Variable-amplitude filament guide device for automatic soft bobbin winder

A technology of loose winding machine and yarn guiding device, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc. It can solve the problems of uneven dyeing of tight-sided bobbins and tight edge yarn loops, etc., and achieve Improve work efficiency and economic benefits, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

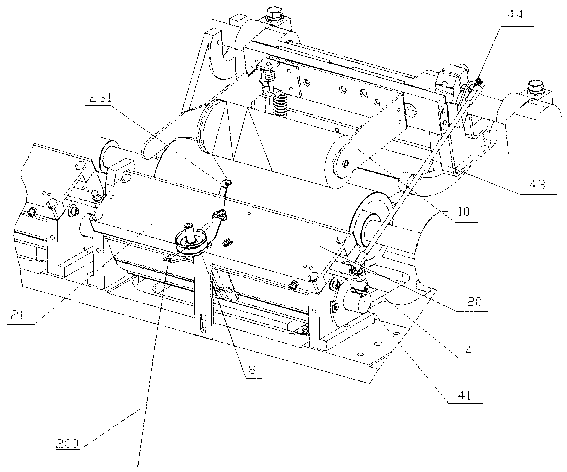

[0020] Such as Figure 1 to Figure 3 Shown is a preferred embodiment of the present invention.

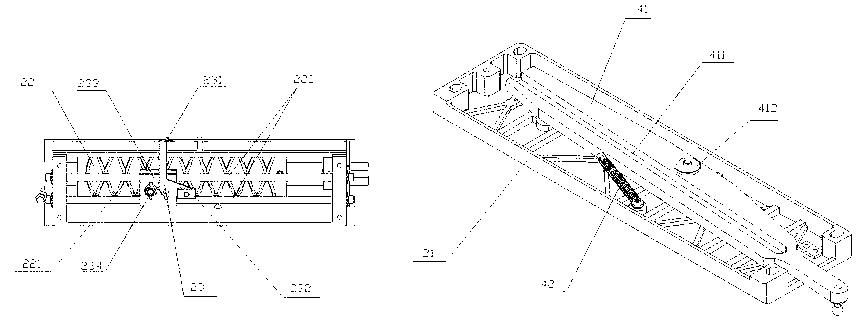

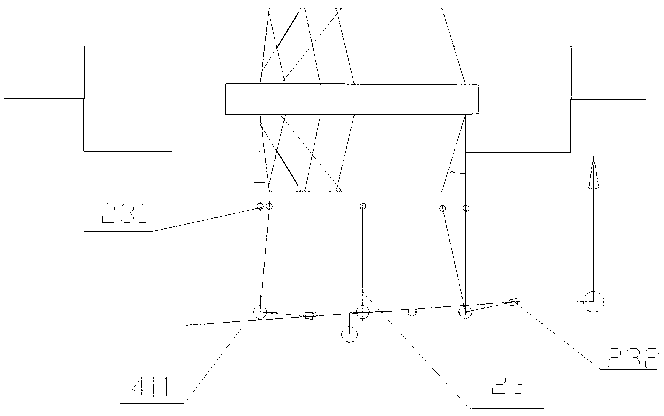

[0021] Such as figure 1 , figure 2 , image 3 As shown, the luffing guide device 4 includes a luffing guide rail 41, a tension spring 42, a movable pull rod 43 and an adjustable rotating rod 44. A chute 411 that can limit the sliding of the guide block is formed in the middle of the luffing guide rail 41. The luffing guide rail 41 One side is movably installed on the inner side of the tank cover plate 211, specifically, it can be movably fixed by the mandrel 412, and the other side is fixed on the tank body 21 by a tension spring, specifically it can be the inside of the tank cover plate, or it can be Other positions of the tank. A movable pull rod 43 is installed on one end of the luffing guide rail 41 protruding from the outside of the tank cylinder, and the movable pull rod 43 is connected with the adjustable rotating rod 44 installed on the winding frame 10 on the same sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com