Elevator and method

A technology for elevators and elevator shafts, applied in the field of elevators for transporting people and/or goods, to achieve the effect of simple and reliable stopper devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

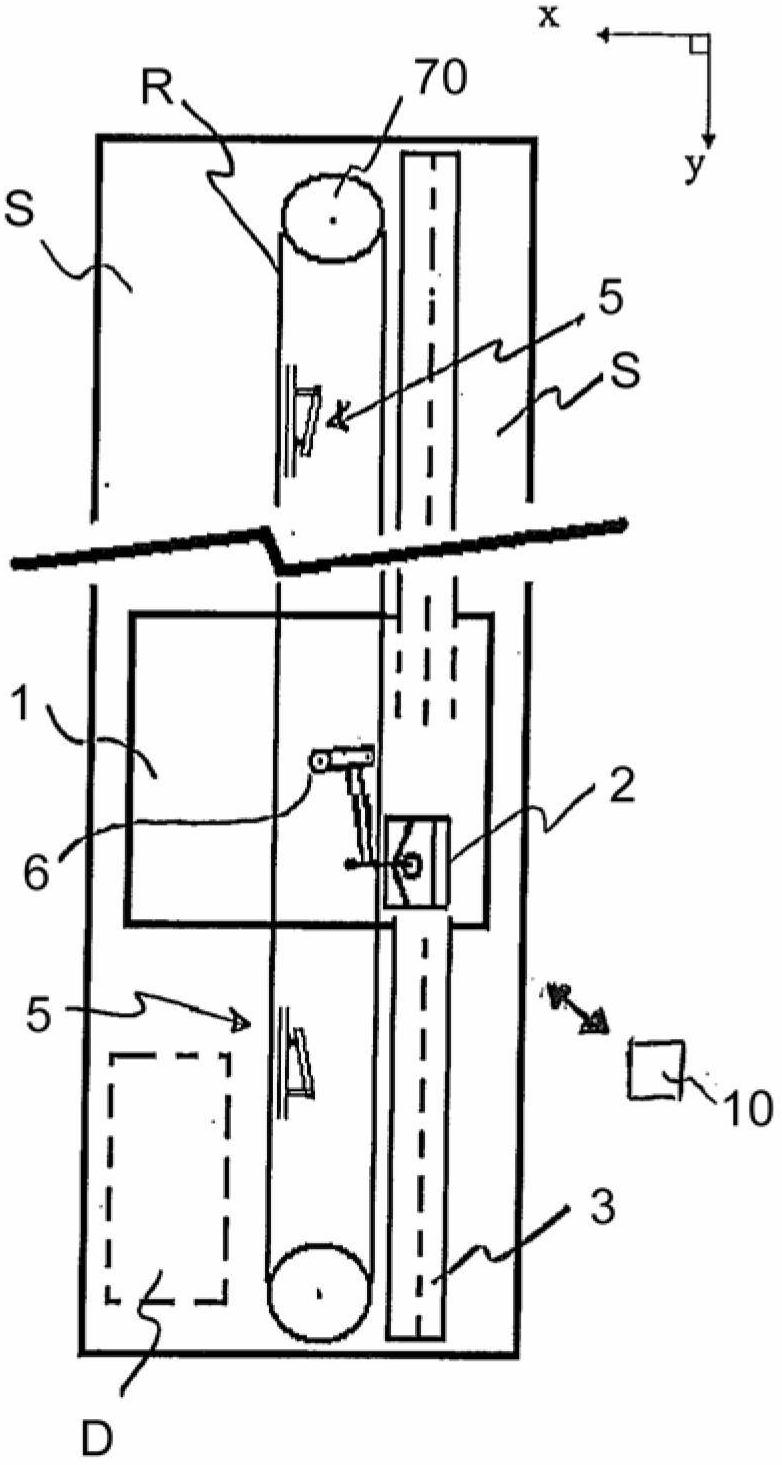

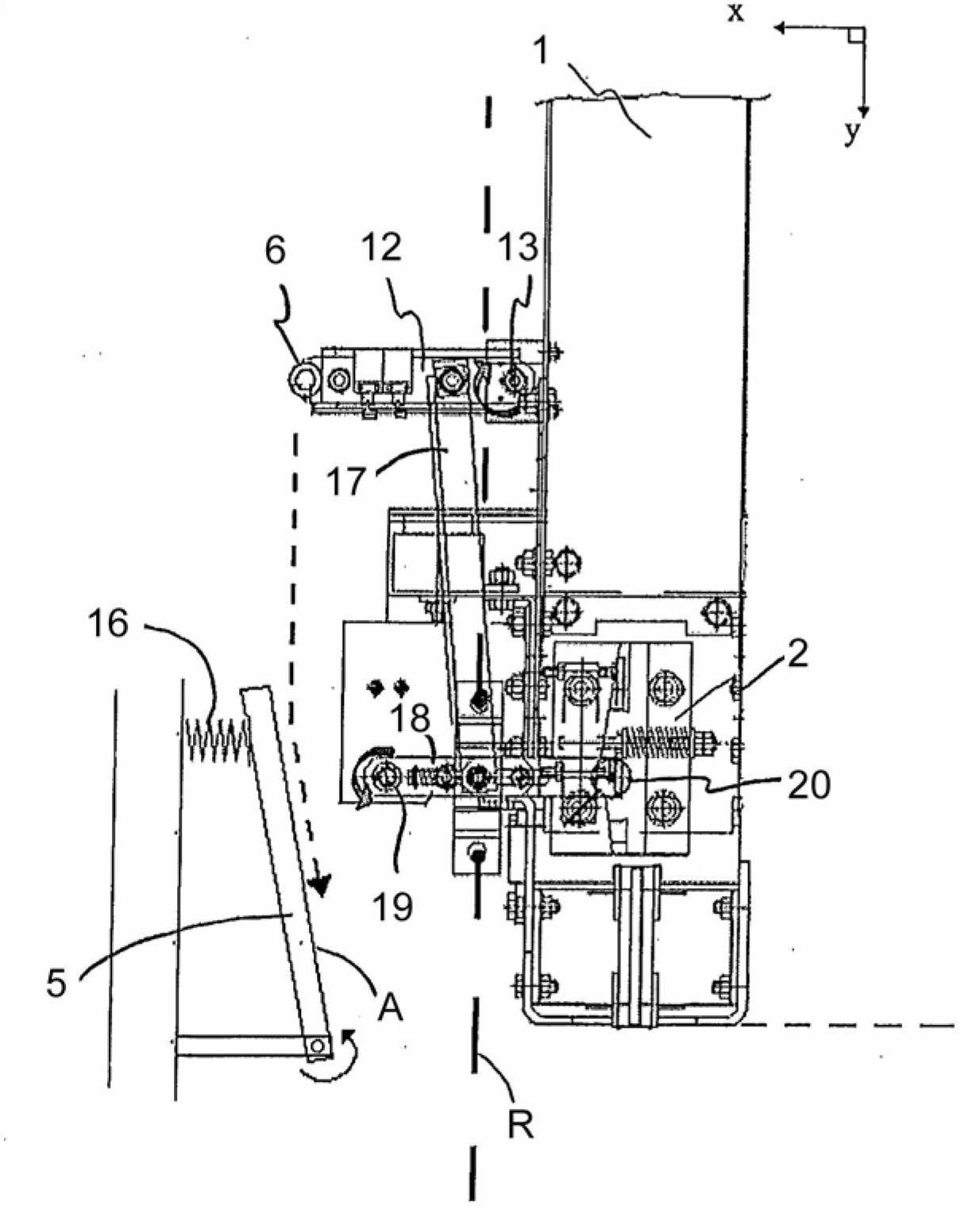

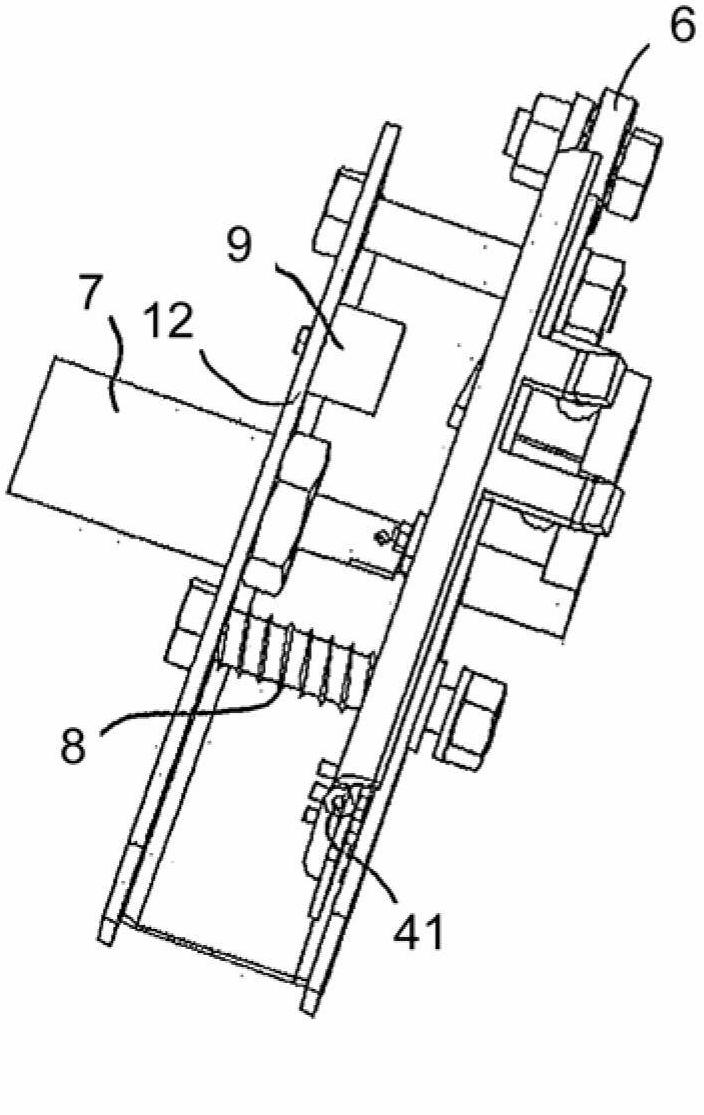

[0056] figure 1 An elevator according to the invention is shown comprising an elevator car 1 , an elevator shaft S and equipment for moving the elevator car (not shown), such as traction sheave machines and hoisting ropes supported on a building. The elevator car 1 comprises a brake 2 to which a movable mechanical stop 6 is connected, by moving the stop 6 the brake 2 is arranged to be turned into a braking position. The elevator shaft S includes a mechanical stop 5 . The stopper 6 on the elevator car is arranged to move between a position I where the stoppers 5, 6 are on the collision path and a position II where the stoppers 5, 6 are not in the collision on the route. When the stopper 6 is in position I after the elevator car 1 has moved towards the end of the elevator shaft a certain distance from this end, the stoppers 5 and 6 collide with each other. Thus, the stopper 6 is arranged to move by means of the supporting force of the stopper 5 in order to turn the brake 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com