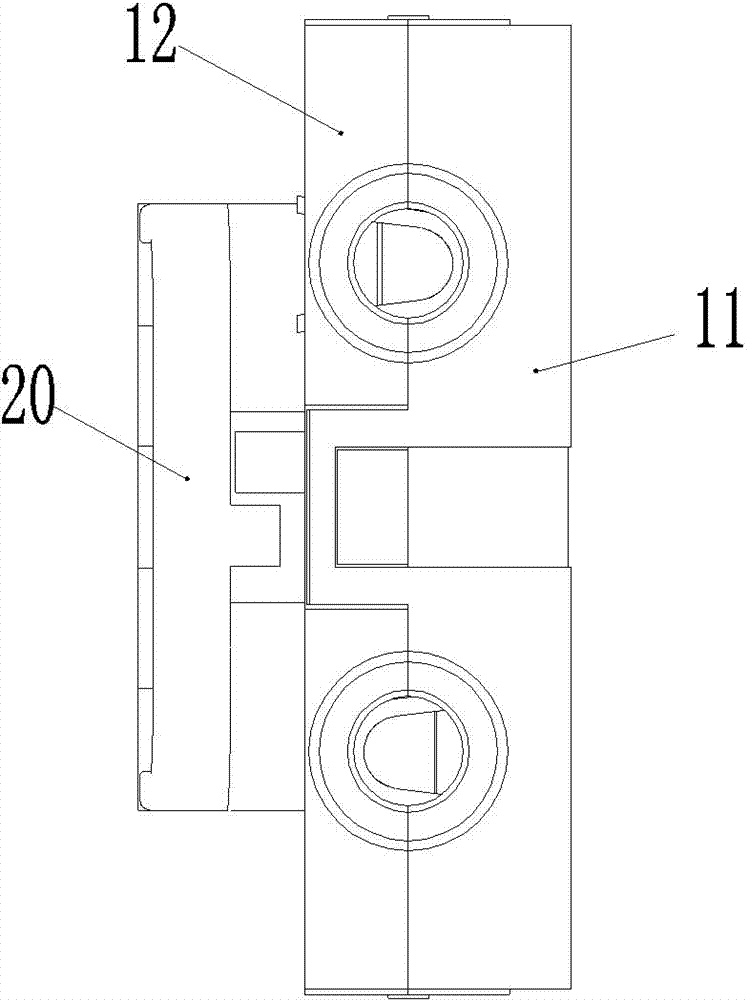

[0029] Embodiment 1 of the electric connector of the present invention that can be crimped cables, such as Figure 1-5As shown, the electrical connector uses the front end as the plug-in end, and includes an insulating shell, which is formed by fastening the cover plate 11 and the base 12 up and down. The lock between the two is fastened, and the structure and working principle of the lock are prior art, and will not be repeated here. The cover plate and the base are further fixed by screws 13 after the lock is initially locked, and the cover plate 11 and the base 12 is respectively provided with the tongue 14 that extends forward at the front end, and the tongue on the cover plate 11 and the base 12 is respectively fixed with conductive sheet 15, and two conductive sheets are arranged on the left and the right, and the front end of conductive sheet 15 is , that is, a conductive strip 15-1 is provided on the part on the corresponding plug tongue, and the conductive strip 15-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com