Apparatus for driving a gas discharge lamp

A technology of gas discharge lamps and arcs, which is applied in the use of gas discharge lamps, lighting devices, electric light sources, etc., and can solve problems such as shortening lamp life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] figure 1 is a block diagram schematically showing an exemplary embodiment of an electronic driver 10 for driving a gas discharge lamp L. As shown in FIG. The driver 10 has output terminals 7, 8 for receiving the lamp and for connecting to the lamp poles. The lamp L is of the type having two electrodes facing each other in a sealed chamber. In a particular embodiment, the lamp is a xenon discharge lamp for use in automobiles. During operation, a discharge is maintained in the chamber, which is indicated as an arc.

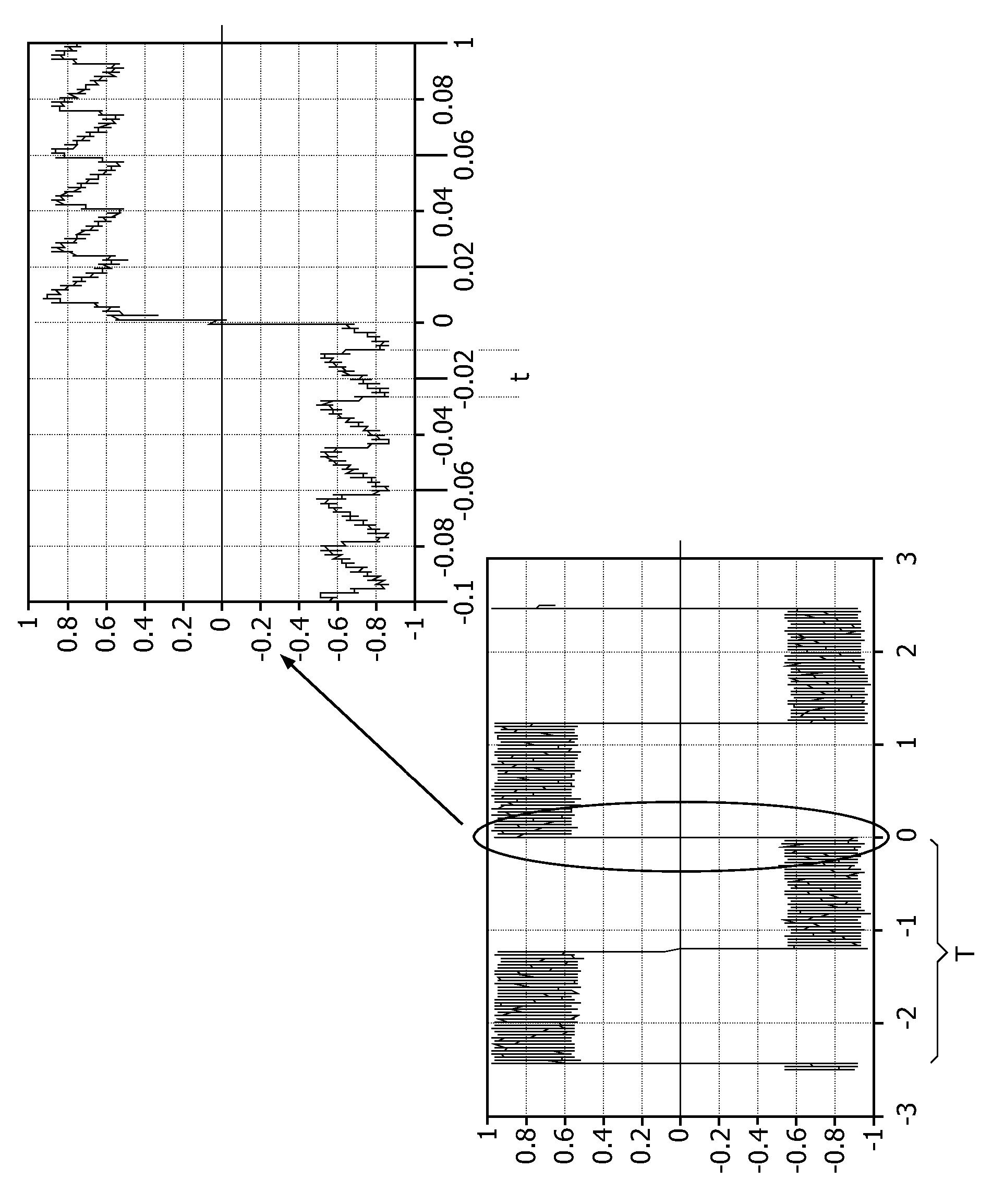

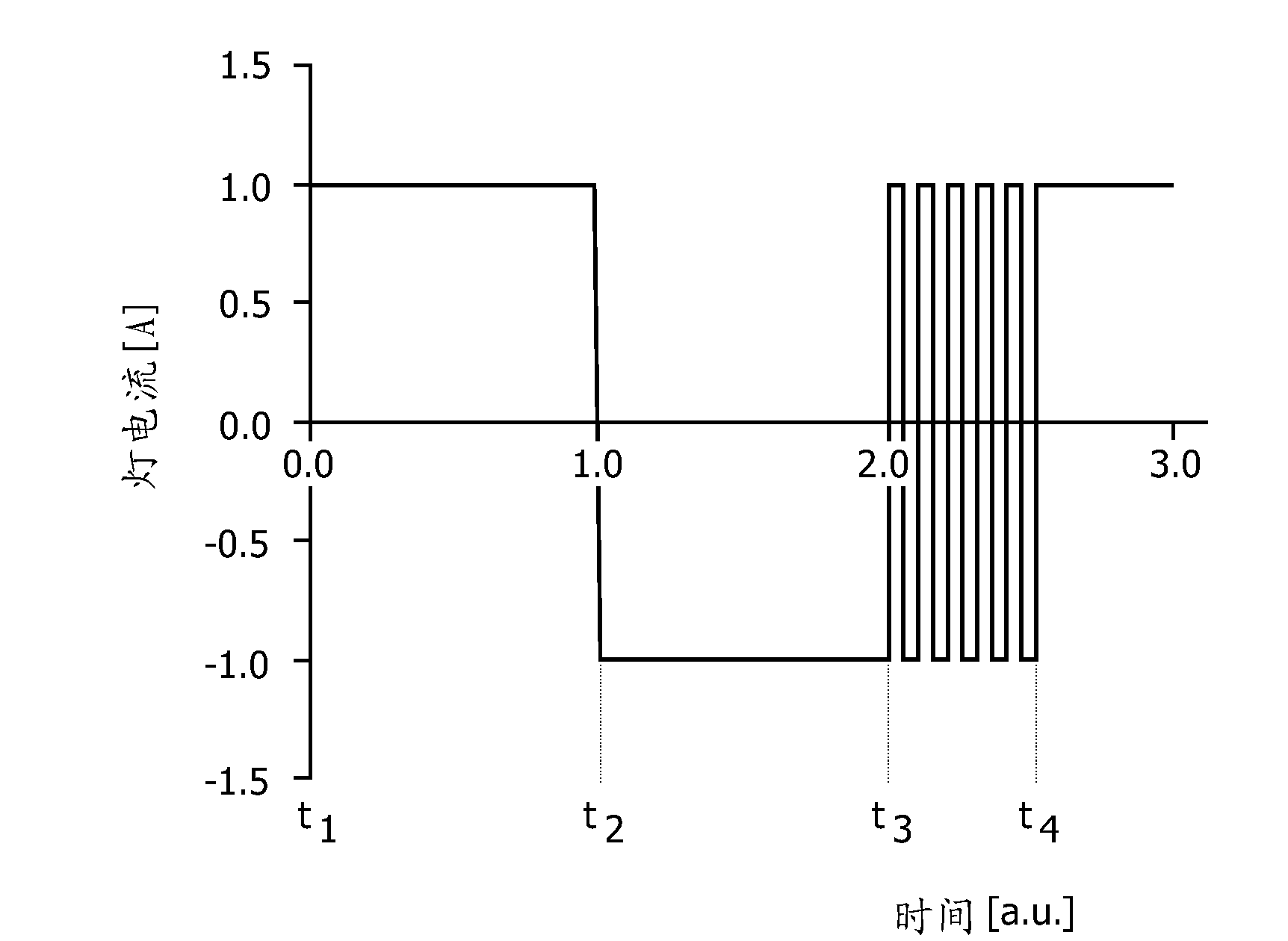

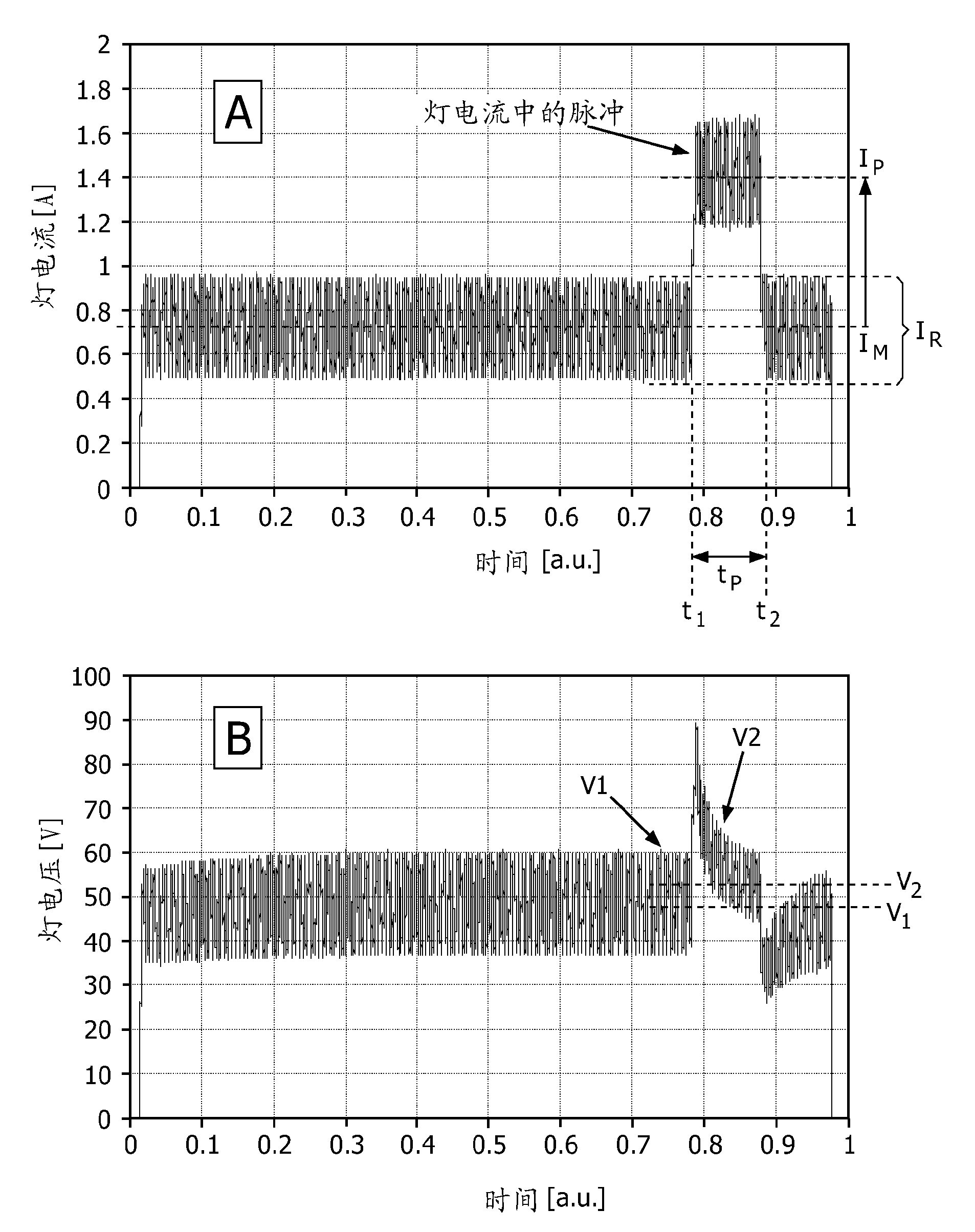

[0021] In the electronic lamp driver according to the invention, the current applied to the lamp can be regarded as comprising three mutually independent current components. For this reason, the following explanation diagrammatically assumes that the lamp driver comprises three functionally independent Current sources, the output terminals of which are coupled in parallel with the device output terminals 7, 8, such that the lamp L receives the sum of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com